Method for manufacturing component figure, distributing structure, and image display device

A manufacturing method and component technology, which can be used in the manufacture of discharge tubes/lamps, photoengraving processes of patterned surfaces, semiconductor/solid-state device manufacturing, etc., and can solve problems such as short circuits between wirings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

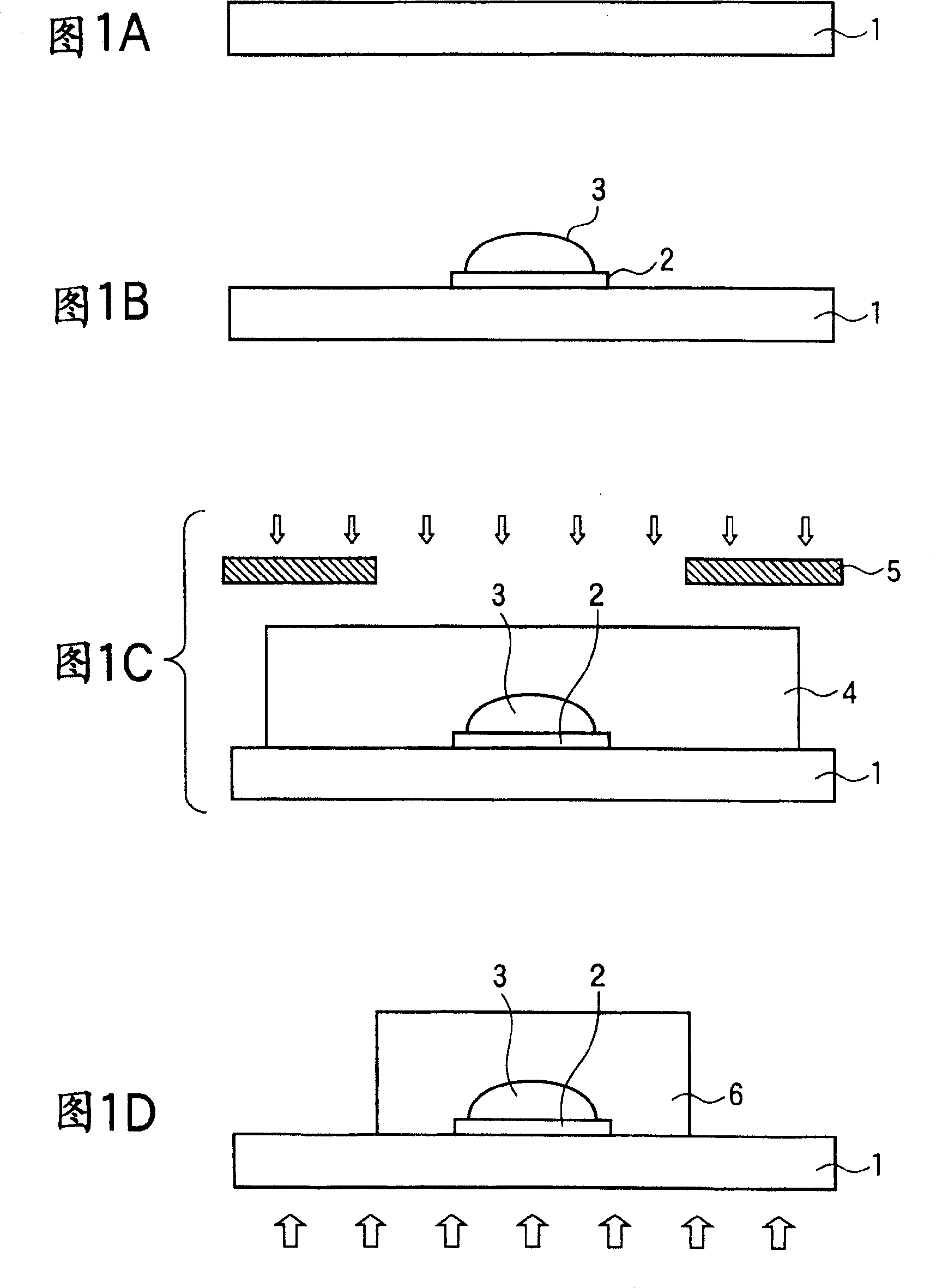

[0084] One embodiment of the method for forming an insulating film according to the present invention will be described with reference to FIG. 1 .

[0085] First, a translucent substrate 1 such as glass through which light for exposure can pass is prepared ( FIG. 1( a )).

