Filter device

A filter device and filter element technology, which is applied in filtration separation, membrane filter, mobile filter element filter, etc., can solve the problems of high manufacturing cost and energy consumption, decreased filtration efficiency, material wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

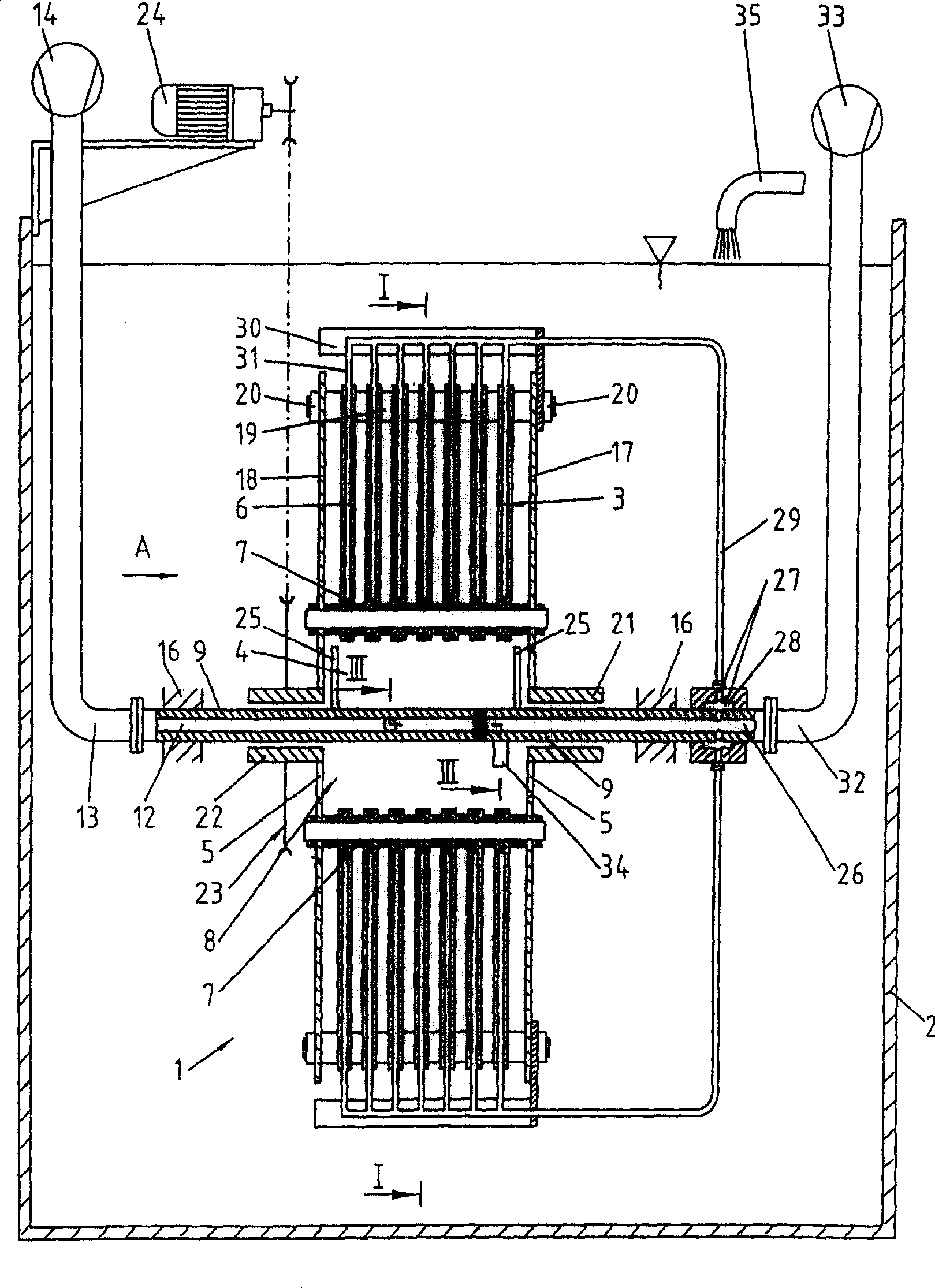

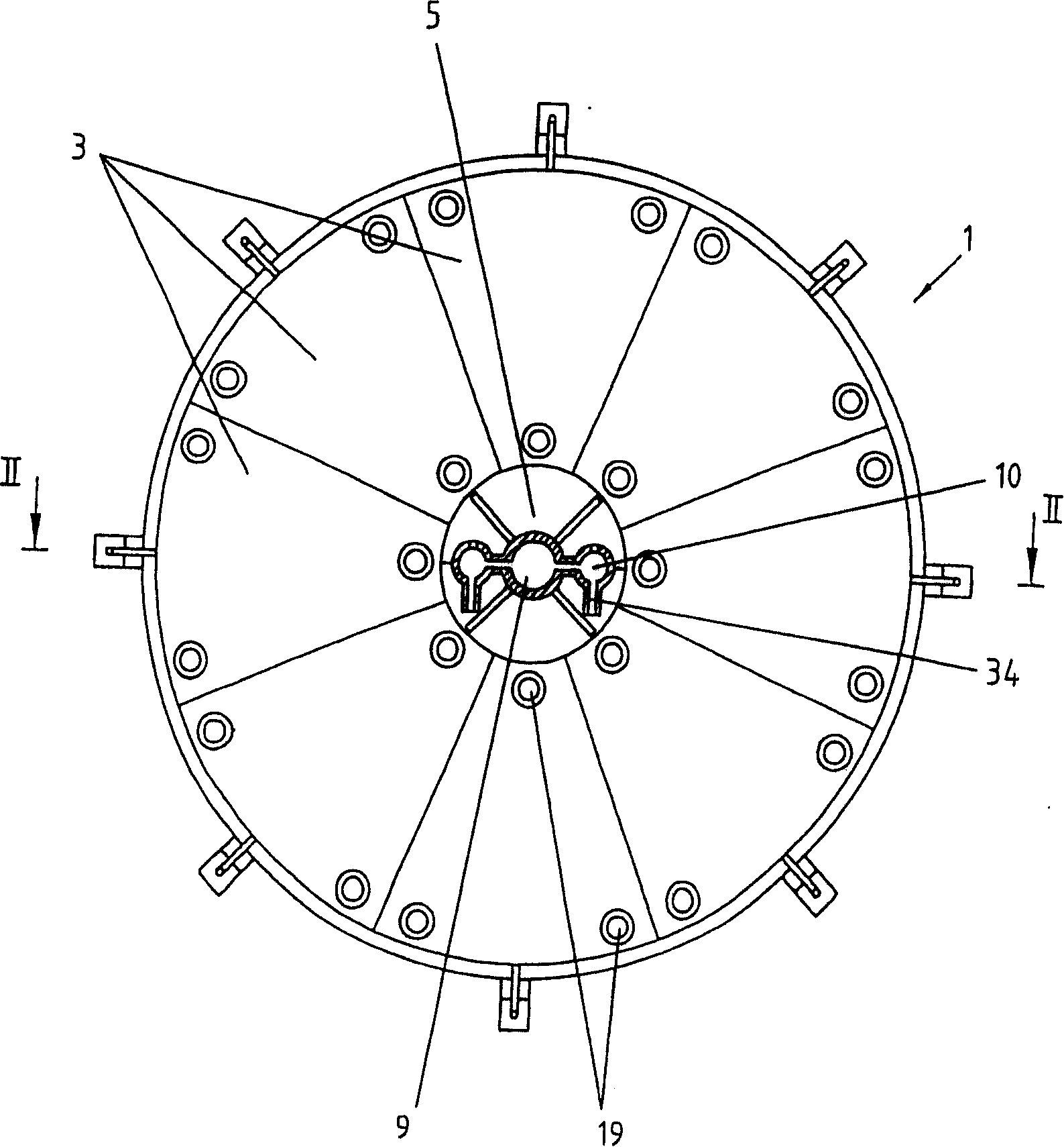

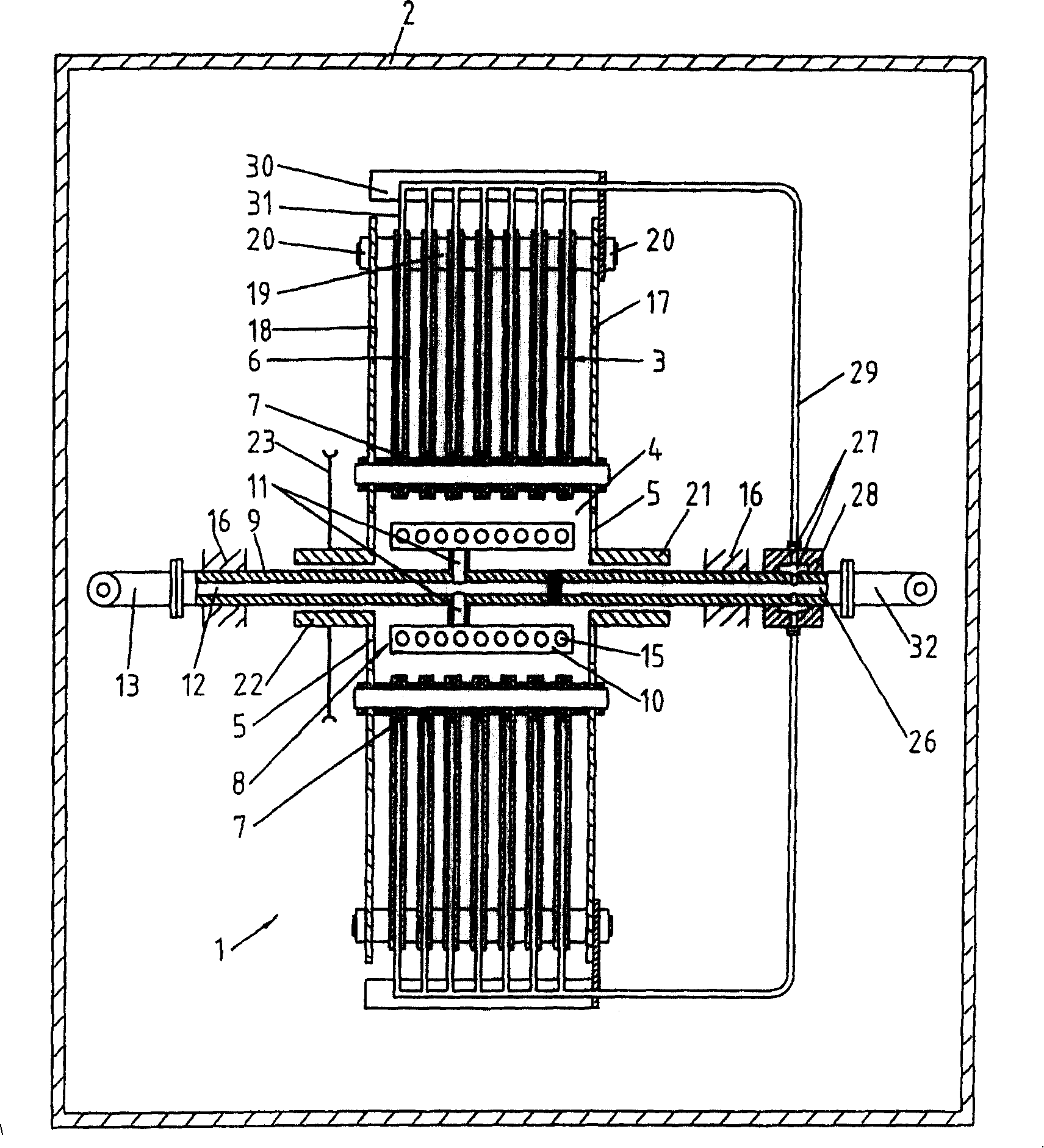

[0024] Figures 1 to 3 A first preferred embodiment of the invention is shown: the filter device 1 is arranged rotatably in a liquid-filled container 2 . It has multiple filter modules 3 . The individual filter modules 3 are combined to form a plate-shaped filter element 6 with, for example, a circular or polygonal perimeter. The individual filter elements 6 are connected at a spacing of, for example, 4 to 8 mm. The filter module 3 making up the filter element 6 is formed, for example, from a plurality of substantially parallel filter plates (not shown), as is known per se. The filtrate is led off through a filter plate with filters on both sides. The distance between the filter elements 6 can be adjusted by means of the spacer discs 7 . A ventilation device 8 is fixed horizontally in the cavity 4 . The ventilation device 8 consists of hollow bodies 10 arranged parallel to a hollow shaft 9, which extend over the entire width in which the filter element 6 is present, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com