Turbine fan

A turbo fan and fan blade technology, which is applied in the field of turbo fans, can solve the problems of high manufacturing cost and increased manufacturing cost, and achieve the effects of reducing manufacturing cost, improving yield and ensuring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0108] Examples and comparative examples

[0109] Hereinafter, examples and comparative examples are given to describe the turbo fan of the present invention and the turbo fan of a comparative example (Patent Document 3).

[0110] [Example]

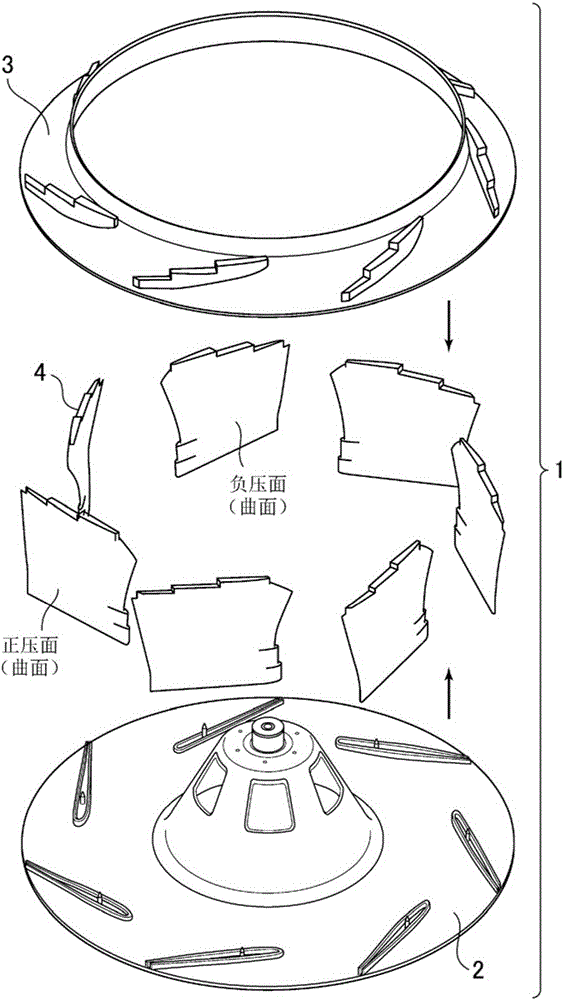

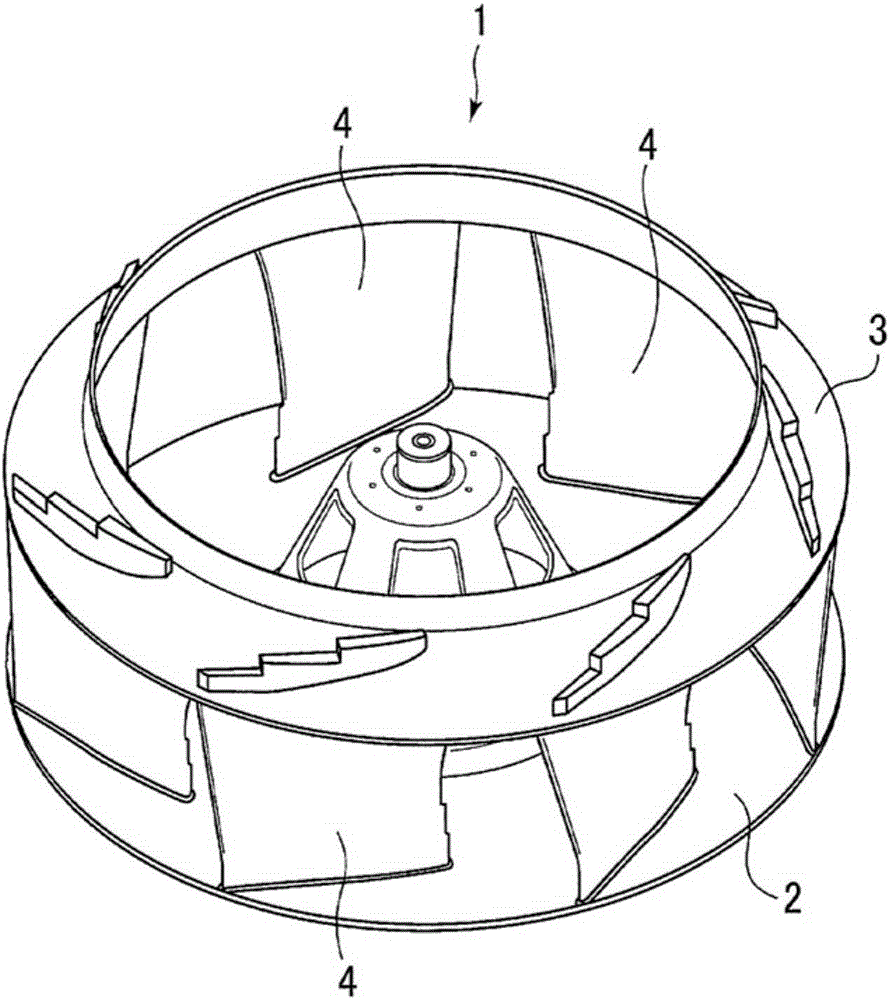

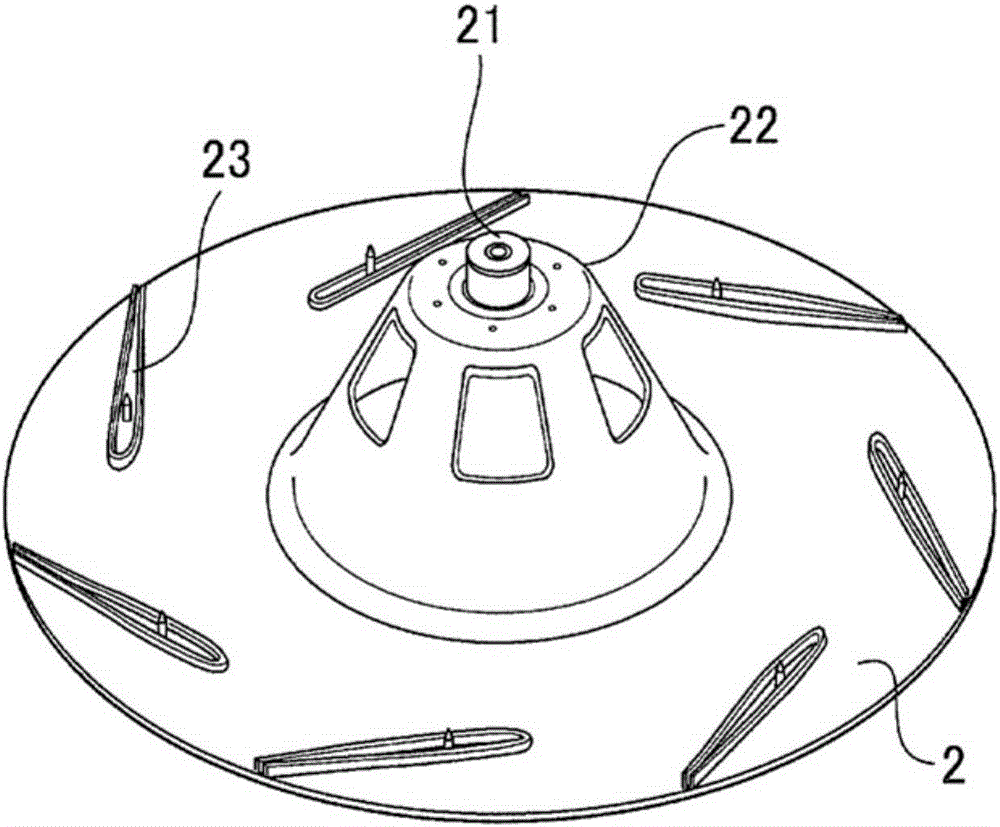

[0111] In this embodiment, acrylonitrile-butadiene-styrene (acrylonitrile-butadiene-styrene, ABS) resin is used for injection molding, respectively, as figure 1 The main board 2, the wind deflector 3, and the fan blade member 4 (component 41 and component 42) are the components of the turbofan. In addition, in the blade member 4, the member 41 and the member 42 are inserted into each other and integrated to produce a turbofan.

[0112] These components are like It is integrally formed as described in "Assembly and Joining of Turbo Fan." Regarding the processing conditions of ultrasonic welding, the pressing force was set to 0.1 to 0.2 MPa, the power of the welding machine was set to 2000 W, and the pressing time was set to 1.0 second. The tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com