Saddle regulating and fixing apparatus for tubular knitting machine

A technology of a circular knitting machine and a fixing device, which is applied in weft knitting, a circular machine for weft knitting with a single action needle, knitting, etc., and can solve problems such as poor stability of the saddle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

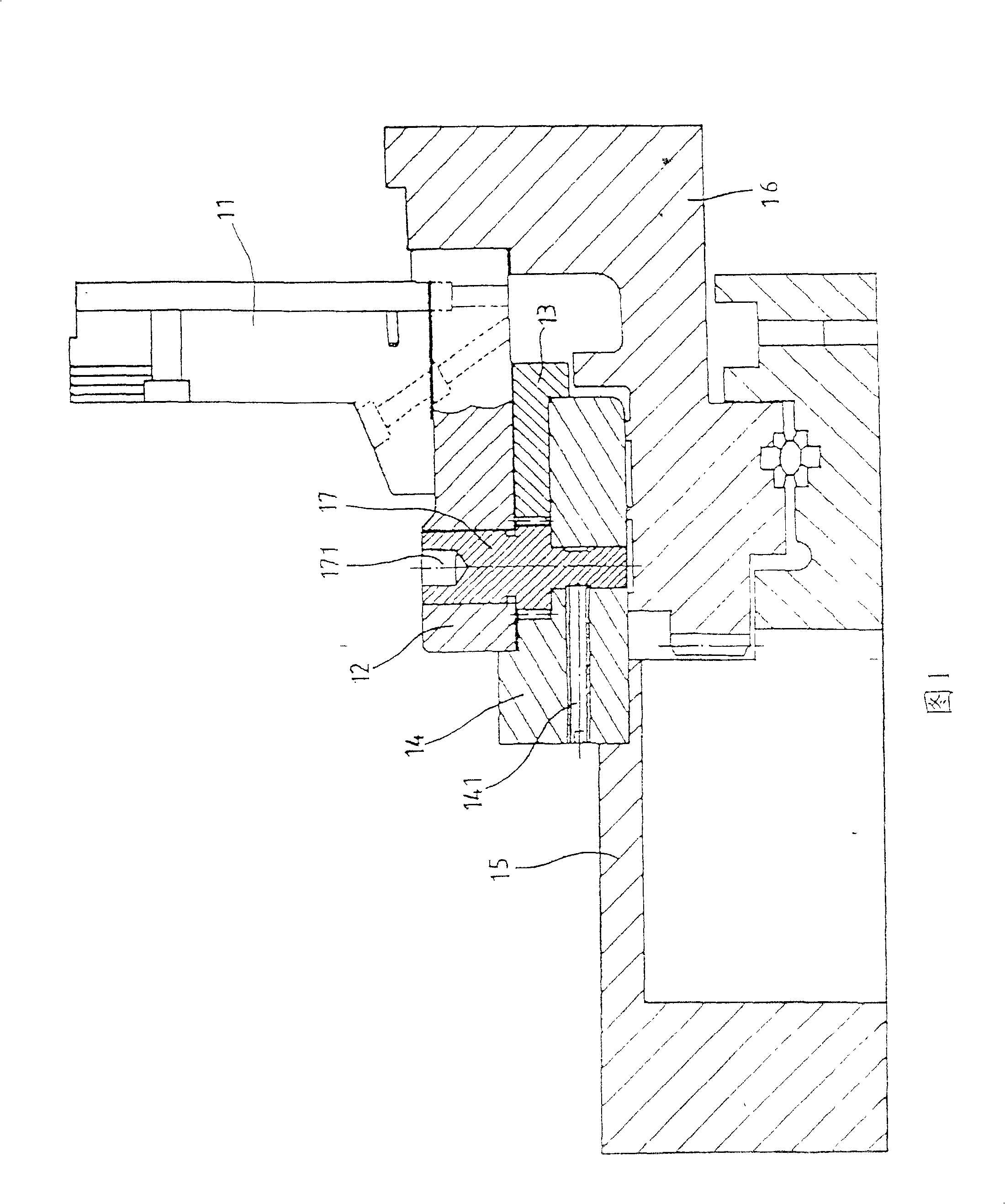

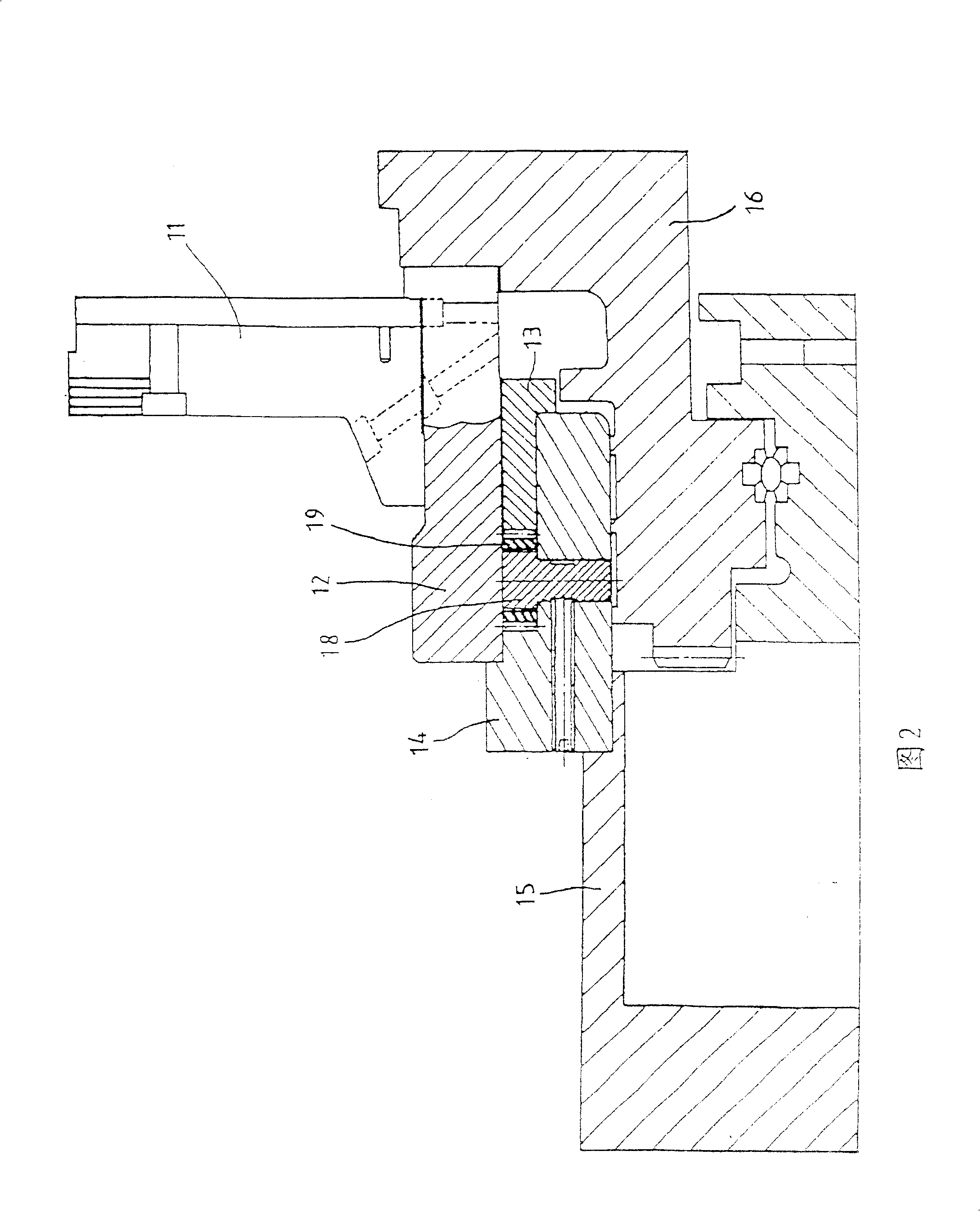

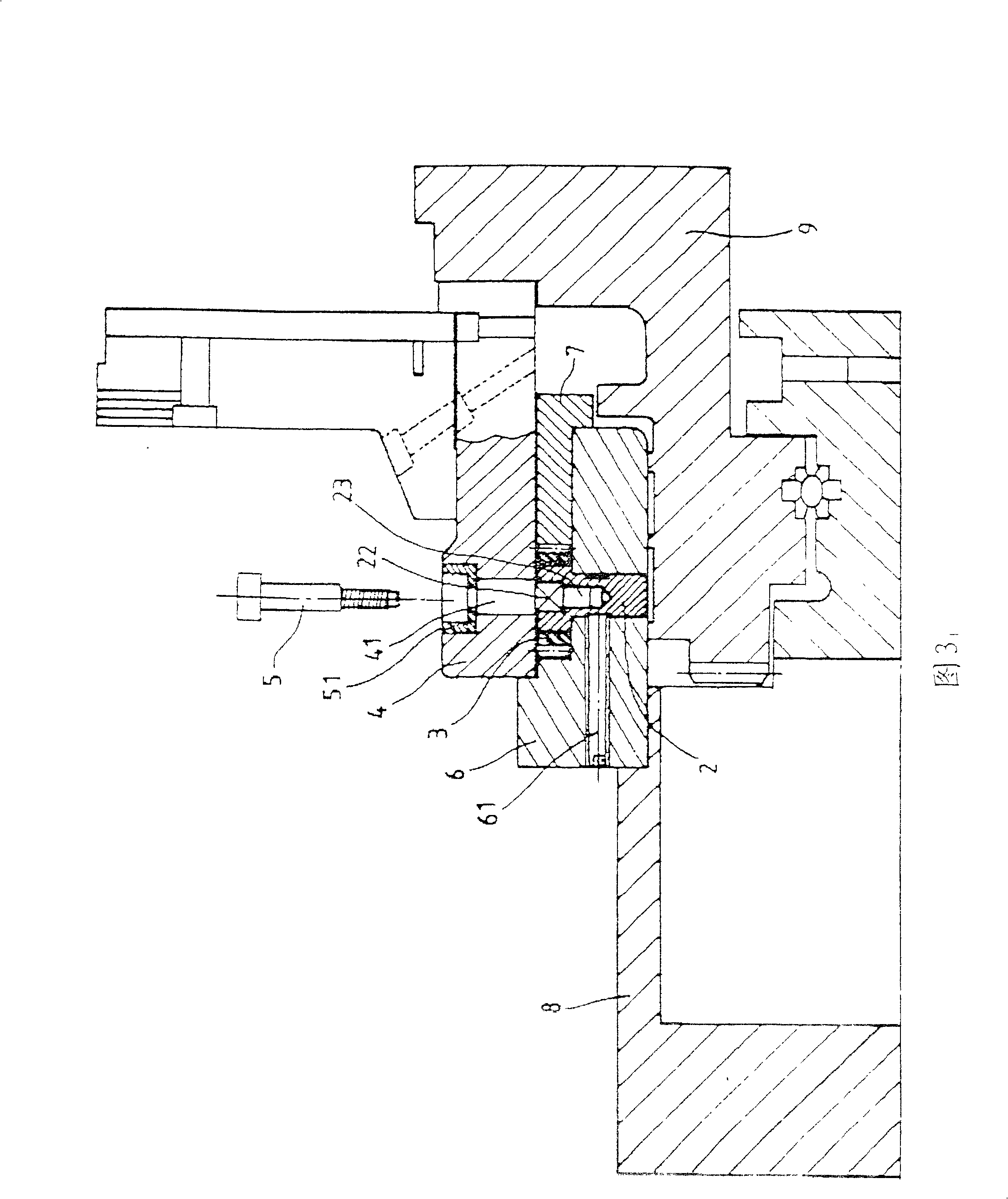

[0029] First, please refer to Figures 3 to 5, the saddle adjustment and fixing device disclosed in the present invention includes:

[0030] An adjustment gear shaft 2 is installed on the washer 6, and the outer periphery of the cap is provided with a threaded portion 21, and the top surface is provided with an inner hexagon 22, and the bottom of the inner hexagon 22 is provided with a screw hole 23, and the outer side is provided with a screw hole 23. There is a positioning groove 24;

[0031] A small gear 3 meshes with the saddle elevating gear 7, and its shaft hole is provided with a thread 31 that can be spun onto the threaded portion 21 of the cap body of the adjustment gear shaft 2;

[0032] A positioning hole 41 is located at the screw hole 23 of the saddle 4 relative to the adjustment gear shaft 2;

[0033] A bolt 5 is locked downward through the positioning hole 41 and fixed on the adjustment gear shaft 2 .

[0034] Furthermore, a positioning sleeve 51 may be provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com