Automatic control system of mechanical press

An automatic control system, a technology of mechanical presses, applied in the direction of presses, electrical program control, program control in sequence/logic controllers, etc. Manual adjustment work, reducing the number of components, ensuring the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

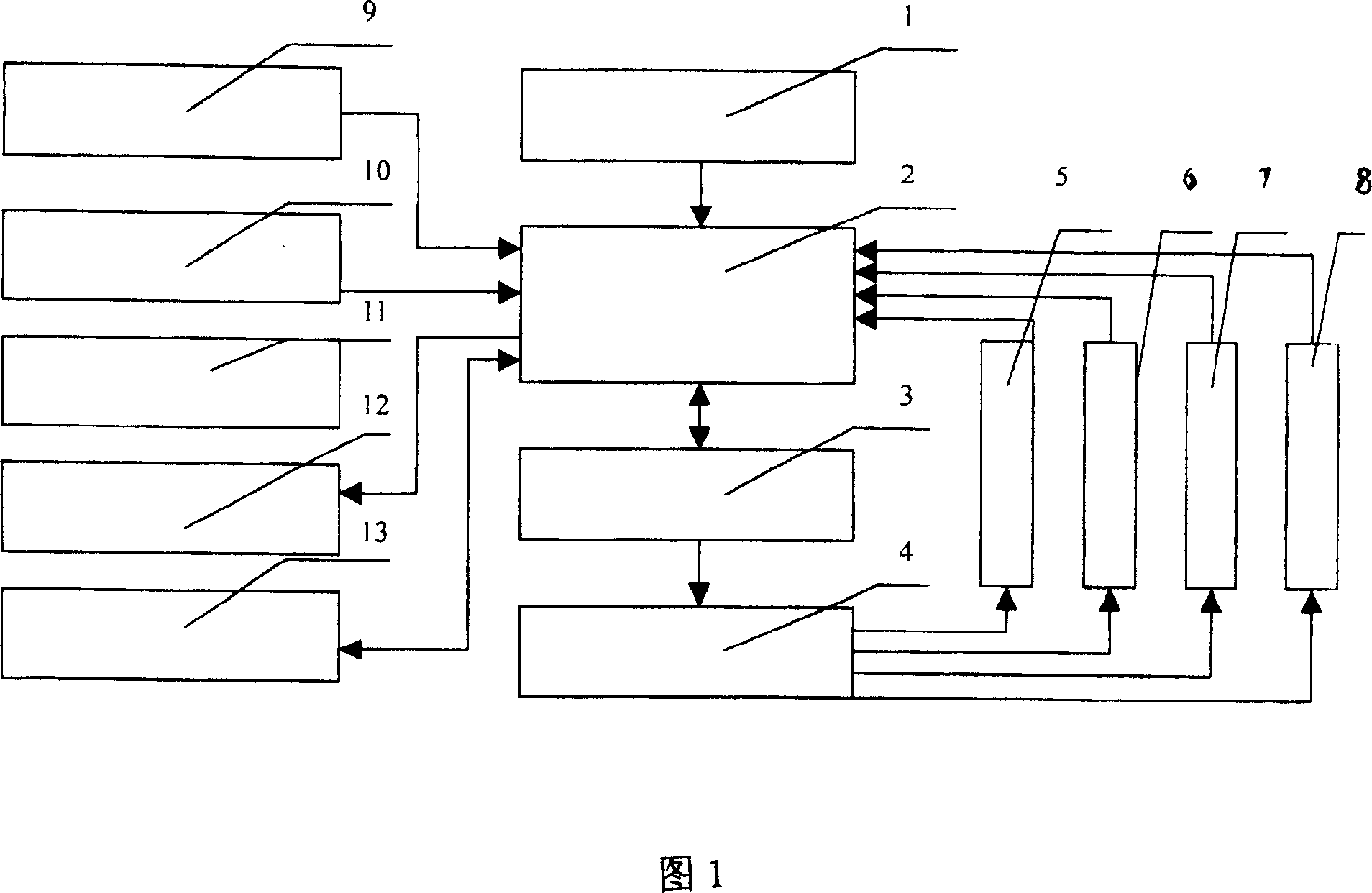

[0033] As shown in FIG. 1 , the present invention includes a console 1 , a dedicated controller 2 , an electric control cabinet 3 equipped with an actuator, a resolver 5 , an encoder 6 , a safety double valve 7 and a proximity switch 8 .

[0034] The console 1 and the dedicated controller 2 are electrically connected, and the console 1 sends the operation and stop signals of the press to the dedicated controller 2 . When there is no abnormality in the feeding device 10, the safety light curtain 9 and the safety double valve 7, the press and its external equipment operate according to the signals sent by the console, otherwise they cannot be started.

[0035] The resolver 5 is connected to the crankshaft of the press through a flange or coupling, and is used as a sensor of the crankshaft angle / slider stroke of the press, and transmits the collected crankshaft angle / slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com