Pressure holding device for producing composite parts by infusion of resin and related methods

A technology of holding device and pressurizing device, applied in the field of aeronautics, can solve the problem that the holding pressure can no longer be ensured to be transmitted to the mold, and achieve the effect of reducing the occupation time and increasing the productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

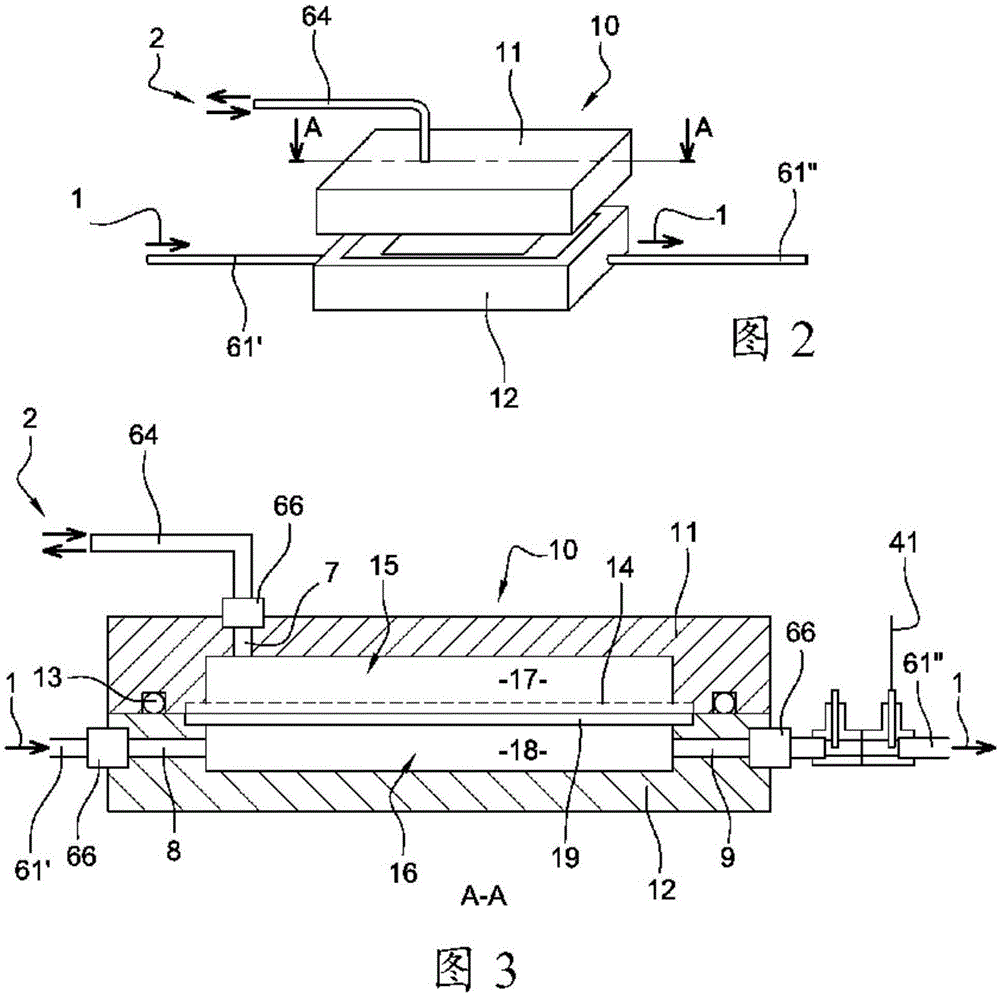

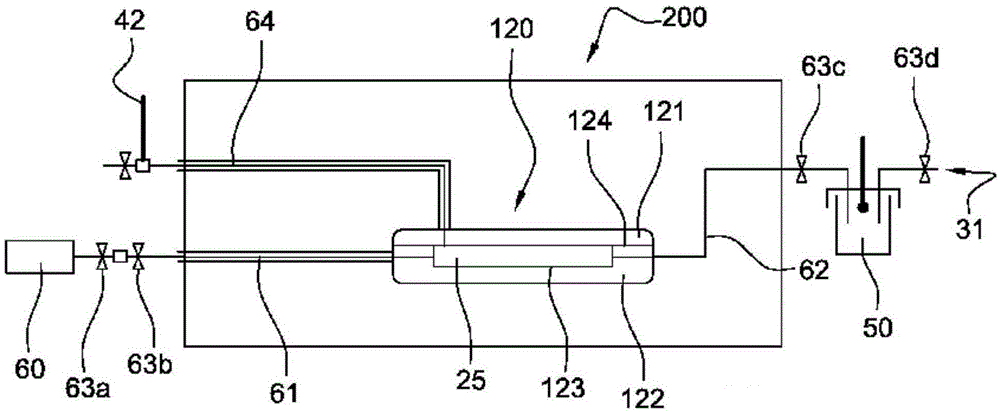

[0052] In all figures, unless otherwise stated, the same elements are provided with the same reference numerals.

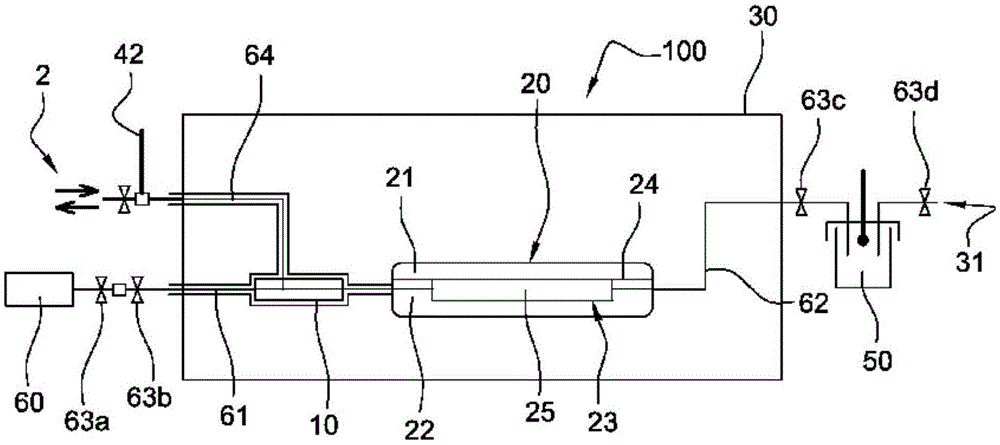

[0053] figure 1 A schematic diagram showing a first embodiment of an RTM injection system 100 incorporating a pressure maintaining device 10 according to the present invention.

[0054] The system 100 includes conventional elements so that parts made of composite materials can be manufactured by RTM injection. To this end, the system 100 includes:

[0055] - resin injector 60;

[0056] - an injection mold 20 having two parts, an upper part 21 and a lower part 22, separated by a connecting surface 24 and comprising a cavity 23 having the shape of the part to be produced, into which a braided preform is inserted pieces 25;

[0057] - resin pool 50;

[0058] - an injection pipe 61 connecting the injector 60 to the injection mold 20;

[0059] - a resin outlet pipe 62 connecting the injection mold 20 to the resin pool 50;

[0060] - means 31 for generating a vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com