Noise reducing device for rotary compressor

A rotary compressor, noise technology, applied in the field of noise reduction devices, can solve the problems of noise performance reduction, can not reduce the noise of the muffler 20, etc., to achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

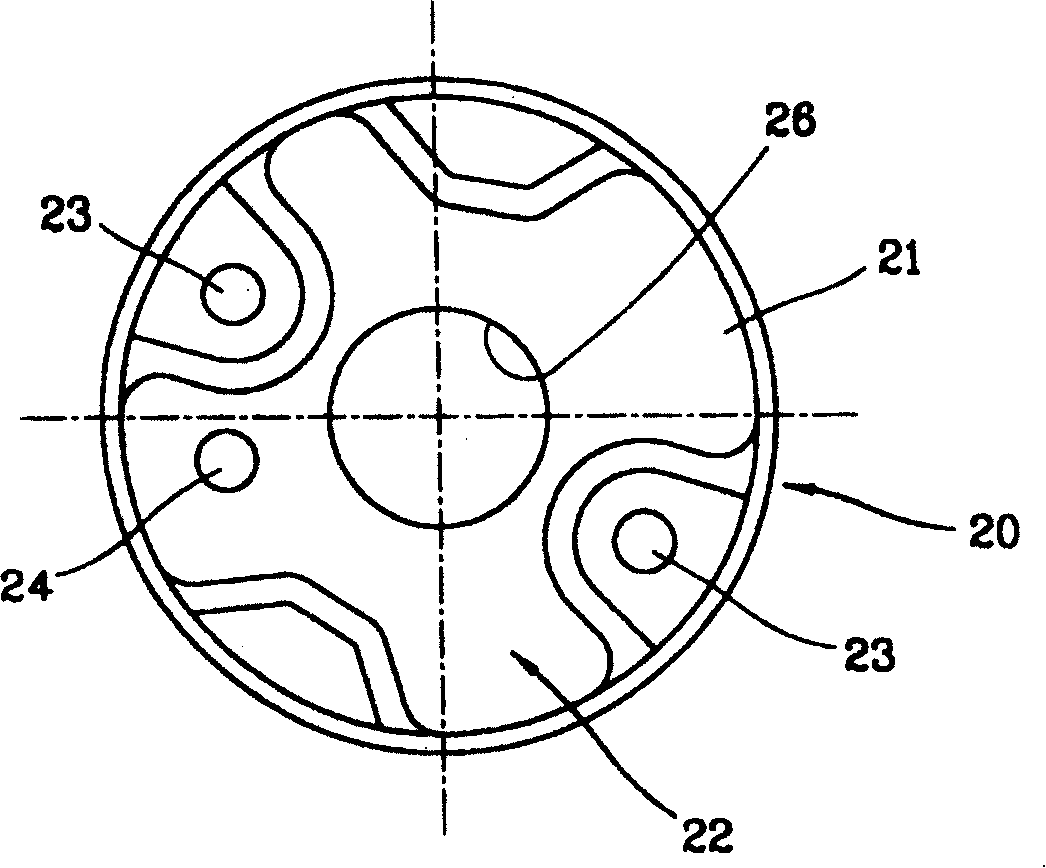

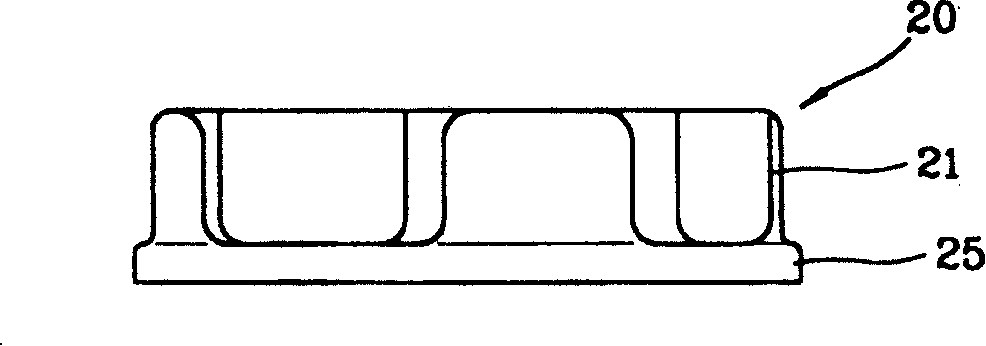

[0039] The present invention will be described in detail below with reference to the accompanying drawings. Components identical to those of the prior art bear the same reference numerals.

