Sewing machine

A sewing machine and sewing thread technology, applied in sewing machine components, sewing equipment, sewing machine ferrule mechanism, etc., can solve the problems of wear, intense bobbin case opening movement, noise, etc., to avoid violent collision, avoid bobbin case vibration, reduce Effects of noise problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

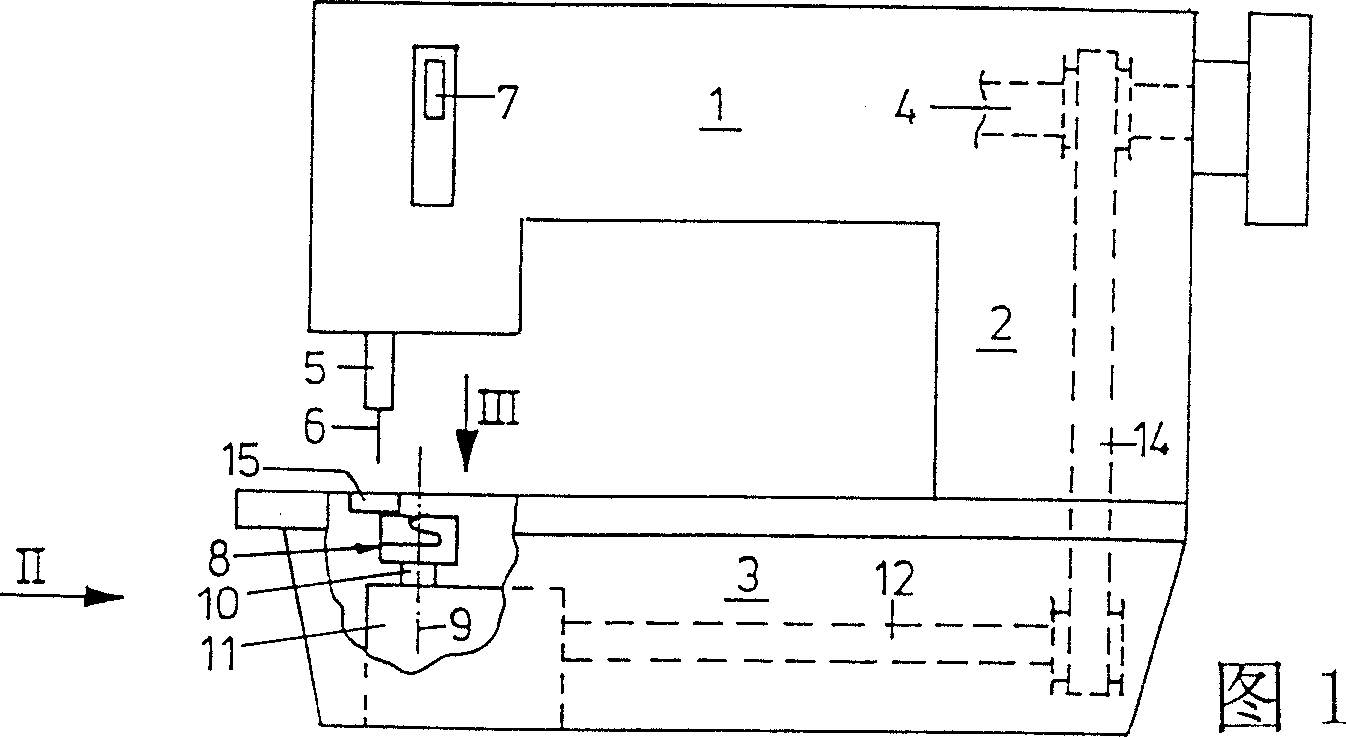

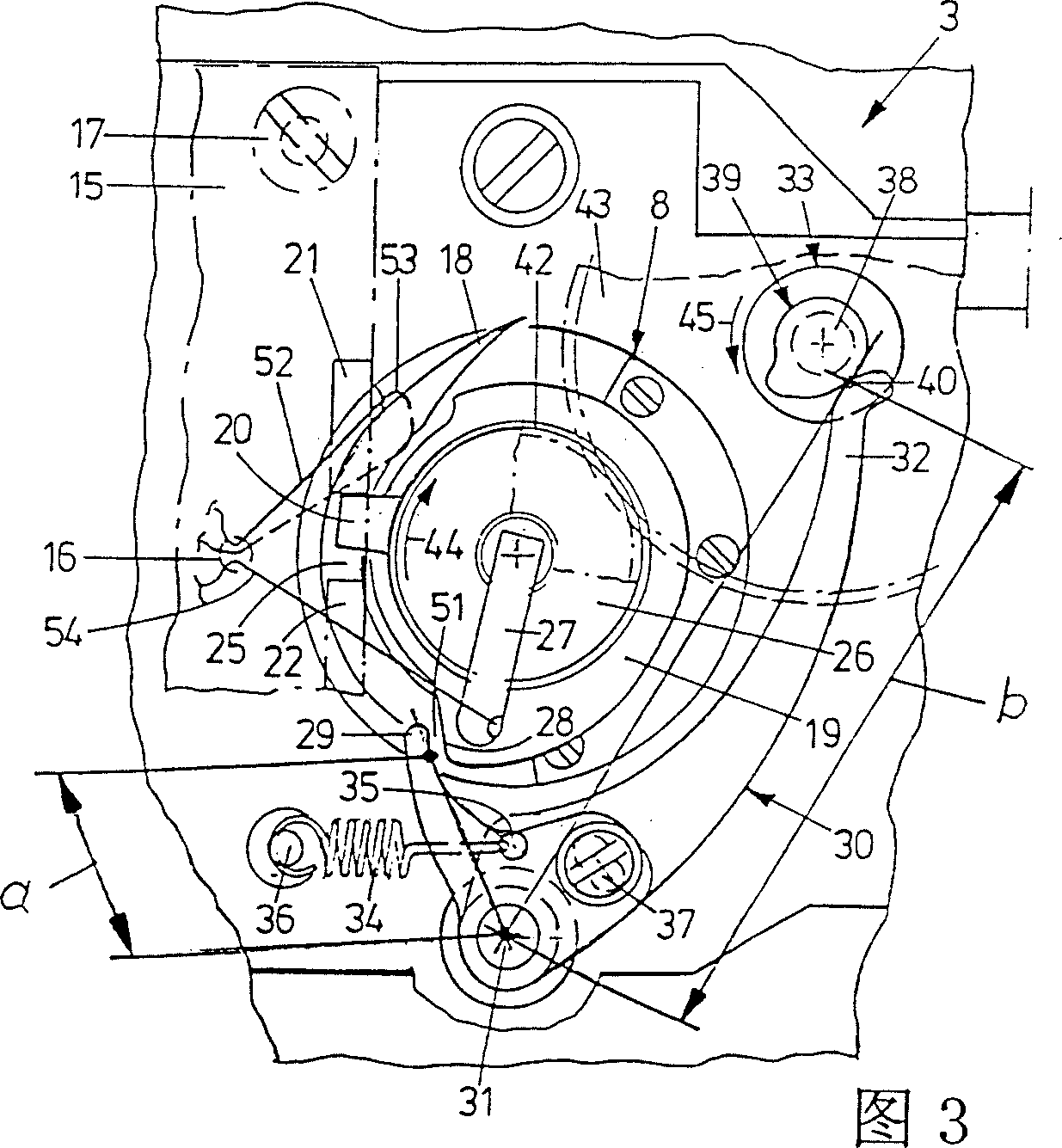

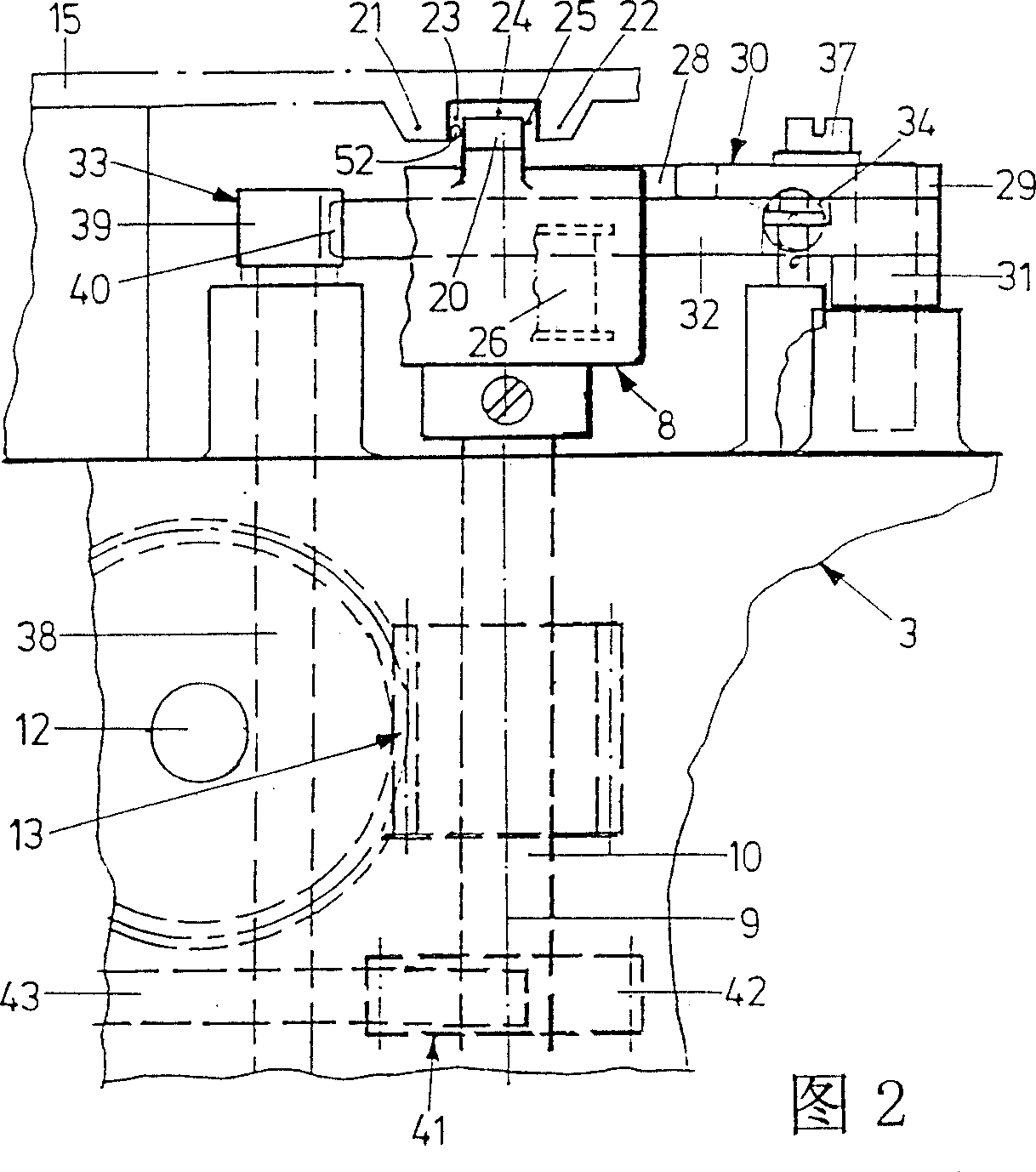

[0036] The double chain stitch sewing machine represented in FIG. 1 has an upper machine arm 1, a vertical vertical chamber 2 and a shell-like base plate 3 at the bottom in a conventional manner. The machine arm shaft 4 is housed in the machine arm 1, and the needle bar 5 is with the sewing needle 6 and can be driven by the machine arm shaft to move up and down. In addition, the arm shaft also drives the thread take-up lever 7 .

[0037] The bottom plate 3 houses a vertical shuttle 8 , that is a shuttle that can be driven to rotate around a vertical axis 9 . The shuttle drive shaft 10 , which supports the shuttle 8 and can be driven in rotation about an axis 9 , is mounted rotatably in a bearing housing 11 mounted in the base plate 3 . Shuttle drive shaft is driven by transmission shaft 12 through helical gear transmission 13 . The power transmission shaft 12 is driven by the machine arm shaft 4 through the toothed belt transmission device 14 again. The gear ratio of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com