Printing device

一种打印装置、打印头的技术,应用在动力传送装置、印刷、打字机等方向,能够解决热板条失效、限制热板条使用寿命、打印装置不经济等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

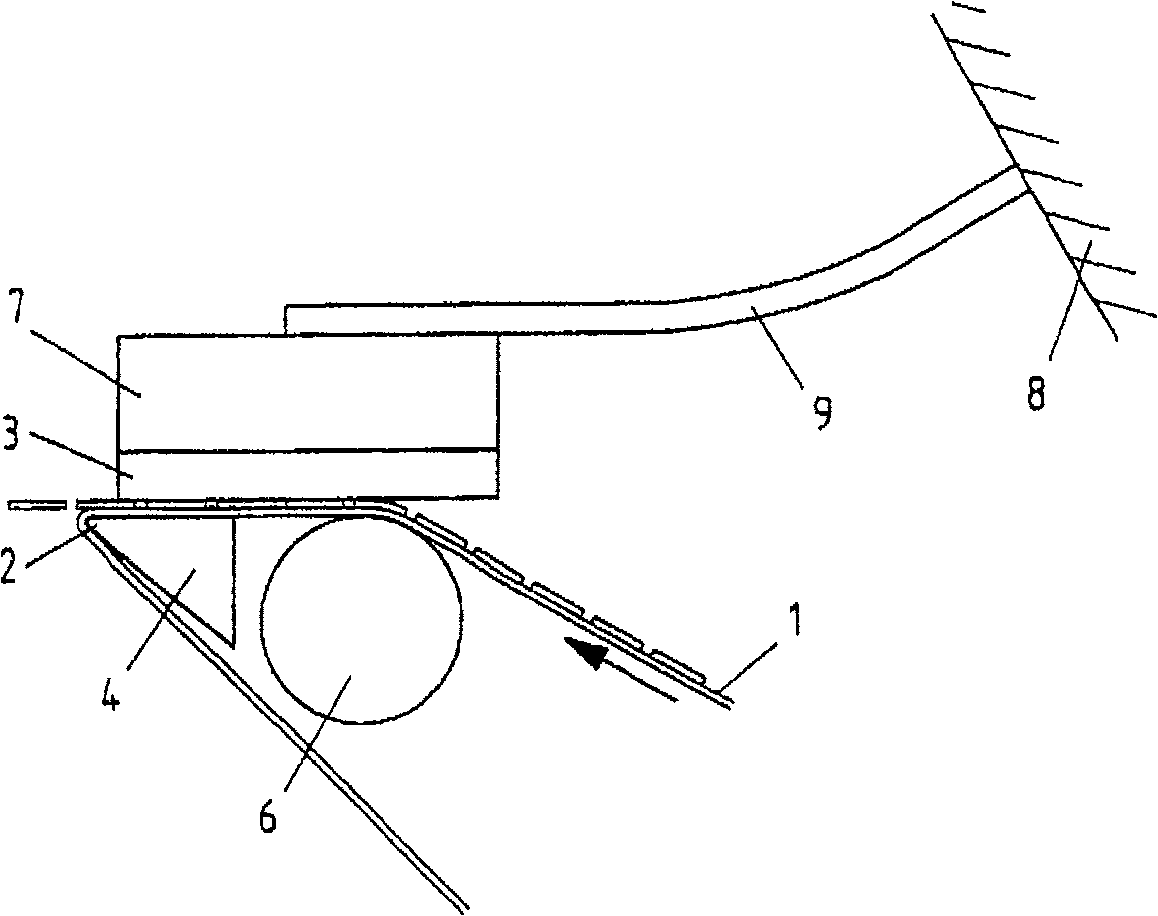

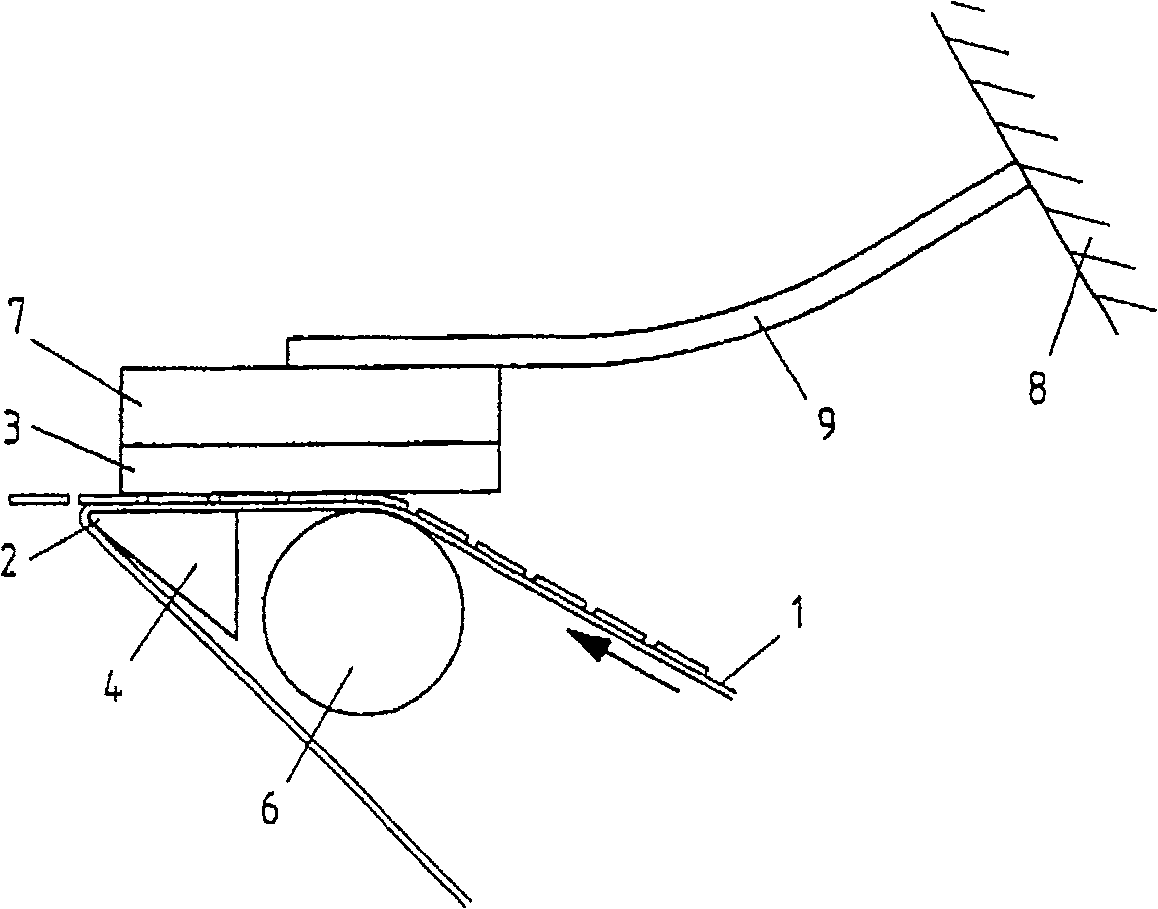

[0017] Such as figure 1 Shown is a printing device for printing a unit of sheet material in the form of a product label supplied by a supply unit (not shown) in the form of an unwinding reel. A sheet unit in the form of a product label 1 made of thermal paper is first conveyed to a print drum 6 forming a counter pressure surface and subsequently moves along the top of a skewer 4 . After this, it reaches the front edge 2 formed on the skewer 4 .

[0018] Arranged above the deflection device 4 is a stationary carrier element 8 , on which an adapter plate 7 is arranged via an elastic holding device 9 , and to which the thermoslat 3 is fastened.

[0019] The unit comprising the thermal strip 3 and the adapter plate 7 can be locked or removed using locking means (not shown) above the illustrated printing device.

[0020] In this arrangement, each set of units comprising adapter plates 7 and thermoslats 3 is designed such that wide thermoslats 3 are associated with thicker adapter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com