Sealing structure with favorable safety for piston cylinder

A sealing structure, piston cylinder technology, applied in the direction of the engine seal, piston, piston ring, etc., can solve the problems of reducing the service life of the sealing ring, sudden changes in movement speed, safety accidents, etc., to prolong the service life, avoid wear, and ensure Safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

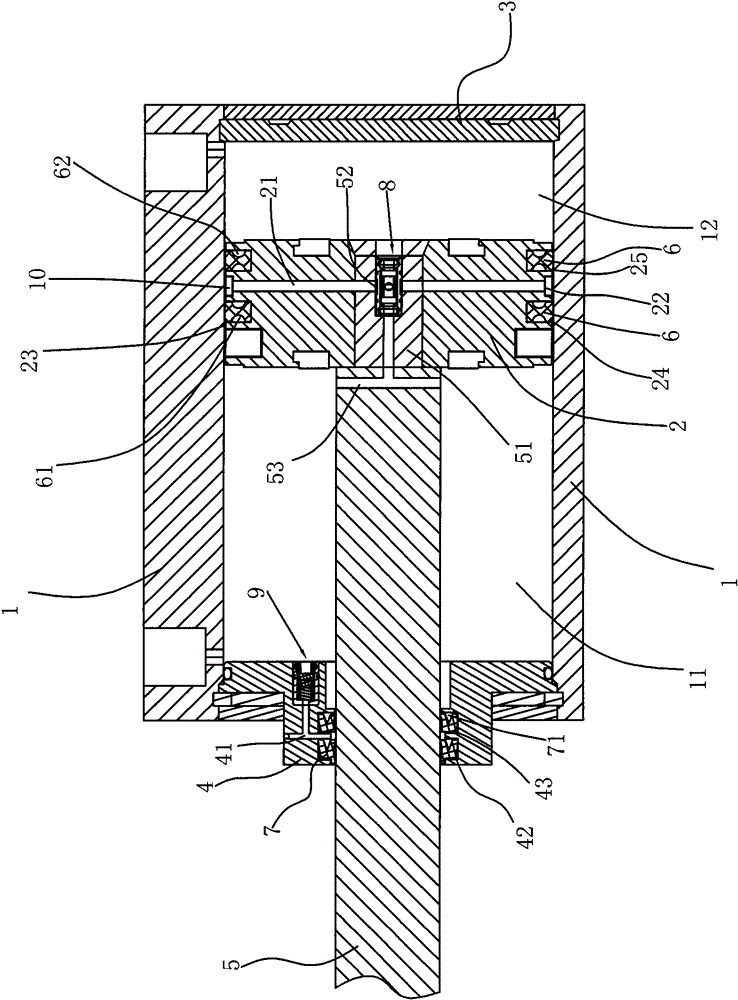

[0033] Such as Figure 1 to Figure 3 As shown, taking the pneumatic cylinder as an example, the safe piston cylinder structure includes:

[0034] The cylinder body 1 is cylindrical, and its inner chamber is divided into a rod chamber 11 and a rodless chamber 12 by a piston 2 described below.

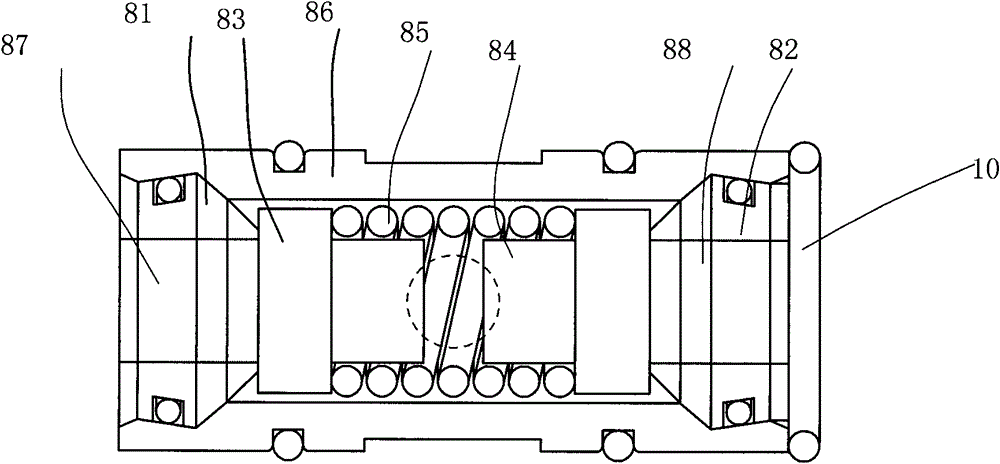

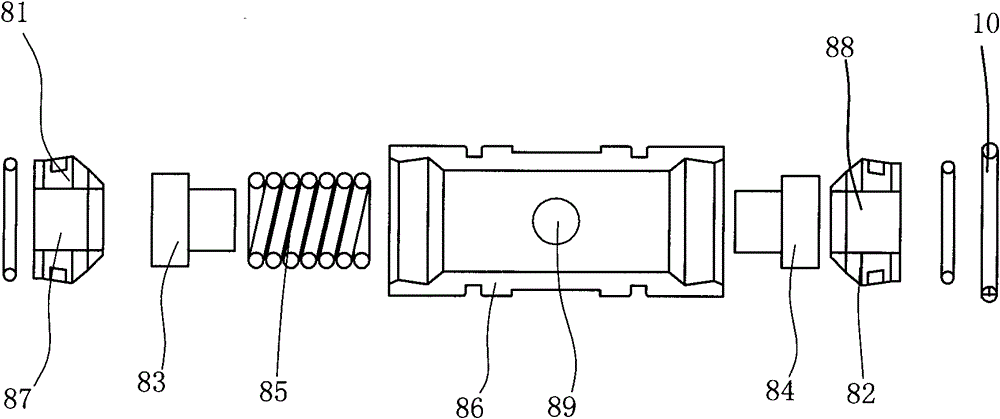

[0035] The piston 2 is movably arranged in the cylinder body 1 , and divides the cylinder body into a rod chamber 11 and a rodless chamber 12 , and there is a small gap 23 between it and the inner wall of the cylinder body 1 . The internal diameter of the piston is provided with a pressure relief hole 21; the peripheral wall of the piston is provided with a circumferential groove 22, and the circumferential groove 22 is provided with a friction block 10 that limits the gap 23 and can lubricate friction, and the circumferential groove 22 is located on the discharge port. Both ends of the pressure hole 21 communicate with the pressure relief hole 21 . On both sides of the circumferential...

Embodiment 2

[0047] Such as figure 2 As shown, the first pressure-sensitive valve in this embodiment is set at the eccentric position of the piston, so that the first pressure-sensitive valve directly communicates with the rodless cavity, and the piston rod does not need to be provided with a piston rod pressure relief channel. This structure can effectively ensure the hardness of the piston rod and increase its service life.

[0048] Other content is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com