Honeycomb type heat accumulation body composite pouring die and manufacturing method of the heat accumulation body

A manufacturing method and heat accumulator technology, applied in the manufacture of tools, molds, ceramic molding machines, etc., can solve the problems of long time occupation of steel molds, low turnover rate of steel molds, and inconvenient manufacturing, so as to reduce production costs and improve production costs. Effects on labor productivity and ease of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

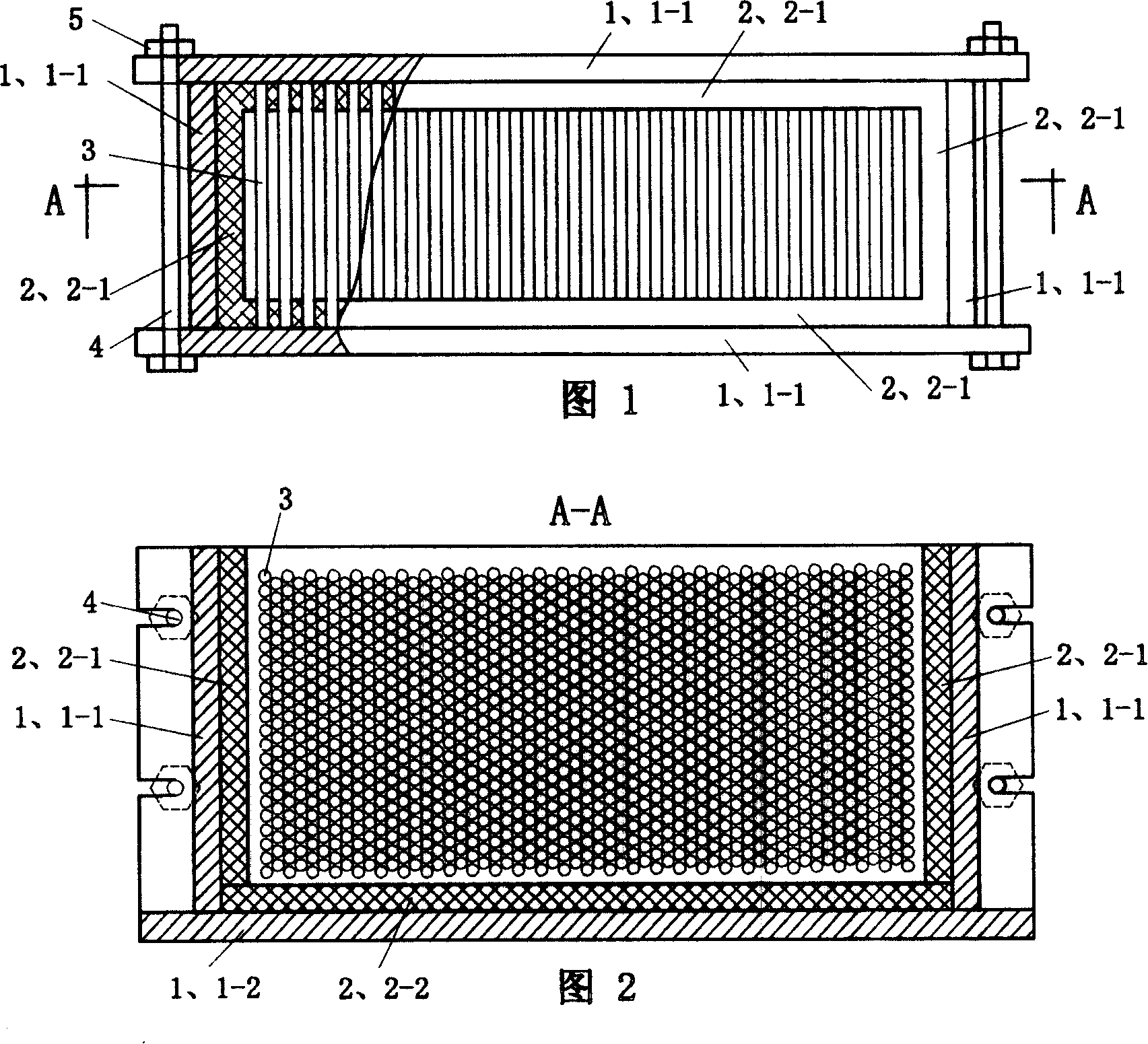

[0022] (embodiment 1, composite casting mold)

[0023] Embodiment 1 shown in the accompanying drawings has a steel mold 1, and the steel mold 1 is formed by detachably connecting a bottom plate 1-1 and four side plates 1-2. The detachable connection adopts that four side plates 1-2 are connected on the bottom plate 1-1 by mortise, and bolts 4 are connected between two pairs of sides, and are fastened by nuts 5 . The steel mold 1 is provided with a matching combustible inner mold 2, and the combustible inner mold 2 is also composed of a bottom plate 2-1 and four side plates 2-2, and between the four side plates 2-2 and the bottom plate 2-1 and adjacent sides The boards are bonded together. The materials for making the combustible inner mold 2 and the combustible mold core 2-3 can be plastics and / or rubber and / or wood. The base plate 2-1 and the four side plates 2-2 of the combustible inner mold 2 can be made of a unified material, or can be made of different materials. The m...

Embodiment 2

[0024] (embodiment 2, composite casting mold)

[0025] Two of the four side plates of the combustible inner mold 2 of embodiment 2 are provided with core holes 2-2-1 made of rubber, the other two side plates are made of plastic, and the bottom plate 1-1 is made of wood , all the other are identical with embodiment 1.

Embodiment 3

[0026] (embodiment 3, honeycomb heat accumulator manufacturing method,)

[0027] The raw material formula of Example 3 generally takes 40-60 parts of aggregate by weight; 30-50 parts of base material; 7-12 parts of binder; and 0.06-1.3 parts of water reducing agent. The above-mentioned aggregate adopts corundum particles, high-alumina bauxite particles, mullite particles or cordierite particles; Calcium aluminate cement and high-temperature alumina micropowder or silica fume; the above-mentioned water reducer uses sodium tripolyphosphate or sodium hexametaphosphate. In this example, 50 parts of mullite particles are used as the aggregate, 40 parts of sintered mullite powder are used as the base material, 5 parts of pure calcium aluminate cement and 5 parts of high-temperature alumina micropowder are used as the binder, and tripolyphosphoric acid is used as the water reducing agent. Sodium 1 part. Accurately weigh the above raw materials into the conical double-screw mixer ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com