Bus allocation method of 350 KA aluminium electrolytic tank

A busbar configuration and aluminum electrolytic cell technology, which is applied in the field of cathode busbar configuration, can solve problems affecting electrolytic cells, aluminum liquid level uplift, fluctuations, etc., and achieve the effects of improving production efficiency, stable operation, and small magnetic field gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

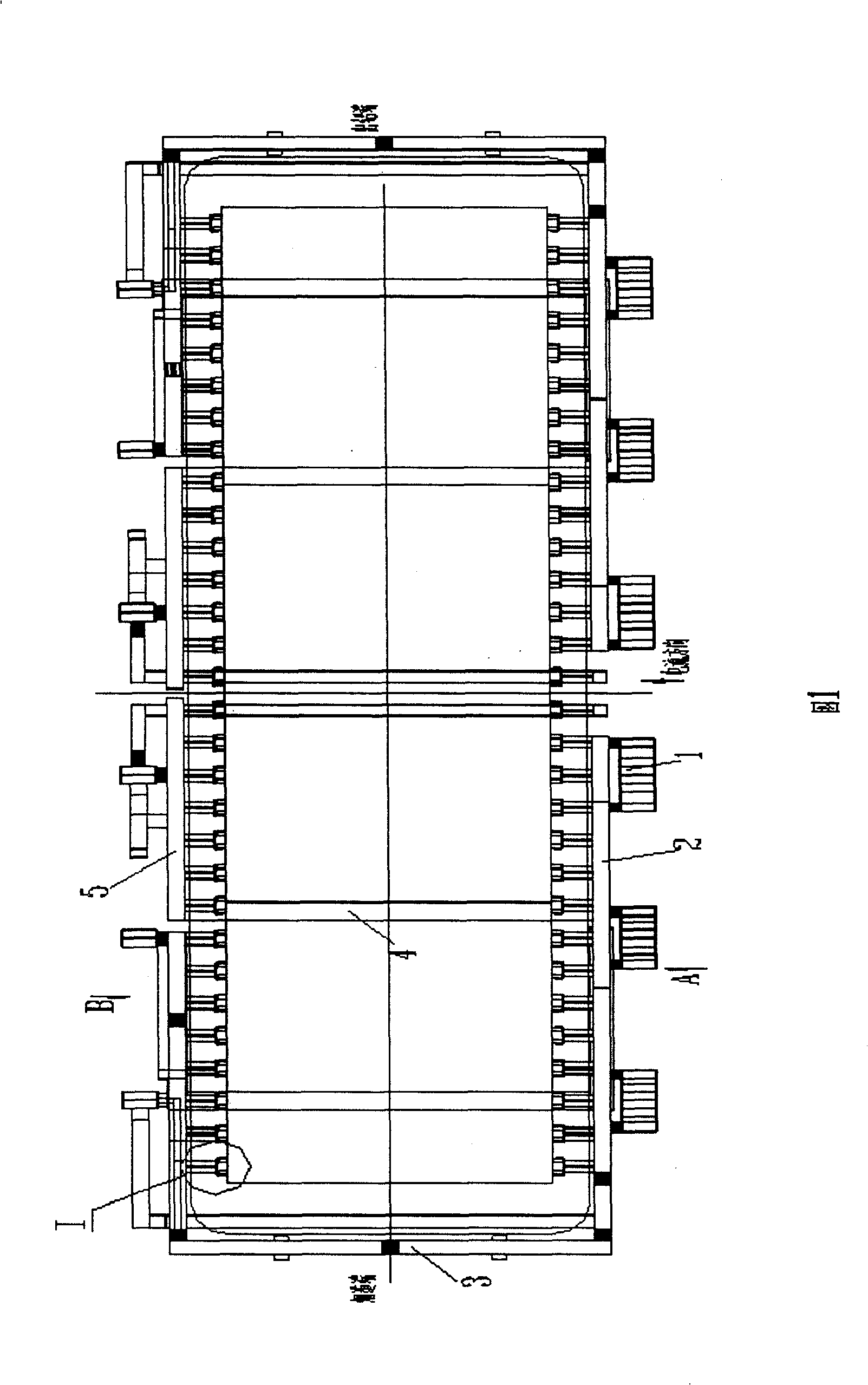

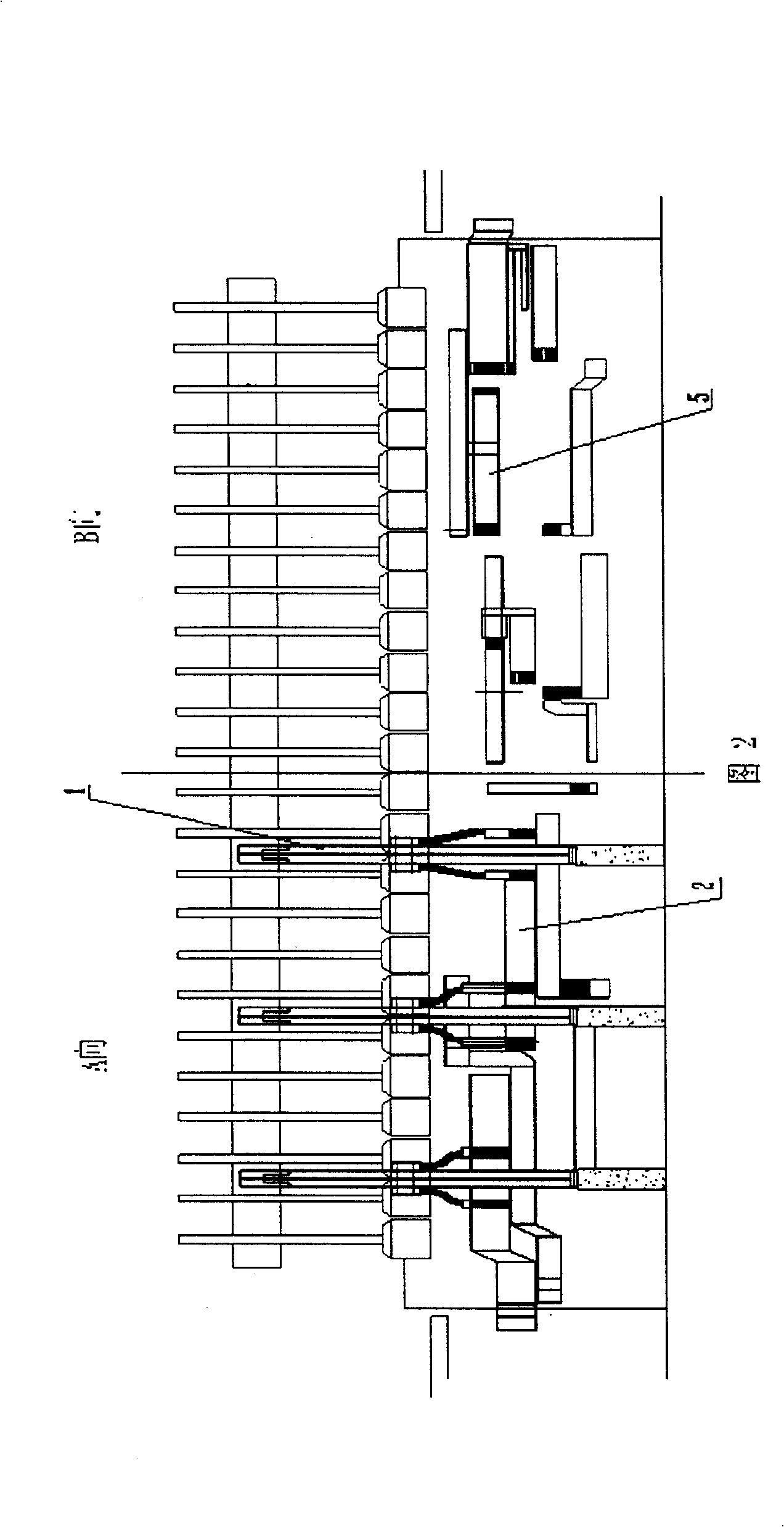

