Frictional disk drive mechanism of multiple rollers

A technology of transmission mechanism and friction disc, which is applied in the direction of friction transmission device, transmission device, mechanical equipment, etc., can solve the problems of continuous adjustment of transmission ratio, unstable operation of transmission mechanism, unstable change of transmission ratio, etc., and achieve Ensure stability, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

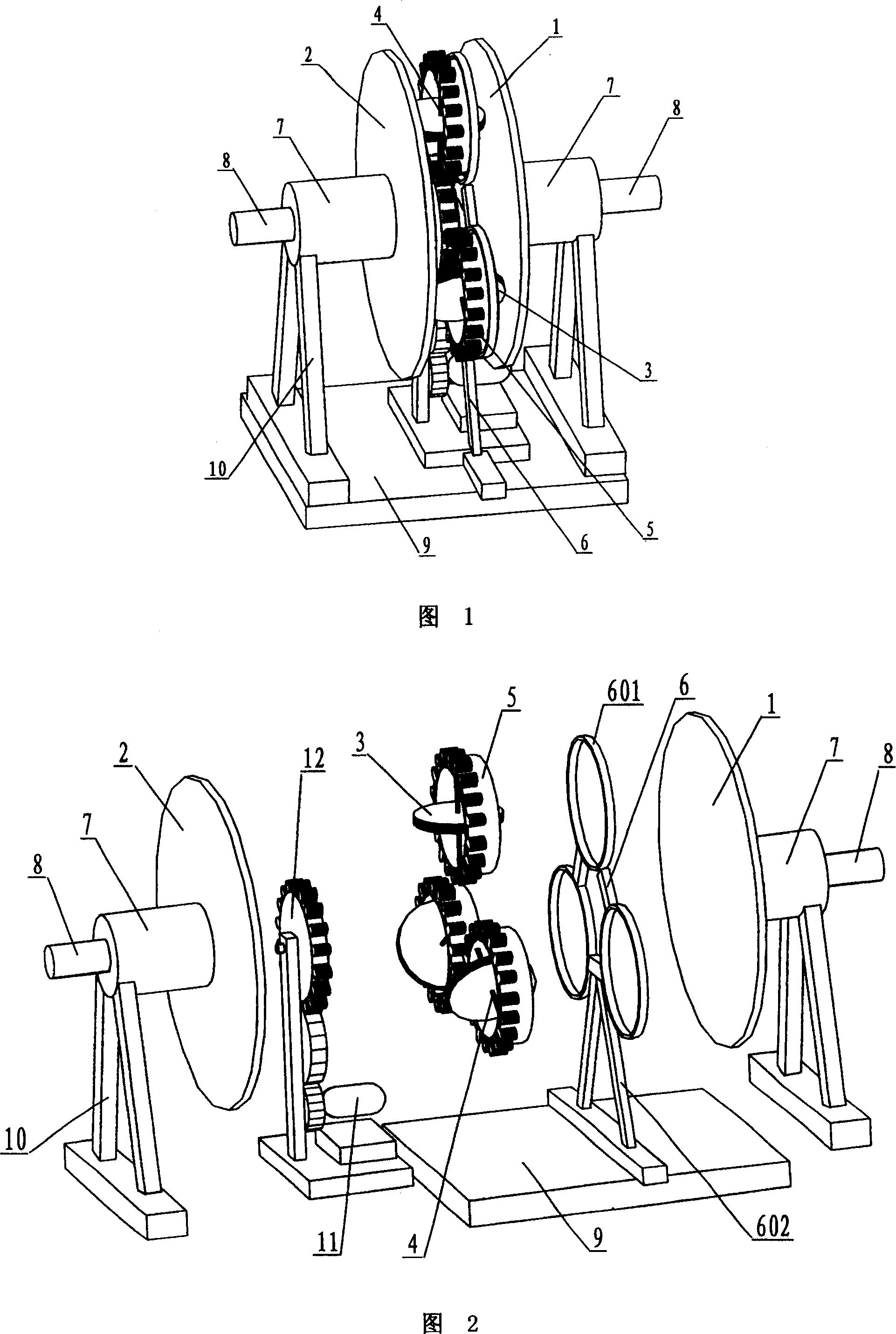

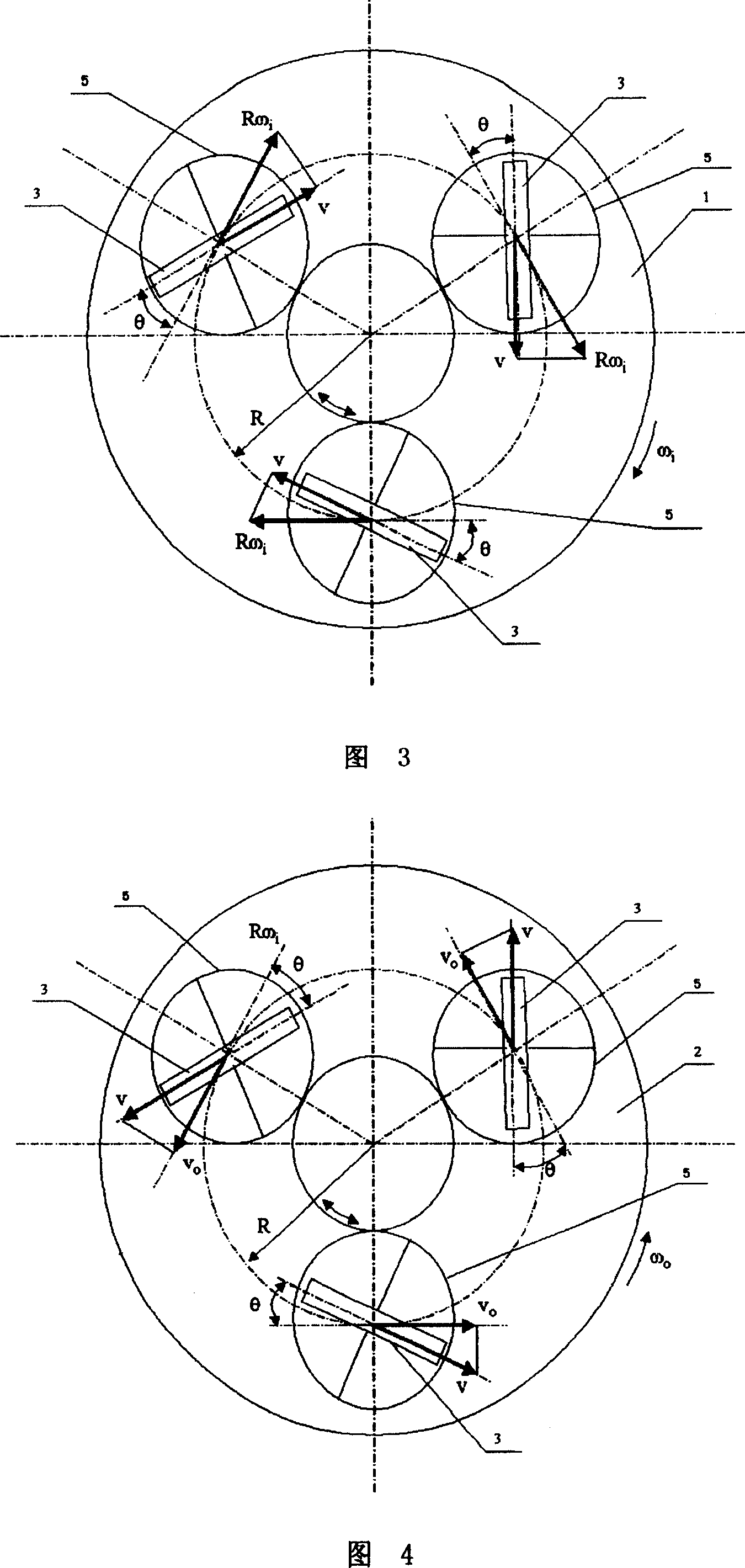

[0025] As shown in Figures 1 and 2, the transmission mechanism includes a base 9, an input disc 1, and an output disc 2, and the shafts 8 of the two discs 1 and 2 are respectively supported on the base 9 by a bracket 10 through a bearing 7 . Between the input disk 1 and the output disk 2, there are three speed regulating rollers 3 that can roll on the disk surfaces of the two disks 1 and 2, and each speed regulating roller 3 is evenly distributed on the disk surfaces between the two disks 1 and 2 Above, a steering linkage mechanism is arranged between the rotating shafts 4 of each speed regulating roller 3 .

[0026] As shown in Figures 1, 2 and 5, the transmission mechanism also includes three (same number as the speed regulating roller 3) circular rings 5, and a bracket 6 for supporting the circular rings 5 on a plane. A speed regulating roller 3 is arranged in a circular ring 5 , and the two ends of the rotating shaft 4 of the speed regulating roller 3 are connected on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com