Rear projection screen

A transmissive screen technology, applied in television, optics, instruments, etc., can solve problems such as small focal length, uneven color of the transmissive screen 10, and increased difference in the angle of light emission of three-color images.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] next to Figure 1~3 Specific examples of the illustrated implementation forms are described.

no. 1 Embodiment

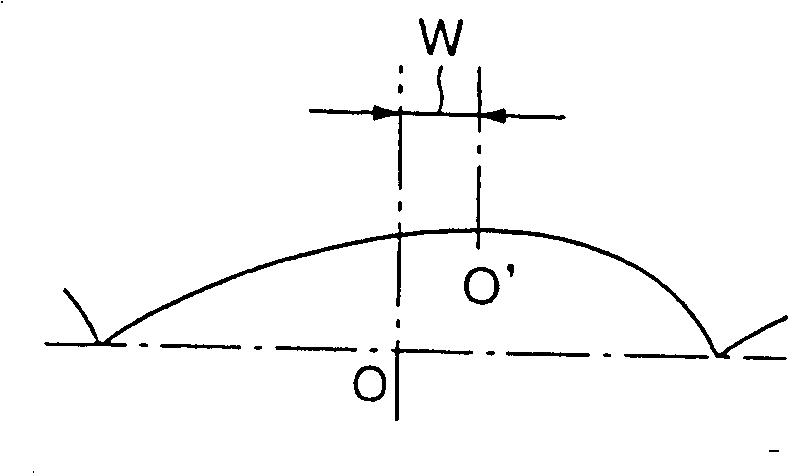

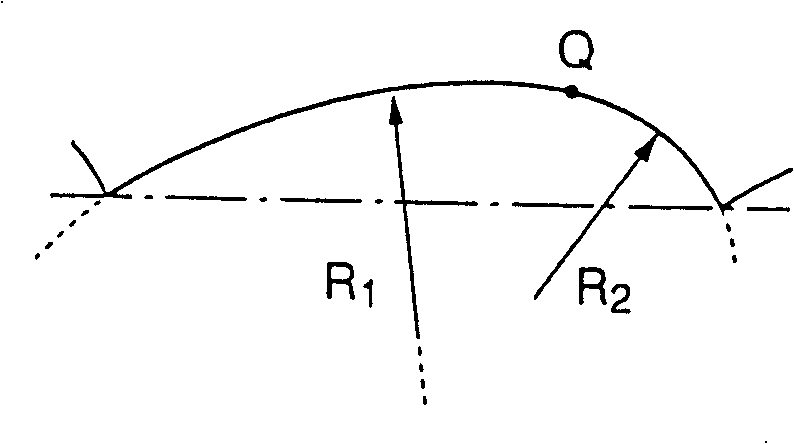

[0048] The first embodiment refers to the following example, that is, in figure 1 In the embodiment shown, the top of the lens arranged in the convex lens at the top and bottom of the outer edge of the screen surface can deviate from the central position of the convex lens along the direction of the center of the screen surface, and the outer edge of the screen surface The direction of diffusion of the top end and the bottom end of the portion may be inclined toward the central portion of the screen surface.

