A device for forming tooth form of sprocket gear for power transmission apparatus of cahinless bicycle

A power transmission and bicycle technology, applied in the field of gear-shaped devices, can solve the problems of inability to guarantee durability, increase in volume and weight, inability to overcome precision machining, machining efficiency and productivity limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred embodiments according to the present invention will be specifically described below with reference to the corresponding drawings.

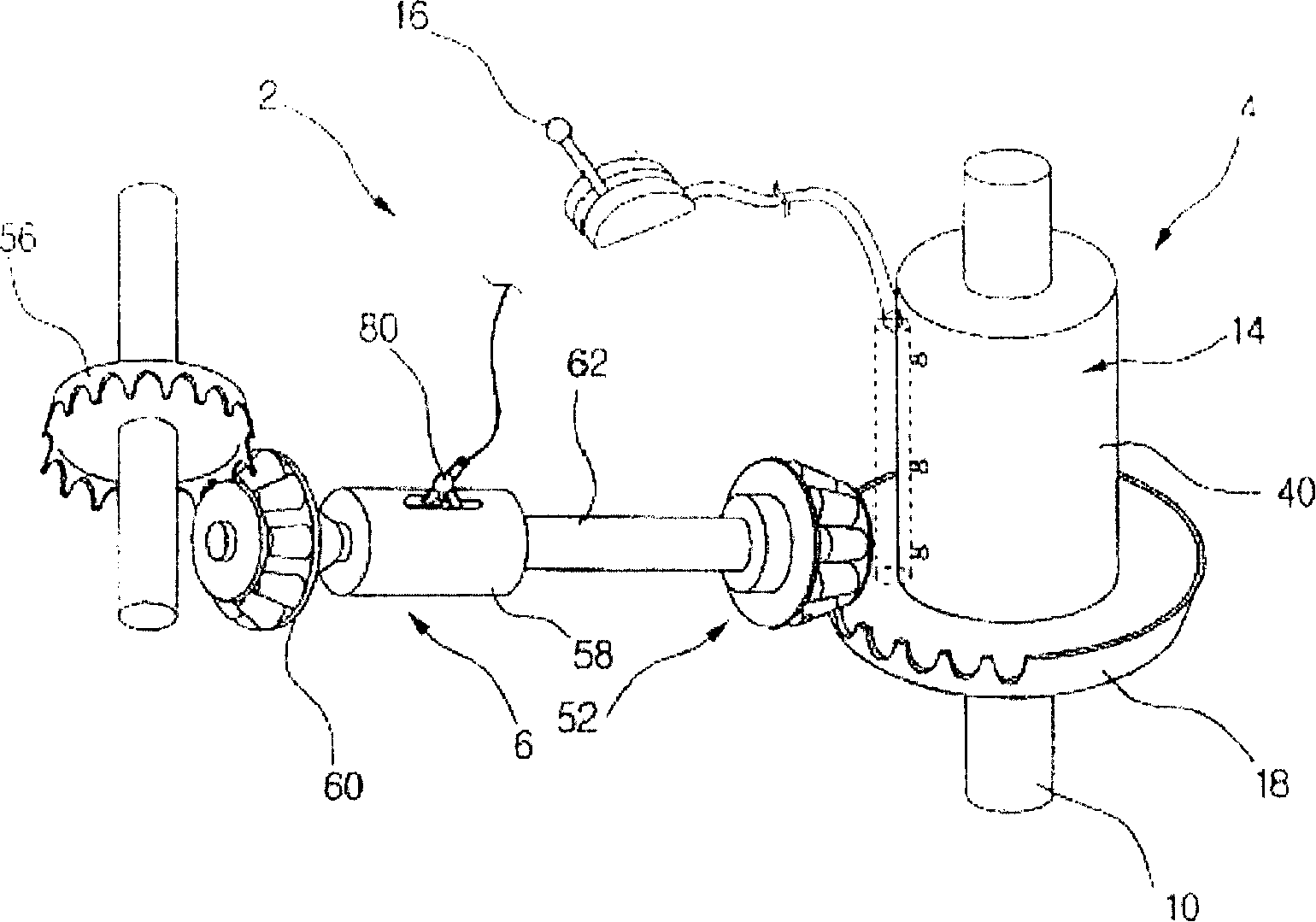

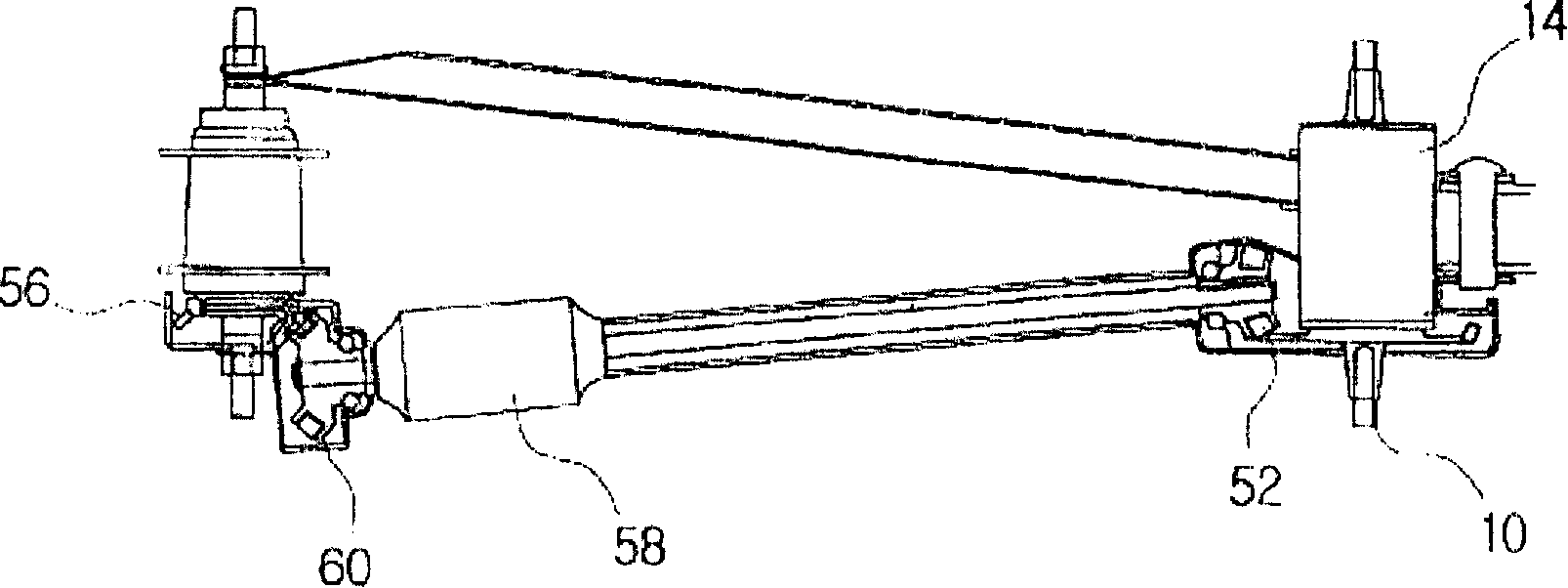

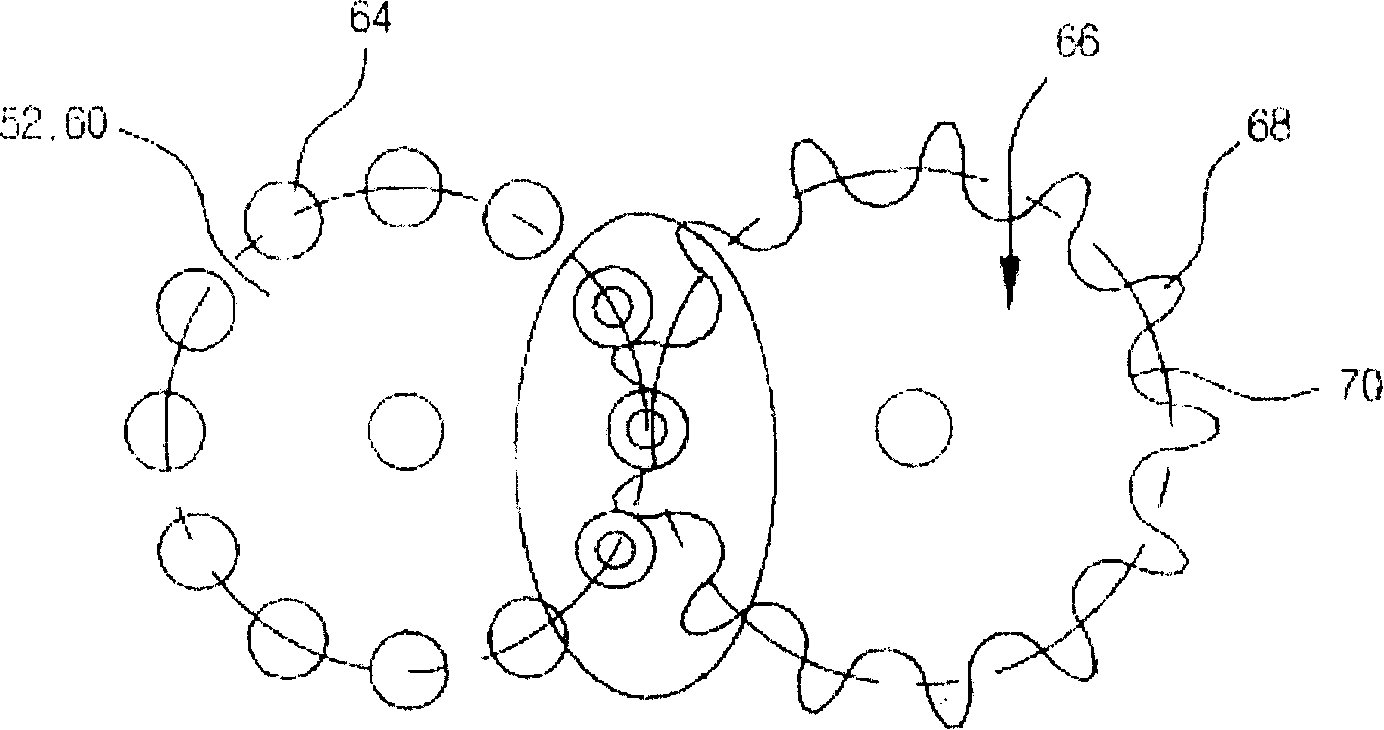

[0035] Figure 5 A device for forming the tooth profile of a sprocket in a chainless bicycle power transmission device according to an embodiment of the present invention is shown, wherein the device of the present invention is indicated by reference numeral 80 . Figure 6 An embodiment of a gear mesh between a pin gear and a face sprocket machined according to the invention is shown.

[0036] The device 80 for forming the tooth profile of a sprocket in a chainless bicycle power transmission device comprises first and second main drive motors 82, 84, a first gear unit 86, a second gear unit 88, a tooth forming unit of a crown sprocket 90 and the tooth forming unit 92 of the plane sprocket.

[0037] The first and second main drive motors 82 , 84 are spaced and electrically connected to each other within the base frame 98 and coop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com