Stator iron core for rotary electric machine

A technology of stator iron core and rotary motor, which is applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, etc., and can solve problems such as poor assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

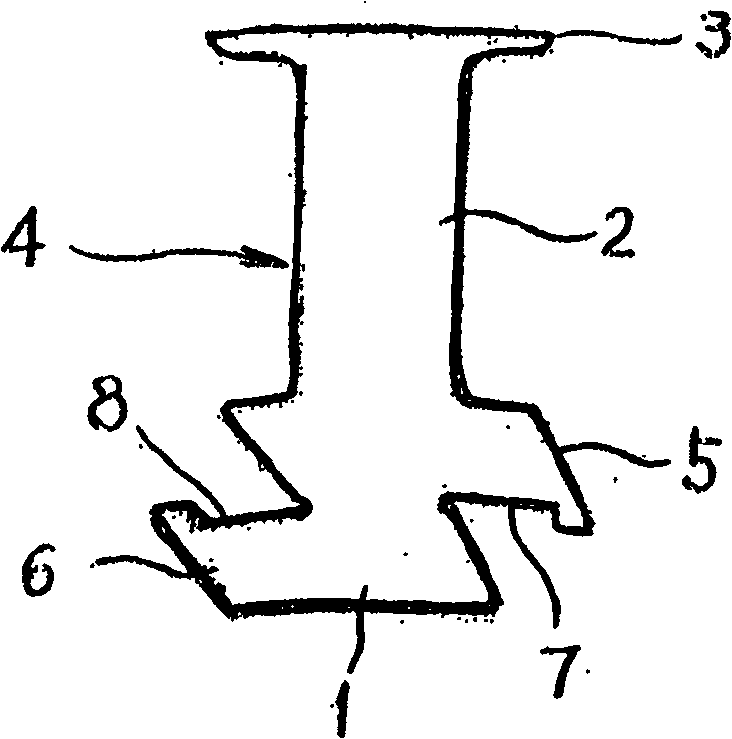

[0018] In the stator core of the rotary electric machine of the present invention, such as figure 1 As shown, the core element 4 is divided into magnetic pole units composed of a yoke portion 1 , a magnetic pole portion 2 , and a claw portion 3 .

[0019] In the core element 4, the lower protruding arm part 5 is provided in the upper stage of one side of the yoke part 1, and the upper protruding arm part 6 is provided in the lower stage of the other side.

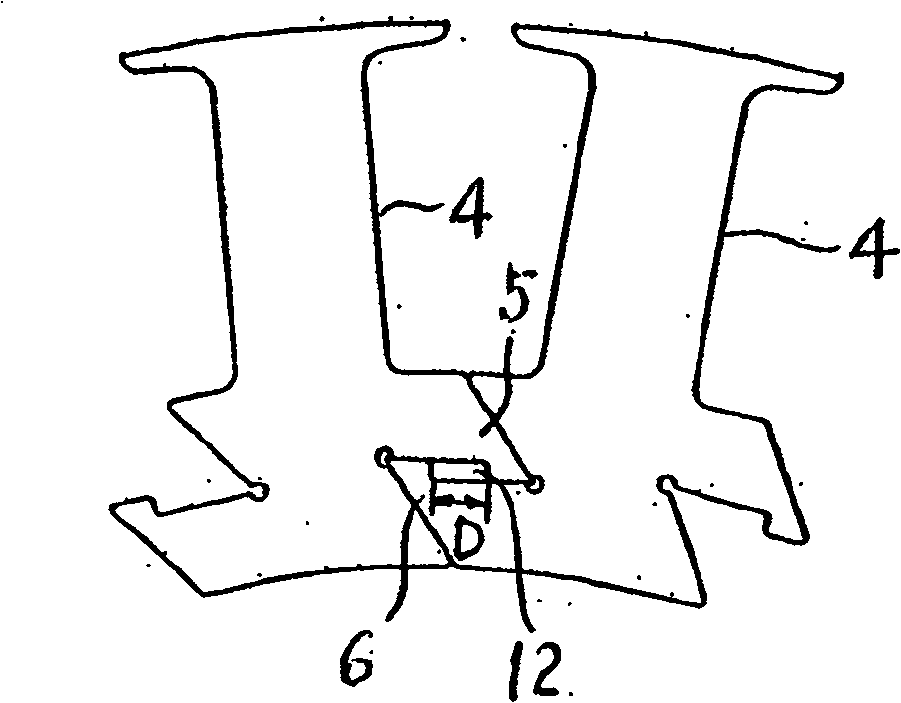

[0020] In addition, a notch 7 is formed on the lower protruding arm portion 5, and a notch 8 is formed on the upper protruding arm portion 6, as figure 2 As shown, the facing downward protruding arm portions 5 and upward protruding arm portions 6 on adjacent core elements 4 are movably engaged with each other within a predetermined range D along the adjacent direction (circumferential direction).

