Piezoelectric valve and method for manufacturing said piezoelectric valve

A manufacturing method and piezoelectric technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., It can solve the problems of inaccurate movement and small stroke, and achieve the effect of excellent water resistance and high compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present disclosure will be described based on the drawings.

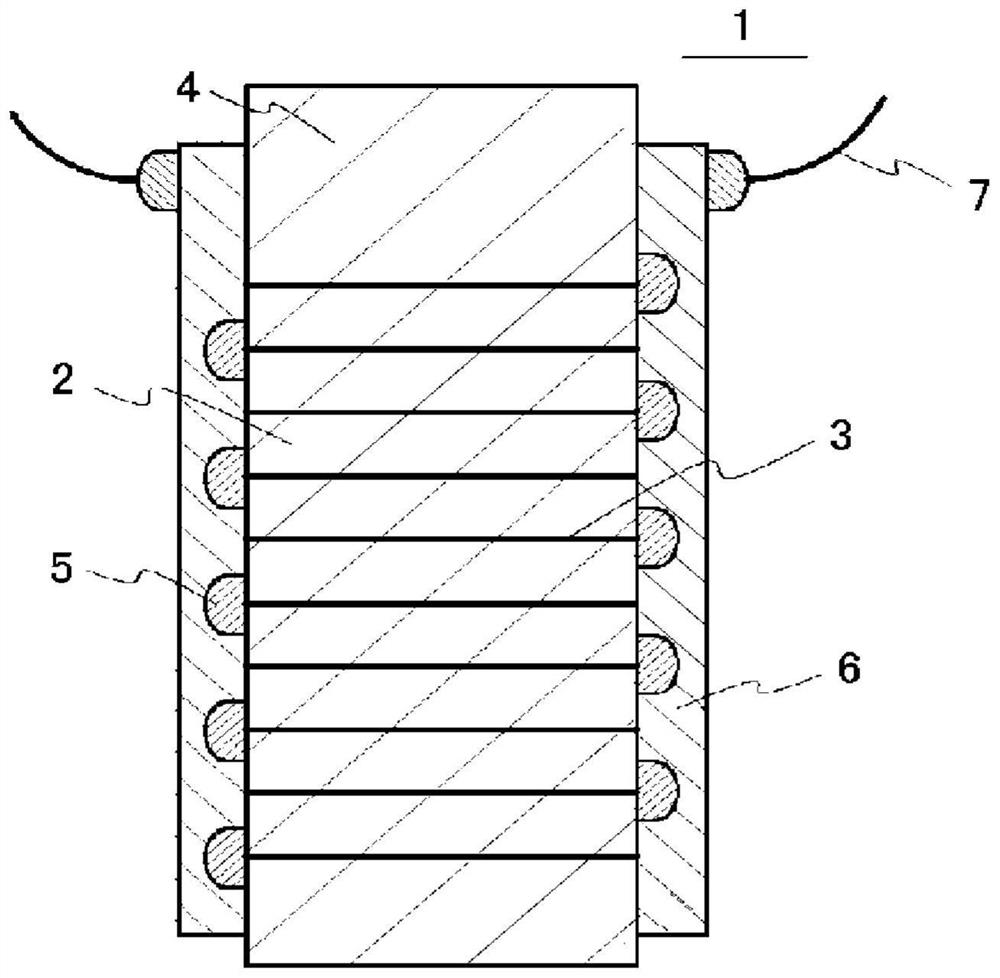

[0049] figure 1 It is a representative example of a multilayer piezoelectric element (hereinafter, referred to as a "piezoelectric element"), and shows a cross-sectional view.

[0050] figure 1 The illustrated piezoelectric element 1 has a laminated body 4 in which piezoelectric ceramic layers 2 and internal electrode layers 3 are alternately laminated. The internal electrode layer 3 is exposed on the side surface of the laminated body 4 . The exposed side surfaces of each of the internal electrode layers 3 are covered with insulating layers 5 every other layer. Furthermore, the laminated body 4 has the external electrode 6 which covers the insulating layer 5 and is electrically connected to the internal electrode layer 3 which is not covered with the insulating layer 5 .

