Portable grounding rod installation power machine device

A technology for power machinery and grounding rods, which is applied to cable installation devices, cable installations, electrical components, etc., can solve problems such as uneconomical construction methods, difficult access for excavation machinery, and inability to drive grounding poles, and achieves improved automation and efficiency. The effect of intelligent level, saving construction labor costs, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solution and advantages of the present invention clearer, a portable grounding rod installation power mechanical device of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and should not be used to limit the protection scope of the present invention.

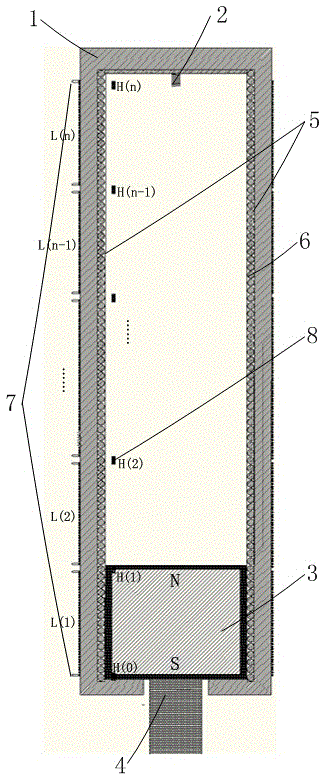

[0021] attached figure 1 A schematic diagram of the cross-sectional structure of the present invention is given in , a portable ground rod installation power mechanical device, including: steel cylinder 1, spring 2, iron core 3, iron hammer 4, guide rail pair 5, ball 6, coil 7, and Hall Seoul sensor8.

[0022] Wherein, the steel cylinder 1 is in the shape of a hollow cylinder, and its height depends on the requirements of different striking forces. There are various height models, and its l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap