Detachable reinforcement cage installation platform

A technology for installing platforms and reinforcement cages, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of difficult operation, difficult installation of reinforcement cages, low operation safety, etc., to achieve convenient assembly and disassembly, improve construction efficiency, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

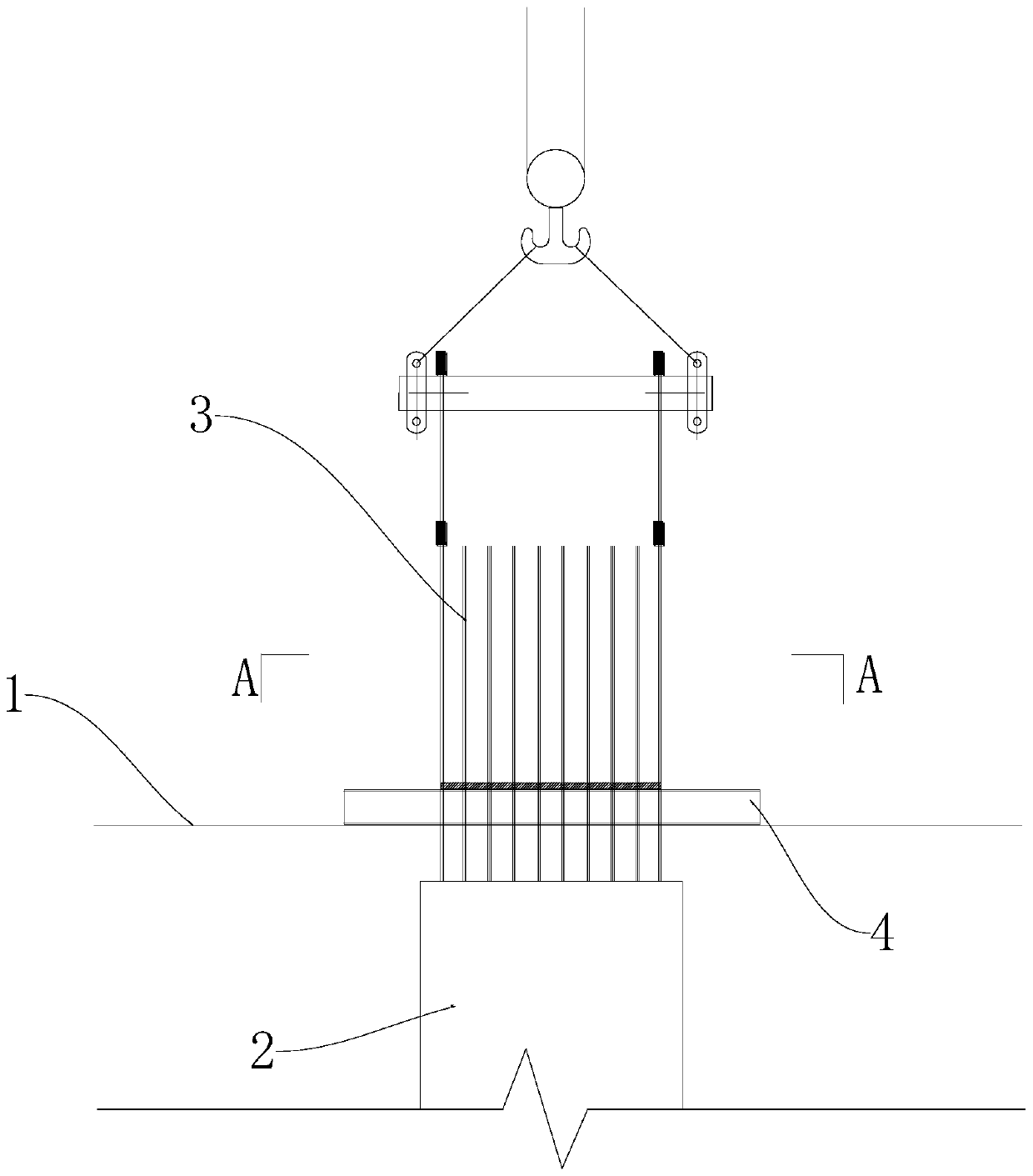

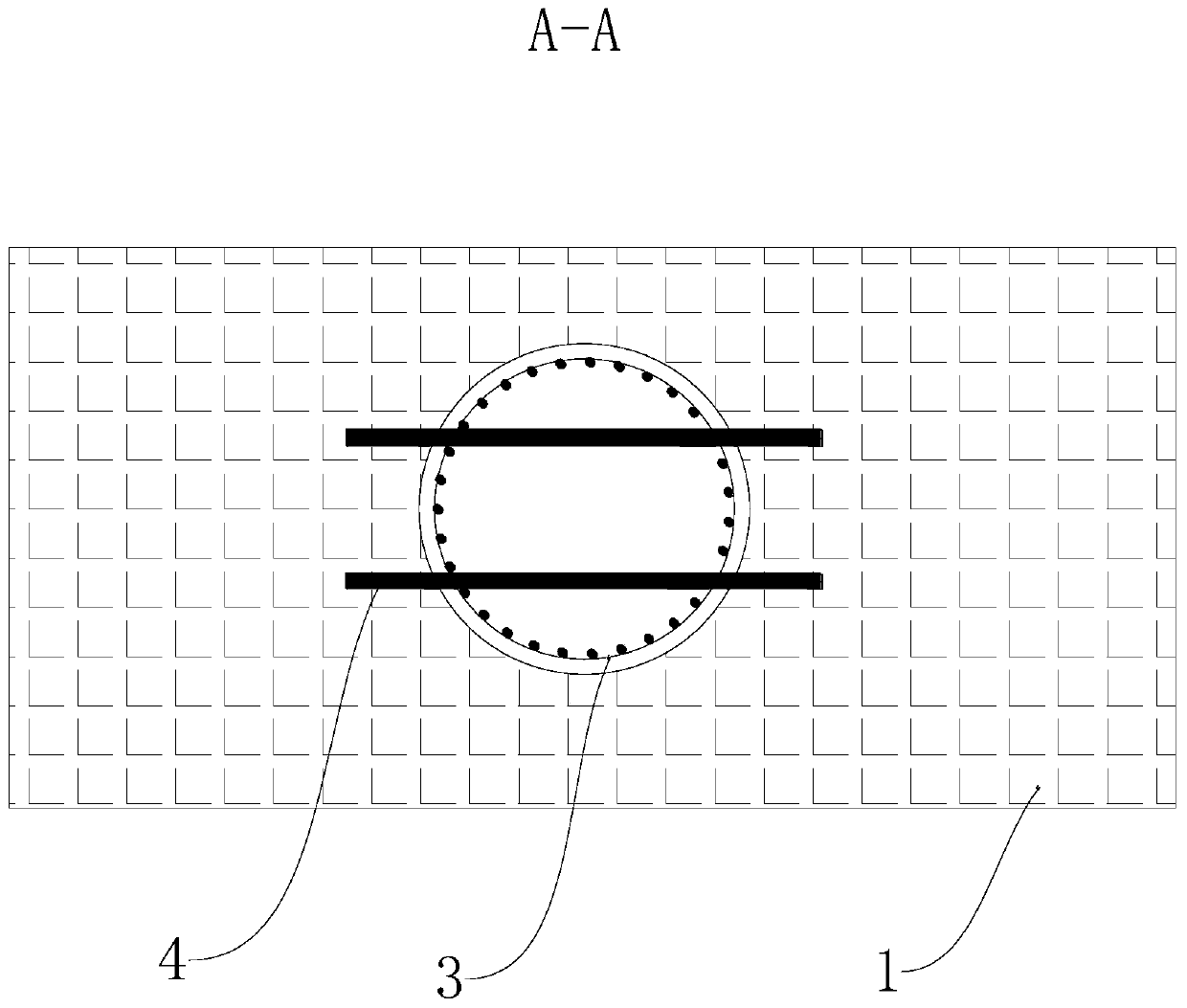

