Tyre dismounting machine

A technology of tire disassembly and disassembly machine, which is applied in tire installation, tire parts, transportation and packaging, etc. It can solve the problems of overturning heavy tires, slow disassembly work, and low work efficiency, so as to overcome pressure deviation, improve work efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

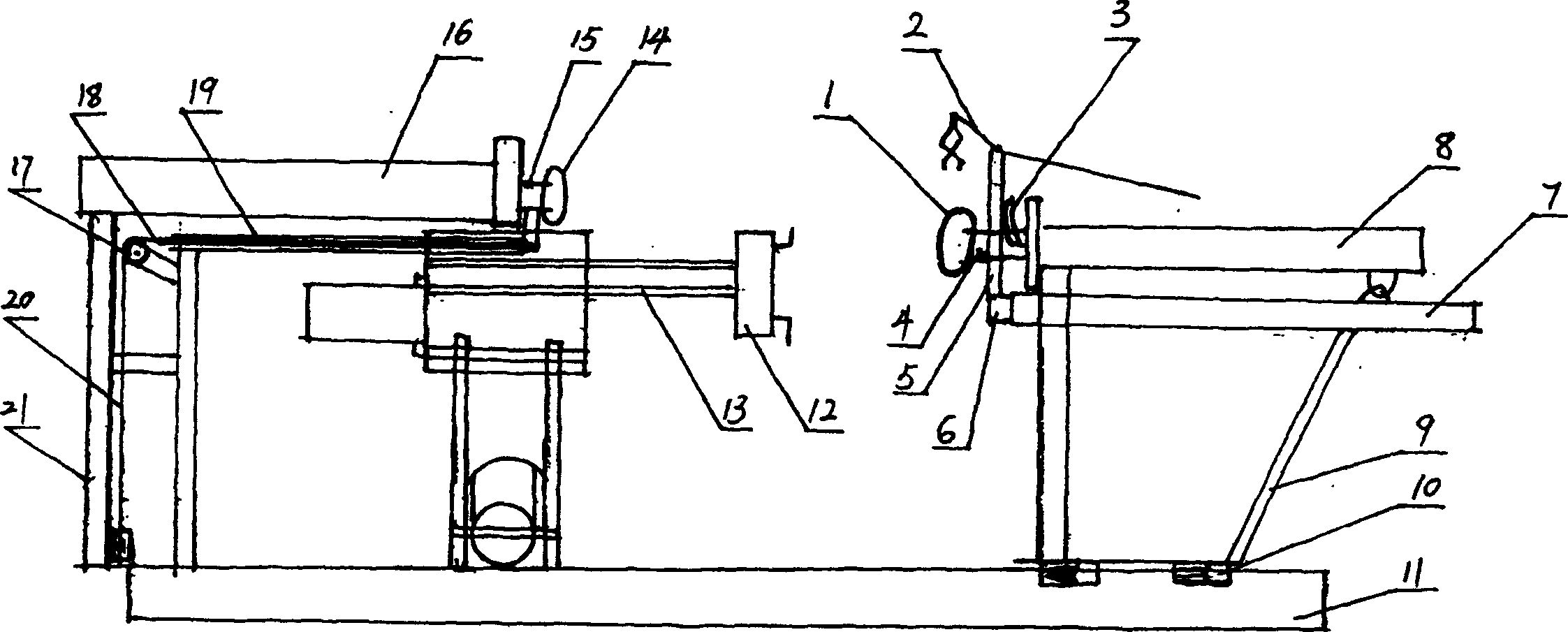

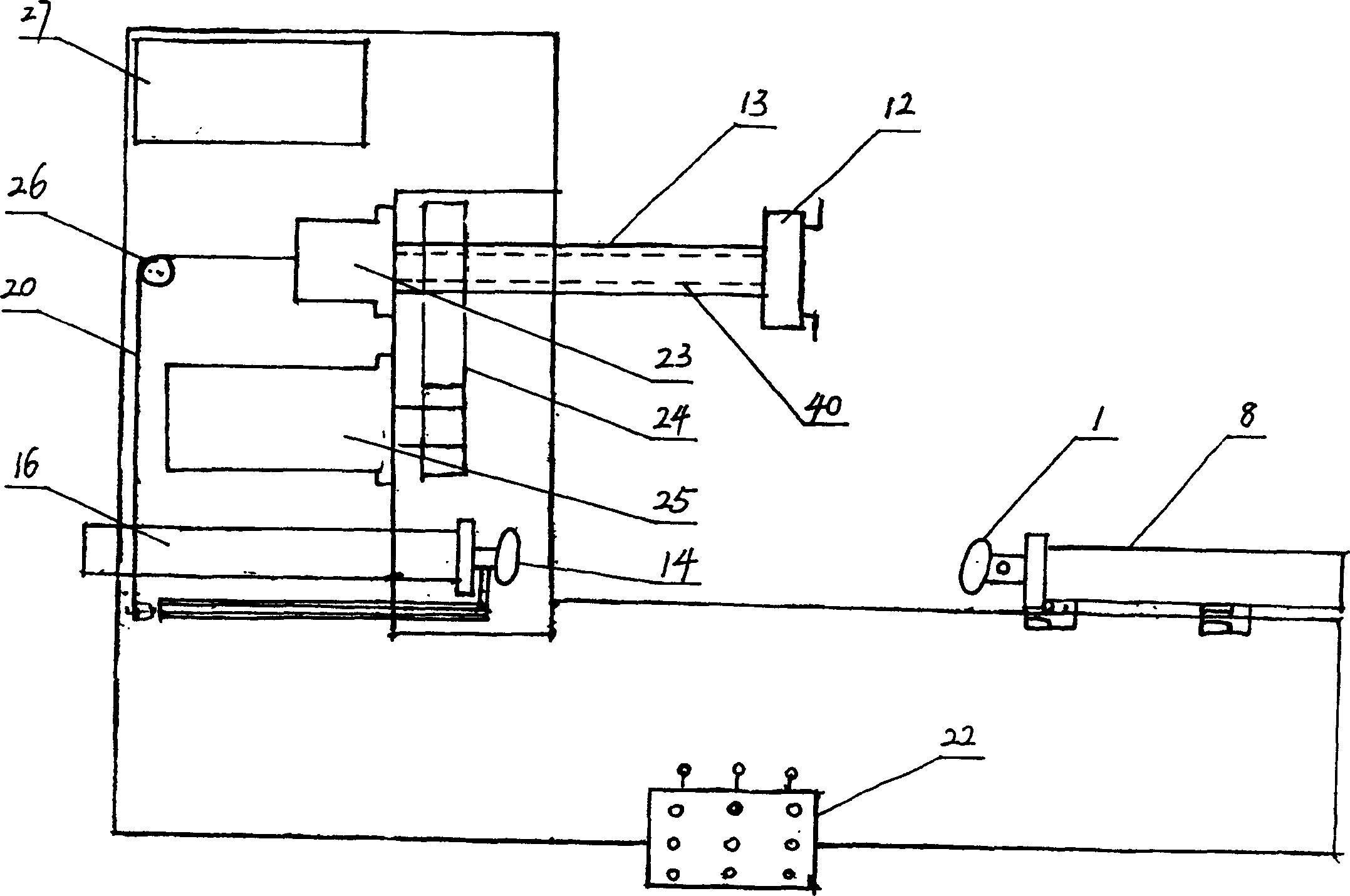

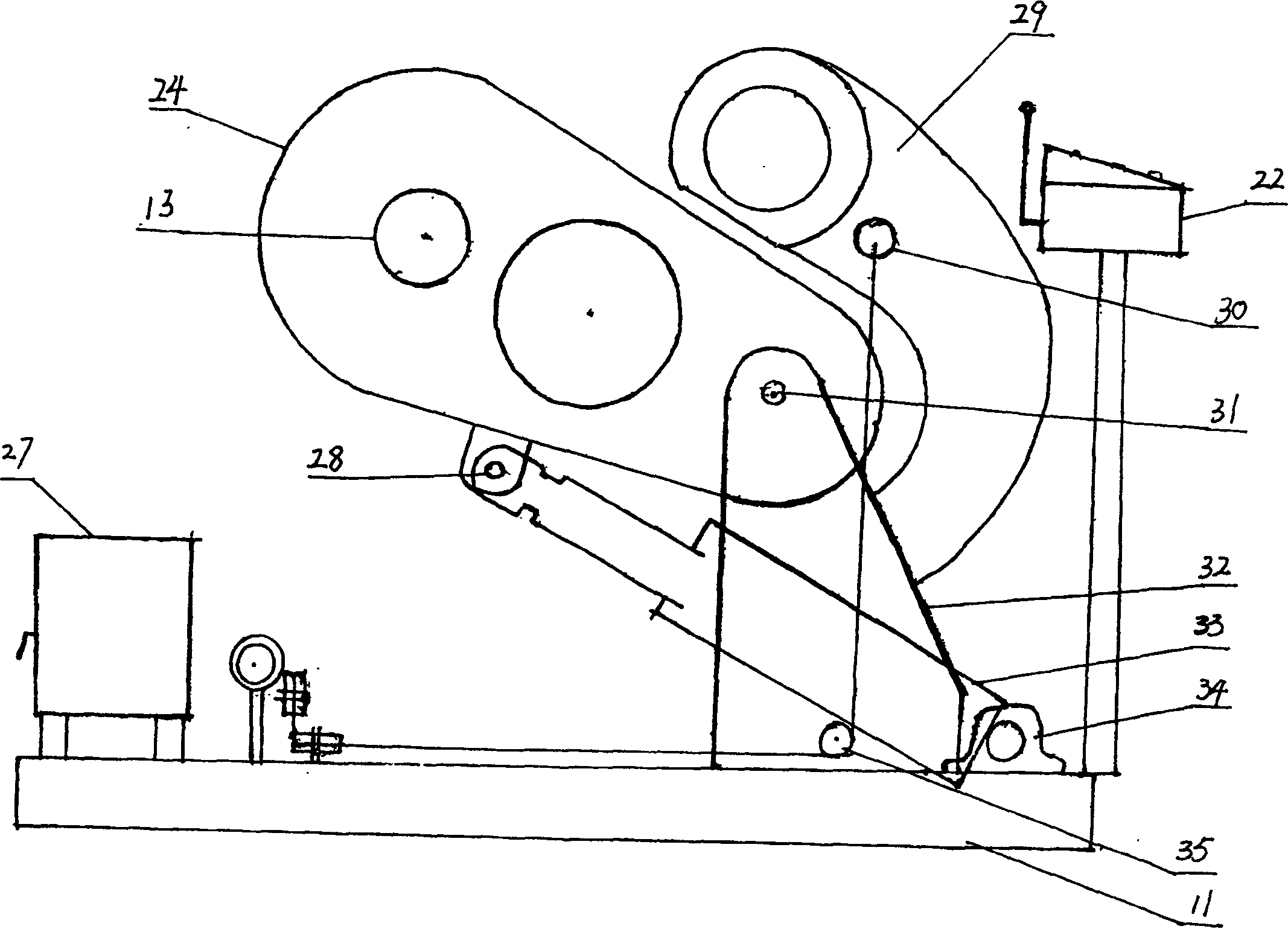

[0030] Figure 1~6 It is a schematic diagram of the structure of an embodiment of the present invention, and the present invention is described below with reference to the accompanying drawings:

[0031] The invention mainly consists of a main tire pushing mechanism, a retaining ring disassembling mechanism, a rear tire pushing mechanism, a rotating mechanism, and a follow-up assist mechanism.

[0032] The main tire pushing mechanism, such as figure 1 , Including the frame 9, the main push placenta 1, the main push tire cylinder 8. The main push placenta 1 is mounted on the main push tire cylinder 8. The front end of the piston rod 4 of the main push tire cylinder 8 is hinged with the piston rod and formed a certain inclination angle, which is convenient for the main push placenta to enter the toe and the retaining ring At the same time, when the tire rotates, the main placenta can rotate with it and reduce friction. The main tire cylinder is installed on the frame 9, and the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com