Access and connection device for mechanical hand

A transfer device and manipulator technology, applied in the direction of manipulators, claw arms, chucks, etc., can solve the problems of decreased reliability, unbalanced force, large rotation diameter, etc. Uniform, small radius of gyration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

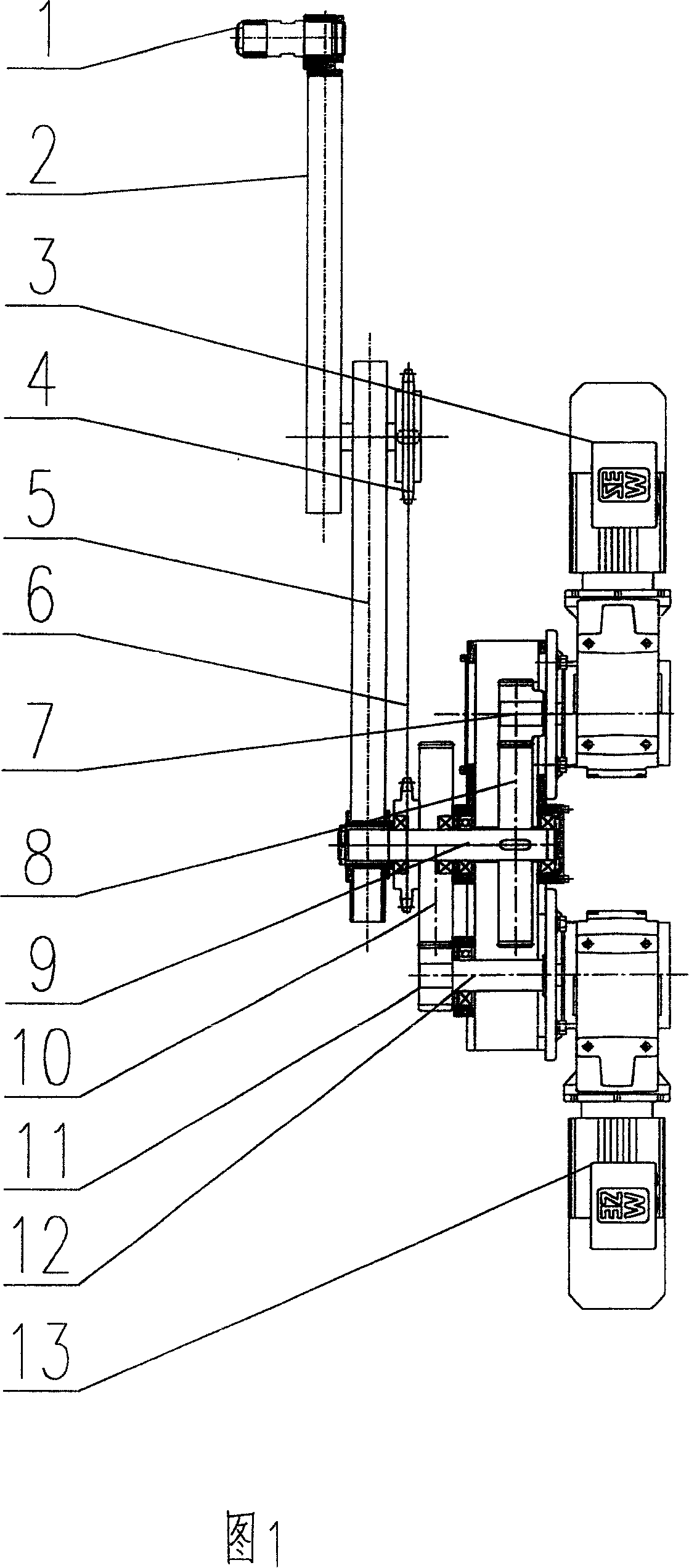

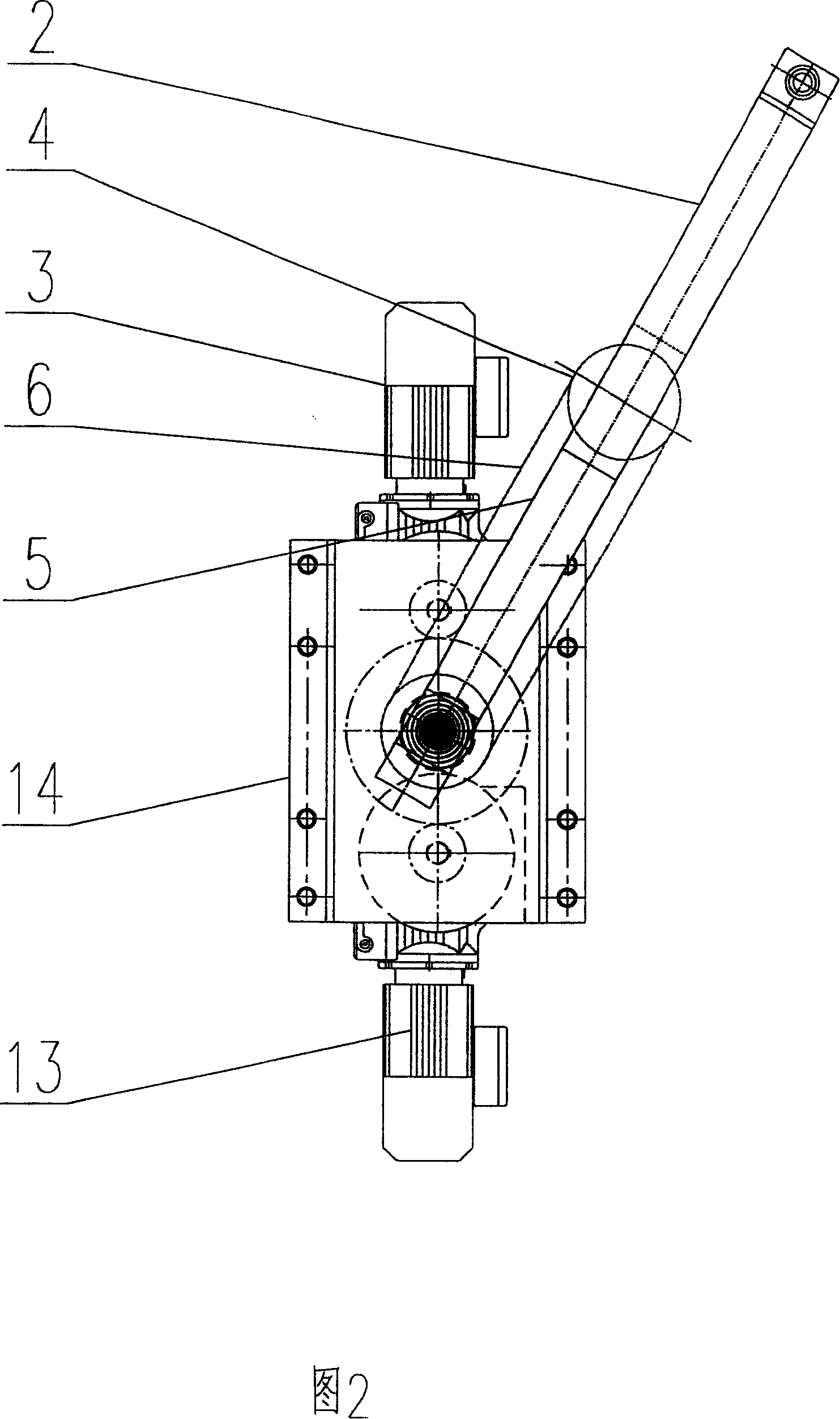

[0013] Referring to Figures 1 and 2, the manipulator access transfer device of the present invention is mainly composed of a forearm 2, a rear arm 5, a gripper 1 and a driving mechanism.

[0014] The rear end of the forearm 2 is hinged with the front end of the rear arm 5 , and the claw 1 is mounted on the front end of the forearm 2 .

[0015] The drive mechanism is composed of two groups of drive reduction motors 3 and 13, gears and the like. One group consists of the first drive reduction motor 3, the first pinion 7, the first large gear 8, and the main drive shaft 9. The first small gear 7 is installed on the first drive reduction motor 3, and the first large gear 8 is installed on the main transmission shaft 9 with a key. The first large gear 8 and the first small gear 7 are a pair of meshing gears. 5 rear ends link to each other with main transmission shaft 9 with key, drive a pair of first small gear 7 and the first bull gear 8 operation after the first drive reduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com