Pipette tip

A liquid pipetting and liquid storage chamber technology, applied in the field of pipetting guns, can solve the problems of inserting the handle of the pipette gun into the pipette tip, damage to the pipette tip, inaccurate experimental data, etc. Good versatility, anti-pollution, easy to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

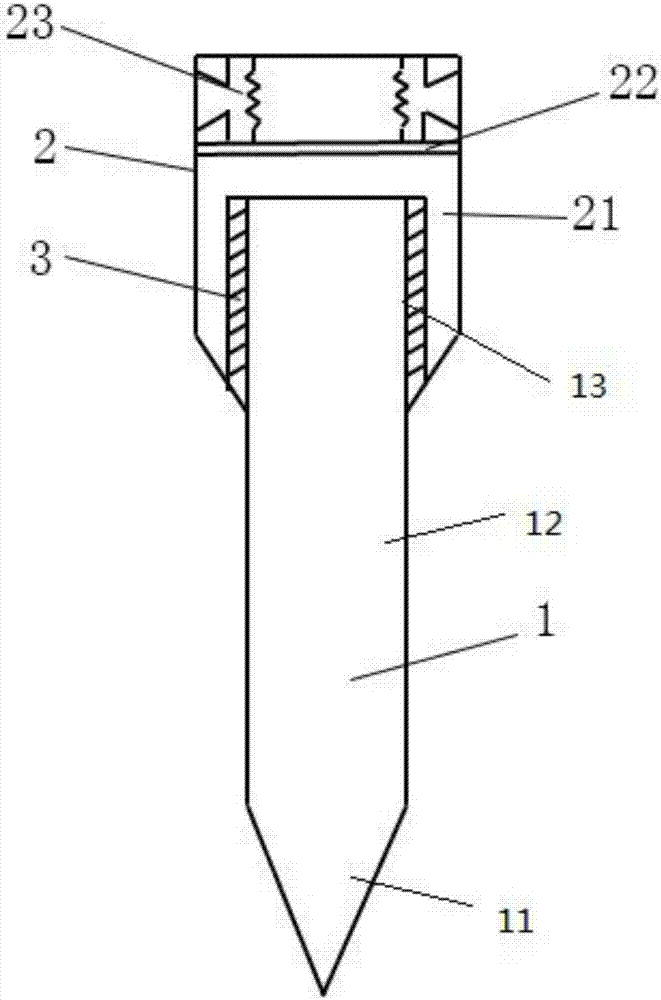

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] figure 1 It is a structural schematic diagram of the present invention. Such as figure 1 As shown, the pipette head of the present invention includes a first pipette head 1 and a second pipette head 2 . The first pipette tip 1 includes a beak-shaped liquid suction end 11 connected in sequence, a liquid storage chamber 12 with a uniform diameter, and a tip tail 13; the tip tail 13 is sealed, and several filters are arranged on its side. hole 3, a filter layer is provided outside the filter hole 3, through which the pollutants inside the first pipette tip 1 are blocked in the first pipette tip 1, and will not enter the second Inside the pipette tip 2.

[0024] The second pipette tip 2 includes a cover 21, a filter layer 22 and a connecting groove 23; the cover 21 is sleeved outside the tip tail 13 of the first pipette tip 1, and the second The pipette tip 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com