Catalytic system for preparing polar group-containing polyolefin and preparation method of the polyolefin

A catalytic system and polar group technology, applied in the field of polyolefin materials, can solve the problems of reduced copolymerization activity, catalyst deactivation, and low molecular weight of polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

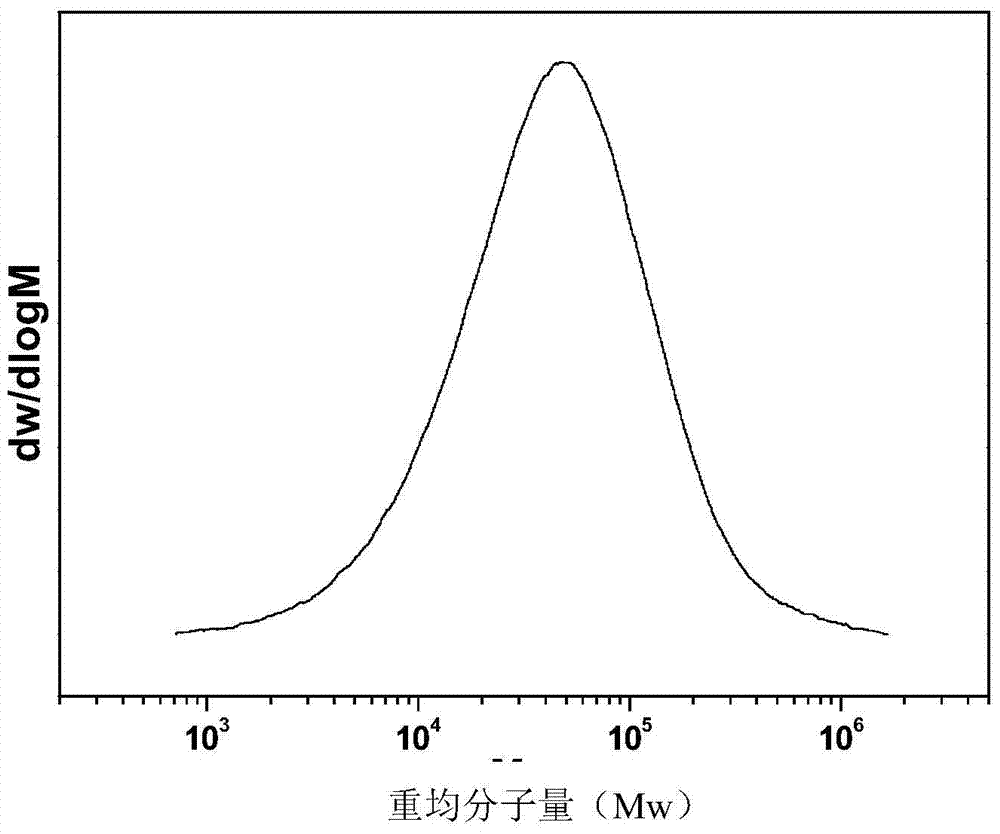

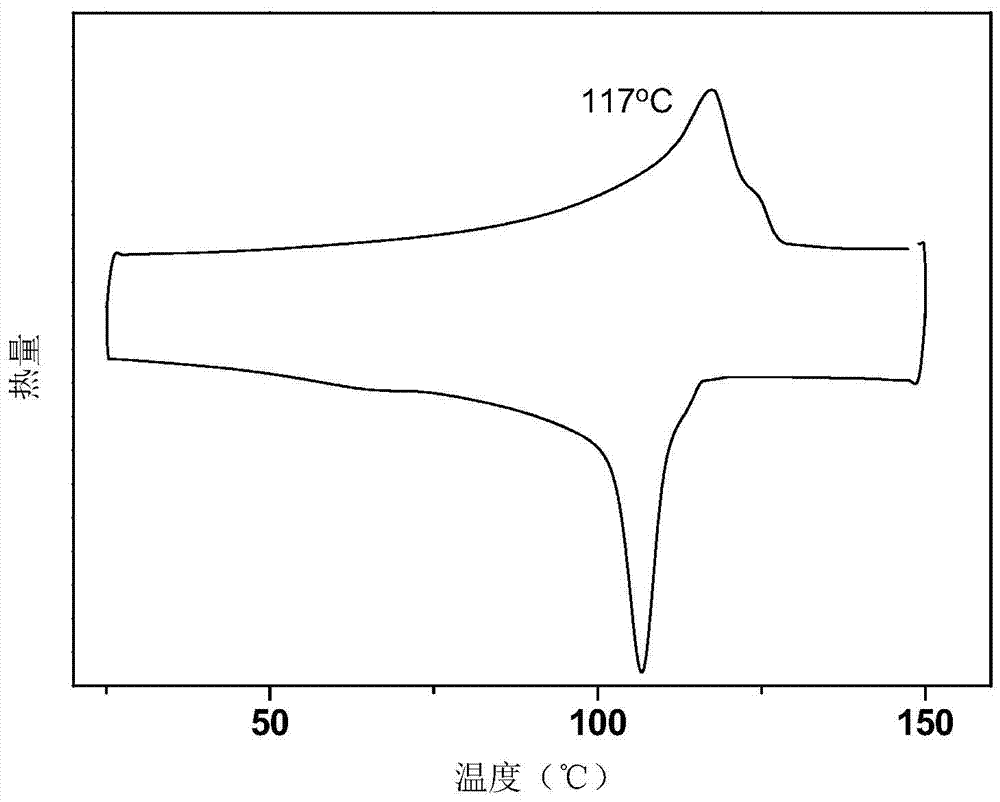

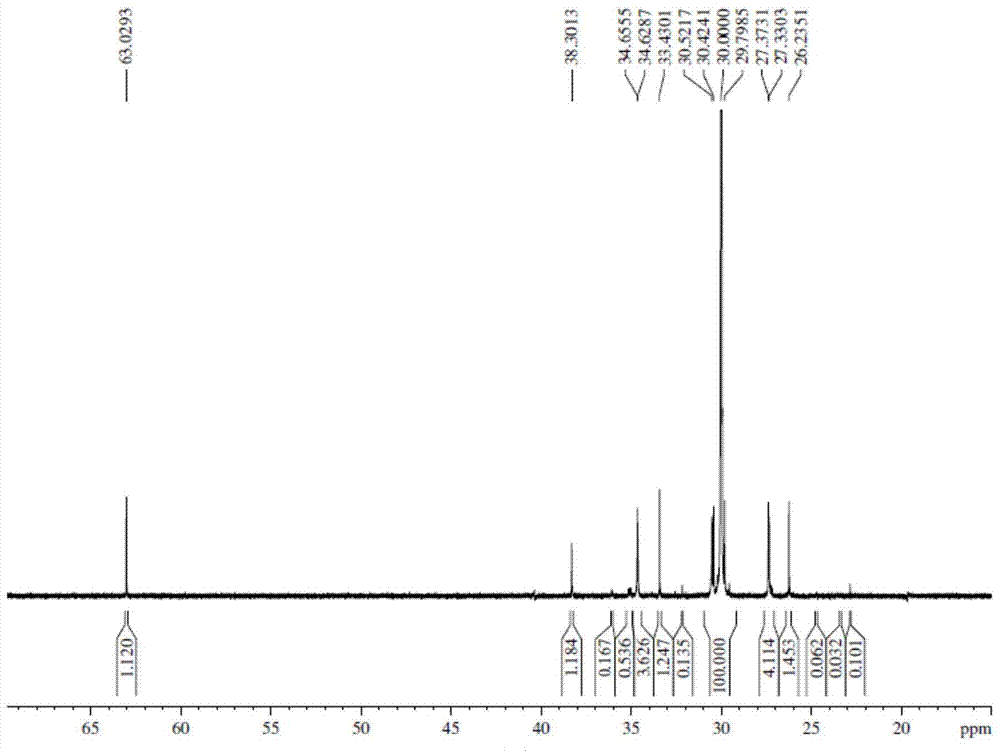

[0057] Fully dry the polymerization device, then vacuumize it and flush it with nitrogen, repeat three times. The polymerization device is vacuumized again, controlled by a solenoid valve, charged with ethylene, 25.8 milliliters of toluene is added at 25° C., 0.1 milliliters of 9-decen-1-alcohol is added, 0.6 milliliters of triisobutylaluminum toluene solution (1.1 mol / mL), stirred for 10 minutes. Add 3 mL of MAO toluene solution (1.67 mol / ml) and 1 ml of transition metal compound (X=Cl) solution (10 micromol / ml) described in formula I, and start timing. After 20 minutes, turn off ethylene, add acidified ethanol to the reaction solution, stir for more than 6 hours, filter to obtain the polymer, vacuum dry the obtained polymer at 60° C. for 24 hours, and weigh to obtain 0.49 g of the polymer. The specific reaction conditions and results are listed in Table 1. The CPC test curve, DSC curve and the compound that present embodiment makes 13 C-NMR test results are as follows ...

Embodiment 2