[0086] Thereafter, if necessary, after forming the base layer 2 made of a conductor such as platinum, a conductive paste is applied by printing or the like, followed by firing. Thus, a wiring pattern 3 having a thickness of, for example, about 5 μm to 20 μm can be formed ( FIG. 1( b )). Here, the angle formed by the side surface of the wiring pattern 3 and the surface of the substrate 1 is an obtuse angle.

[0087] Thereafter, negative photosensitive insulating paste 4 is applied and dried by a printing method ( FIG. 1( c )). The film thickness after drying is, for example, about 10 μm to 40 μm. In addition, as the photosensitive insulating paste, well-known materials composed of, for example, 40% by vol...

Embodiment approach 2

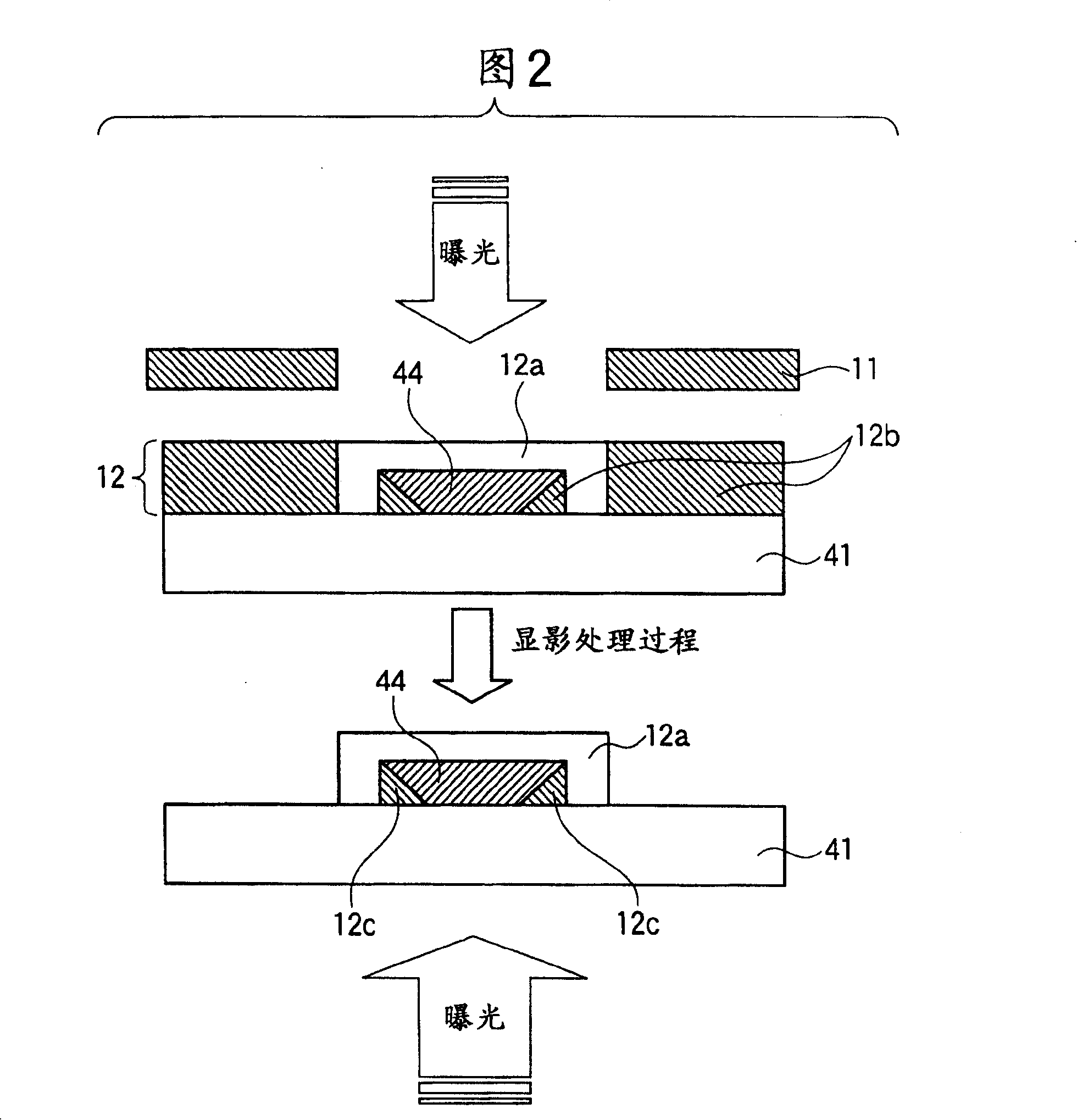

[0093] Next, as an example of application of the above-mentioned method of forming an insulating film according to a preferred embodiment of the present invention, centering on the electron source substrate shown in FIG. ,Be explained.

