Proton exchange membrane fuel cell stack

A fuel cell stack and proton exchange membrane technology, applied in solid electrolyte fuel cells, fuel cell grouping, etc., can solve problems such as increased contact resistance, inconsistent degree of tightness, uneven contact between unipolar plates and current collectors, and achieve The effect of small contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below by accompanying drawing and embodiment the present invention will be further described:

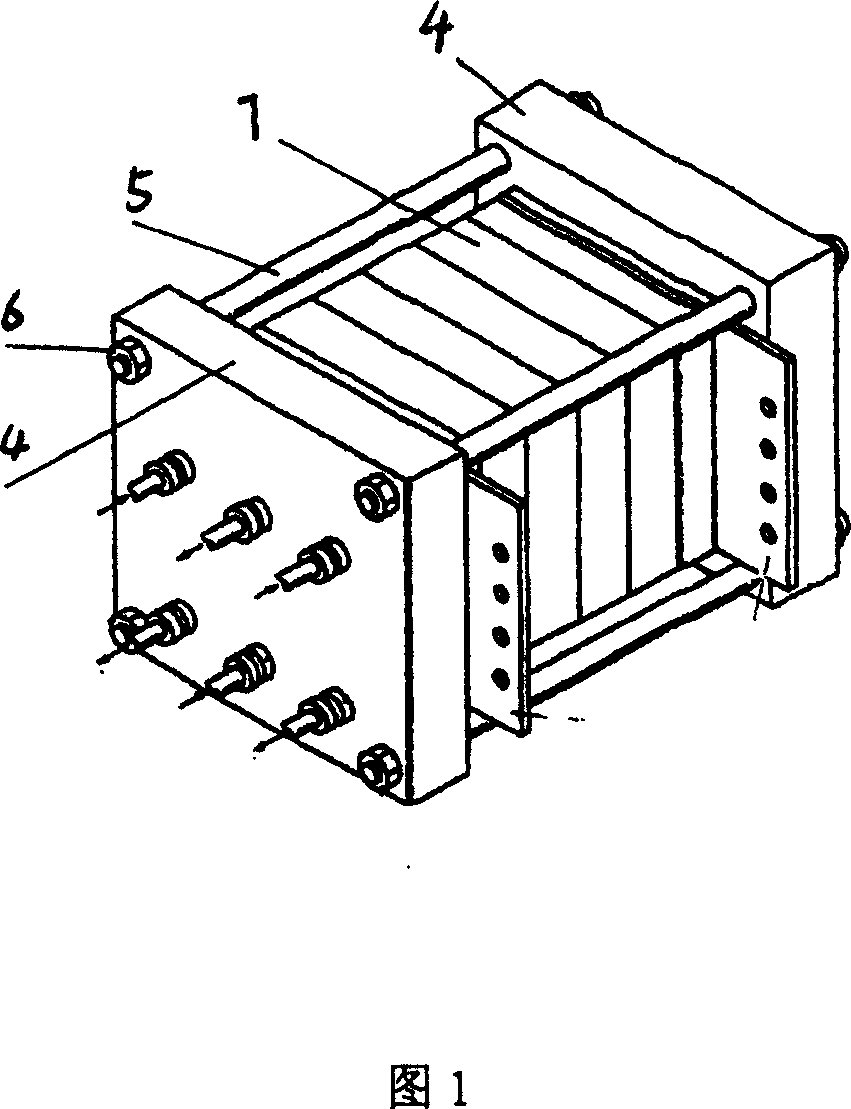

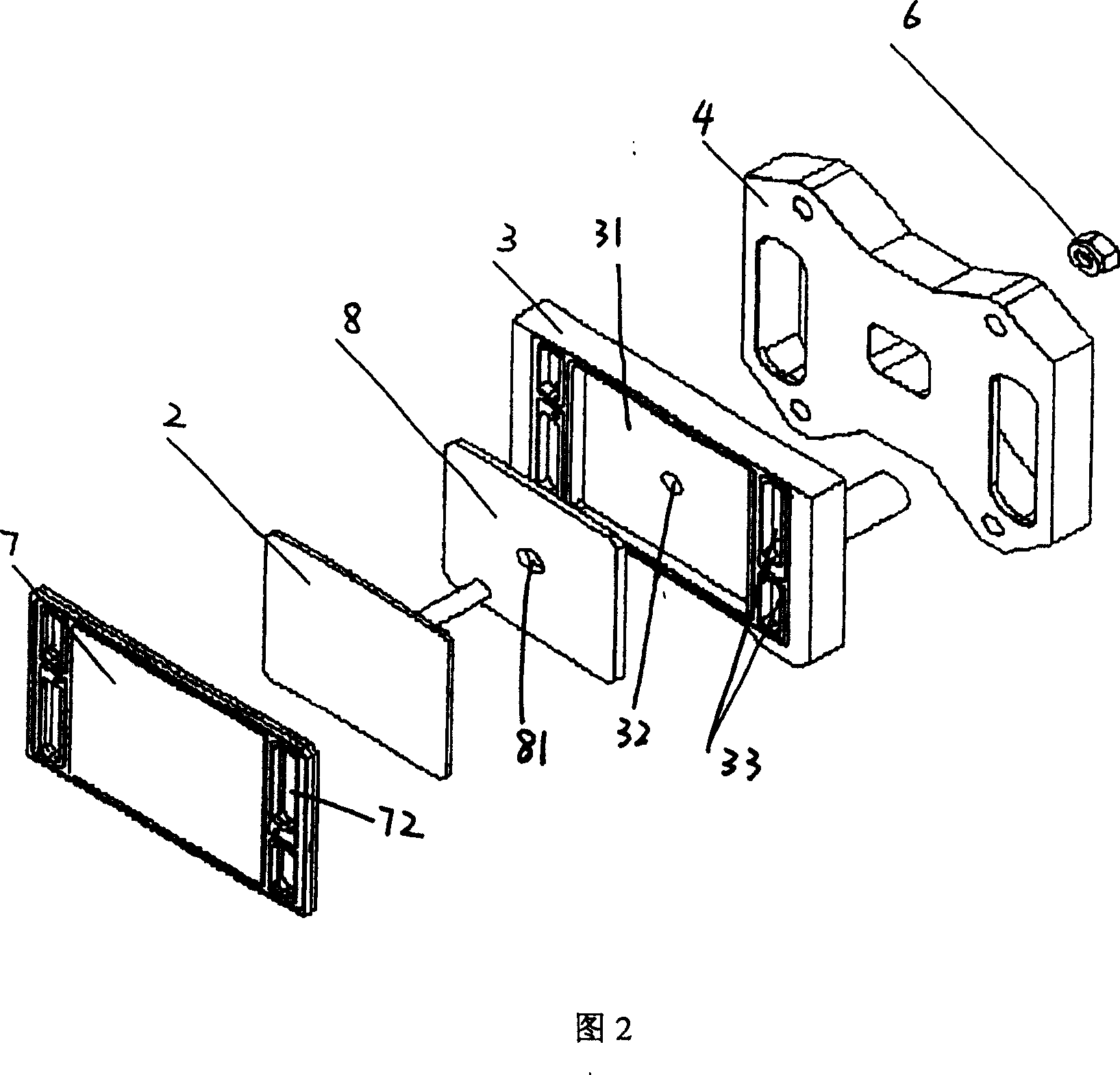

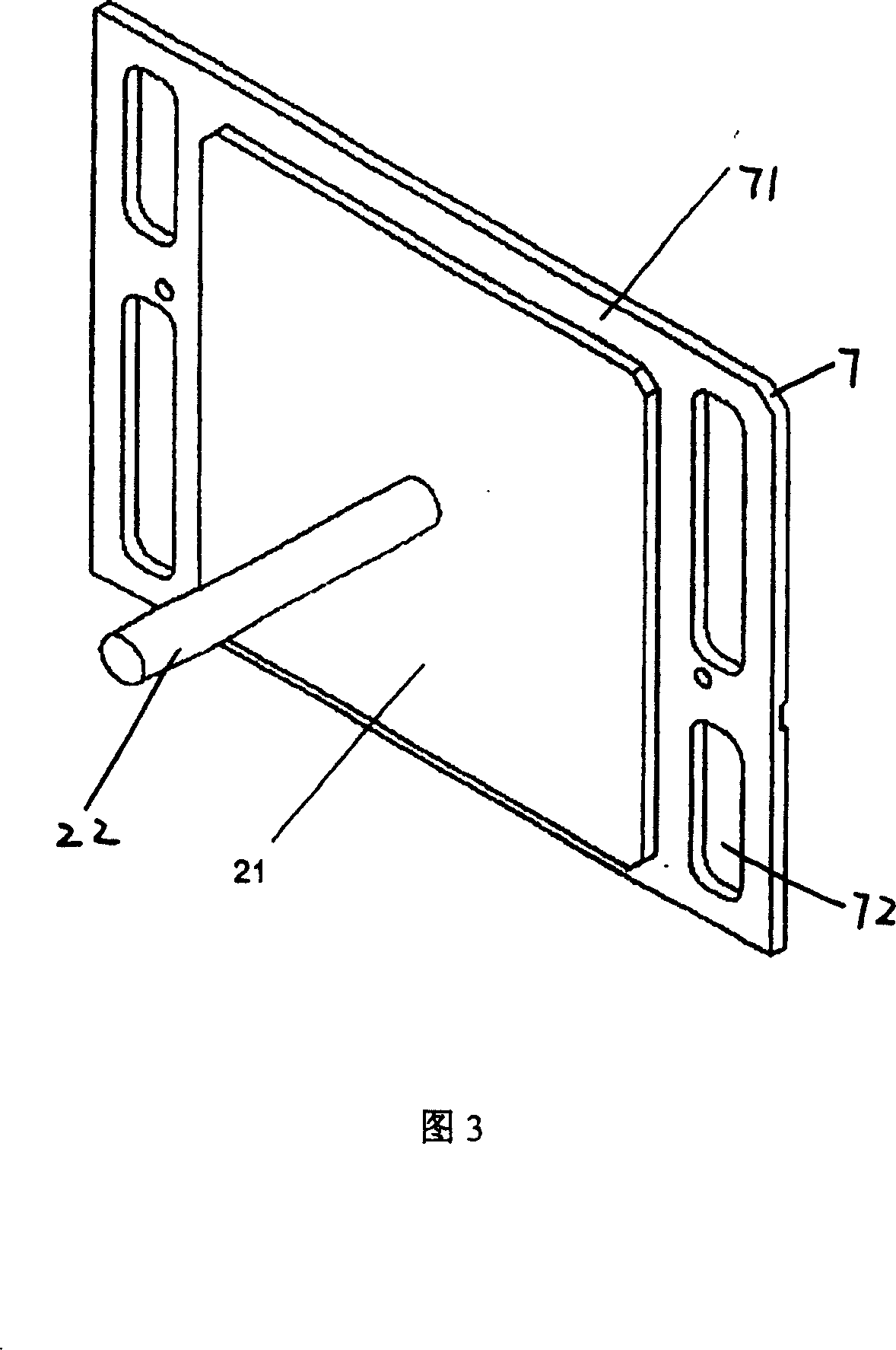

[0019] As shown in Figures 1-4, a proton exchange membrane fuel cell stack according to the present invention includes a single cell group 1, a current collector 2, a gas collector plate 3, an end plate 4, and a connecting rod 5 and nuts 6, the single battery pack 1 includes unipolar plates 7 located at both ends thereof, on the outside of the unipolar plates 7, current collectors 2, gas collector plates 3 and end plates 4 are stacked in sequence, and the connecting rods 5 pass through through holes on the end plates 4 on both sides, and fasten the parts by tightening the nuts 6 on the connecting rods; The reaction gas through hole 72 around the electric area 71, the current collector 2 includes a metal plate 21 and a current lead-out terminal 22 located on the metal plate 21, and a concave cavity is provided on the side of the gas collector plate 3 opposite to the current co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com