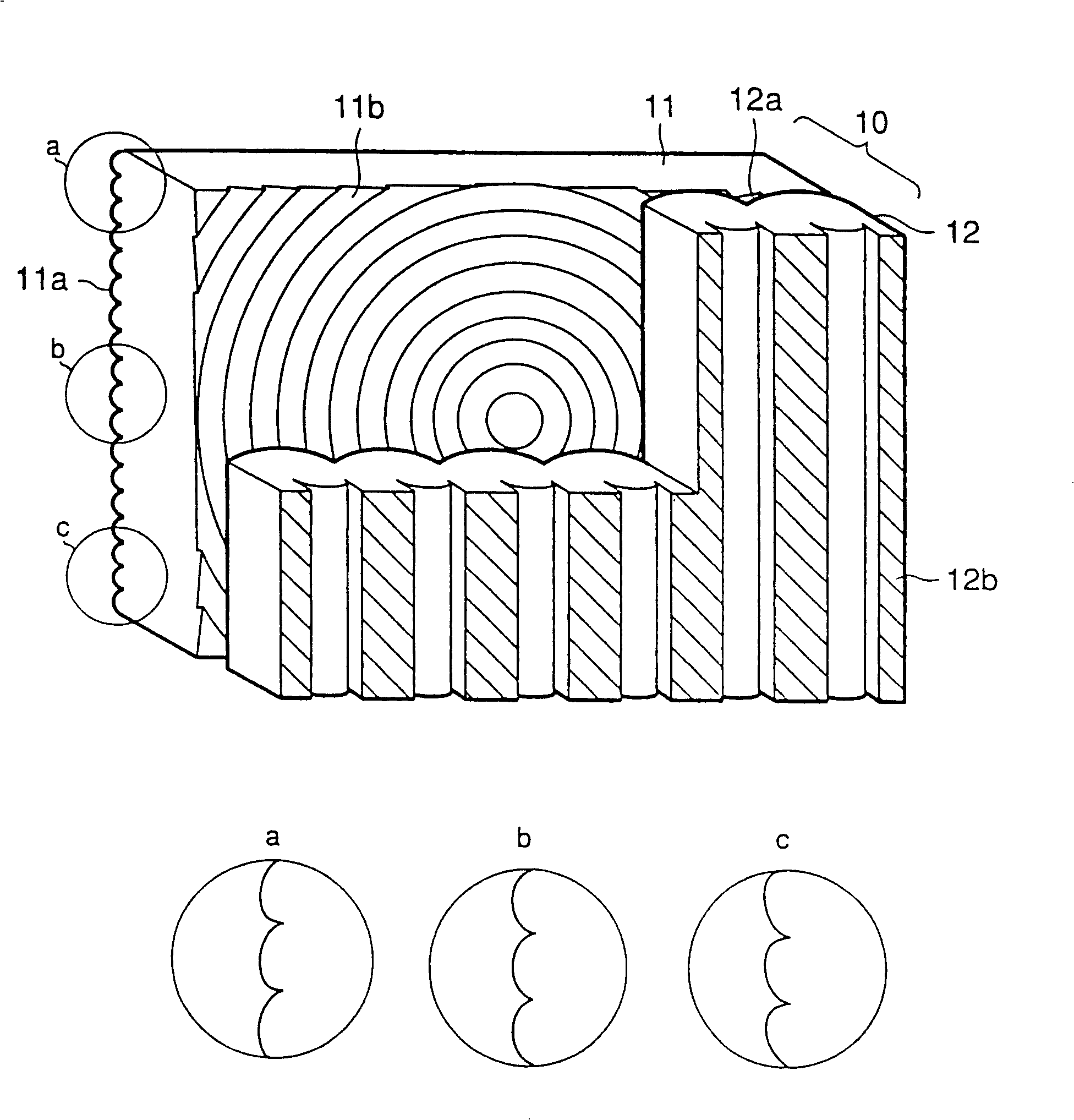

[0049] In this embodiment, as a transmissive screen for a 60" (inch) rear projection TV set, a figure 1 A transmissive screen 10 is shown. In addition, in the Fresnel lens 11, the lenticular lens 11a for vertical diffusion is formed on the light incident side, and the circular Fresnel lens 11b is formed on the light exit side.

[0050] Here, the mold 32 for forming the lenticular lens 11a for vertical diffusion uses a cutter 31 having a cross-sectional shape in which...

no. 2 Embodiment

[0063] The 2nd embodiment is the following embodiment, and this embodiment refers to figure 1 In the embodiment shown, the lens top of the convex lens that is arranged on the top end and the bottom end of the outer edge of the screen surface can deviate from the central position of the convex lens along the end direction of the screen surface, as the outer edge of the screen surface. The diffusion directions of the top end and the bottom end are inclined toward the end of the screen surface. The basic structure of this embodiment is the same as that of the above-mentioned first embodiment.

[0064] In this case, since the lens shape is the same, only the deviation direction of the top of the lens is different, so the diffusion characteristic diagram of the top, center, and bottom of the biconvex lens for vertical diffusion is opposite to that of the first example. They are shown in Fig. The states shown in 9, 8 and 7.

[0065] When measuring the transmissive screen 10 at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com