Desuperheater with pressure pushing function

A desuperheater and pressure technology, applied in fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., can solve the problem that ball valves cannot be used for high-temperature and high-pressure fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

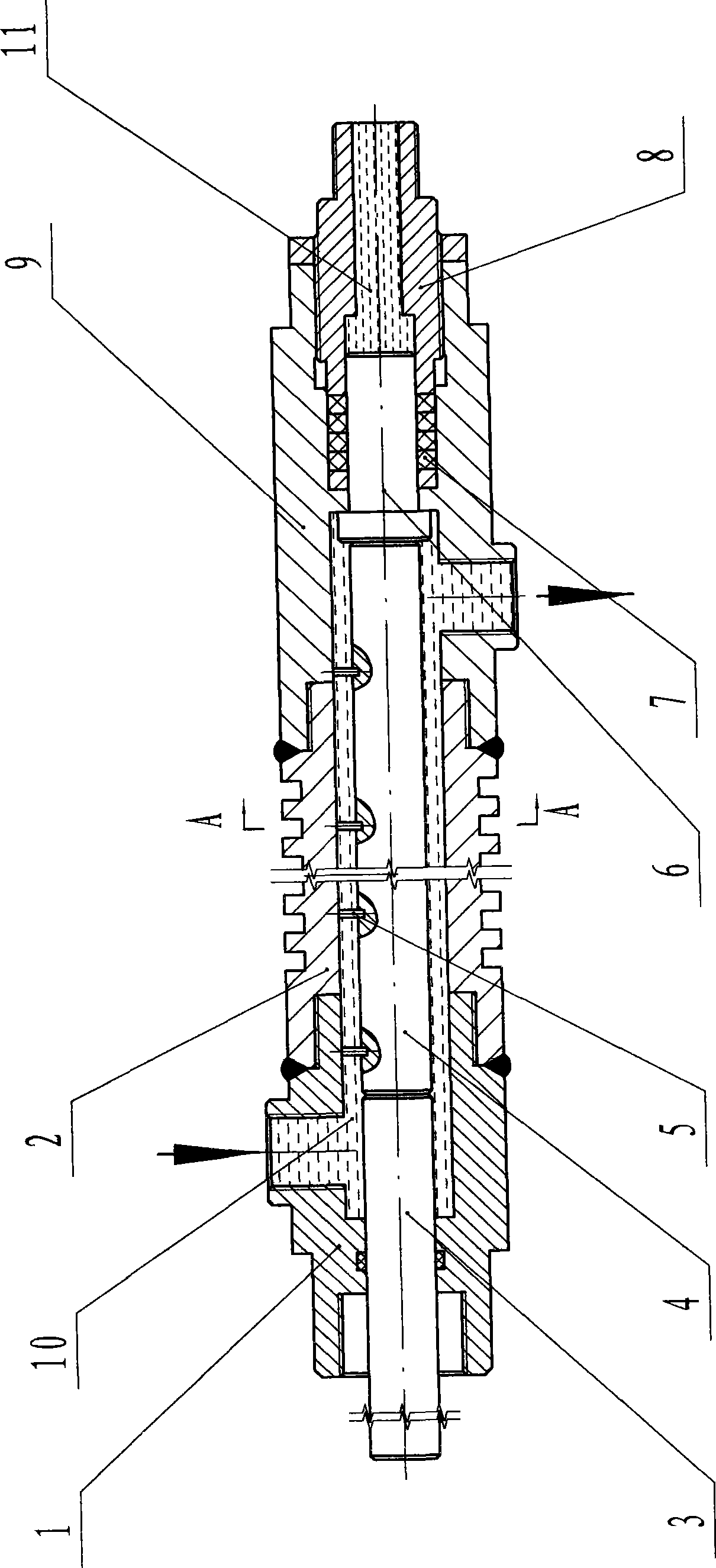

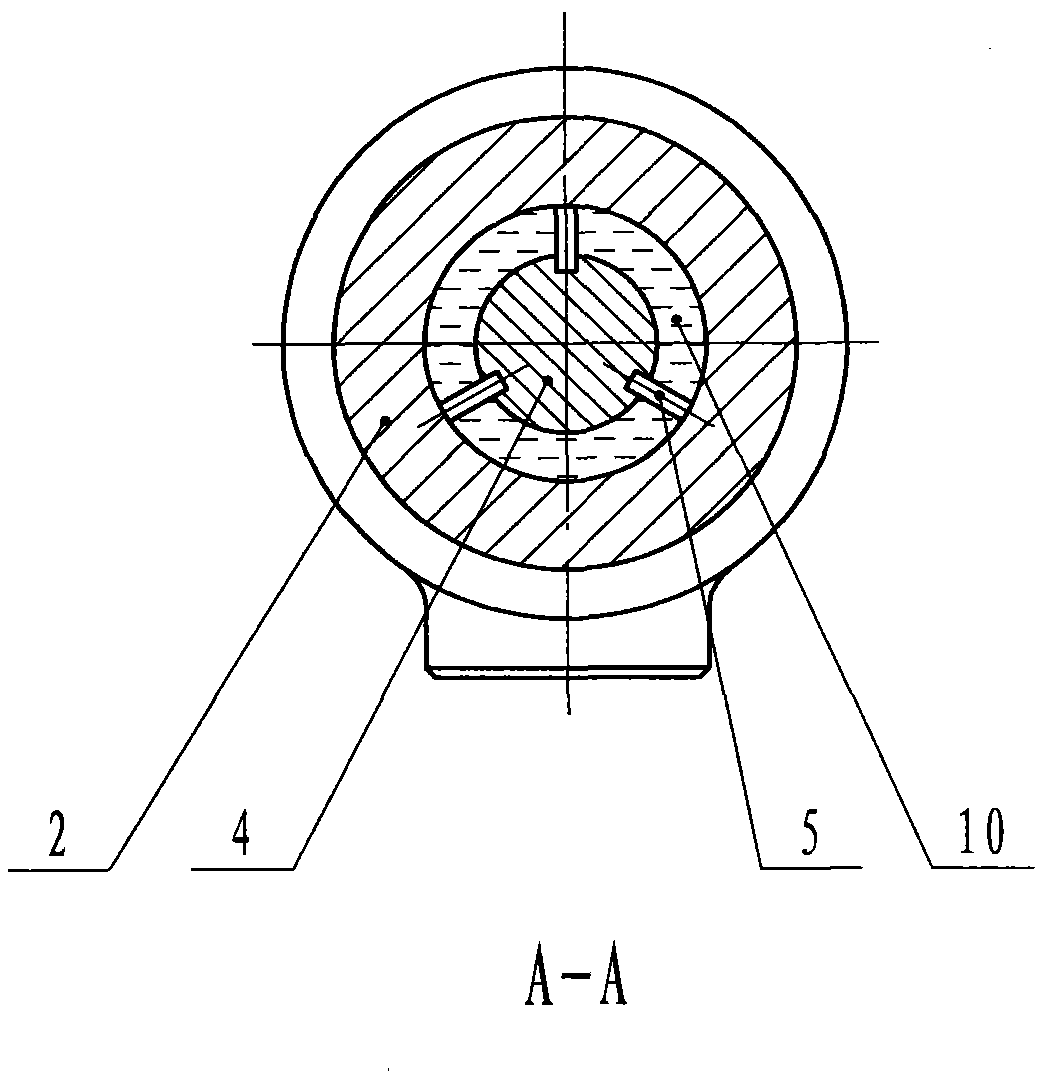

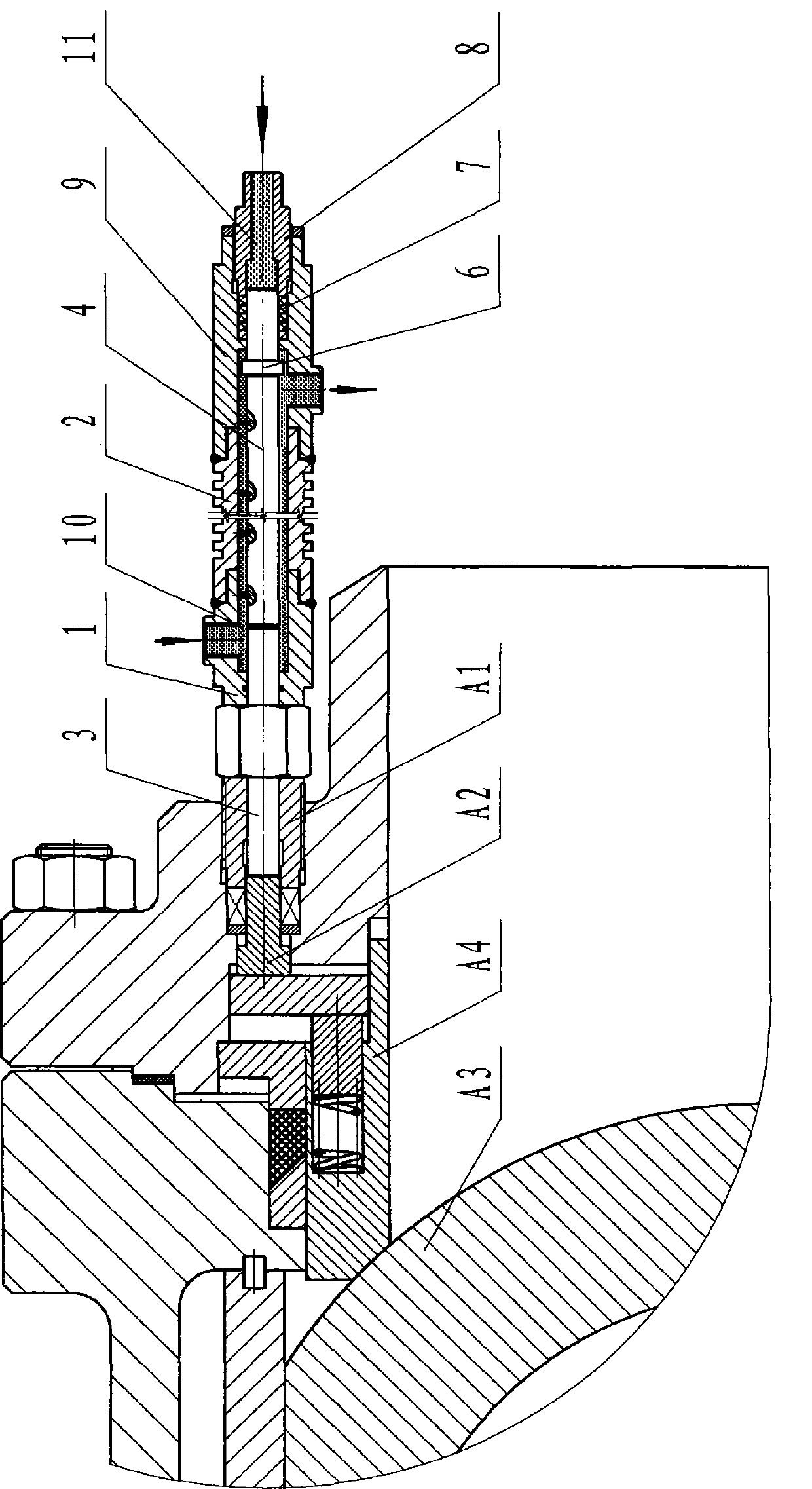

[0018] Such as figure 1 , figure 2 A desuperheater with pressure propulsion function is shown, which includes a joint body 1 with a coolant inlet, and the inner side of the joint body 1 is connected with the threaded sealing ring pressure sleeve A1 in the new low-torque non-wearing fixed ball valve , the outer side is in a sealed connection with the coolant flow tube 2, and the coolant flow tube 3 is in a sealed connection with the main body 9 with a coolant outlet in the pressure propulsion device, forming a coolant inlet and outlet channel between them .

[0019] The pressure propelling device has a main body 9, the inner hole of the main body 9 is equipped with a piston 6, and the piston 6 has a thick round rod part and a thin round rod part, and the thin round rod part is sealed with the seal installed in the main body 9 stepped holes. The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com