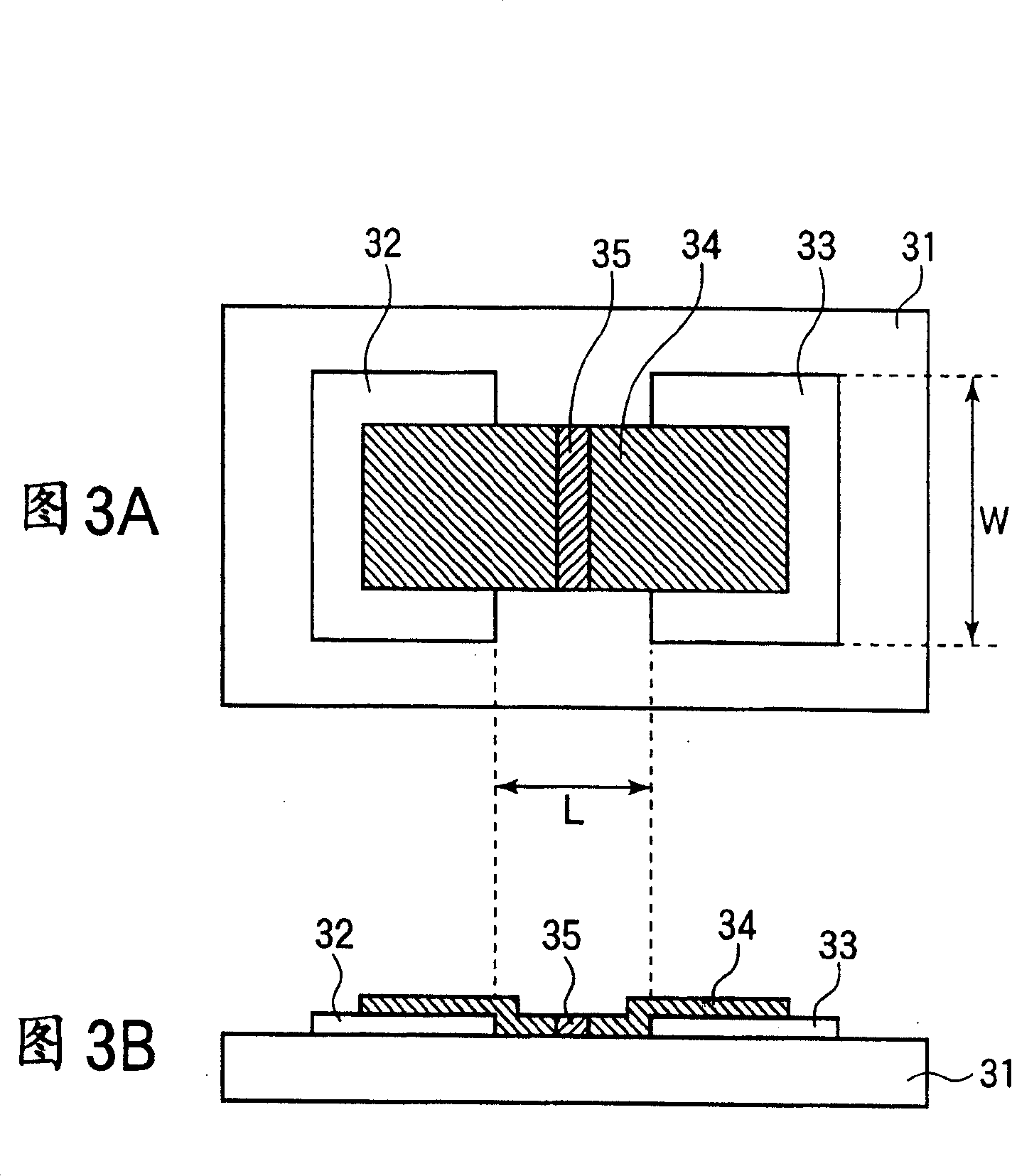

[0094] As the electron emission element formed on the electron source substrate of this embodiment, it is preferable to use a two-terminal type cold cathode that can be driven by a matrix. For example, a surface conduction type electron emission element and a horizontal type as shown in FIG. Field emission type electron emission element (FE), etc. Shown here is an example of formation of the surface conduction type electron emission element shown in FIG. 3 .

[0095] (Formation of device electrodes)

[0096] First, on a well-cleaned substrate 41, a plurality of element electrodes 42, 43 are arranged and formed by photolithography or the like (FIG. 4).

[0097] The substrate 41 is made of glass or the like, and its size and thickness can hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com