Coaxial corrugated tube cable connector with notched metal clip line structure

A cable connector, metal ring technology, applied in conductive connection, electrical connection seat, clamping/spring connection, etc., can solve the problems of limited contact area between spring and cable, uneven connection between head and tail, and difficult to control the size, etc. Achieve the effect of easy grasping of opening size, convenient and labor-saving insertion, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

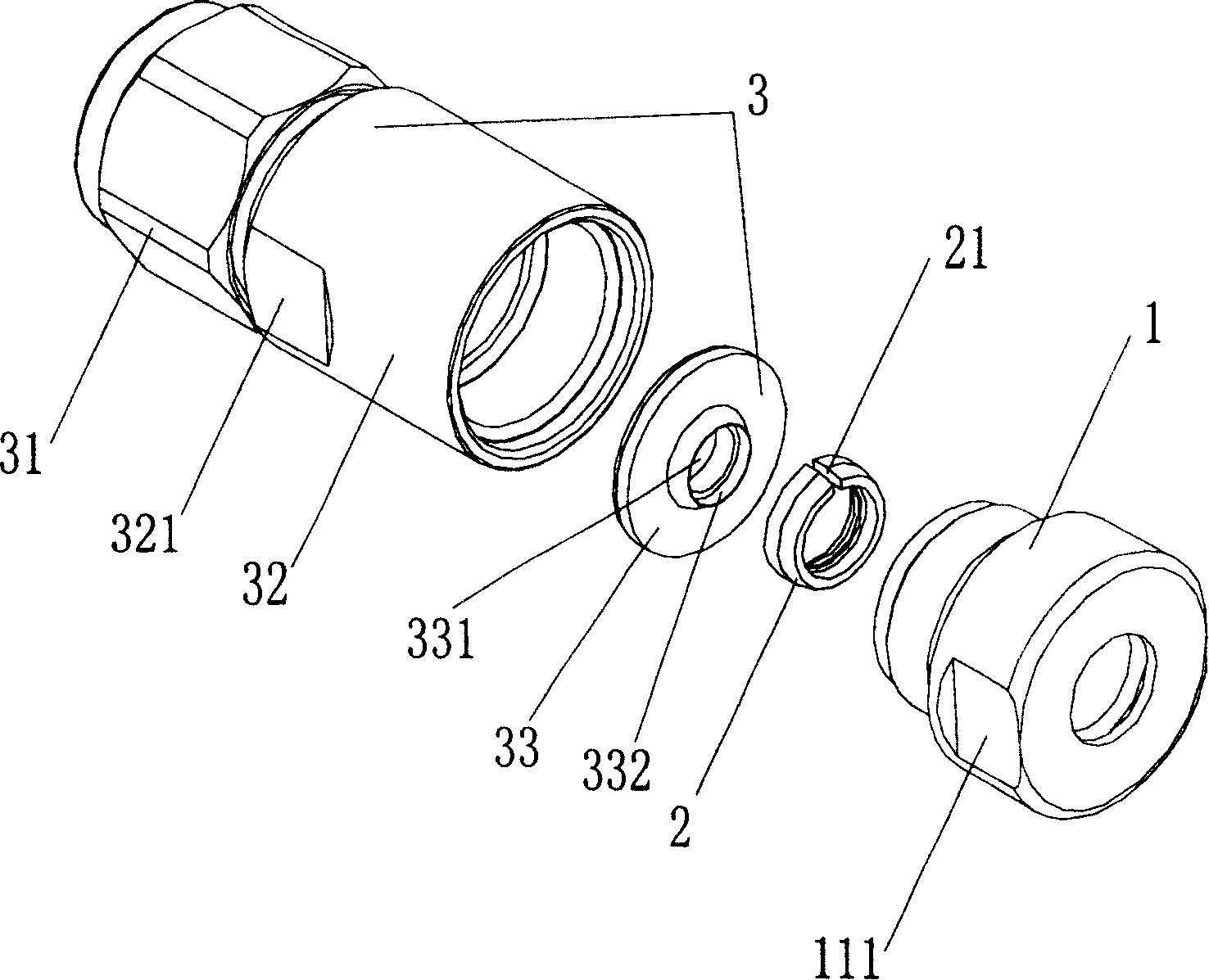

[0014] In order to further understand the technical features and content of the present invention, the following detailed description will be given in conjunction with the accompanying drawings. see figure 1 , the invention discloses a coaxial corrugated tube radio frequency connector with an open metal ring clamping structure, including a terminal nut 1, a metal ring 2 arranged at the front end of the terminal nut 1 and a joint outer conductor 3 matched with the terminal nut 1 .

