Low-hydrogenloss hydrogenation of high-output qulified diesel oil

A diesel and hydrogen consumption technology, applied in the field of hydrocarbon oil cracking, can solve the problems of lowering the yield of middle distillate oil, limited precision of gas phase stream separated by stripping, increasing investment and operating costs, etc., and achieves the effect of high cetane number.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

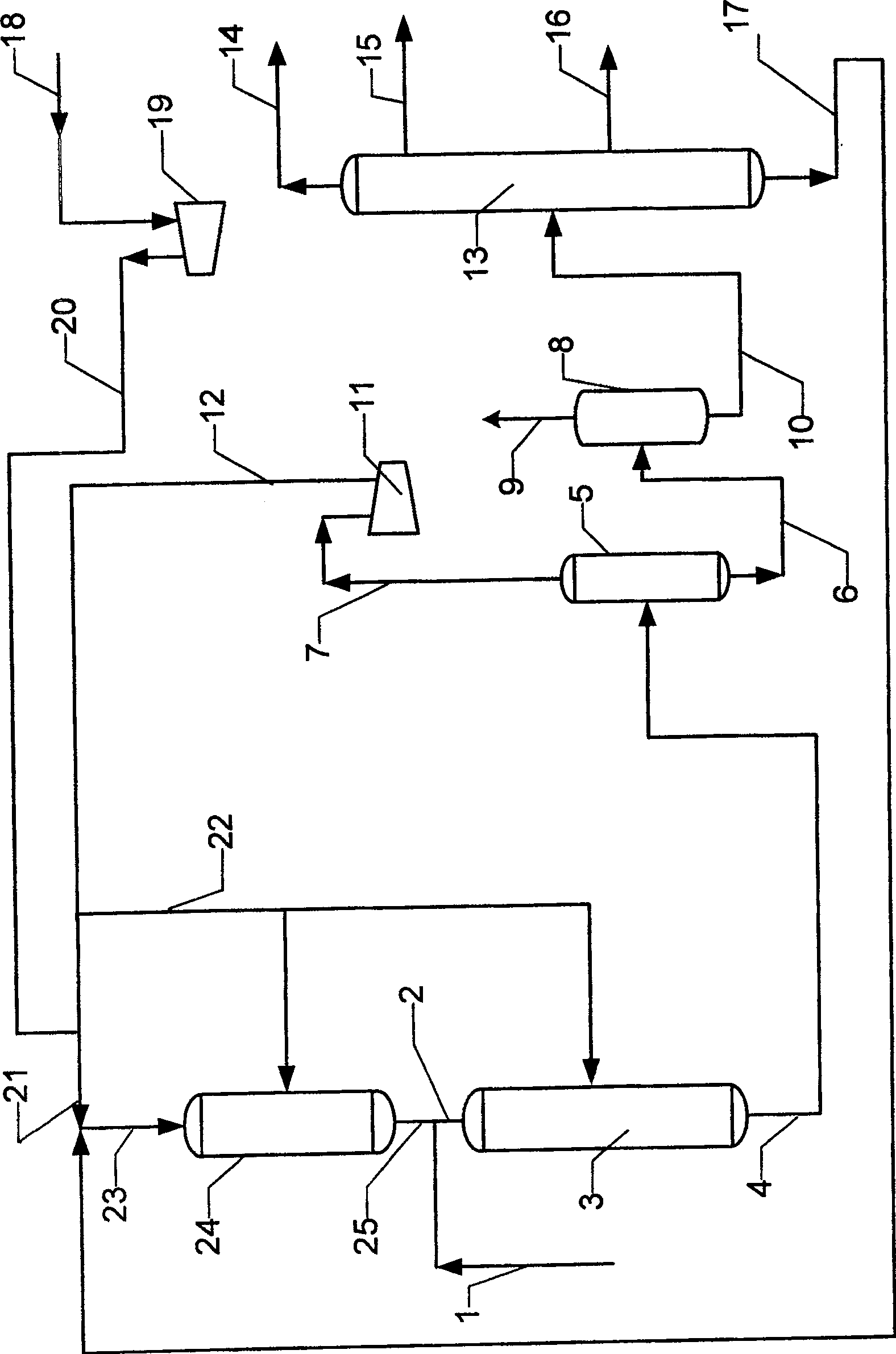

[0033] Feedstock A is a mixture of 20% by weight catalytic diesel oil and 80% by weight vacuum gas oil. The properties of the feedstock oil are shown in Table 1. The raw material oil is mixed with the reaction effluent of the hydrocracking reactor and then enters the hydrotreating reactor for reaction under the action of the hydrotreating catalyst; the reaction effluent of the hydrotreating reactor is cooled and separated to obtain various fraction products, Wherein the tail oil fraction is recycled back to the hydrocracking reactor for hydrocracking reaction, the hydroprocessing catalyst and the hydrocracking catalyst are packed in two reactors respectively, and the loading volume ratio of the hydroprocessing catalyst and the hydrocracking catalyst is 64:36. Reaction conditions and product distribution are listed in Table 2 and Table 3 respectively, as can be seen from Table 3, using the method of the present invention, the hydrogen consumption of raw material oil A is 2.0% b...

Embodiment 2

[0035] The feedstock oil B is vacuum gas oil, and the properties of the feedstock oil are shown in Table 1. Processing stock oil B according to the method of the present invention, the loading volume ratio of hydrotreating catalyst and hydrocracking catalyst is 60:40, and reaction condition, product distribution and product property are listed in Table 5, Table 6 and Table 7 respectively, by Table 6 It can be seen that, using the method of the present invention, the hydrogen consumption of feedstock B is 2.1% by weight, which is less than the 2.6% by weight of conventional hydrocracking unit for processing feedstock A; and the yield of diesel fraction (150-370°C) is as high as 80.0% Heavy%. It can be seen from Table 7 that the aromatic potential of the heavy naphtha fraction is 52% by weight, which is a high-quality reforming raw material; the density of the diesel fraction is 0.825g / cm 3 , the sulfur content is less than 30ppm, the polycyclic aromatic hydrocarbon content is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com