[0059] Fully dry the polymerization device, then vacuumize it and flush it with nitrogen, repeat three times. The polymerization device is vacuumized again, controlled by a solenoid valve, charged with ethylene, 25.1 milliliters of toluene is added at 25° C., 0.2 milliliters of 9-decen-1-ol is added, 1.2 milliliters of triisobutylaluminum toluene solution (1.1 mol / mL), stirred for 10 minutes. Add 3 mL of MAO toluene solution (1.67 mol / ml) and 1 ml of transition metal compound (X=Cl) solution (10 micromol / ml) described in formula I, and start timing. After 20 minutes, turn off ethylene, add acidified ethanol to the reaction solution, stir for more than 6 hours, filter to obtain the polymer, vacuum dry at 60° C. for 24 hours, and weigh to obtain 0.61 g of the polymer. The specific reaction conditions and results are listed in Table 1.

Embodiment 3

[0061] Fully dry the polymerization device, then vacuumize it and flush it with nitrogen, repeat three times. The polymerization device is vacuumized again, controlled by a solenoid valve, charged with ethylene, 24.4 milliliters of toluene is added at 25° C., 0.3 milliliters of 9-decen-1-alcohol is added, 1.8 milliliters of triisobutylaluminum toluene solution (1.1 mol / mL), stirred for 10 minutes. Add 3 mL of MAO toluene solution (1.67 mol / ml) and 1 ml of transition metal compound (X=Cl) solution (10 micromol / ml) described in formula I, and start timing. After 20 minutes, turn off the ethylene, add acidified ethanol to the reaction solution, stir for more than 6 hours, filter to obtain the polymer, vacuum dry at 60° C. for 24 hours, and weigh to obtain 0.43 g of the polymer. The specific reaction conditions and results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com