Non-contact displacement loudspeaker high-low-pitch control device

A control device and a displacement-type technology, which is applied in the direction of sound-generating devices and instruments, can solve problems such as the decline in reliability, and achieve the effect of improving driving safety factor, meeting requirements and wishes, and responding quickly and timely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

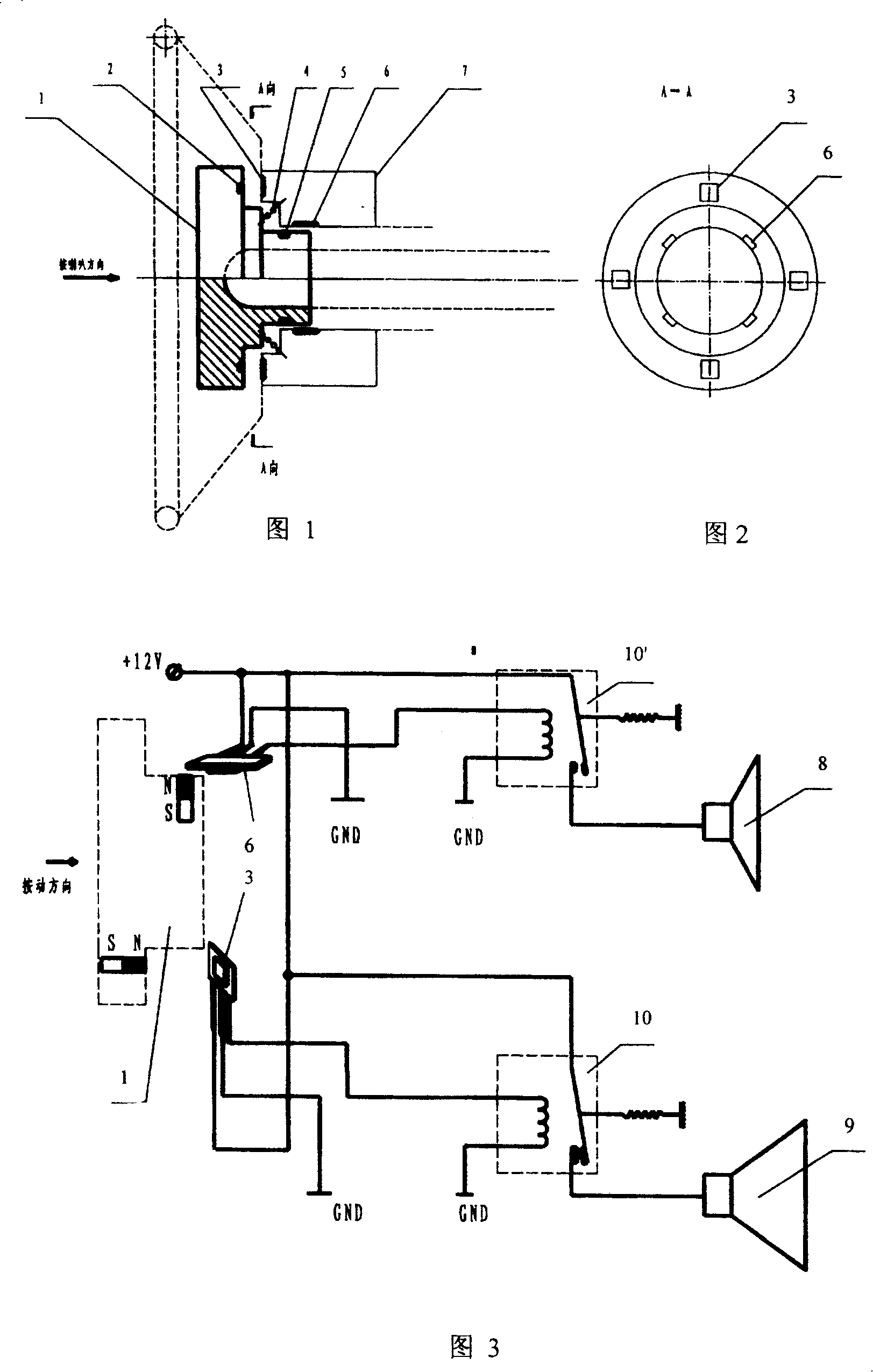

[0010] The specific scheme and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0011] The structure of the present invention is: it is mainly made up of horn button 1, horn Hall element fixing seat 7, tweeter, woofer 9, 8 and relay 10, 10 ', and horn Hall element fixing seat 7 can adopt ladder shape, and it fixes On the steering wheel column, the horn button also adopts a stepped shape corresponding to the Hall element, which is set in the horn Hall element fixing seat 7, and can move in the hole of the horn Hall element fixing seat 7 along the steering wheel column. A return spring 4 is installed between the horn button 1 and the horn Hall element fixing seat 7, and two rows of ring magnets 2, 5 and the treble Hall element 3 and Bass hall element 6, horn button 1 rotates with the steering wheel, horn button 1 makes two rows of ring magnets 2, 5 have a certain distance from Hall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com