Dip-coating assembly line

A process method and assembly line technology, applied in the field of process flow, can solve problems such as adverse effects of operators, low work efficiency, and increased cost, and achieve high market promotion value, maintain smoothness, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

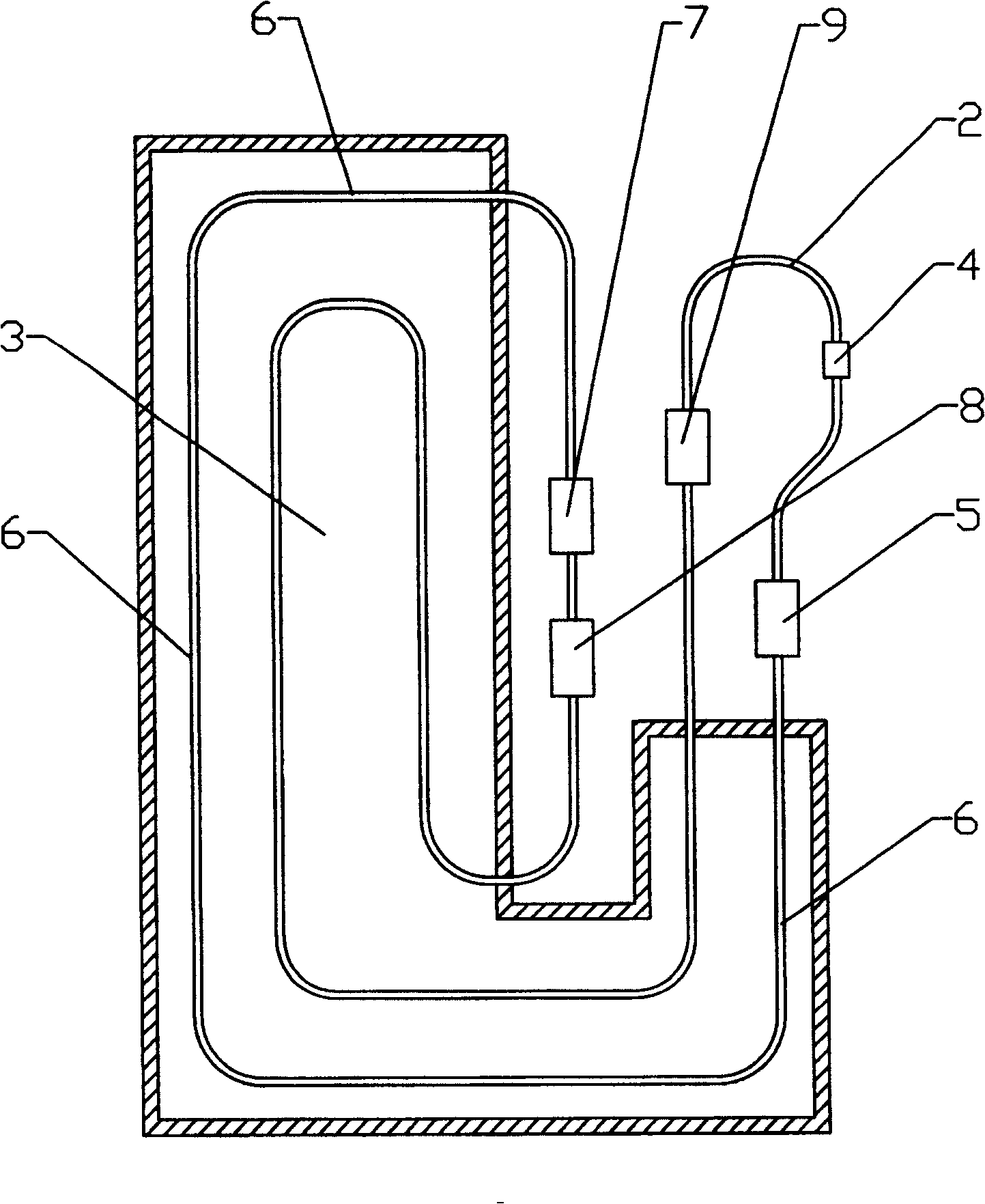

[0020] Example: such as figure 1 As shown, the dip coating line includes a circulation track 2 and a drying chamber 3, and the circulation track 2 includes a pendant area 4, an upper primer area 5, a drying area 6, a sanding area 7, a top paint area 8, an unloading area The workpiece area 9, the drying area 6 is located in the drying room 3, the drying room 3 is provided with a hot air system, and the sanding area 7 is located outside the drying room 3.