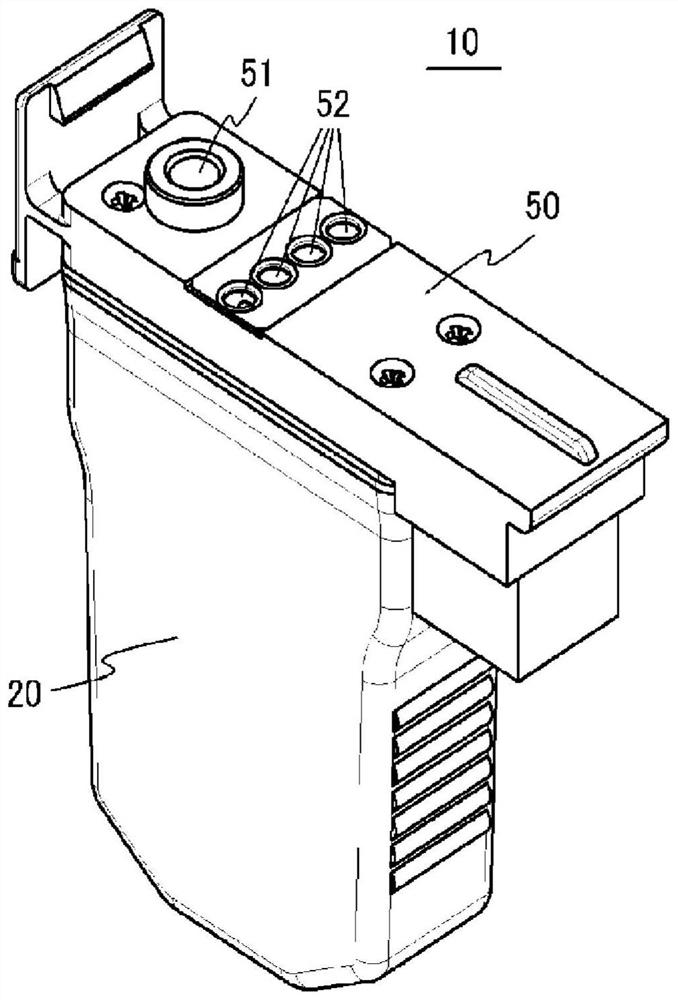

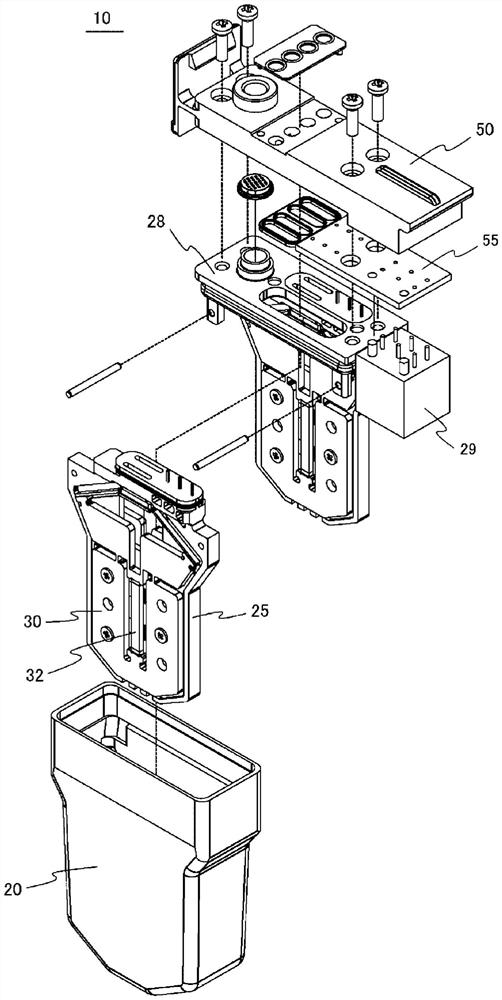

[0051] figure 2 It is an example of a piezoelectric valve, and shows a perspective view. image 3 express fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com