Color-protecting concentrated laundry detergent and preparation method thereof

A technology for laundry detergent and color protection, applied in the field of detergents, can solve problems such as difficulty in meeting demand, limiting laundry detergent color protection, wrinkle resistance, softness, and single performance of highly concentrated laundry detergents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

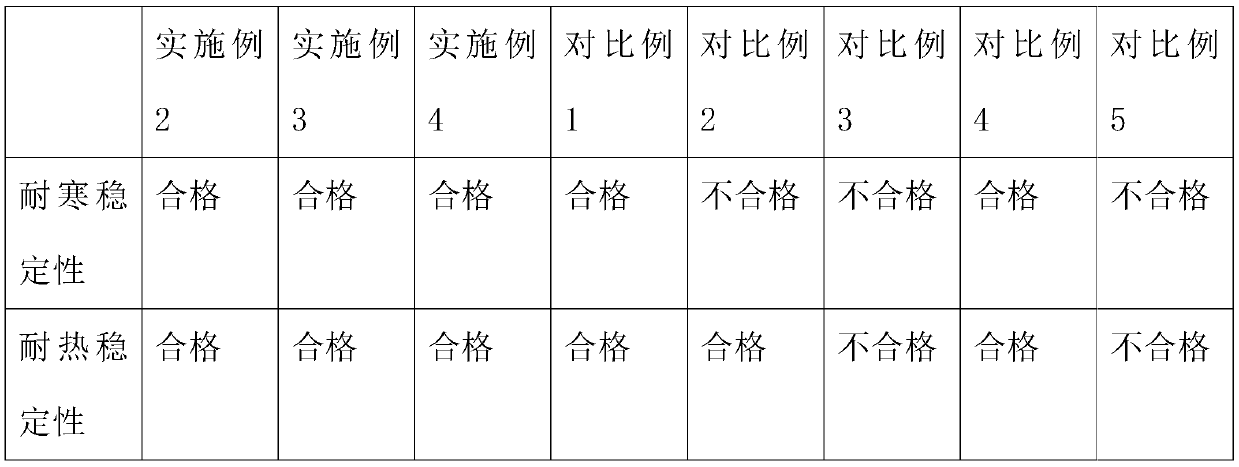

Examples

Embodiment 1

[0023] A kind of color-protecting concentrated laundry detergent, by mass percentage, comprises following raw material:

[0024] Fatty alcohol polyoxyethylene ether AEO-9 20-30%, dodecyl glucoside 5-10%, fatty acid methyl ester ethoxylate sulfonate FMES 20-30%, sodium dodecylbenzene sulfonate 10 -15%, triethanolamine 3-5%, plant polysaccharide 0.05-0.15%, wheat germ protein hydrolyzate 0.5-2%, co-solvent 4-10%, methylisothiazolinone 0-1%, essence 0-1 %, deionized water 10-25%.

Embodiment 2

[0026] A kind of color-protecting concentrated laundry detergent, by mass percentage, comprises following raw material:

[0027] Fatty alcohol polyoxyethylene ether AEO-9 20%, lauryl glucoside 10%, fatty acid methyl ester ethoxylate sulfonate FMES 30%, sodium dodecylbenzene sulfonate 10%, triethanolamine 3% , konjac polysaccharide 0.05%, wheat germ protein hydrolyzate 2%, ethanol 5%, deionized water to make up to 100%.

[0028] Wherein, the hydrolyzate of wheat germ protein is obtained by hydrolysis of wheat germ protein through alkaline protease, and the preparation method is as follows:

[0029] (1) Wheat germ protein is fully dissolved in water, and the obtained mass fraction is 3% wheat germ protein solution;

[0030] (2) Add alkaline protease to the wheat protein germ solution so that the mass ratio of alkaline protease to wheat germ protein is 1:100, then hydrolyze for 4 hours under the conditions of pH 7.5 and temperature 40° C., inactivate the enzyme, Ready to serve ...

Embodiment 3

[0036] A kind of color-protecting concentrated laundry detergent, by mass percentage, comprises following raw material:

[0037] Fatty alcohol polyoxyethylene ether AEO-9 25%, lauryl glucoside 5%, fatty acid methyl ester ethoxylate sulfonate FMES 20%, sodium dodecylbenzene sulfonate 15%, triethanolamine 5% , 0.15% soybean polysaccharide, 0.5% wheat germ protein hydrolyzate, 10% glycerol, 1% Kathon, 1% essence, deionized water to make up to 100%.

[0038] Wherein, the hydrolyzate of wheat germ protein is obtained by hydrolysis of wheat germ protein through alkaline protease, and the preparation method is as follows:

[0039] (1) Wheat germ protein is fully dissolved in water, and the obtained mass fraction is 5% wheat germ protein solution;

[0040] (2) Add alkaline protease to the wheat protein germ solution, so that the mass ratio of alkaline protease to wheat germ protein is 2:100, then hydrolyze for 4 hours under the conditions of pH 8.5 and temperature 55°C, and inactivat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com