Wall Mounted Aluminum Electrolytic Cathode

A technology for aluminum electrolysis and aluminum electrolysis cell, which is applied in the field of wall-type aluminum electrolysis cathode structure, can solve problems such as insufficient energy saving, and achieve the effects of avoiding scouring, facilitating maintenance and replacement, and solving poor stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

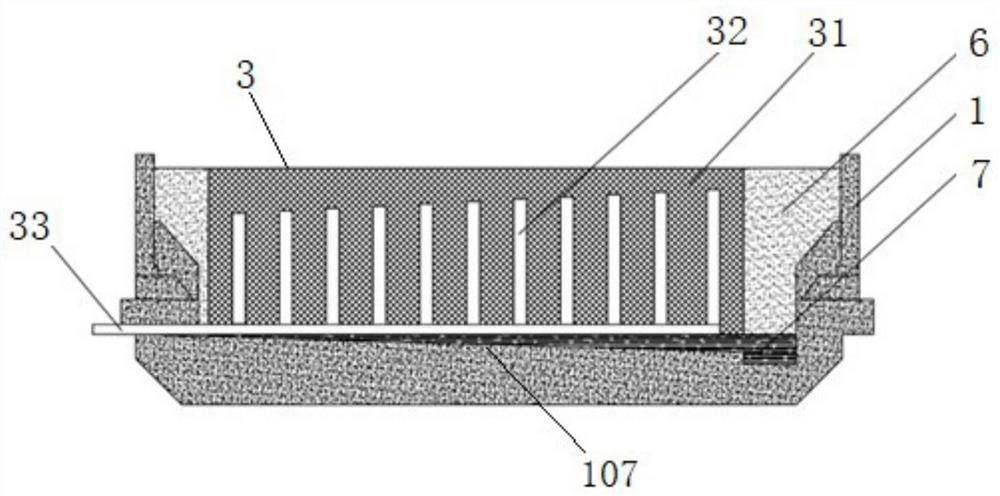

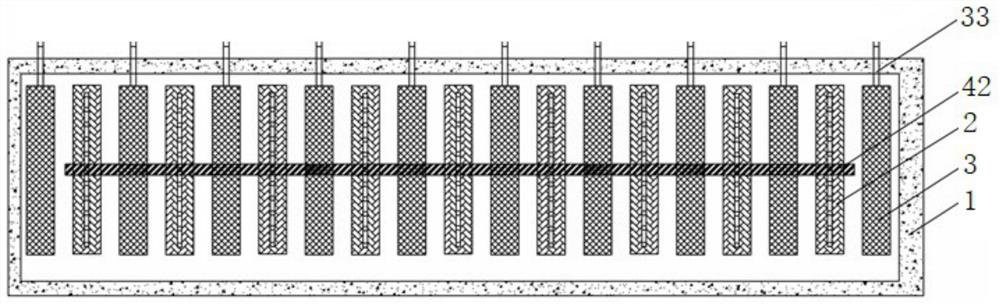

[0028] see Figure 1-4 , the aluminum electrolytic cell in the diagram is a specific implementation of the wall-type aluminum electrolytic cathode of the present invention, specifically as figure 1 As shown, the cathode 3 is a plate-shaped structure, which is fixedly arranged inside the cell body 1 of the aluminum electrolytic cell along the vertical direction, and the bottom of the cathode 3 is fixedly placed on the bottom of the cell body 1, and in the cell body of the aluminum electrolytic cell A structure similar to a partition is formed inside, and the anode 2, which is also a plate-shaped structure, separates the interior of the aluminum electrolytic cell into at least two electrolytic chambers, such as figure 2 As shown, all the electrolysis chambers are distributed along the horizontal direction, and the anode 2 and the cathode 3 are respectively located on both sides of the electrolysis chamber, and the electrolyte between the anode 2 and the cathode 3 is vertically ...

Embodiment 2

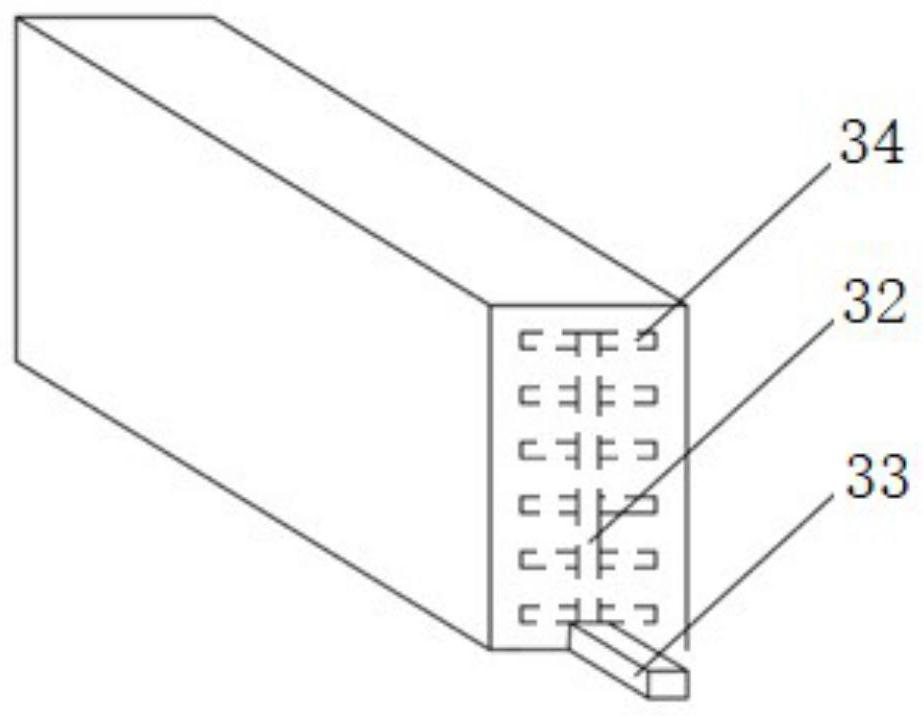

[0037] see Figure 5 , the aluminum electrolytic cell shown in the illustration is another specific implementation of the wall-type aluminum electrolytic cathode of the present invention. The difference between the cathode 3 in this embodiment and the first embodiment is that the horizontal set inside the cathode carbon block 31 The cross section of the current collecting steel rod 33 increases with the distance away from the cathode busbar, that is, the cross section of the horizontal current collecting steel rod 33 is of different sizes gradually, the cross section is still square, and the width of the cross section is uniform, 150mm, away from the horizontal The section height inside the anode carbon block at the extension end of the collector steel rod 33 is 10-50mm higher than the section height at the extension position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com