Concrete complex building of steel meshwork framework, and construction procedure

A concrete and frame technology, which is applied in building structures, buildings, truss structures, etc., can solve the problems that it is difficult to meet the requirements of multi-storey building structures, difficult to assemble, and high cost of industrialization of cladding panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

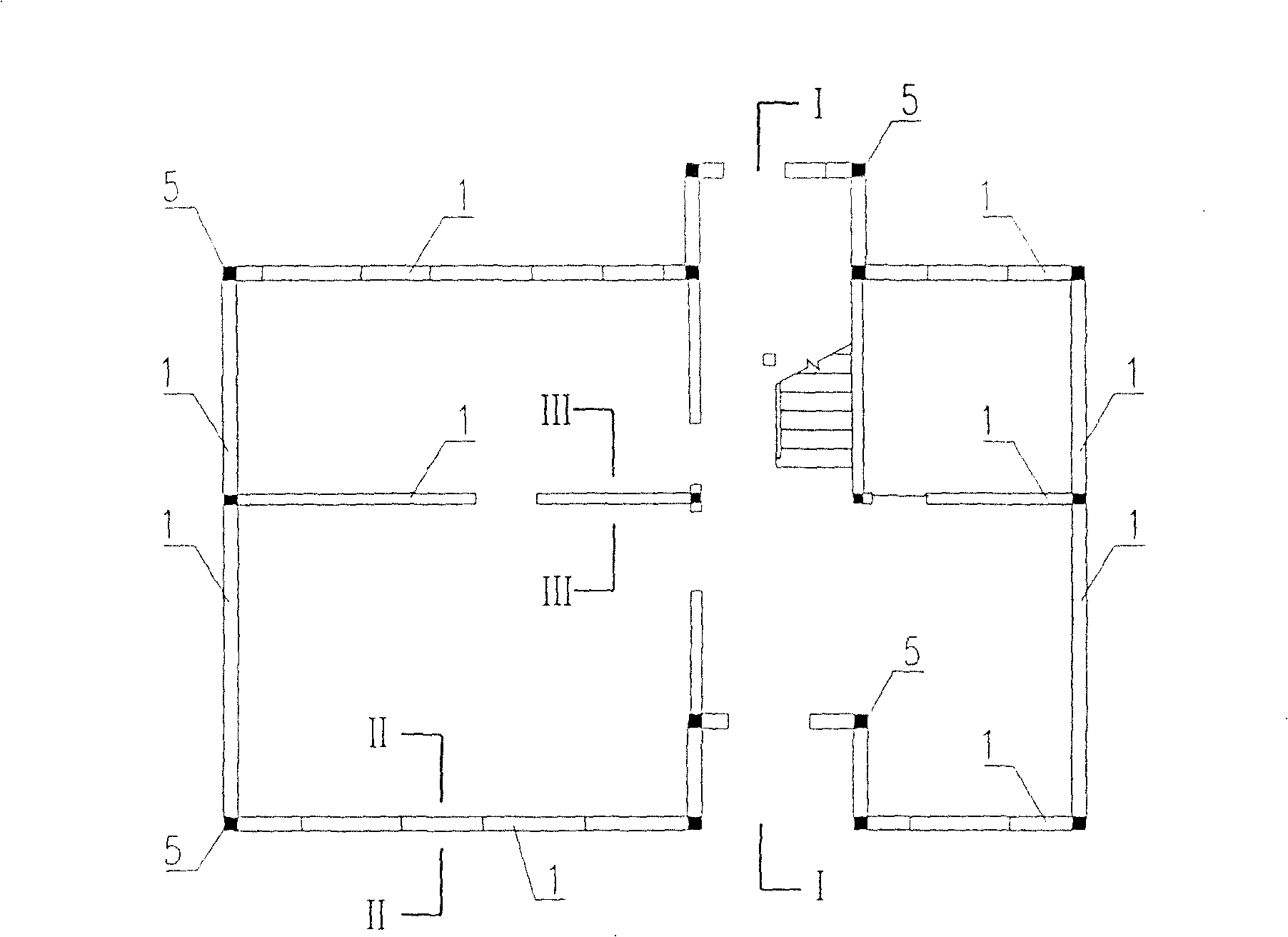

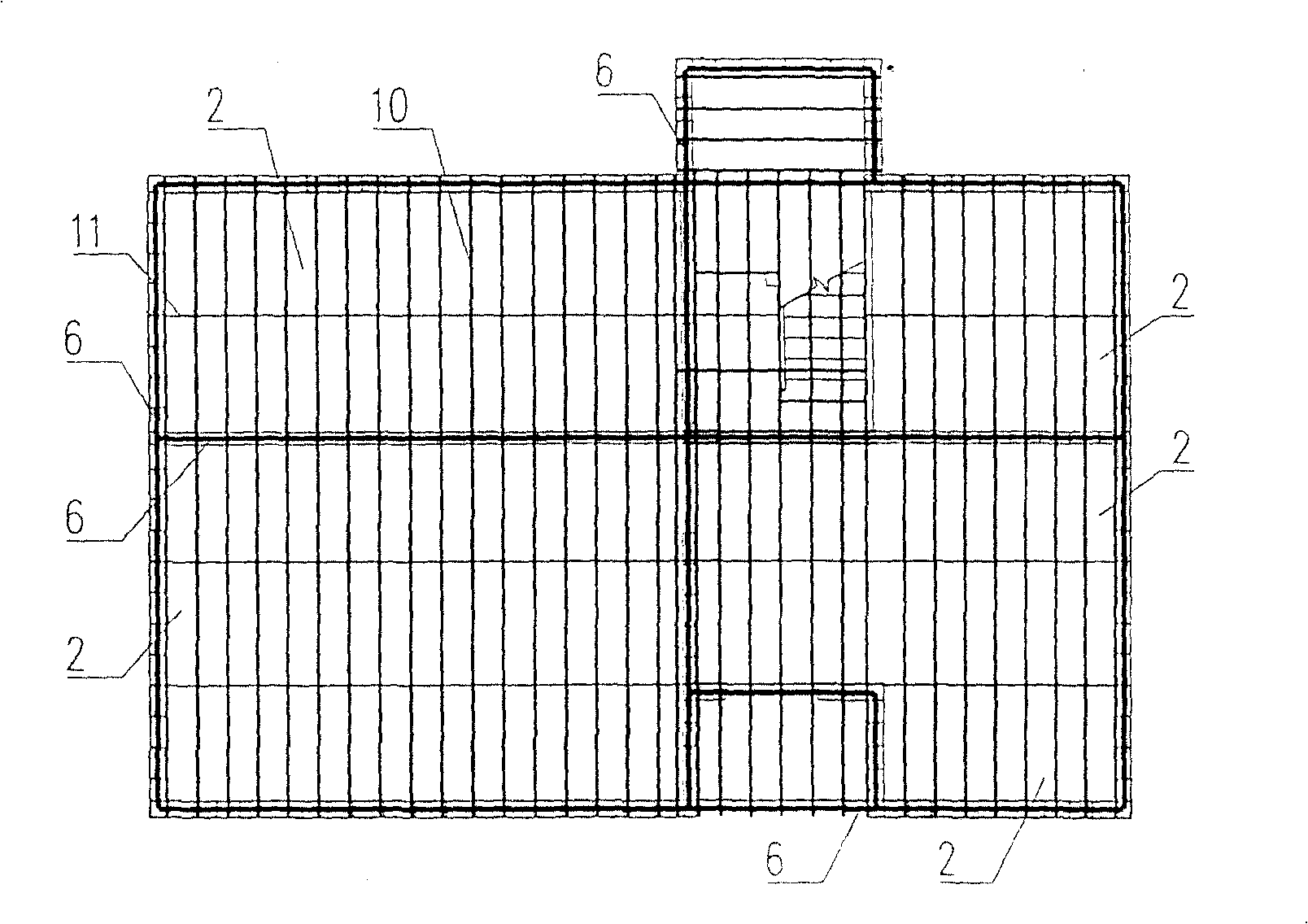

