Automobile wire harness grounding protecting method

A technology of automotive wiring harnesses and wiring harnesses, applied in motor vehicles, transportation and packaging, etc., can solve problems such as poor protection effect, penetration of electrophoretic paint, deformation of grounding surface, etc., to avoid waste, ensure reliability, and simple steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The automobile wiring harness grounding protection method of the present embodiment includes the following steps:

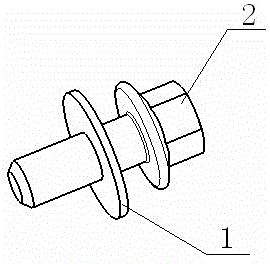

[0019] A: Weld the ground nut on the body, and then use the protection bolt passing through the ground nut to install a protection gasket between the protection bolt and the ground surface of the body, such as figure 1 As shown, the outer diameter of the protective gasket 1 is equal to the outer diameter of the flange surface of the protective bolt 2; the inner diameter of the protective gasket 1 is equal to the outer diameter of the protective bolt 2;

[0020] B: Electrophoresis the car body;

[0021] C: After the electrophoresis is completed, remove the protective bolts and protective gaskets after the body-in-white arrives at the final assembly line, and then use the fastening bolts and ground nuts to fasten the wiring harness.

[0022] The above protective gasket is made of 1.0mm thick red steel cardboard.

[0023] The protective bolt presses the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com