Nitrogenous polymer containing long-chain allyl ester and maleic anhydride monomer and its preparation

A maleic anhydride and polymer technology, applied in the field of nitrogen-containing polymers, can solve problems such as poor compatibility, complex process routes, and high raw material prices, achieve good compatibility, simple preparation methods, and facilitate industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

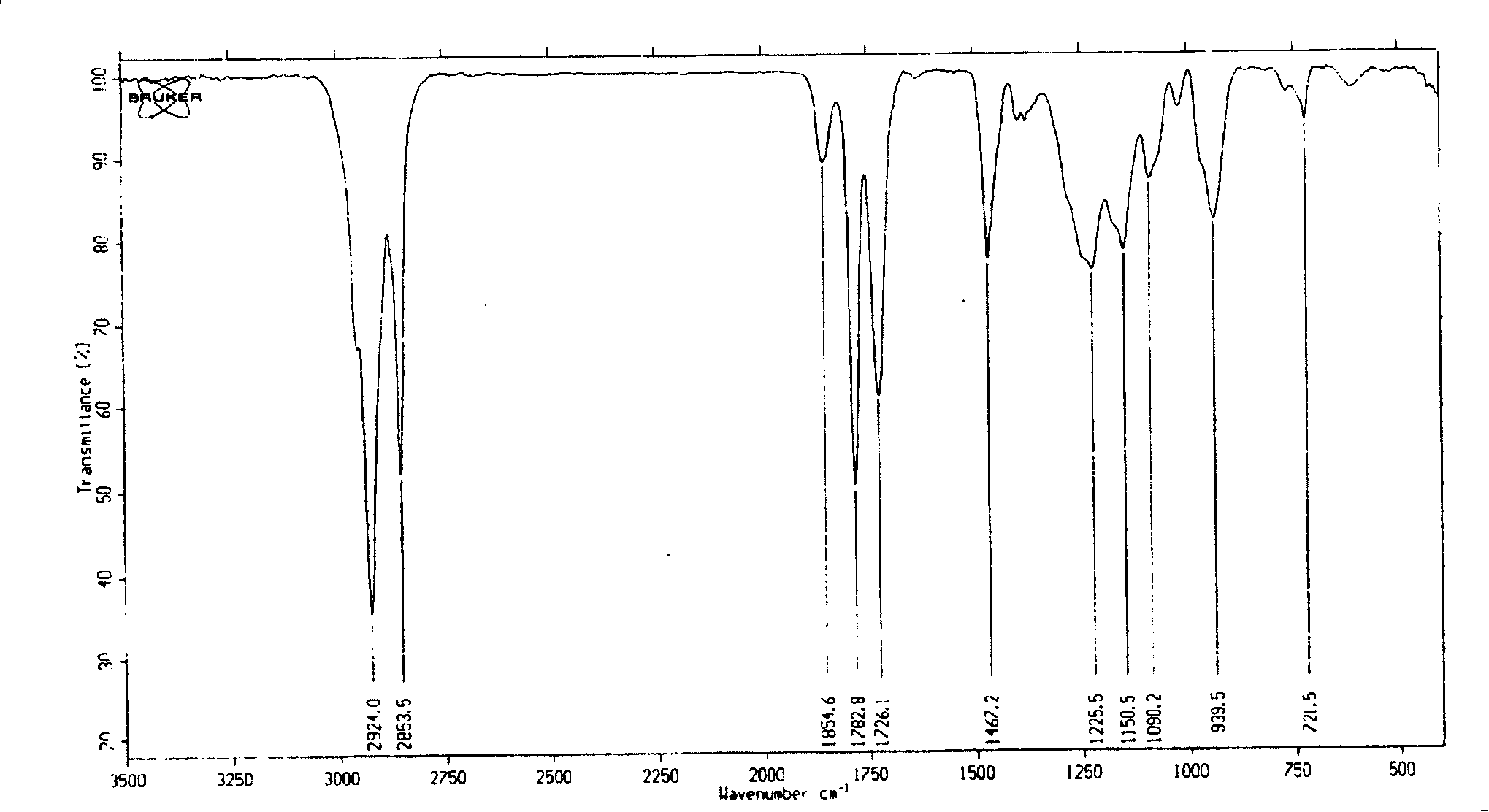

[0037] Take 70 grams of maleic anhydride, 30 grams of tetradecyl methacrylate, and 0.1 gram of azobisisobutyronitrile, put them in a reactor, and under the protection of nitrogen, stir and heat up to 60° C., and react for 4 hours to obtain Copolymer, its infrared spectrum is shown in figure 1 .

