Method for controlling the oil recirculation in an oil-injected screw-type compressor and compressor using this method

A compressor and screw technology, which is used in the field of controlling the oil circulation in the oil-injected screw compressor, can solve the problems of high temperature peaks of the compressor body and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

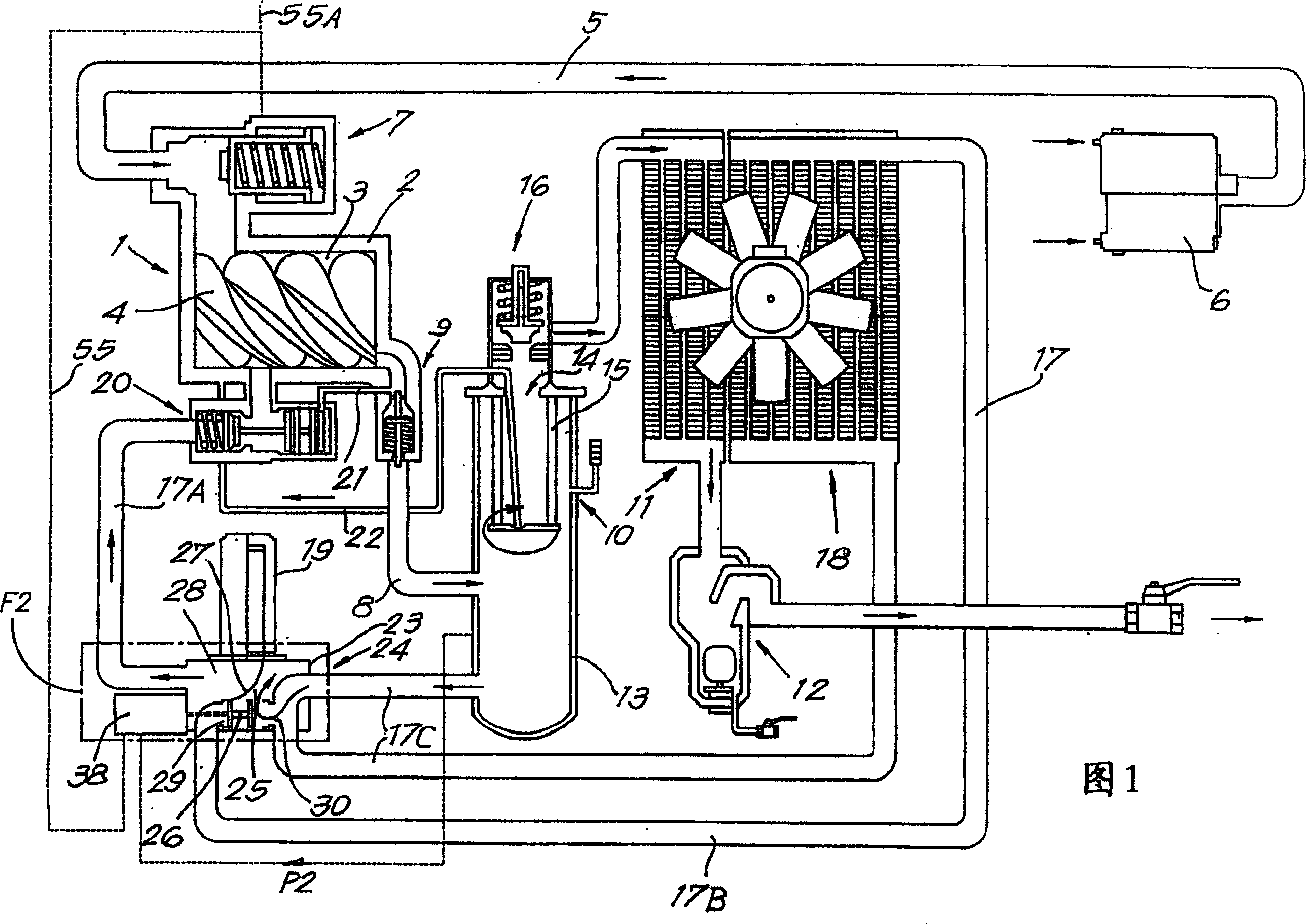

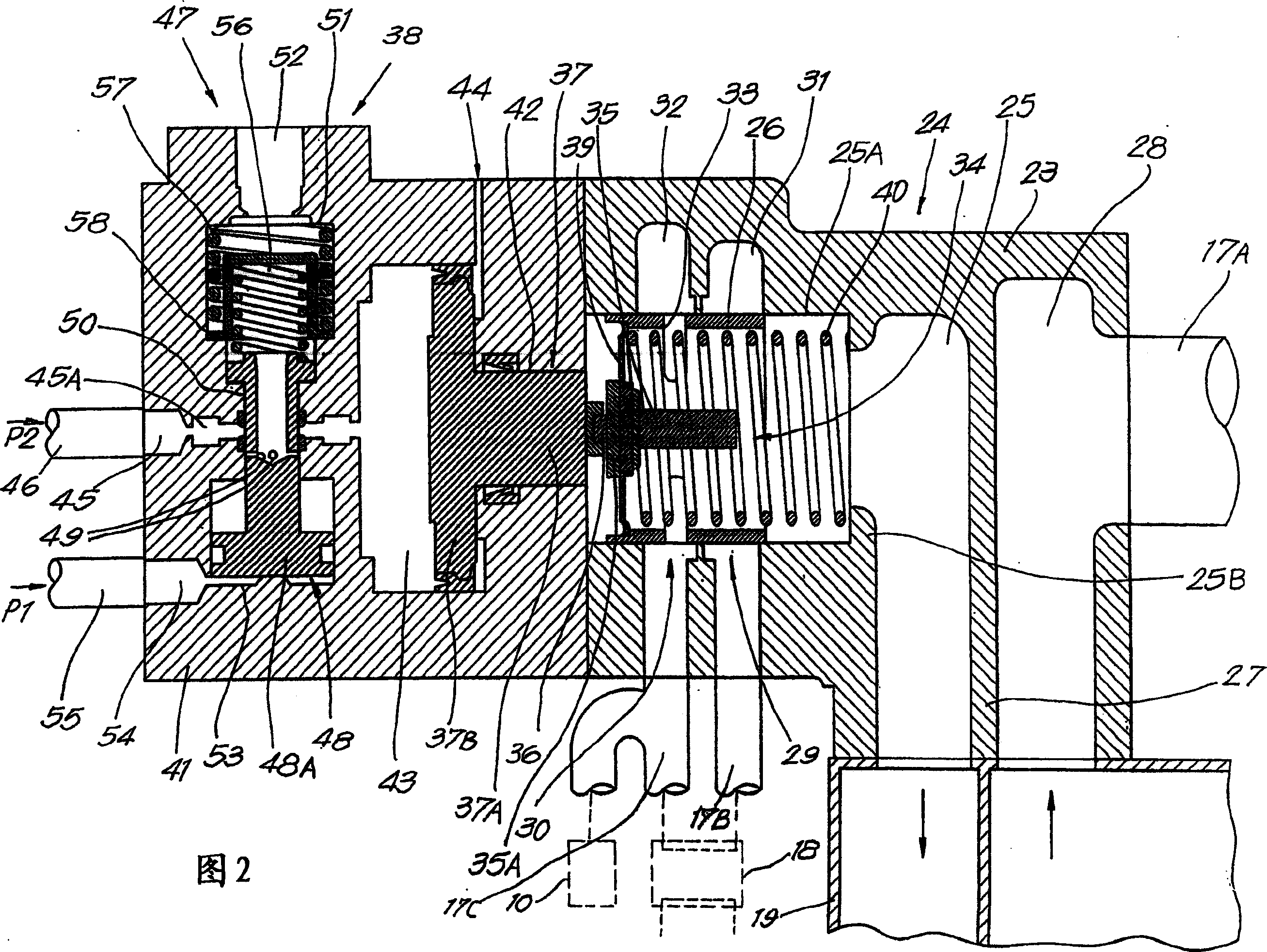

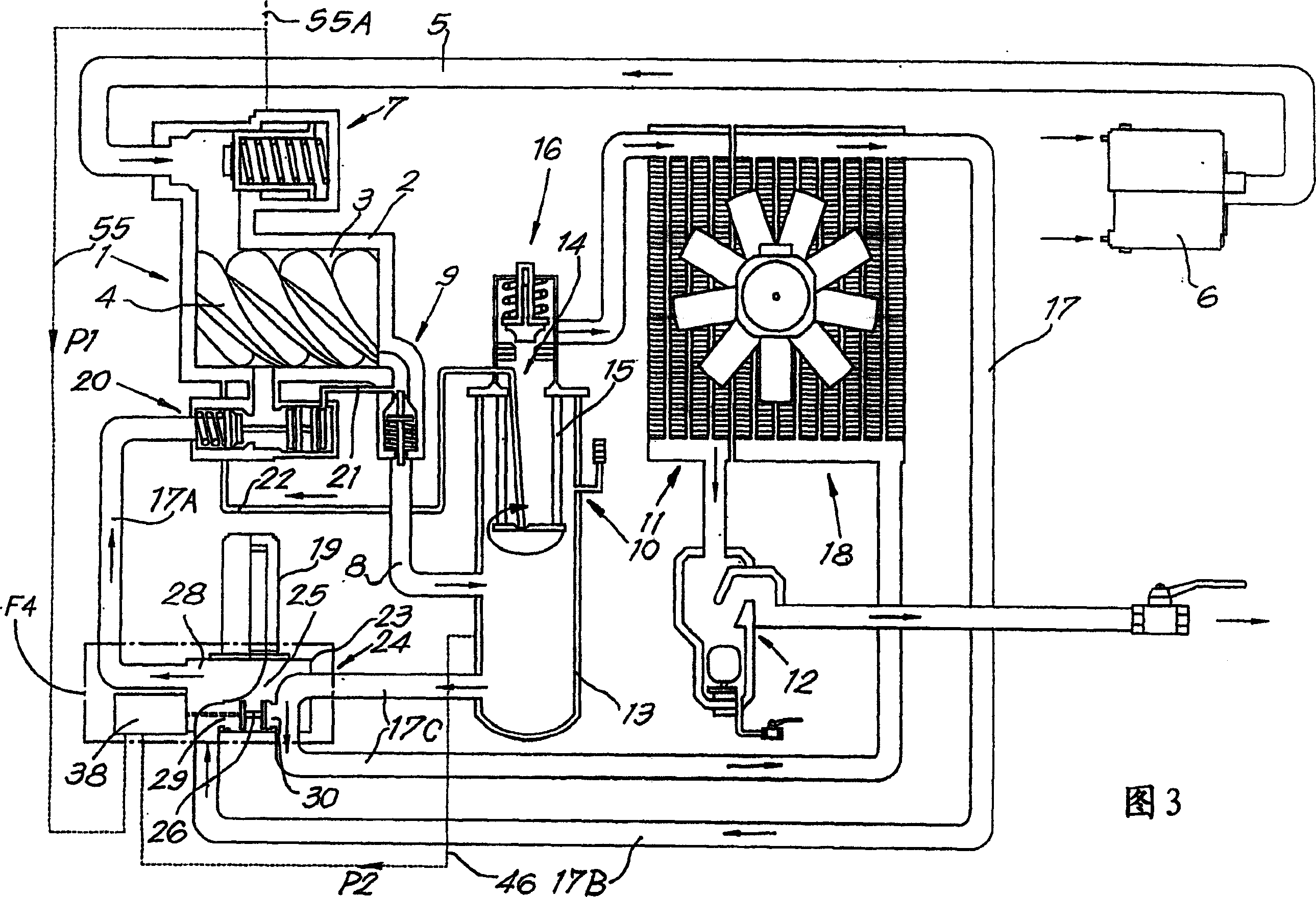

[0029] The screw compressor shown in the various figures comprises a compressor body 1 having a casing 2 enclosing a rotor chamber 3 in which are installed two cooperating helical Rotor 4. The main body of the compressor 1 is driven by a motor (not drawn in the figure).

[0030] On the inlet side, the inlet of the air intake line 5 communicates with the rotor chamber 3, and an air filter 6 and a controllable air intake valve 7 are installed in the air intake line 5, while on the outlet side, the pressure line 8 is connected to the rotor chamber 3 via an outlet valve 9, for example a return valve.

[0031] An oil separator 10 , an air cooler 11 and a water separator 12 are installed sequentially in the pressure line 8 .

[0032] Inside the oil separator 10 there is a container 13 with an outlet 14 at the top. A filter 15 is installed opposite to the outlet 14 in the container 13, and a minimum pressure valve 16 is installed in the outlet 14.

[0033] Most of the oil is coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com