Device for determining at least one parameters of flowing gas-liquid mixture and use of low rectifier as condensation trap for liquid contained in gas stream

A technology of gas-liquid mixture and rectifier, which is applied in the direction of liquid/fluid solid measurement, measurement device, measurement flow/mass flow, etc., can solve the problems of measurement characteristic deterioration, measurement element contamination, etc., and achieve reduced processing costs, good flow conditions, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

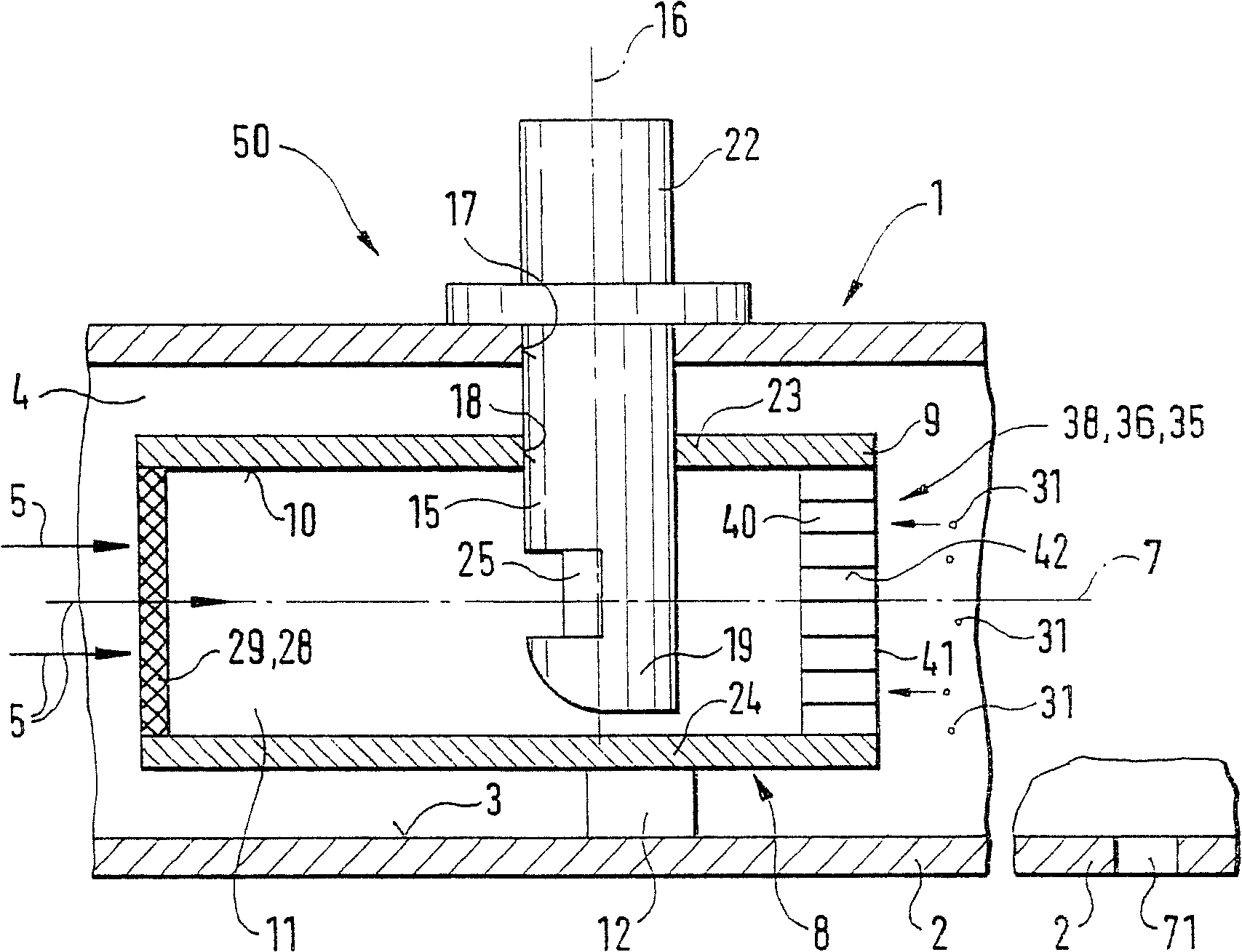

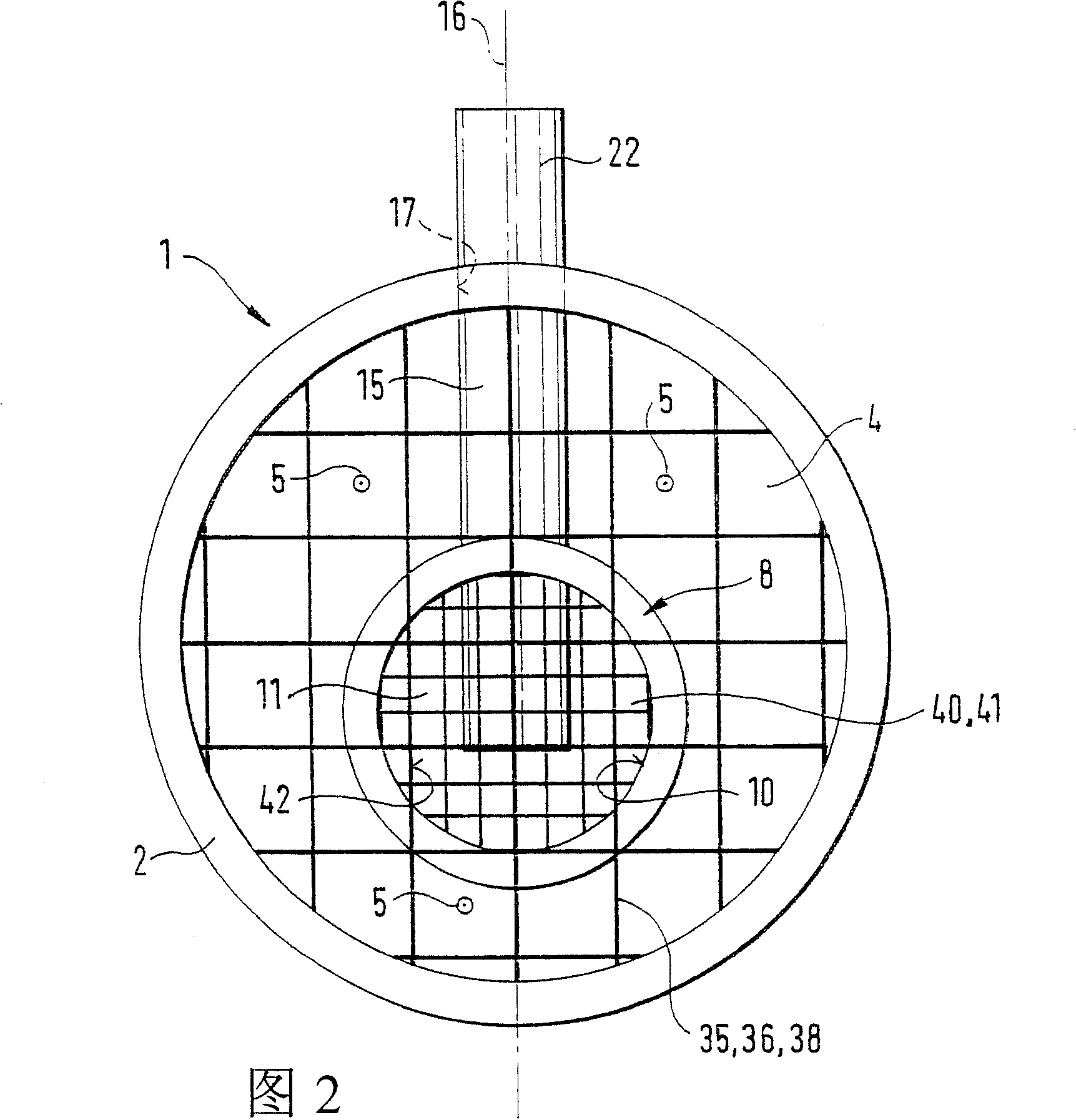

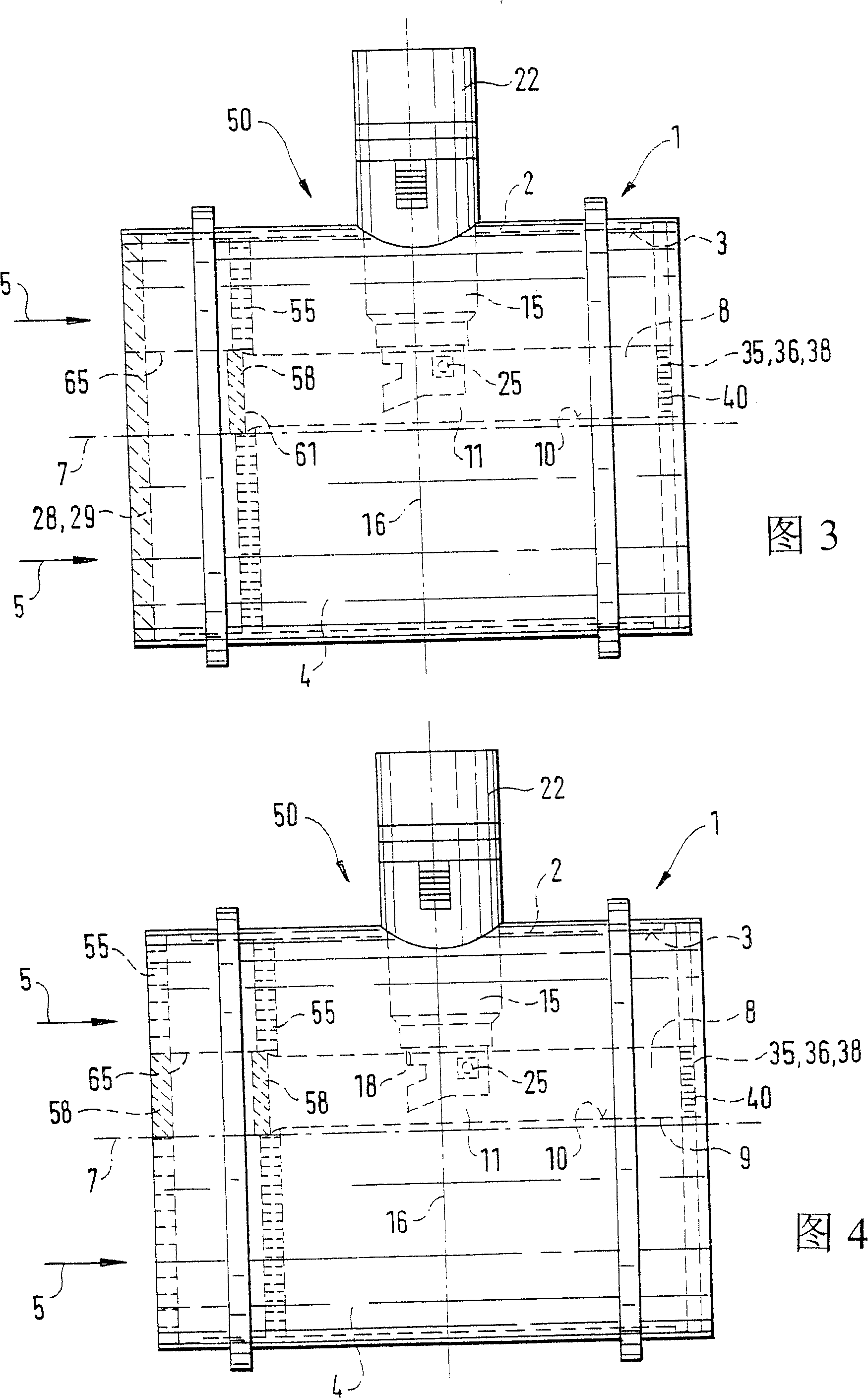

[0020] exist figure 1 In, a first embodiment of a device 50 configured according to the invention is shown in partial sectional view for measuring at least one parameter of a gas-liquid mixture flowing in a pipeline, in particular an intake air volume flow of an internal combustion engine, which The drawings are limited to those elements which are important within the scope of the invention. Wherein 1 represents a pipeline, which can constitute a straight-through section of the intake pipe of the internal combustion engine, or an independent component that can be connected with the intake pipe of the internal combustion engine. In any case, the line 1 is located on the so-called clean room side downstream of an air filter not shown. The air cleaner serves to filter the air taken in by an internal combustion engine of a motor vehicle and should prevent the entry of dirt particles and liquids into the intake manifold as completely as possible.

[0021] Connected to the pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com