Inkjet head unit

A technology of inkjet head and actuator unit, applied in the direction of inking device, printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, presently preferred embodiments of the present invention will be described with reference to the accompanying drawings.

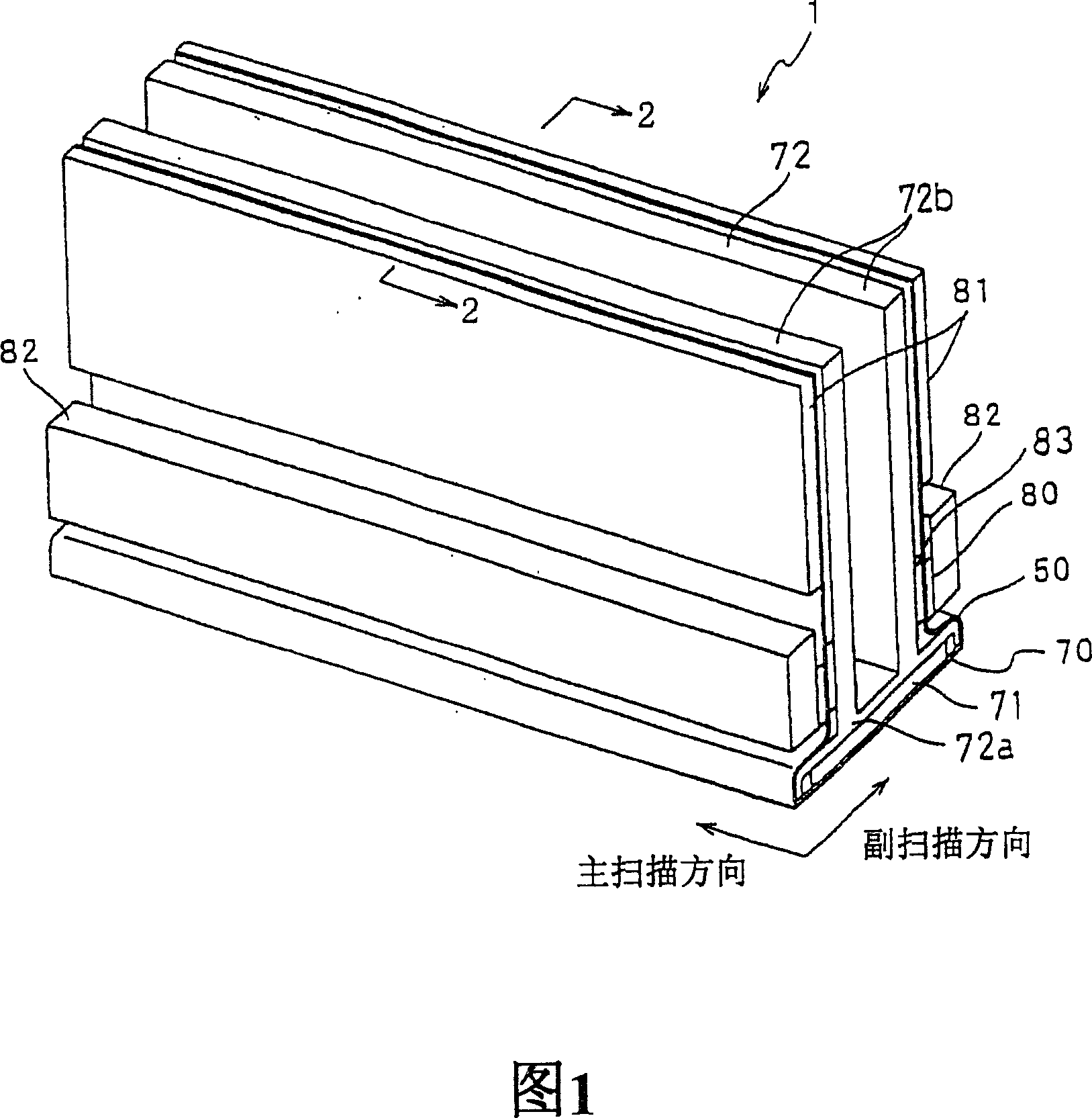

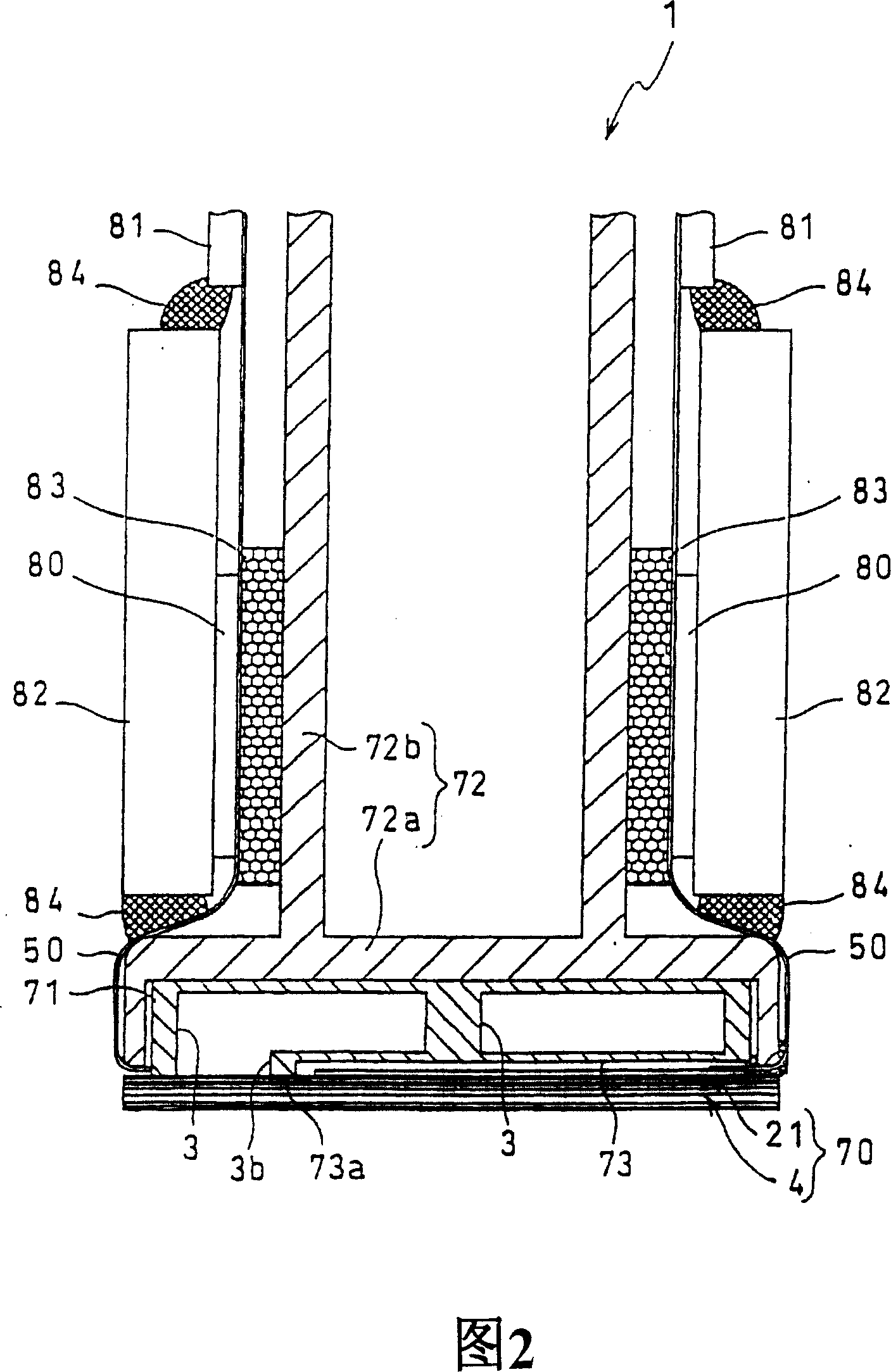

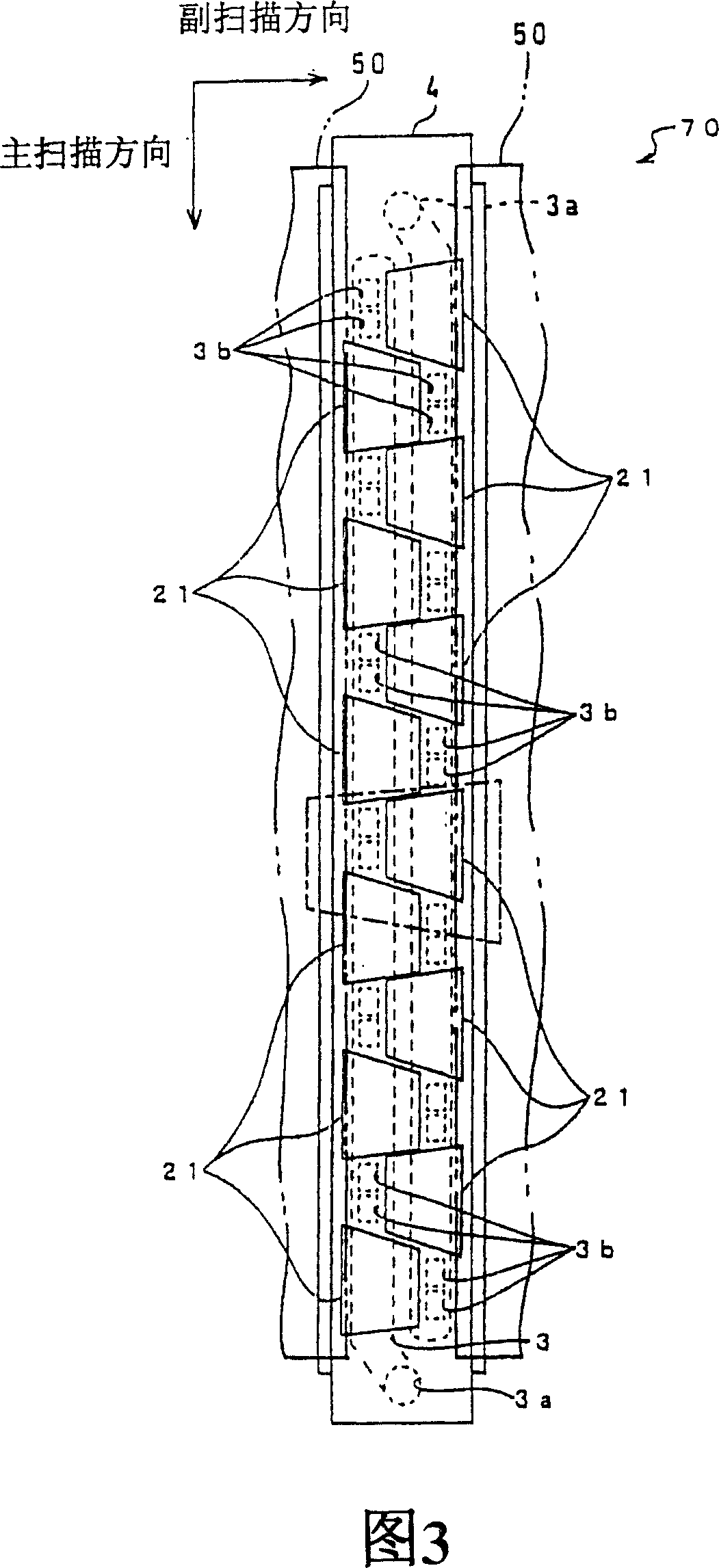

[0043] 1 to 8, an ink jet head unit according to a first embodiment of the present invention will be described. In FIGS. 1 and 2, reference numeral 1 generally denotes an inkjet head unit provided in an inkjet printer (not shown) for ejecting ink droplets onto a recording medium in the form of paper so that Information or images are recorded on the recording medium. The inkjet head unit 1 includes: an inkjet printhead 70 having a rectangular shape in plan view extending in the main scanning direction and a plurality of nozzles 8 through which ink is ejected to paper ( FIGS. 4 and 5 ); A base block 71, which is provided above the print head 70, and two ink tanks 3, 3 are formed in the base block 71, each ink tank 3 serving as a flow of ink to be supplied to the print head 70 aisle.

[0044] The print head 70 includes: a flow channel un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com