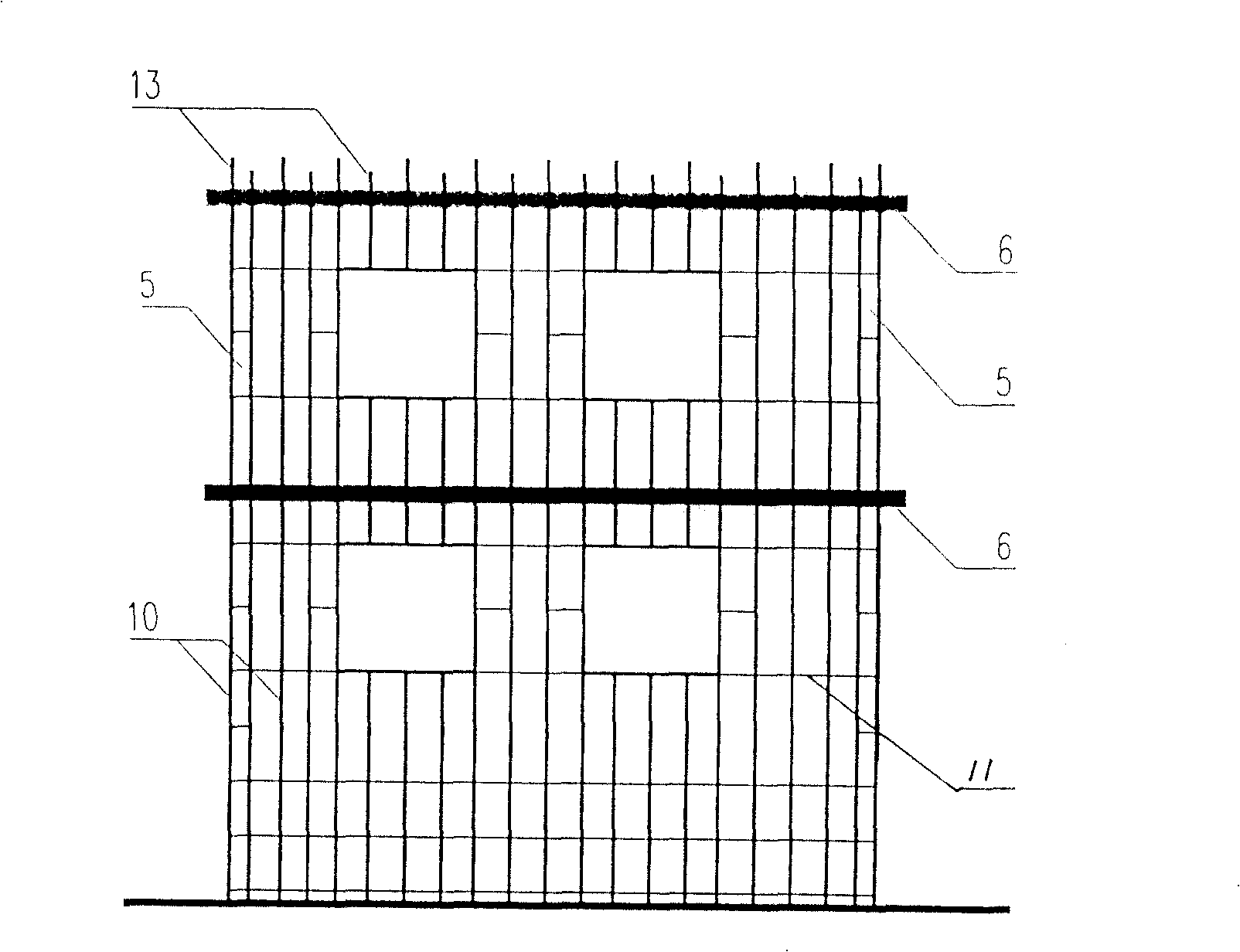

[0082] Figure 1~Figure 14Shown is an embodiment of the present invention, which is a steel mesh framed concrete composite building with a 4-story floor structure. The composite building includes: wall steel framework 1, floor steel framework 2, expanded metal mesh 3, and concrete 4:

[0083] Such as figure 1 , image 3 , Figure 8 , Picture 9 , Picture 11 As shown: the wall steel frame 1: is a steel frame used for the composite building wall, which is formed by vertical lattice steels 10 arranged in parallel with each other and fixed by connecting pieces 11;

[0084] Such as figure 2 , Figure 8 , Picture 9 , Picture 11 Shown: The floor steel frame 2: is a steel frame made of horizontal lattice steels 10 arranged in parallel with each other and fixed by connecting pieces 11 for the composite building floor. The floor steel frame 2 Including roof steel framework;

[0085] Figure 5 Shown is a schematic diagram of lattice steel: lattice steel 10 is a cold-formed lattice-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com