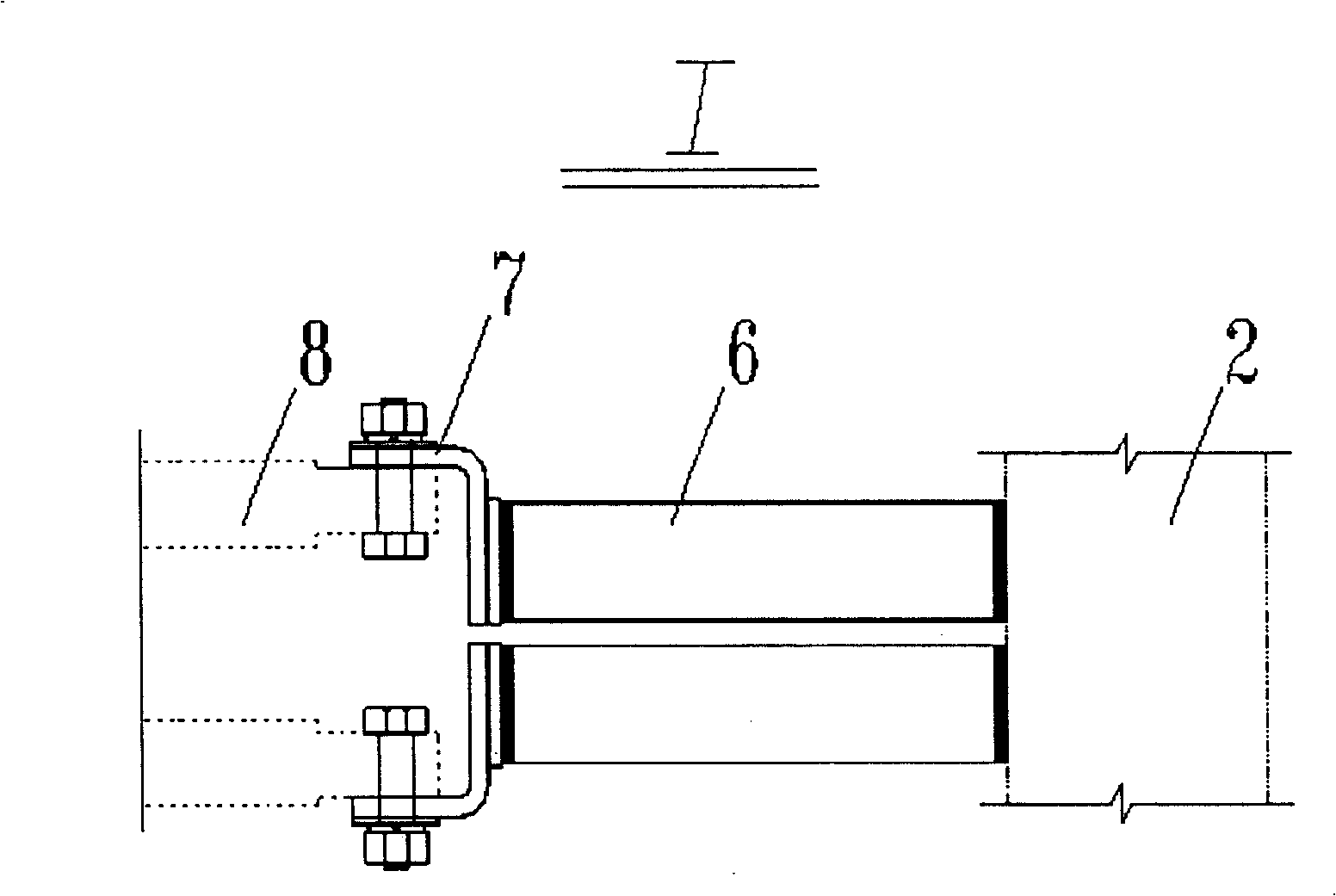

[0013] Embodiment of the present invention: on the power supply side of the electrolyzer, the method of feeding power at 6 points on the large surface is adopted, and 6 column busbars 1 are arranged on the power supply side, and the 6 column busbars 1 are all distributed in equal current proportions. The side busbar 2 and the outlet-side busbar 5 are symmetrically arranged with multi-layer busbars, and the outlet-side busbar 5 is folded horizontally or vertically to increase the current path to the busbar of the downstream slot column to achieve the purpose of current balance, such as Figure 1 shows. The left end of the electrolytic cell is the flue end, and the right end is the aluminum outlet end. There are tank-side busbars 3 at both ends. In order to better compensate the magnetic field of the melt in the tank, the tank-side busbar 3 adopts a stepped configuration, that is, by The elevation from side A to the center of the cell is low, and the elevation from the center of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com