Controllable lifting underpinning tool

A controllable and underpinning technology, which is applied in basic structure engineering, building maintenance, and basic structure repair. , Simple and clear effect of force analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

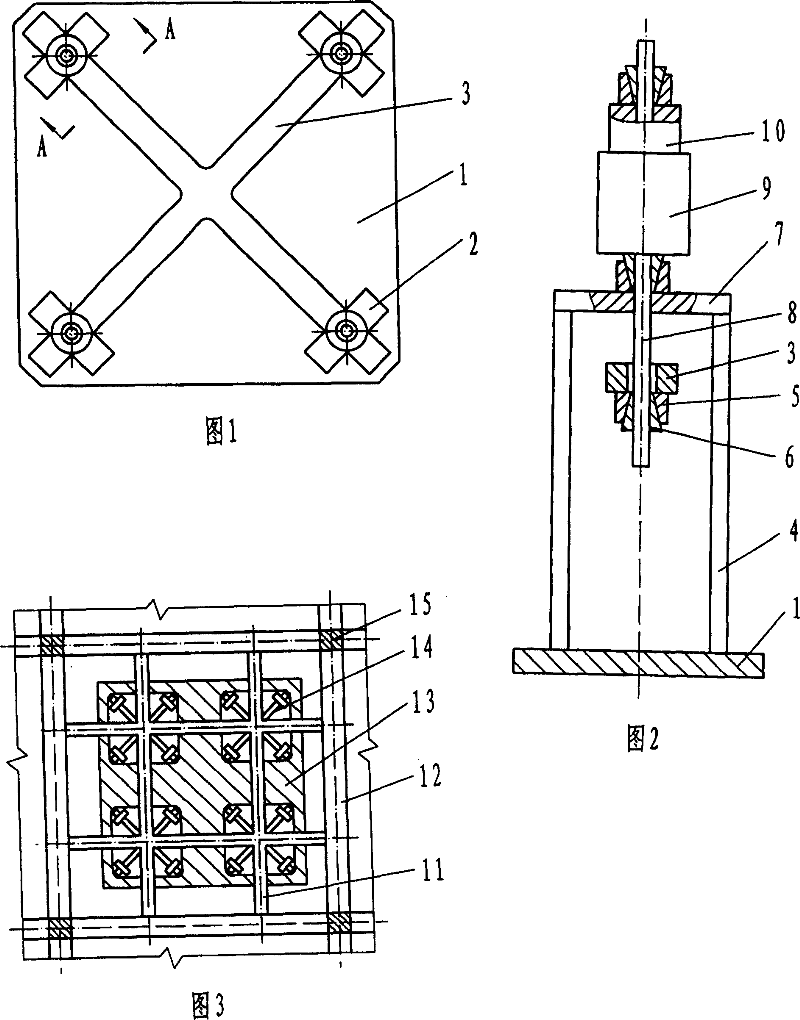

[0016] The structure of the controllable lifting underpinning tool of the present invention is shown in Fig. 1 and Fig. 2 . It consists of a base plate 1, a door frame 2, a lower joist 3 and a lifting device. Two pairs of symmetrical cross-shaped door-shaped frames 2 are arranged on the bottom plate 1 . The lower joist 3 is formed by connecting four sections, which are distributed in a cross shape, and each section extends into a door-shaped frame respectively. Referring to FIG. 2 , the portal frame 2 is welded by steel columns 4 on both sides and upper joists 7 . The lower end of the steel column 4 is welded on the bottom plate 1, and the upper end is welded on the upper joist 7, forming a "door" structure with the upper joist 7. The lifting device is composed of an anchorage, a steel strand 8 and a through-hole jack 9. The anchorage is a ring 5 with an inner cone angle, and the ring 5 is provided with a clip 6 with an inner cone angle, and the steel strand 8 is passed thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com