[0038] figure 1 The infrared spectrum of the copolymerization product is at 1782.8cm -1 and 1854.4cm -1 A strong characteristic peak appears at , which should be attributed to the symmetric and asymmetric stretching vibration peaks of the carbonyl (C=O) of the acid anhydride respectively, and it is at the low frequency of 1782.8cm -1 The spectral band is higher than the high frequency 1854.4cm -1 The band is strong, which is consistent with the carbonyl characteristics of five-membered cyclic anhydrides, indicating that there are cyclic anhydrides in the copolymerization product. The difference between the wave numbers of the two carbonyl characteristic peaks of the acid anhydrid...

Embodiment 2

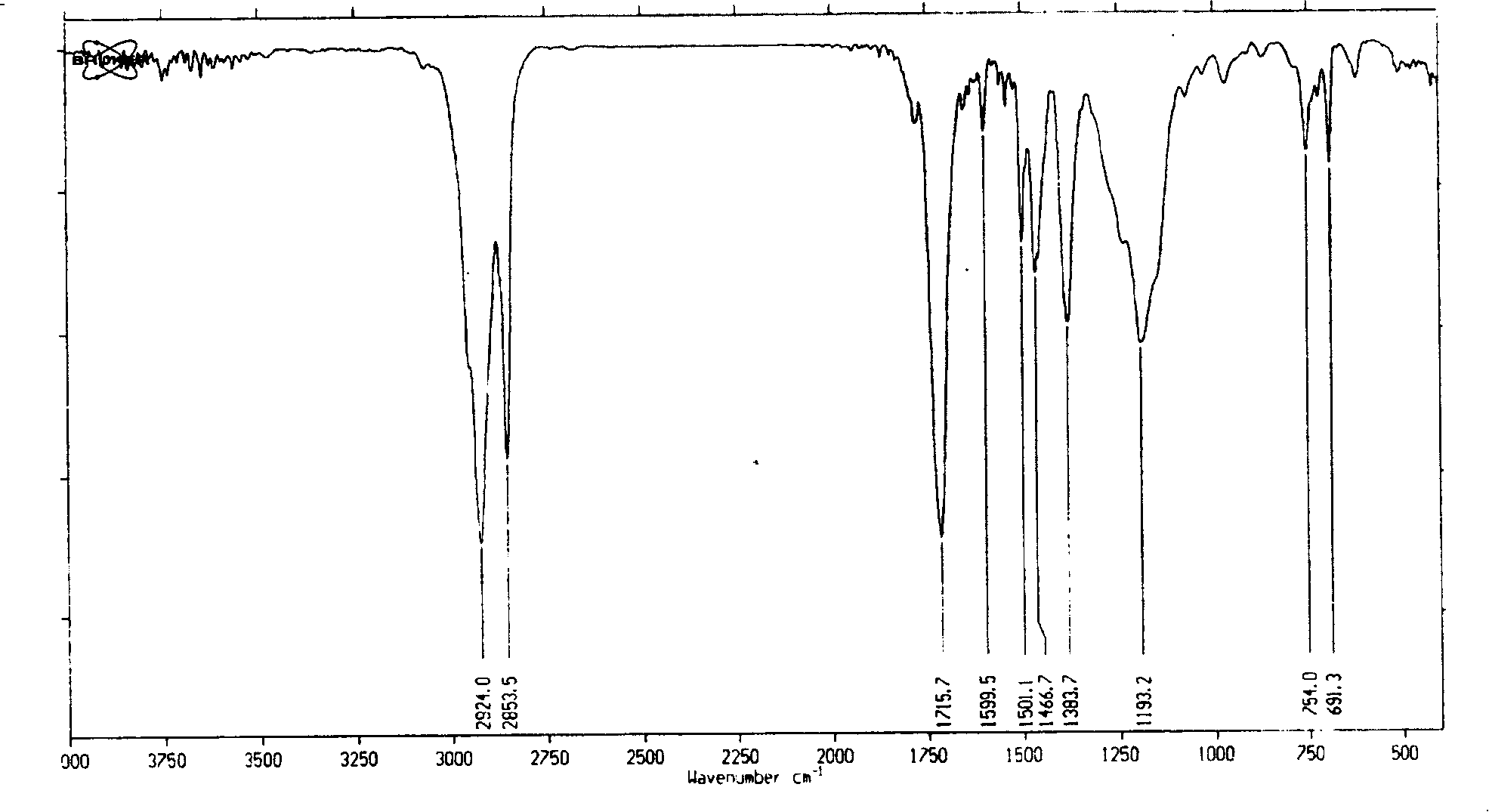

[0042] Using the same method as in Example 1, replacing aniline with 4.5 grams of 3-dimethylamino-1-propylamine, the number-average molecular weight of this nitrogen-containing copolymer is 52,000, and its thermal decomposition temperature is 358° C. -1 For the characteristic peaks of the carbonyl characteristic peaks of cyclic imines, see image 3 .

