Light wallboard mounting machine

A panel installation machine and lightweight wall technology, applied in construction, building construction and other directions, can solve problems such as low work efficiency, installer safety problems, and difficulty in ensuring installation quality, so as to improve work efficiency, improve work safety, The effect of improving installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

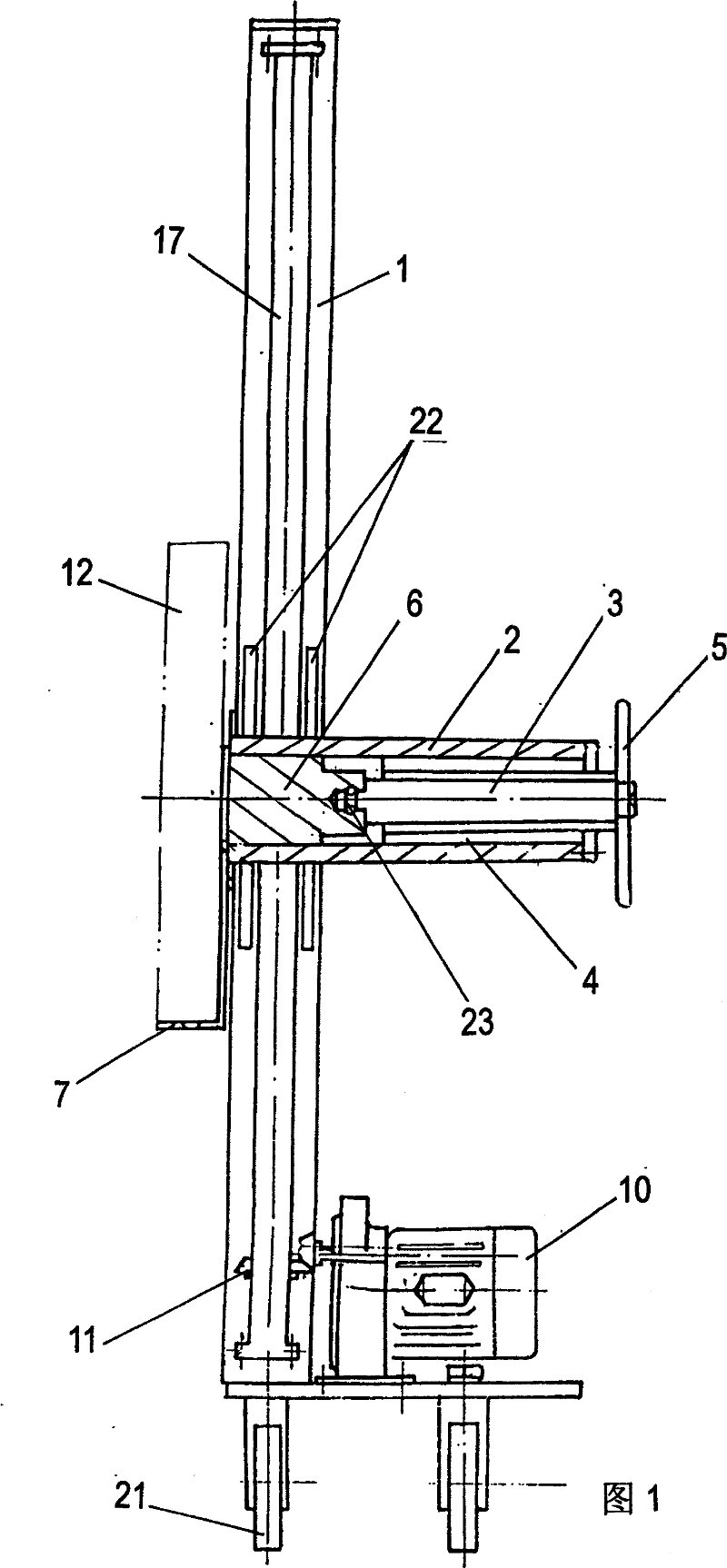

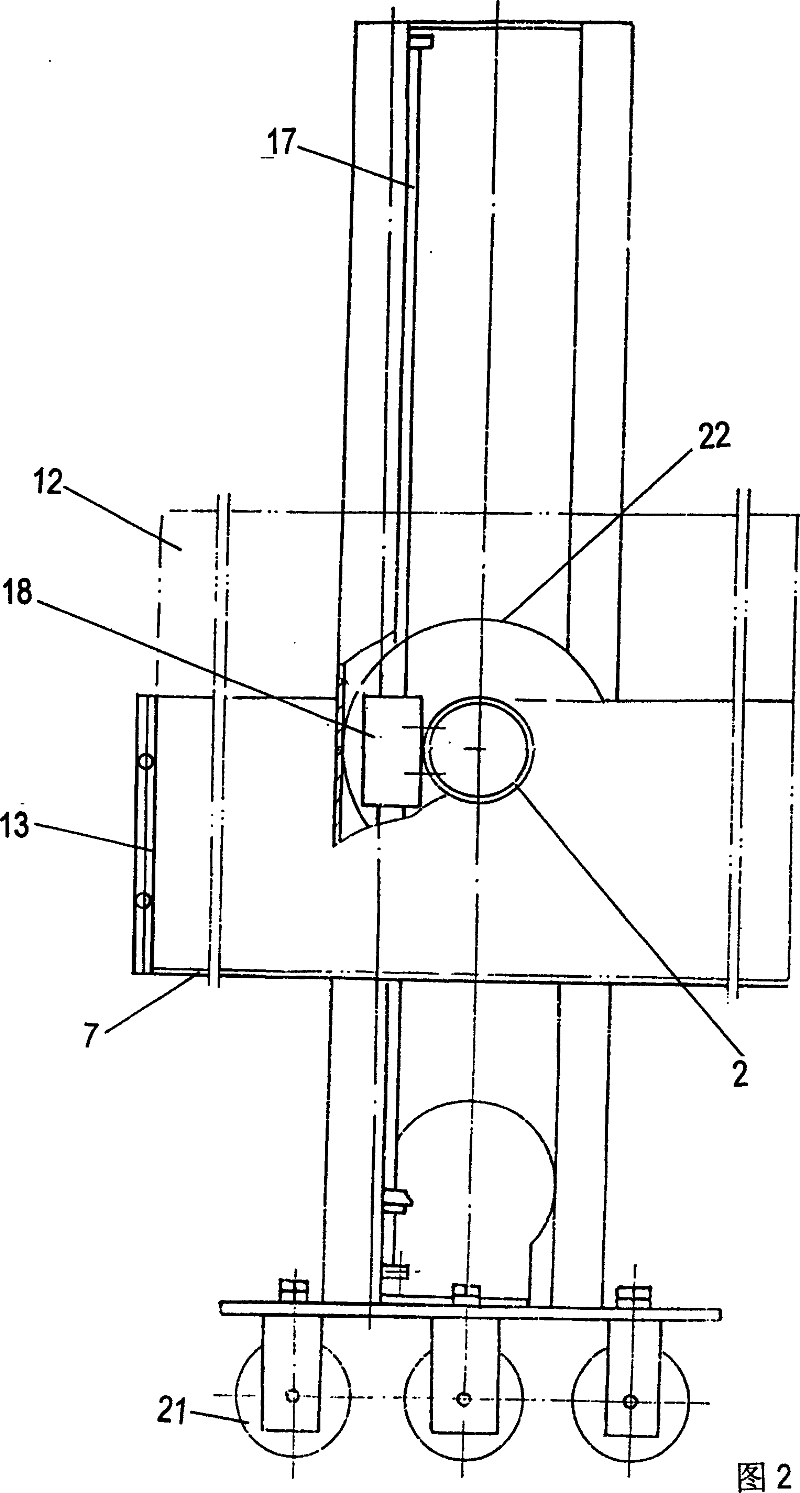

[0016] Referring to Fig. 1, Fig. 2, present embodiment is made of lifting mechanism, horizontal propulsion mechanism and wallboard bracket.

[0017] As shown in FIGS. 1 and 2 , the lifting mechanism has a guide column 1 , and a horizontal sleeve 2 is raised and lowered along the guide column 1 .

