Tire containing sealing agent

A sealant and tire technology, applied to pneumatic tires, tire parts, tires, etc., can solve the problems of ineffective repair and hard rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The implementation of the present invention will be described below according to the embodiments of the present invention illustrated in the accompanying drawings.

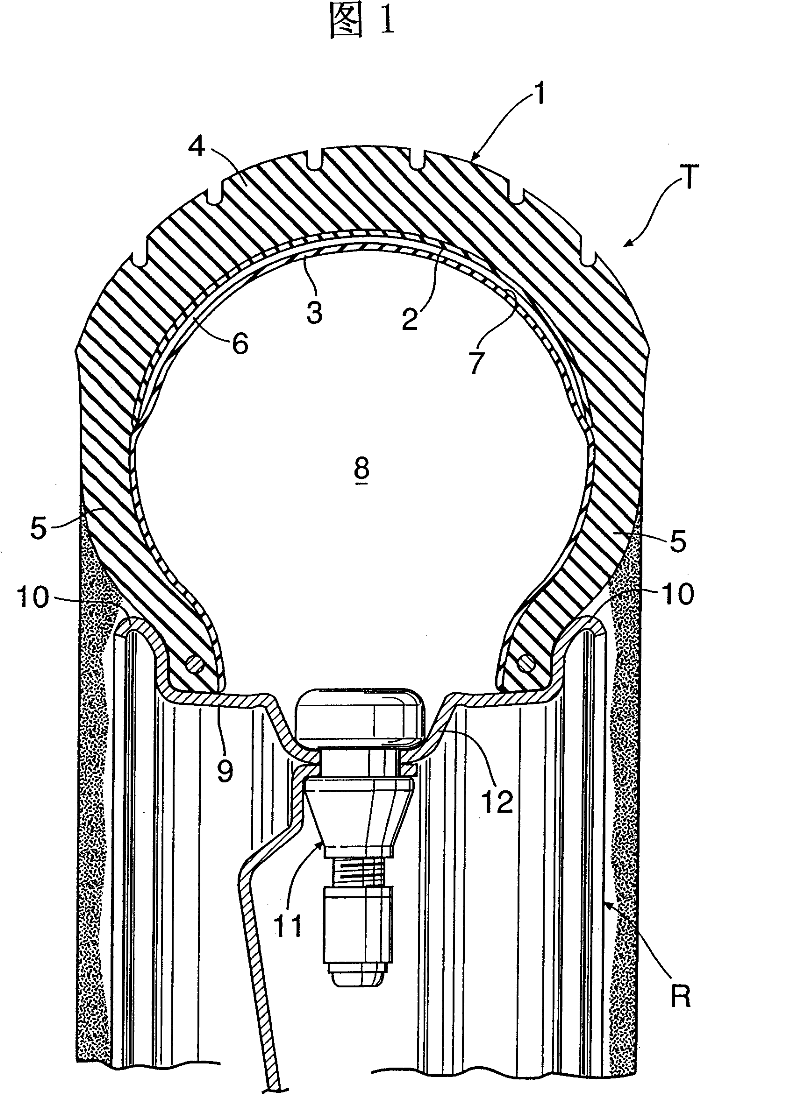

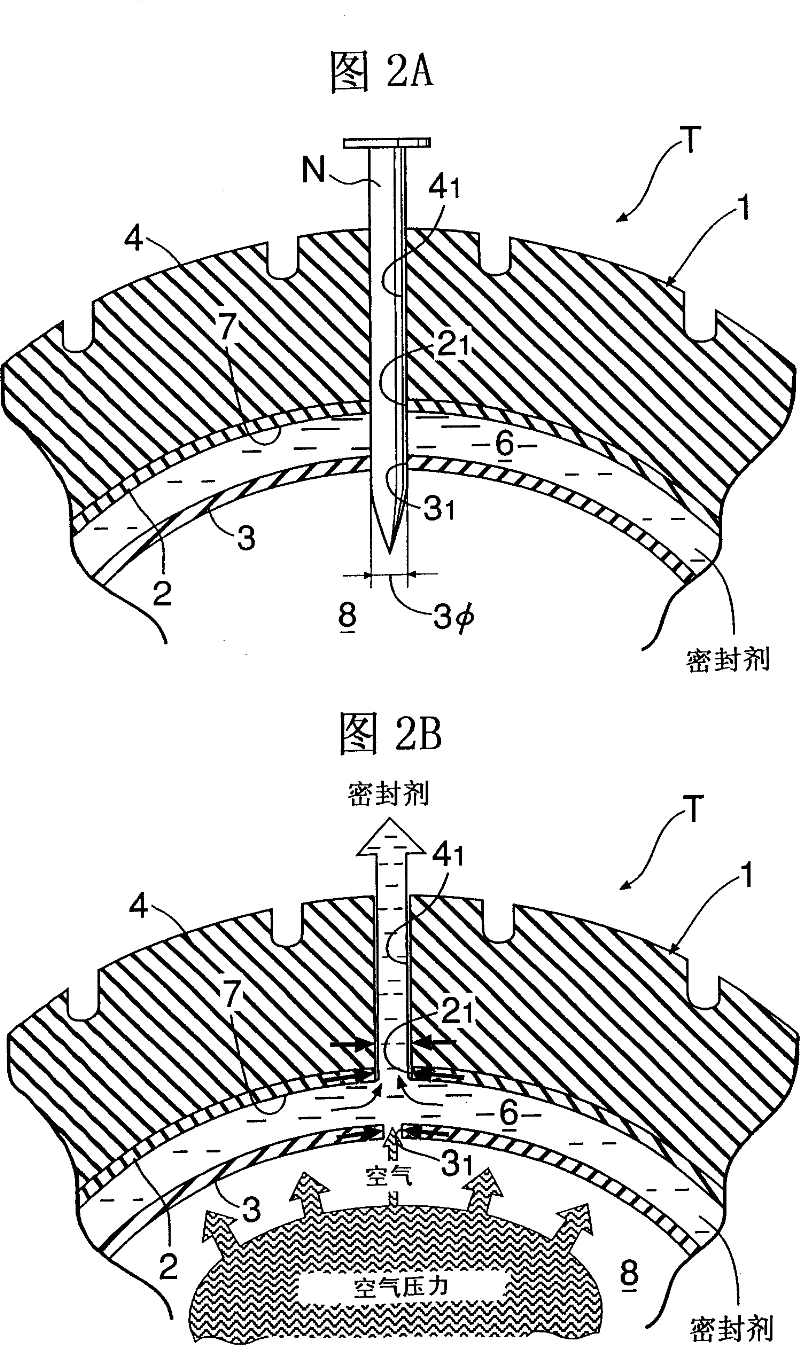

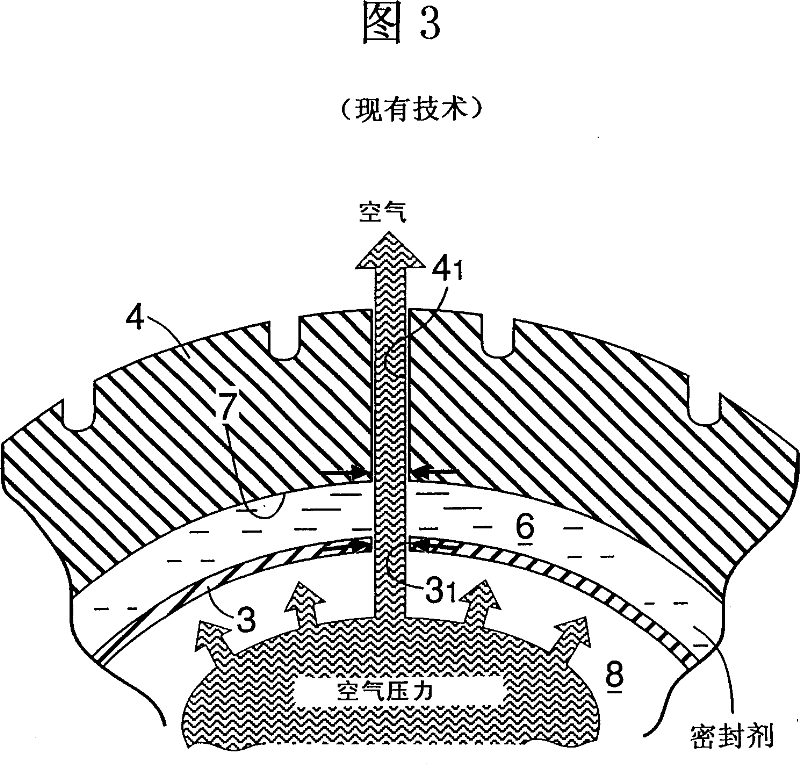

[0010] Fig. 1, Fig. 2A, Fig. 2B are the schematic diagrams of an embodiment of the present invention.

[0011] As shown in FIG. 1, a tubeless tire T composed of a tire main body 1, an outer lining 2 and an inner lining 3 vulcanized and bonded therein is mounted on a rim R of a motorcycle wheel. The outer lining 2 is vulcanized and bonded to the inner surface of the tire tread 4 of the tire main body 1, and at the same time, the left and right sides of the inner lining 3 except the central part are vulcanized and bonded to the left and right side walls 5, 5 of the tire main body 1. on the inner side. Between the central portion of the inner lining 3 and the outer lining 2, a sealant cavity 7 with a slightly arc-shaped cross-section filled with the sealant 6 is defined, and an air cavity 8 with a slightly ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com