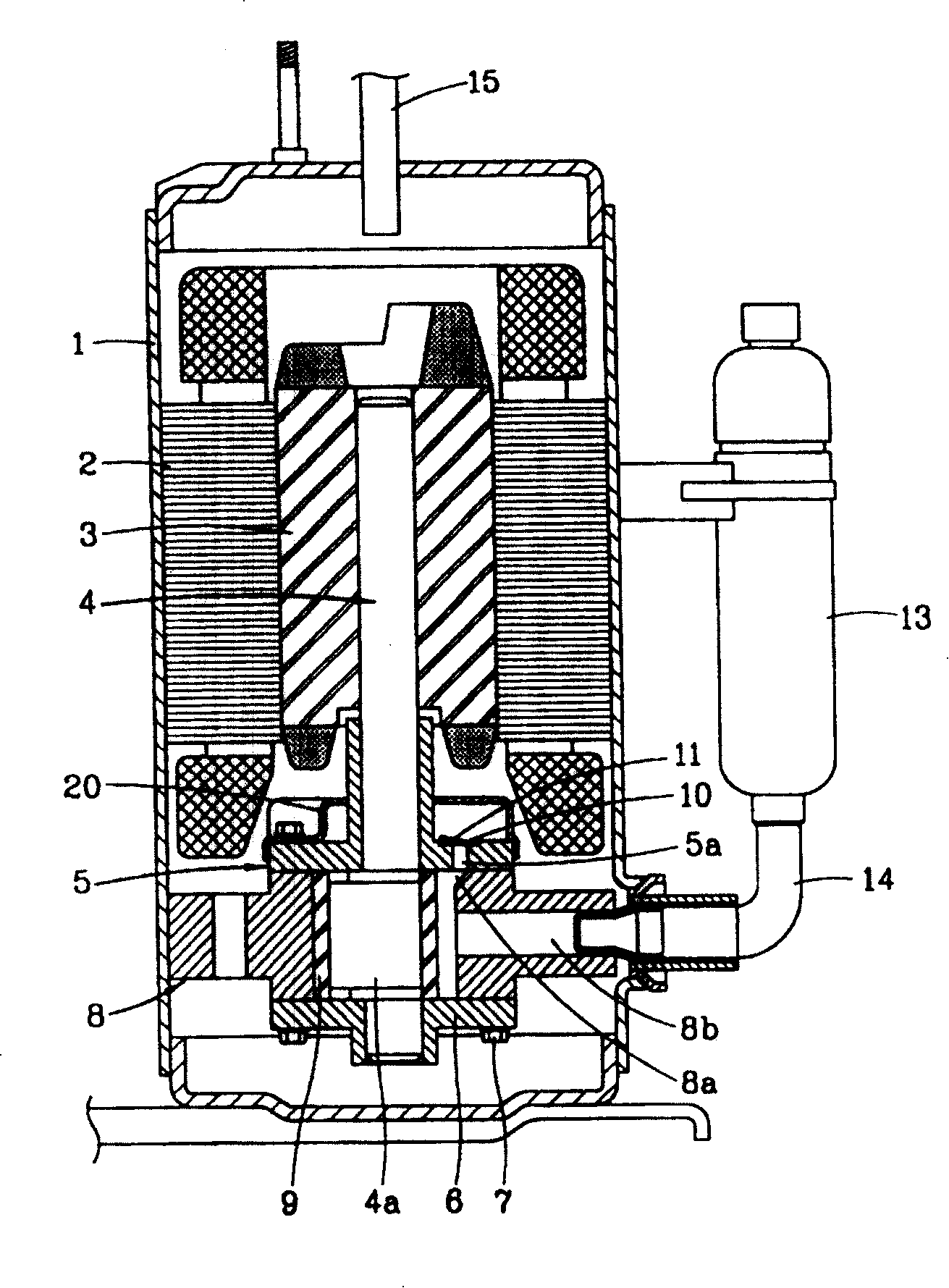

[0040] Such as Figure 4 As shown, the rotary compressor equipped with the noise reduction device of the rotary compressor in the present invention has the following components:

[0041] The inside of the airtight container 1 forms a certain volume space, and has a suction pipe 14 and a discharge pipe 15; the inside of the above-mentioned airtight container 1 is provided with a motor mechanism component, and the above-mentioned motor mechanism component includes a stator 2 and a rotor 3; The shaft 4 has an eccentric portion 4a formed on its lower surface.

[0042] The components of the compression mechanism include a cylinder 8, a rolling piston 9, and a vane (VANE) (not shown in the figure).

[0043] The cylinder 8 accommodates the eccentric portion 4a of the rotating shaft 4 and is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com