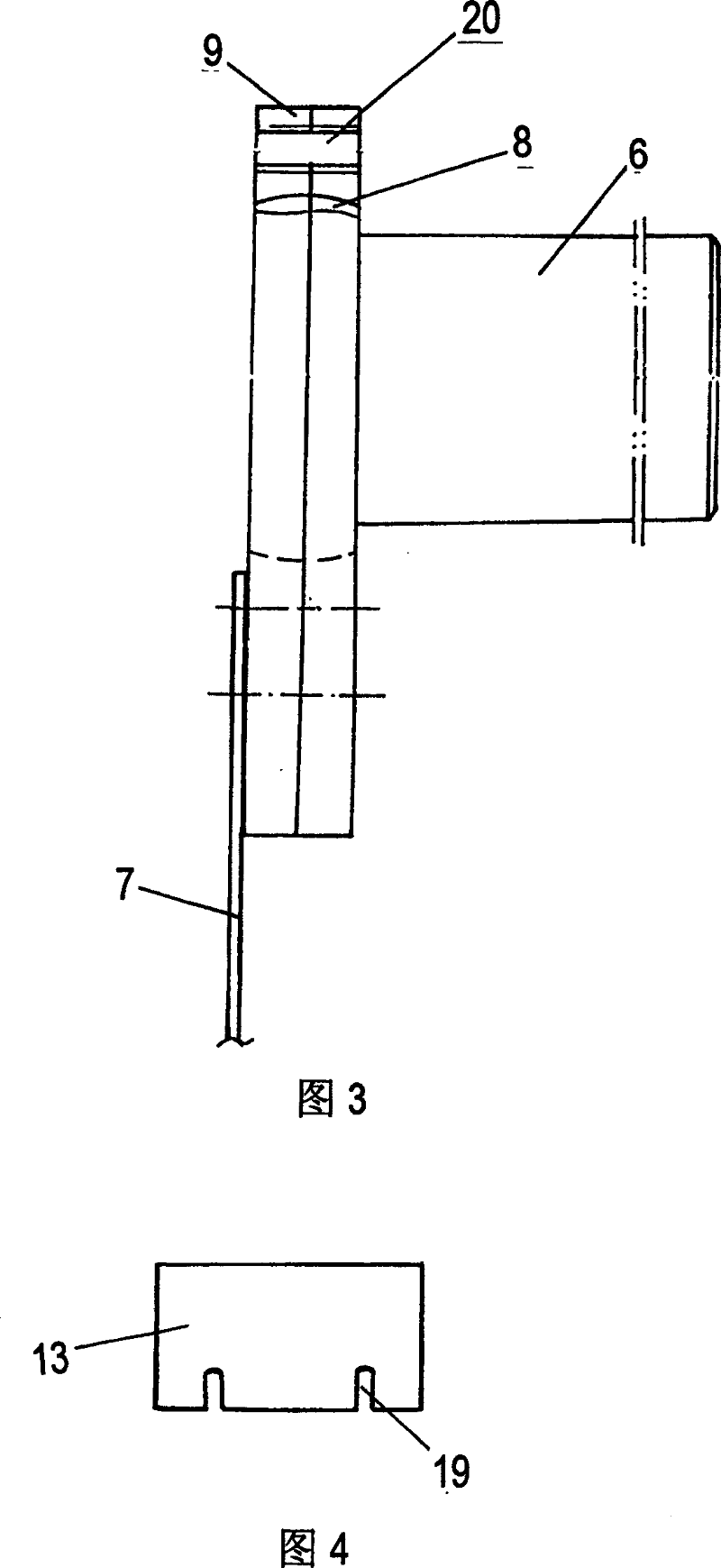

[0018] The horizontal propulsion mechanism is arranged in the horizontal sleeve 2 and consists of a propulsion screw 3 and a nut 4 fixedly arranged in the horizontal sleeve 2 threadedly matched with it; the tail end of the propulsion screw 3 is outside the horizontal sleeve 2 and connected to the Wheel 5, the front end of propulsion screw rod 3 and the bracket shaft 6 slidingly fitted in the horizontal sleeve 2 are dynamically connected by axial pin shaft 23, and wallboard bracket 7 is arranged on the front end of bracket shaft 6.

[0019] In order to ensure the installation quality, the verticality and levelness need to be corrected during the installation process. In order to adapt...

Embodiment 2

[0035] Referring to Fig. 5 and Fig. 6, another embodiment of the present invention is that the hoisting mechanism is a rope traction mechanism, and a steering wheel 14 is arranged on the top of the guide column 1, and one end of the traction rope 15 bypasses the steering wheel 14 and is fixedly connected to the rotating disk 16. The other end is drawn on the horizontal sleeve 2. A drive motor 10 is provided, and the output of the motor provides power for the rotation of the rotating disc 16 . Other structures are the same as in Embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap