Lift head for mould system, roof mould system and method for manufacturing roof

A lifting head and formwork technology, applied in the field of lifting head, can solve problems such as component falling, and achieve the effect of improving construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

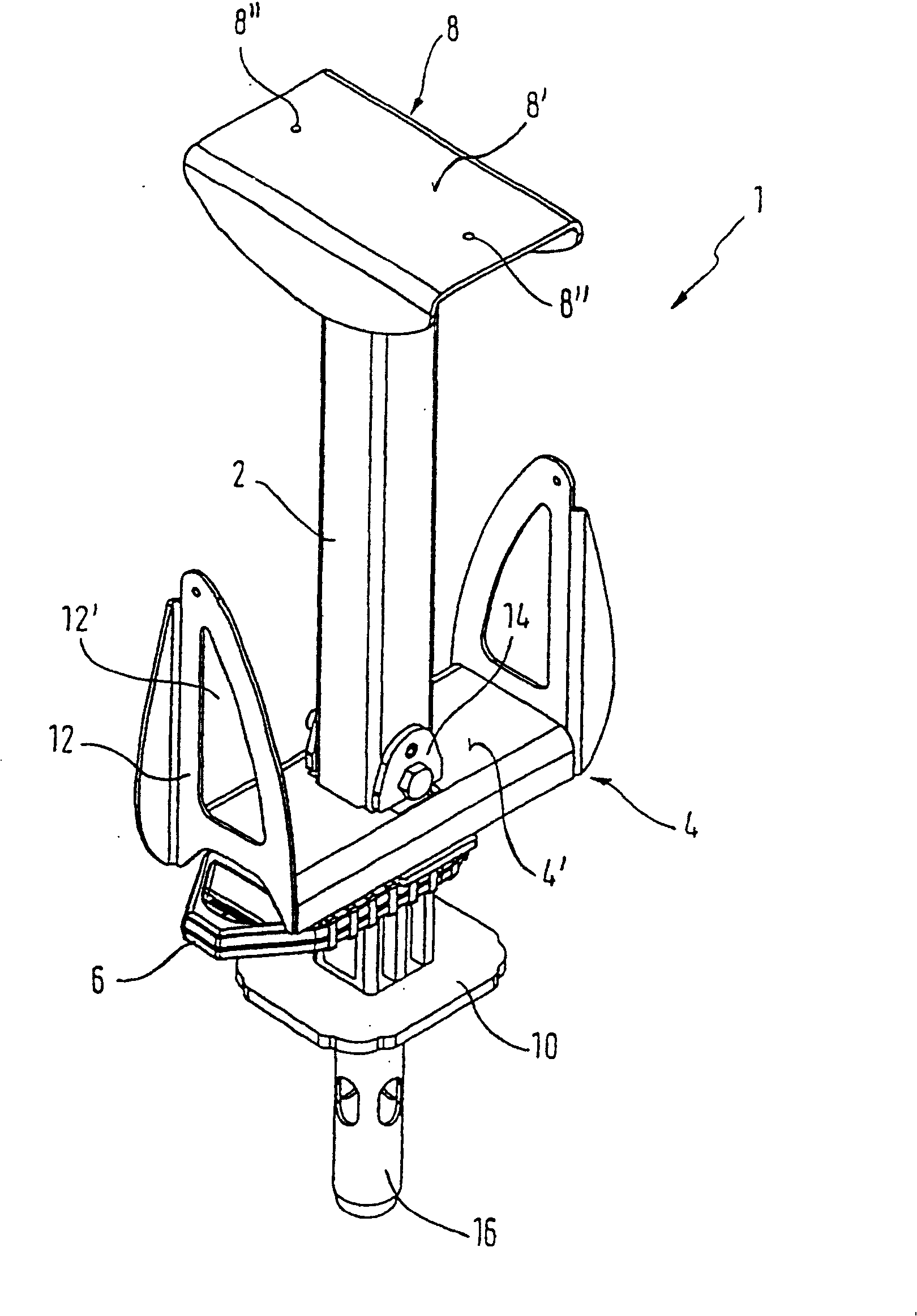

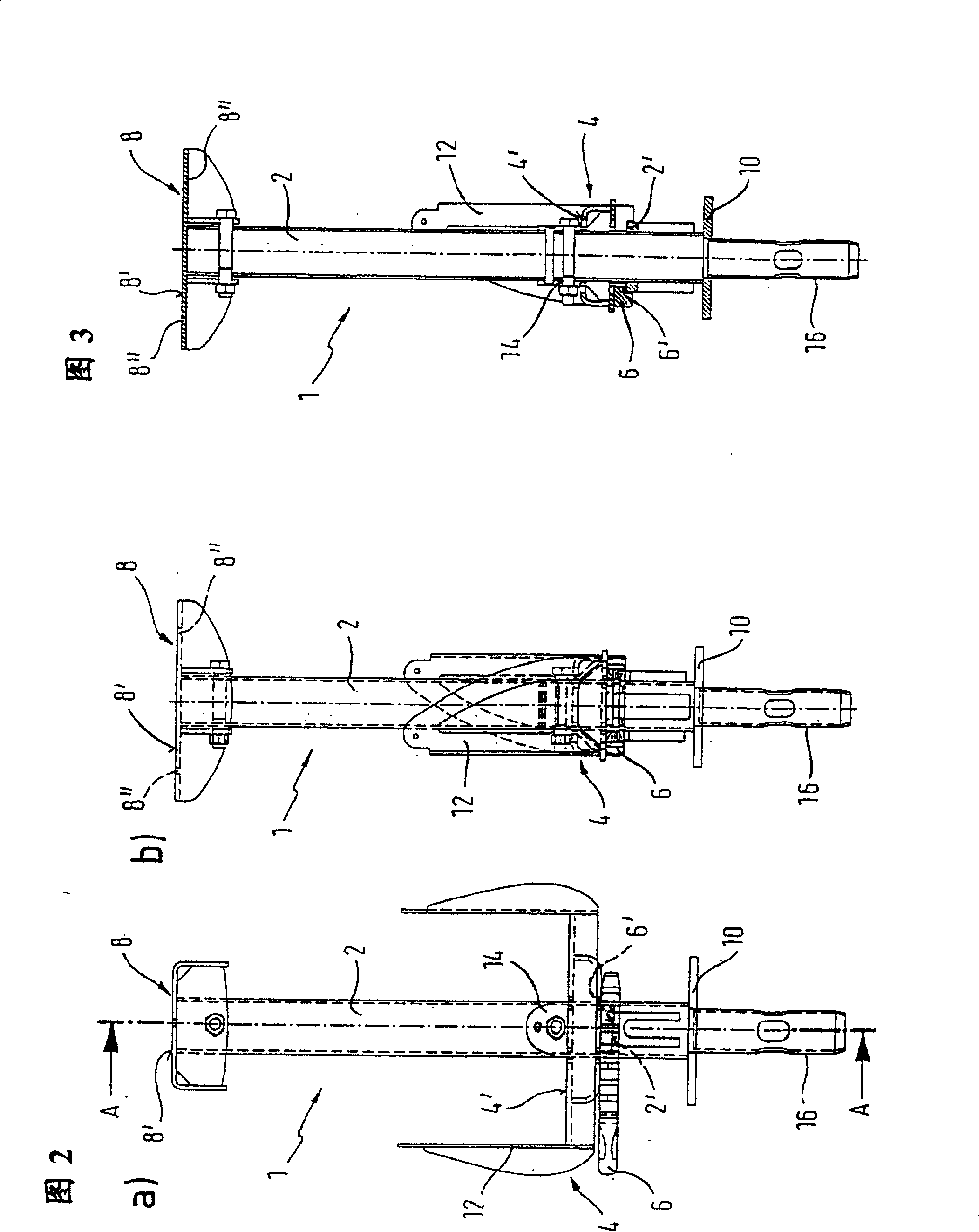

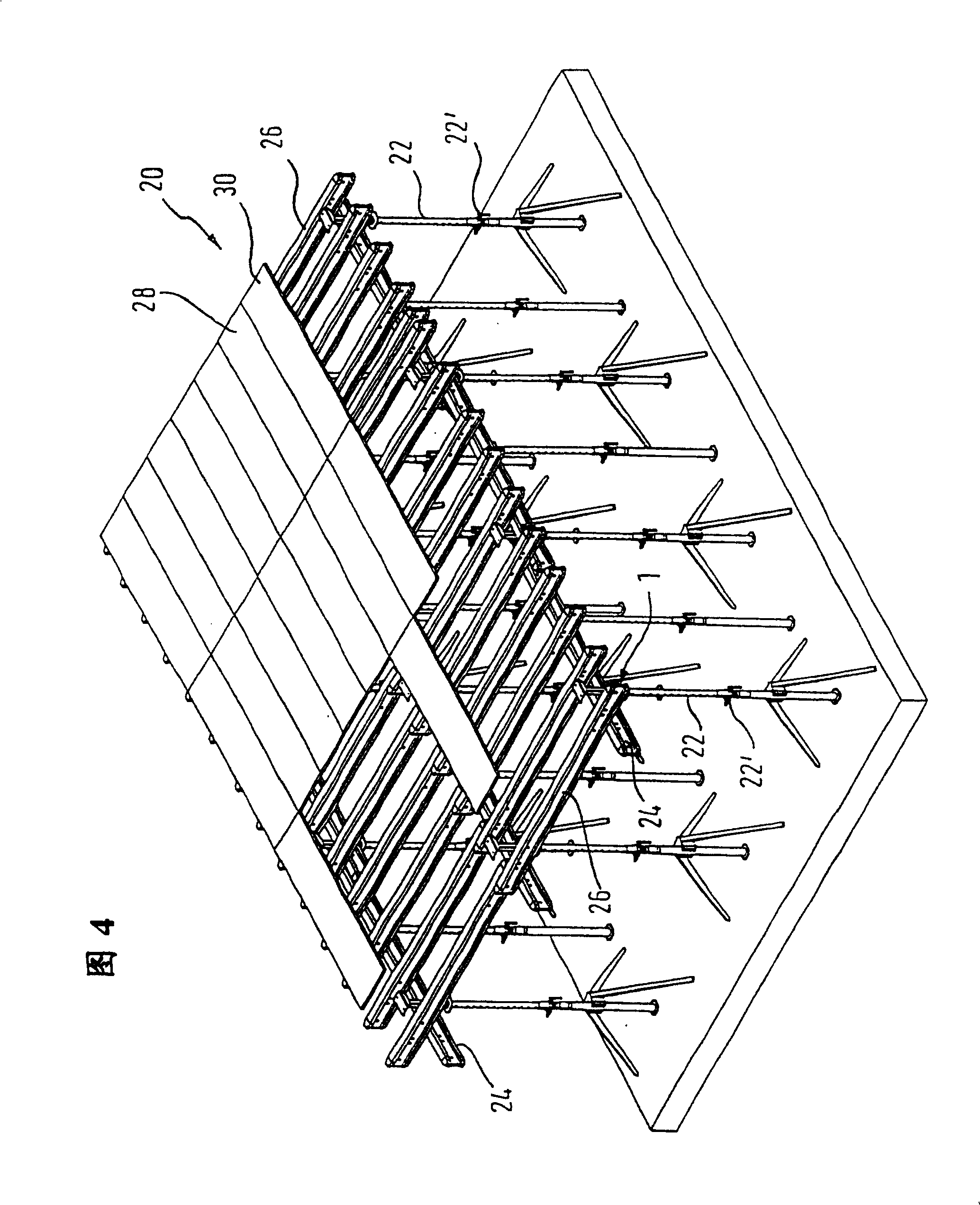

[0034] Refer below figure 1 Preferred embodiments of the present invention will be described in detail. figure 1 3 to 3 schematically represent a lifting head 1 according to a preferred embodiment of the invention. Lifting head 1 comprises a base body 2, a beam support element 4 with a support surface 4' which is movably arranged on the base body 2, a fixing element 6 arranged below the beam support element 4, by means of which the beam support element can be Fixed with respect to the base body 2, it also includes a formwork support element 8 with a formwork support surface 8' disposed on the upper end of the base body 2.

[0035] The beam support element 4 is displaceable along the base body 2 between a first stop element 14 and a second stop element 10 . Although the first stop element 14 can be made integral with the base body 2 or connected to it by welding or similar techniques, in a preferred structure of the lifting head 1 it is particularly preferred that the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com