LSI inspection method and apparatus, and LSI tester

An inspection method and inspection device technology, applied to measuring devices, instruments, measuring electronics, etc., can solve problems such as rising costs and misjudgment of good products as defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, embodiments of the present invention will be described with reference to the drawings. It should be mentioned that in this specification, high-speed interfaces specifically refer to IEEE1394, USB, etc., with a communication speed of several hundred Mbps or more; and low-speed interfaces, specifically, interfaces with a communication speed of several tens of Mbps or less.

[0034] (1st embodiment)

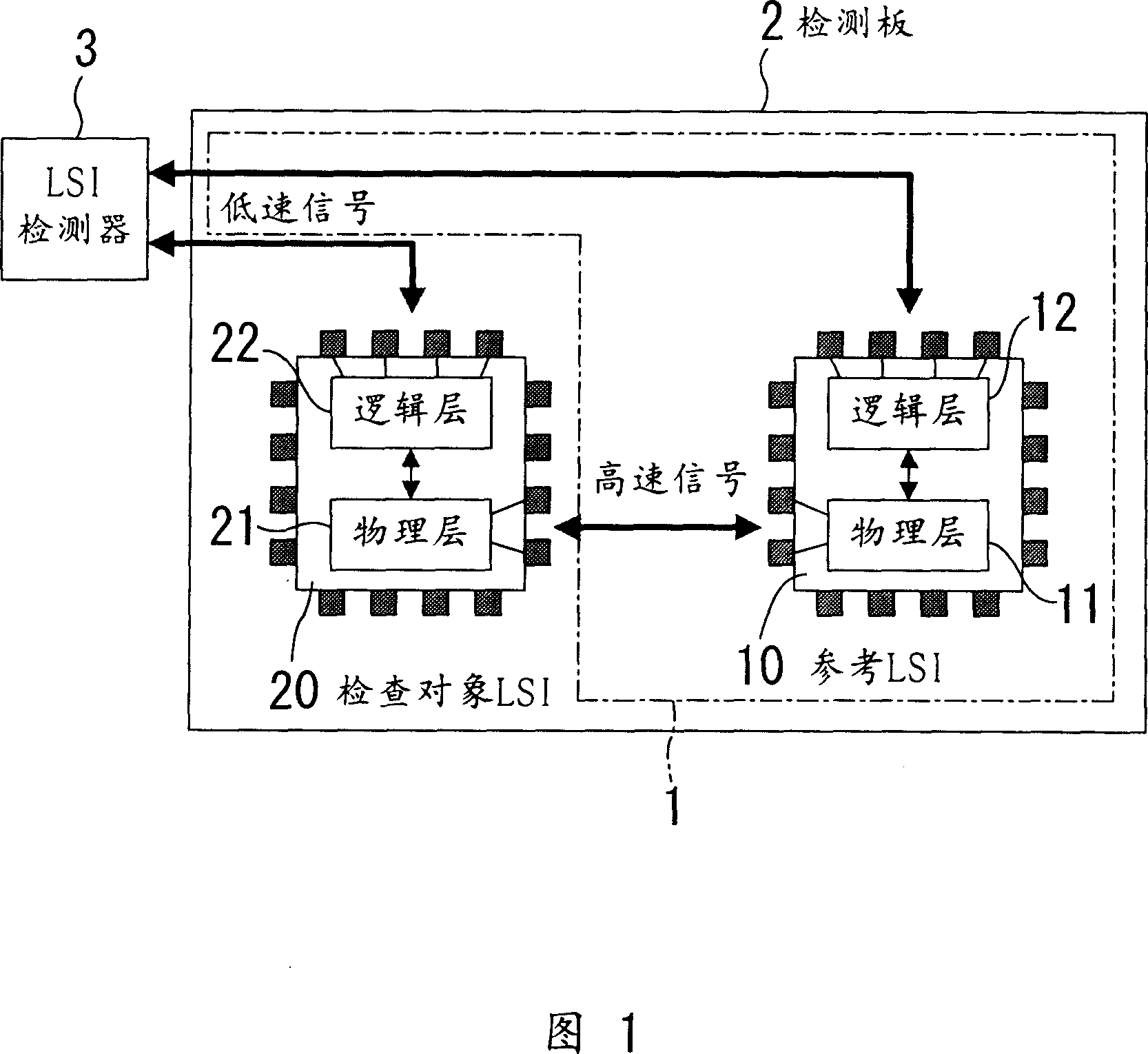

[0035] FIG. 1 shows the configuration of an LSI inspection system according to a first embodiment of the present invention. In FIG. 1 , the inspection target LSI 20 has a physical layer unit 21 having a function of connecting to the outside of the LSI at high speed, and a logical layer unit 22 connected to the physical layer unit 21 and having a function of connecting to the outside of the LSI at a low speed. . For example, in an LSI equipped with IEEE1394a-2000, the physical layer has drivers, receivers, serializers, deserializers, and mediation circuits for h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com