Gas compressor

A gas compressor and compressor technology, applied in the field of gas compressors, can solve problems such as poor effect, and achieve the effects of preventing chattering, reliable contact, and improving blade pressure output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] first embodiment

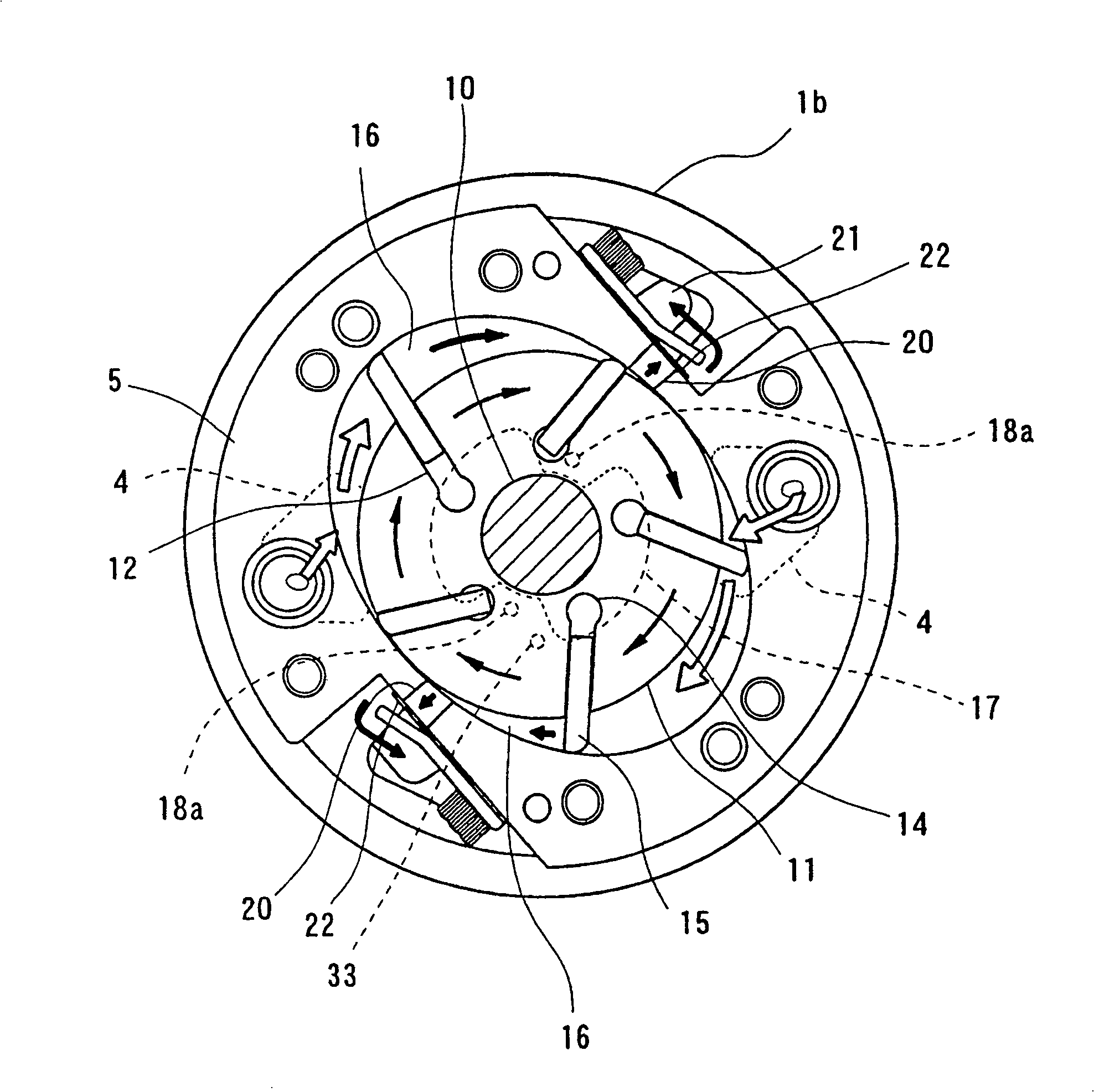

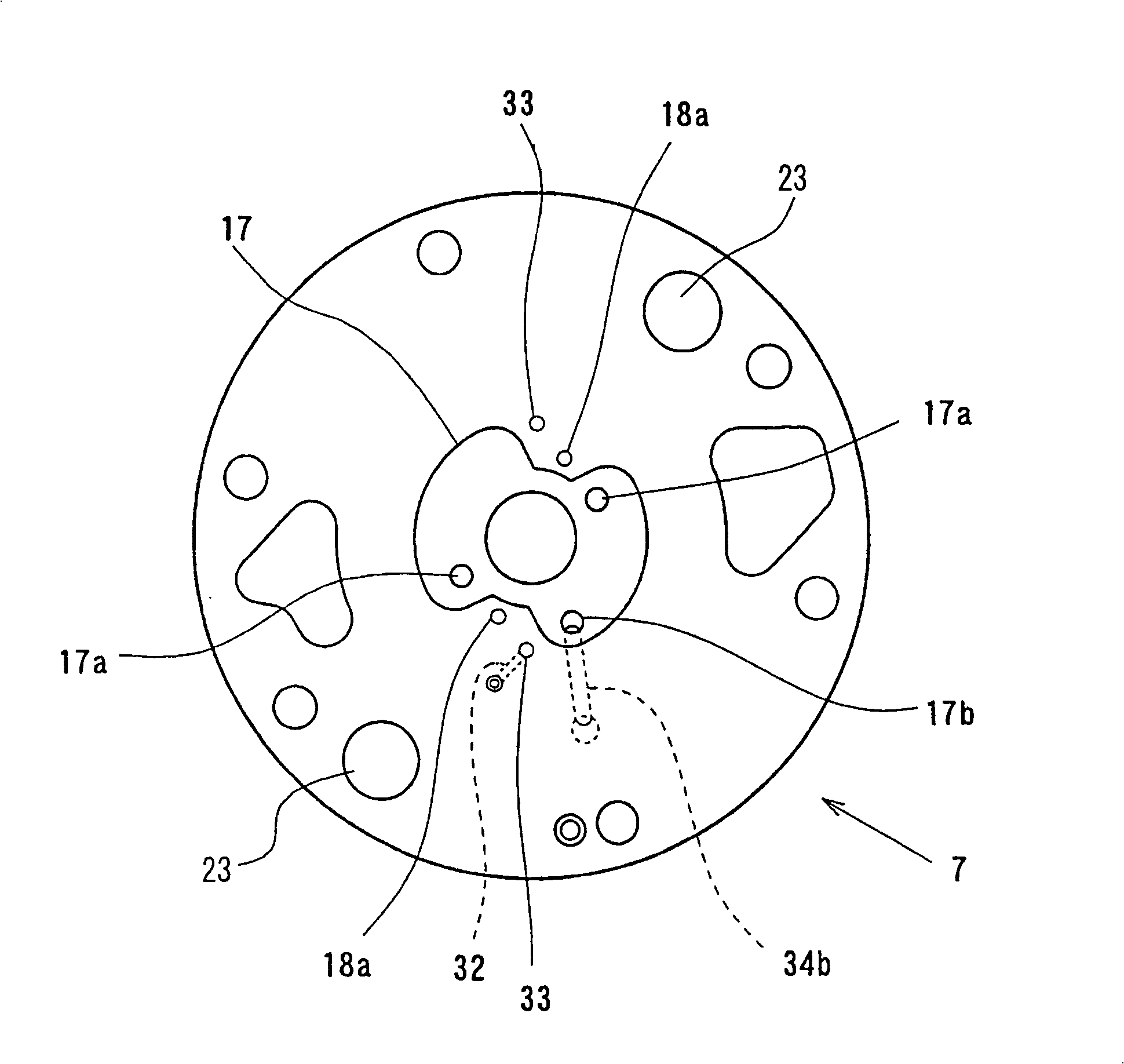

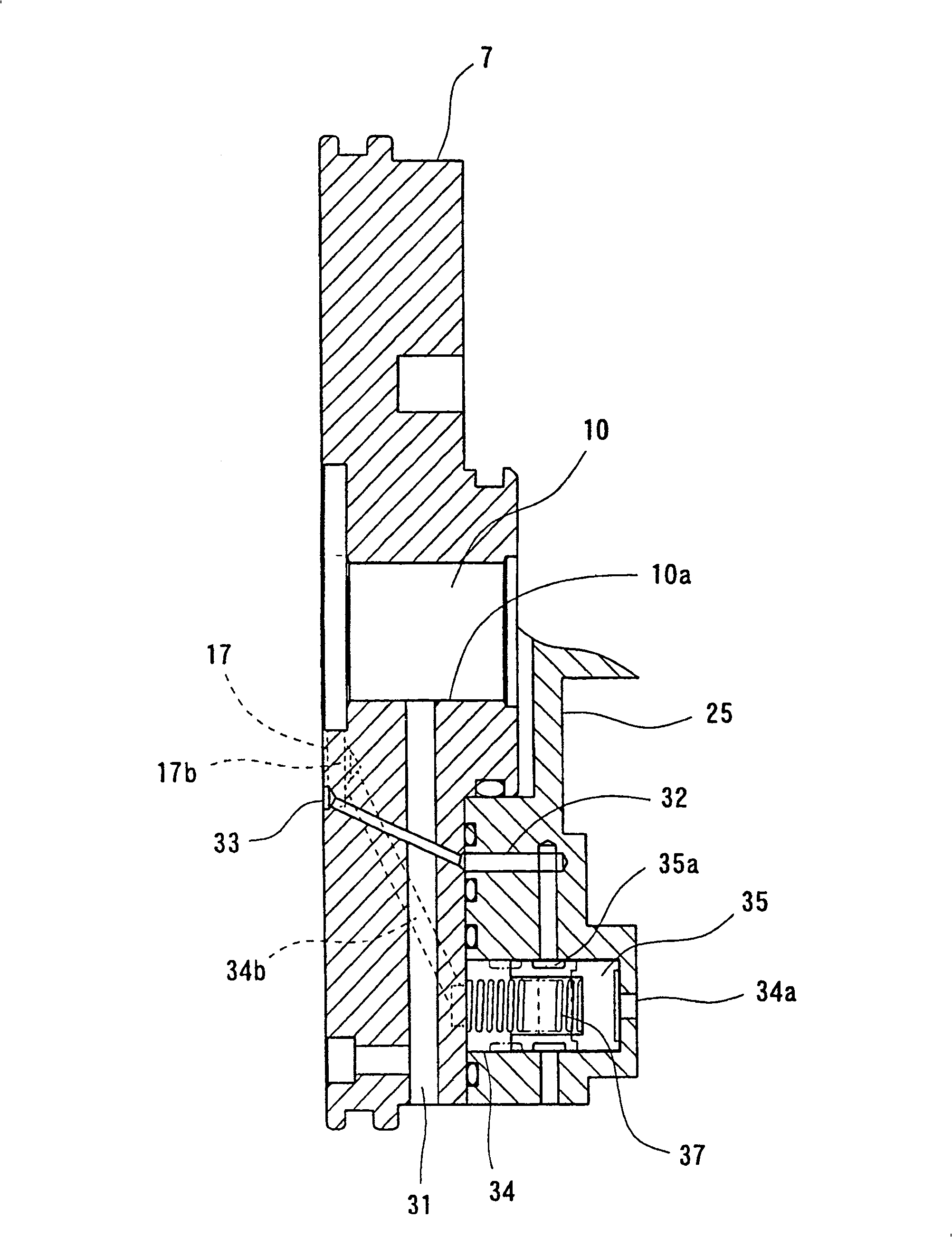

[0043] The following will refer to figure 1 6 to introduce the first embodiment of the present invention. The same components as those in the prior art are denoted by the same reference numerals, and the general structure of the gas compressor will be described with reference to FIG. 10 .

[0044] Like the conventional structure, the gas compressor of the present invention is equipped with a cylinder 5 having an elliptical inner surface, and front and rear side cylinders 6 and 7 arranged at axial ends of the cylinder 5 . The front casing 1 a is mounted on the front side of the front cylinder block 6 , and the rear casing 1 b extends from the rear side of the rear cylinder block 7 to the front cylinder block 6 . The suction port 2 is provided in the front case 1a, and the suction chamber 3 is provided in the front case 1a to communicate with the suction port 2.

[0045] Such as figure 1 As shown, the rotating body 11 is installed in the cylinder 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com