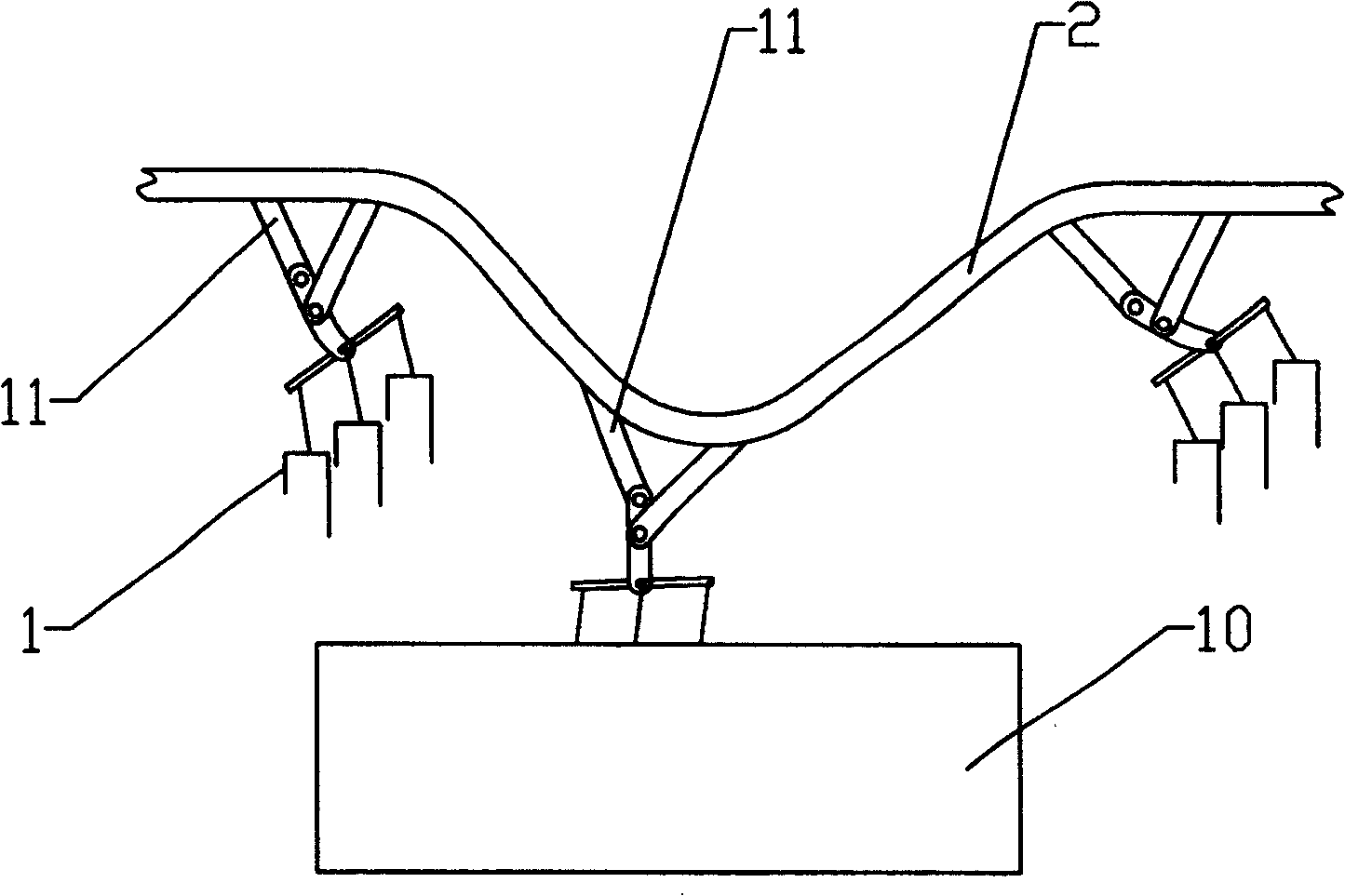

[0021] like figure 2 As shown, the circulation track 2 at the primer area 5 is concave, the bottom of the concave circulation track is provided with a container 10 for holding paint, and the circulation track 2 at the top paint area 8 is concave , the workpiece 1 enters the container for holding the paint at the top paint area 8 to dip-coat the top coat, and the circulating track 2 is provided with a chain, and the chain is provided with several hooks 11 for hanging the workpiece 1, and the chain It is connected with the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com