Milling cutter edge grinding machine

A grinding machine and blade technology, applied in milling cutters, milling machine equipment, metal processing equipment and other directions, can solve the problems of cumbersome, tool breakage, complicated operation process, etc., to increase economic benefits, improve service life, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to better understand the present invention, it will be further described in detail below in conjunction with the accompanying drawings and embodiments.

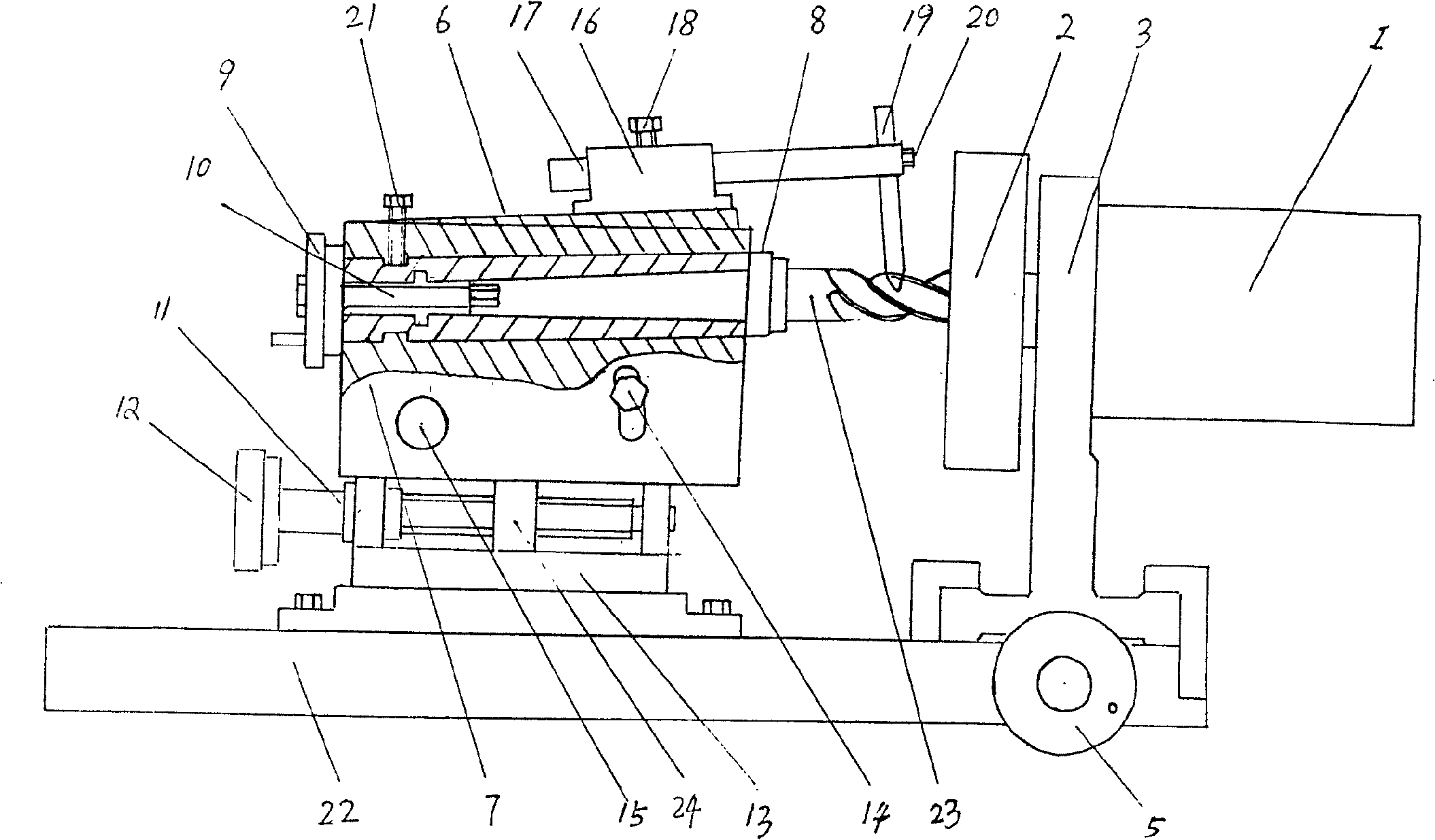

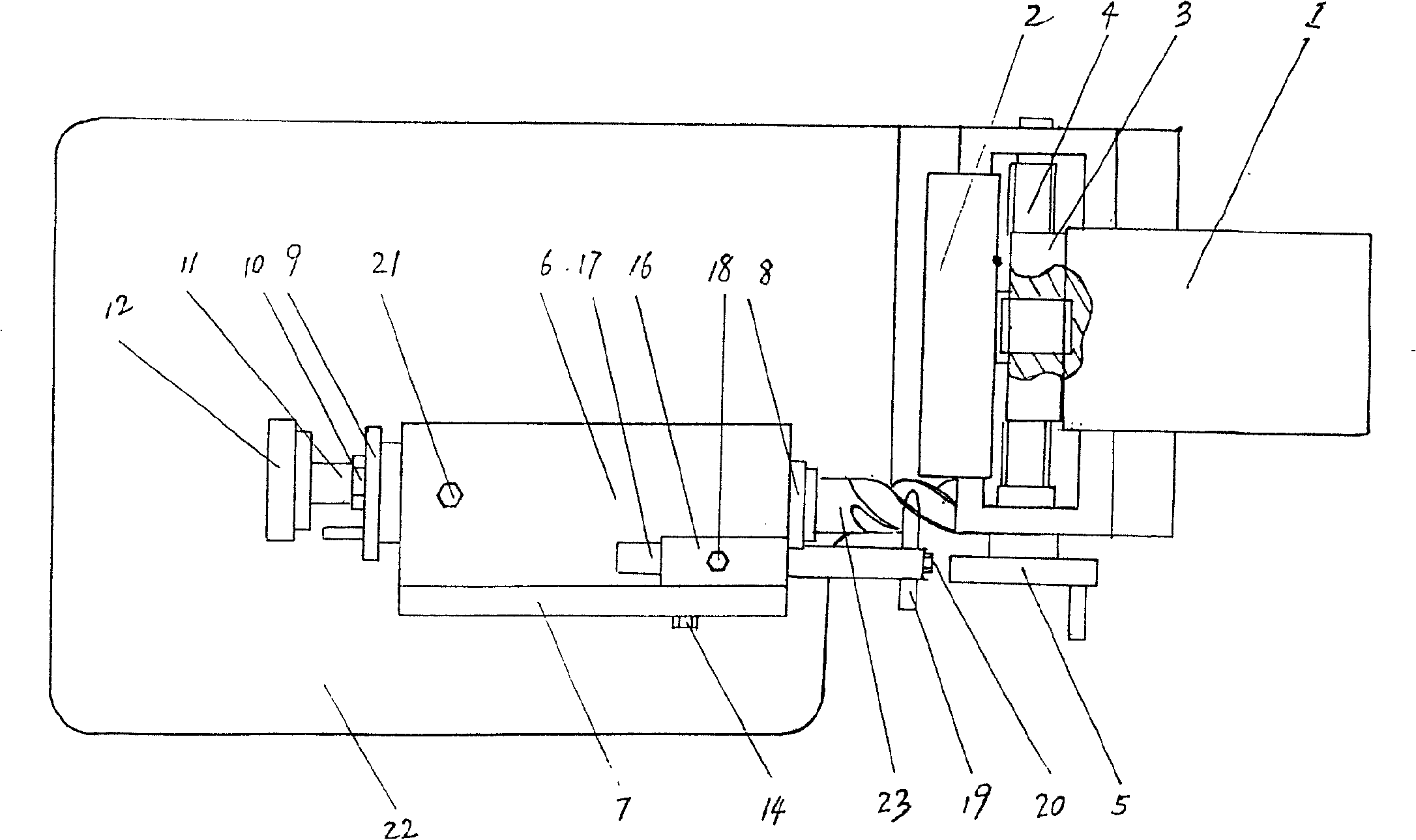

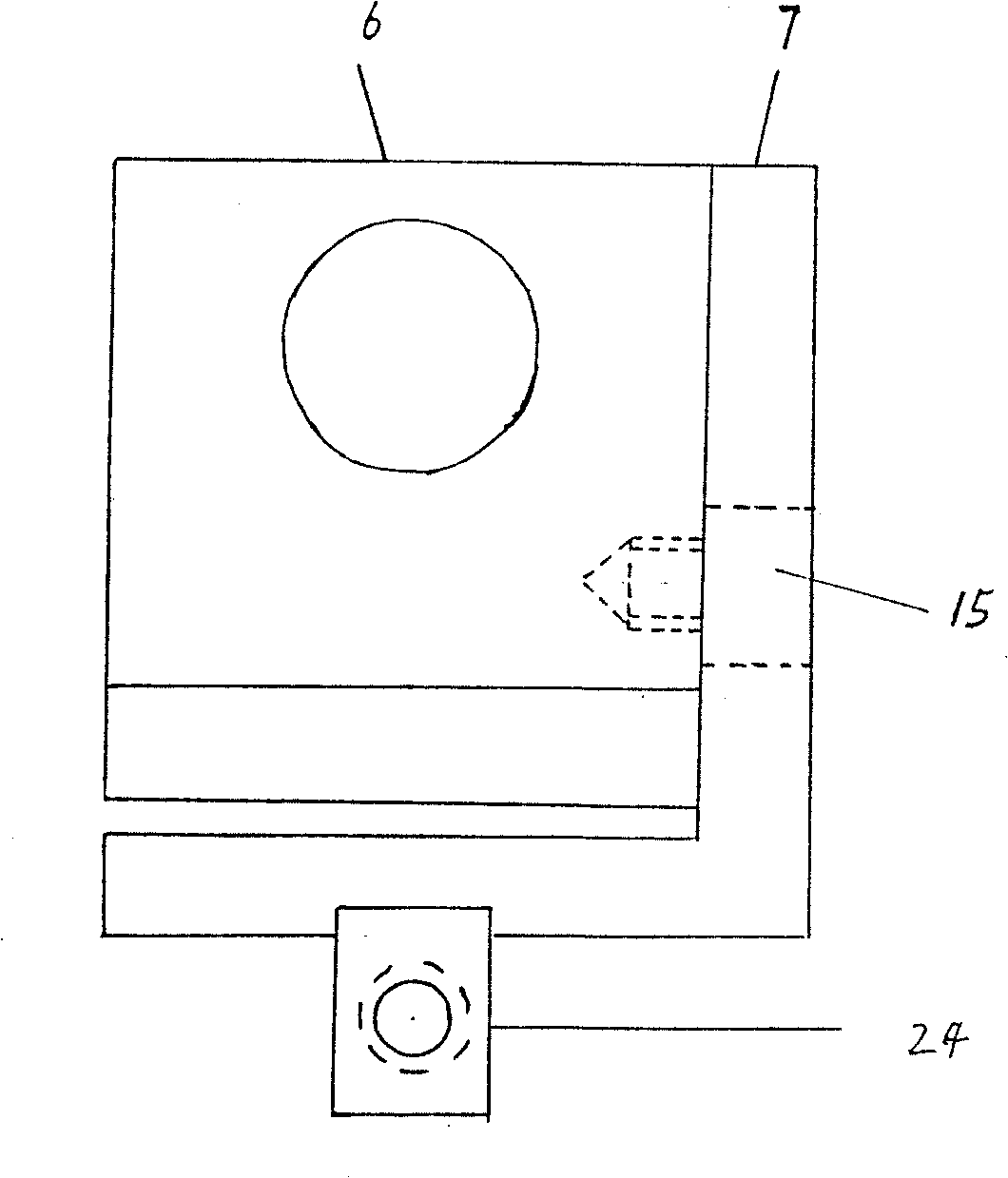

[0010] refer to Figure 1-Figure 3 Visible, milling cutter sharpening of the present invention mainly is by working platform 22, frame plate base 13 and motor support 3 that are fixed on it, motor 1 is housed on the motor support 3, the emery wheel 2 that links to each other with motor, It is composed of the frame plate 7 fixed on the frame plate seat 13, the grinding wheel 2 is fixed on the output end of the output shaft of the motor 1, and there is a longitudinal transmission screw 4 passing through the working platform 22 under the motor support 3, and the longitudinal transmission wire One end of bar 4 is fixed, and the other end is equipped with handle 5, and the bottom of motor support 3 is provided with the first screw nut that cooperates with longitudinal transmission lead screw 4; The plate base 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com