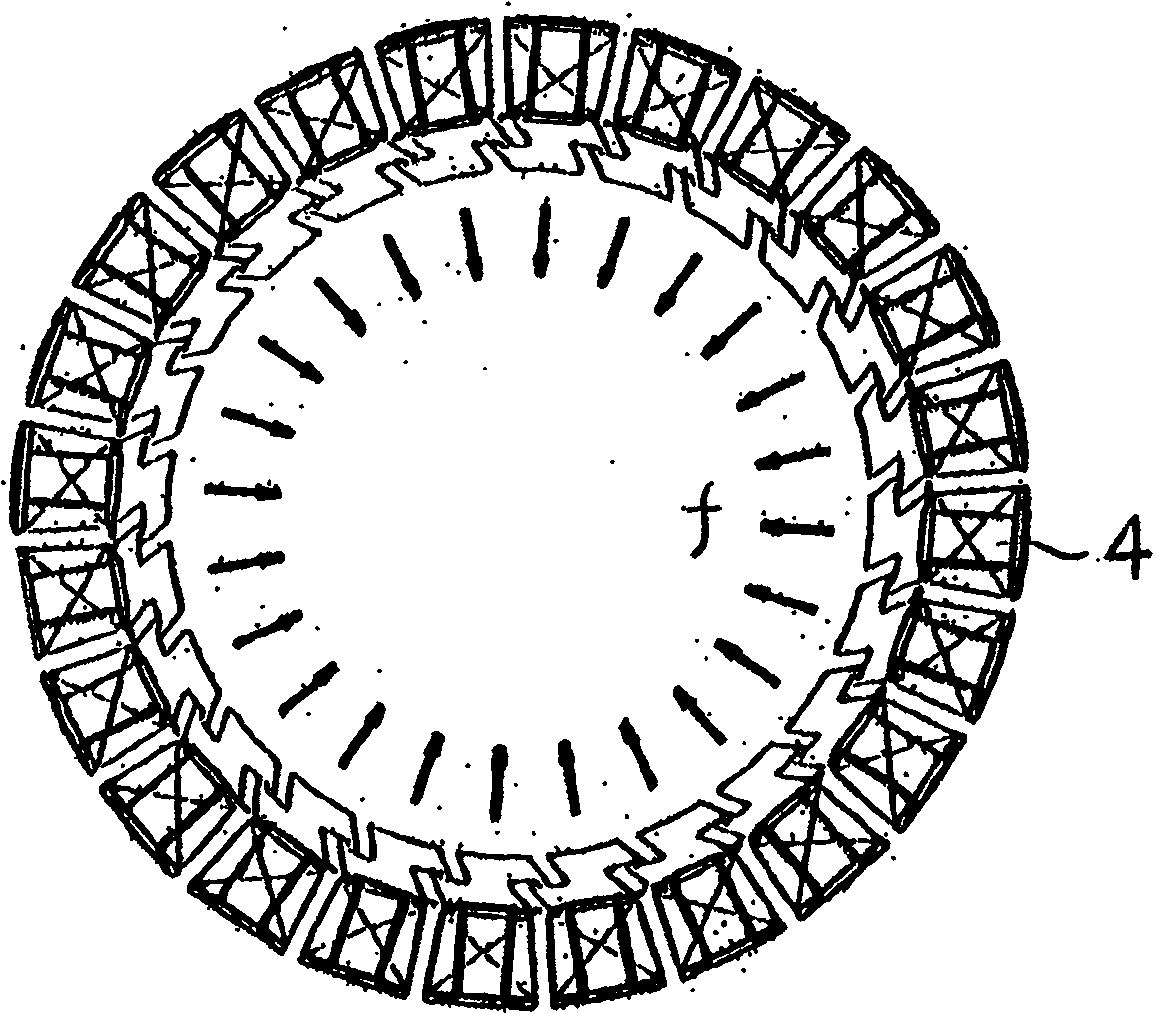

[0021] So, if image 3 and Figure 4 As shown, in the state where the fixed number of core elements 4 are arranged in a ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com