Samphire plant salt as well preparation method and application of samphire plant salt

A technology for plant salt and samphire, which is applied in the field of its preparation and samphire plant salt, and achieves the effects of stable properties, bright appearance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0034] The preparation of embodiment 2 salicornia plant salt and seasoning

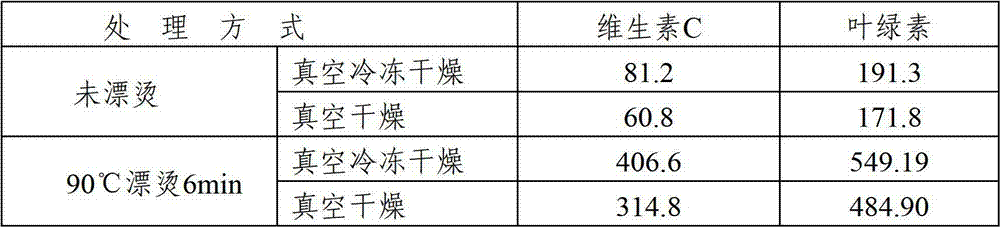

[0035] Select 2000g of fresh salicornia stems that are free from diseases, insect pests, and rot and other abnormal phenomena, and rinse them with clean water; put the washed salicornia stems in 20L, 90°C hot water for 6 minutes; after blanching to protect the green , add water 100mL, mash into a homogenate in batches with a tissue masher; squeeze and filter the homogenate with a 150-mesh filter cloth, discard the filter residue, and combine the filtrate; concentrate the filtrate by rotary evaporation at a vacuum degree of -0.06Mpa and a temperature of 80°C to 1 / 3 of the original volume; freeze the concentrated filtrate at -20°C for 6 hours, put it into a vacuum freeze dryer after it is completely frozen, and dry it at a pressure of 40Pa and a condensation temperature of -50°C to obtain samphire Vegetable salt 107g;

[0036] Take 49g of salicornia plant salt, add moistureproof agent calcium sulfate 7g ...

Embodiment 3

[0037] Example 3 Salicornia plant salt and preparation of seasoning

[0038] Select 2000g of young salicornia seed pods that are fresh, free from diseases and insect pests, and have no abnormal phenomena such as rot, and rinse them with clean water; put the cleaned tender salicornia seed pods into 20L, 85°C hot water for 8 minutes; blanching After protecting the green, add 100mL of water, mash into a homogenate in batches with a tissue grinder; filter the homogenate with a 300-mesh filter cloth, discard the filter residue, and combine the filtrate; concentrate by rotary evaporation at a vacuum degree of -0.08MPa and a temperature of 85°C The filtrate was reduced to 1 / 4 of the original volume; the concentrated filtrate was dried in a vacuum drying oven at a vacuum degree of -0.06MPa and a temperature of 85°C to obtain 103g of salicornia plant salt;

[0039] Take 50g of salicornia plant salt, add 9g of moisture-proof agent calcium sulfate and 12g of soluble starch, mix well, add...

Embodiment 4

[0040] Example 4 Salicornia plant salt and preparation of seasoning

[0041] Select 2000g of young salicornia seed pods that are fresh, free from diseases and insect pests, and have no abnormal phenomena such as rot, and rinse them with clean water; put the washed tender salicornia seed pods into 20L, 100°C hot water for 4 minutes; After scalding to protect the green, add 100mL of water, mash into a homogenate in batches with a tissue grinder; filter the homogenate with a 200-mesh filter cloth, discard the filter residue, and combine the filtrate; concentrate the filtrate by rotary evaporation, vacuum degree -0.06MPa, temperature 85 Concentrate the filtrate by rotary evaporation at ℃ to 1 / 4 of the original volume; place the concentrated filtrate in a -20 ℃ ultra-low temperature refrigerator, freeze it for 6 hours, put it into a vacuum freeze dryer, and dry it at a pressure of 30 Pa and a condensation temperature of -50 ℃. Get 105g of samphire plant salt;

[0042] Take 50g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com