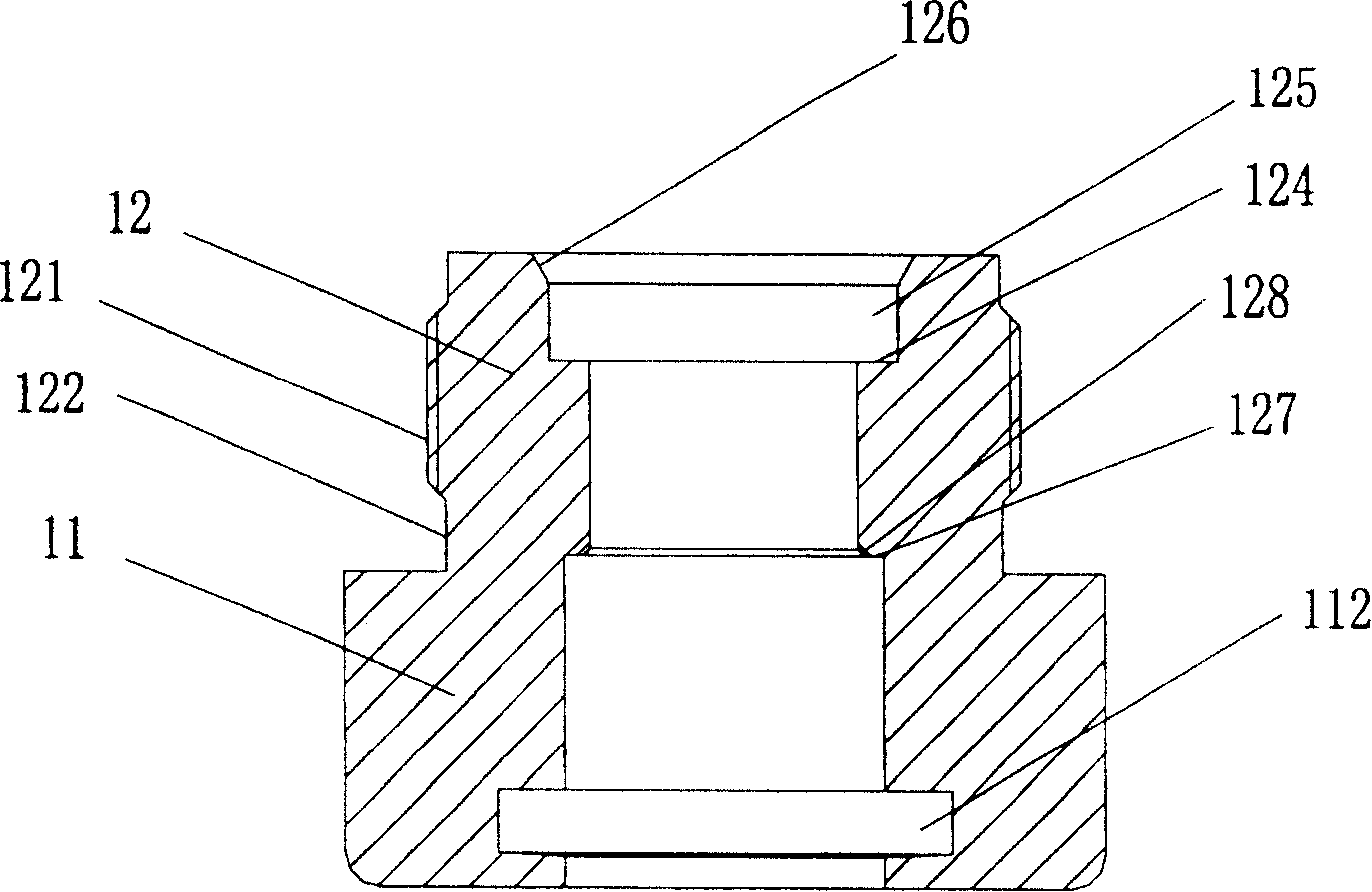

[0015] see figure 2 , The terminal nut 1 is a rotating body, including a body 11 matched with a coaxial corrugated tube cable and a connecting portion 12 at the front end of the body 11 . Both the body 11 and the connecting portion 12 are annular. Wherein, the outer diameter of the main body 11 is larger than the outer diameter of the connecting portion 12 , and the inner diameter of the main body 11 is also larger than the inner diameter of the connecting portion 12 .

[0016] The outer surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com