Embodiment 3

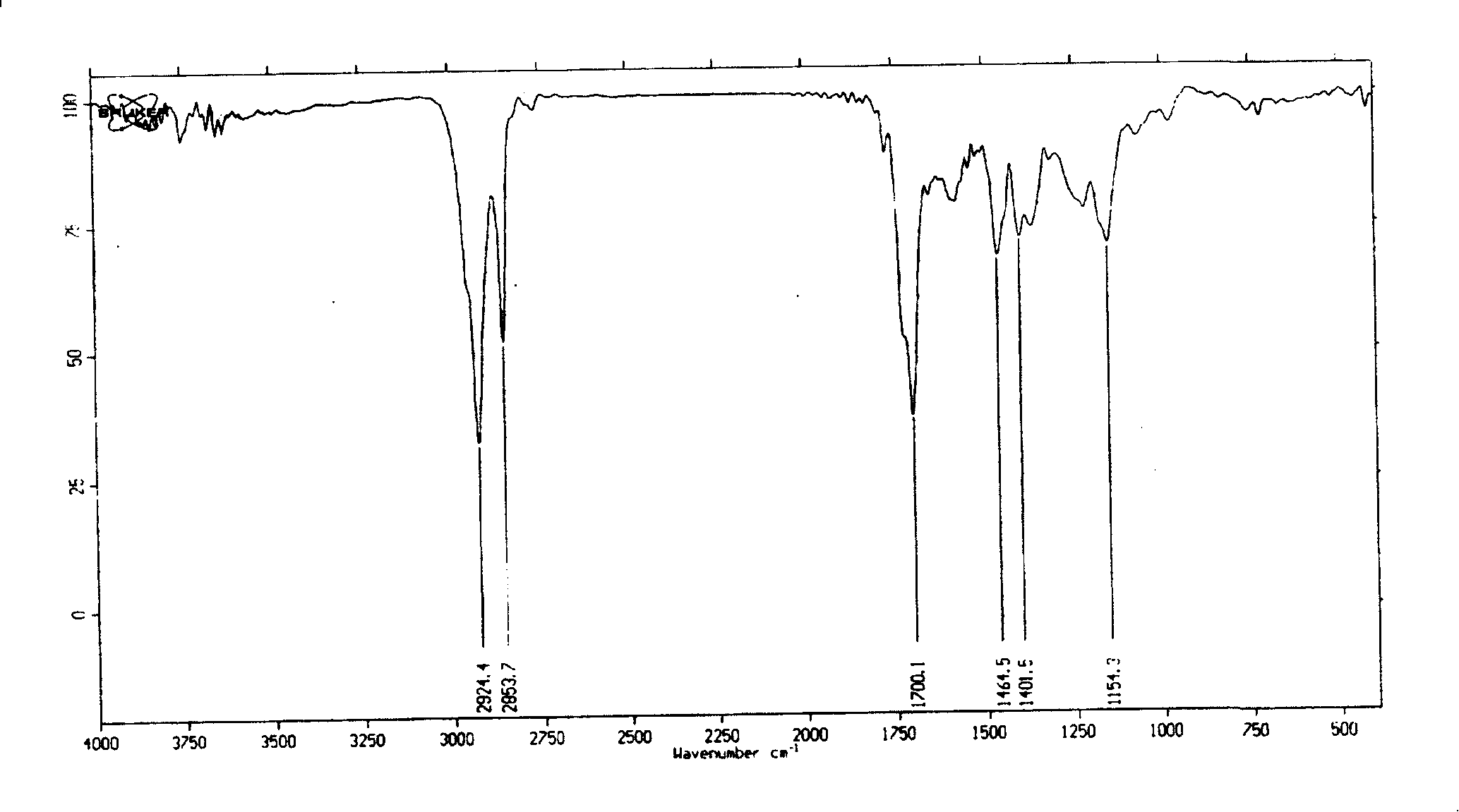

[0044] Take 60 grams of maleic anhydride, 40 grams of carbon dodecyl methacrylate, and 0.12 grams of azobisisobutyronitrile, place them in a reactor, and under nitrogen protection, stir and heat up to 80° C., and react for 3 hours to obtain copolymer;

[0045] 50 grams of the above-mentioned copolymer, 3 grams of 3-dimethylamino-1-propylamine, and 3 grams of n-octadecylamine were dissolved in 250 ml of N, N dimethylformamide, and reacted for 3 hours at a temperature of 80 ° C. Imination and dehydration can obtain the nitrogen-containing copolymer of the present invention.

[0046] The number-average molecular weight of the nitrogen-containing copolymer is 55,000, the thermal decomposition temperature is 358°C, and there is a 1715cm -1 For the characteristic peaks of the carbonyl characteristic peaks of cyclic imines, see Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com