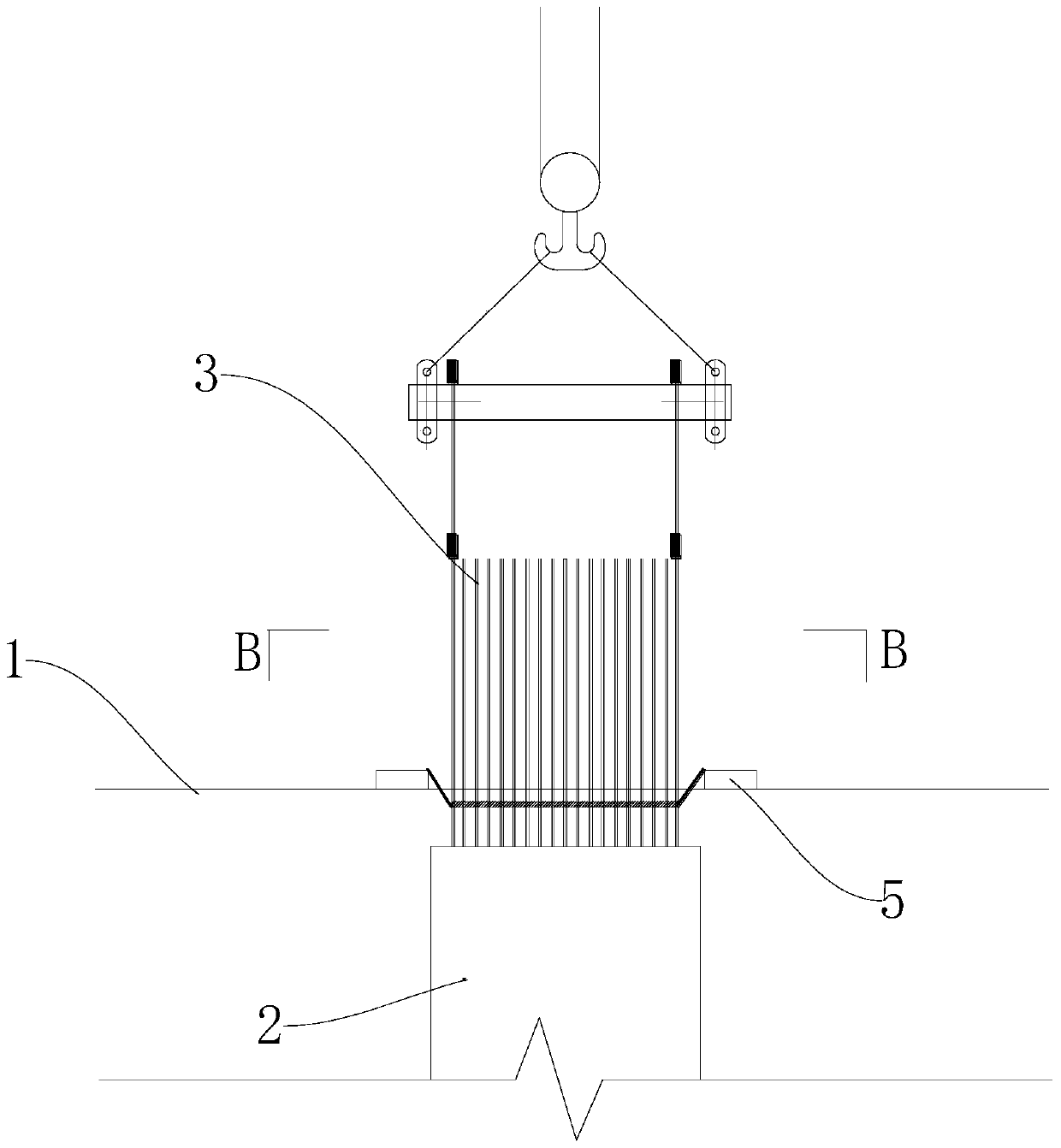

[0031] refer to Image 6 with Figure 7 , the present invention's assembled and disassembled steel cage installation platform 6 includes a pair of first sub-platforms 61 and a pair of second sub-platforms 62, the pair of first sub-platforms 61 are arranged parallel to each other, and the pair of second sub-platforms 62 are arranged on the pair of second sub-platforms. Both ends of the first sub-platform 61 are connected between the pair of first sub-platforms 61 . The interconnected first sub-platform 61 and second sub-platform 62 constitute an installation platform surrounding the reinforcement cage 3 in the circumferential direction. In order to achieve the purpose of "assemblable and disassembled", the assembled and disassembled steel cage installation platform 6 can be different from Image 6 Assembled in the disassembled form ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap