Record paper loading method of printer

A technology for recording paper and printers, which can be used in printing devices, printing, electromagnetic radiation induction, etc., and can solve problems such as paper jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of a roll paper printer to which the present invention is applied will be described below with reference to the drawings.

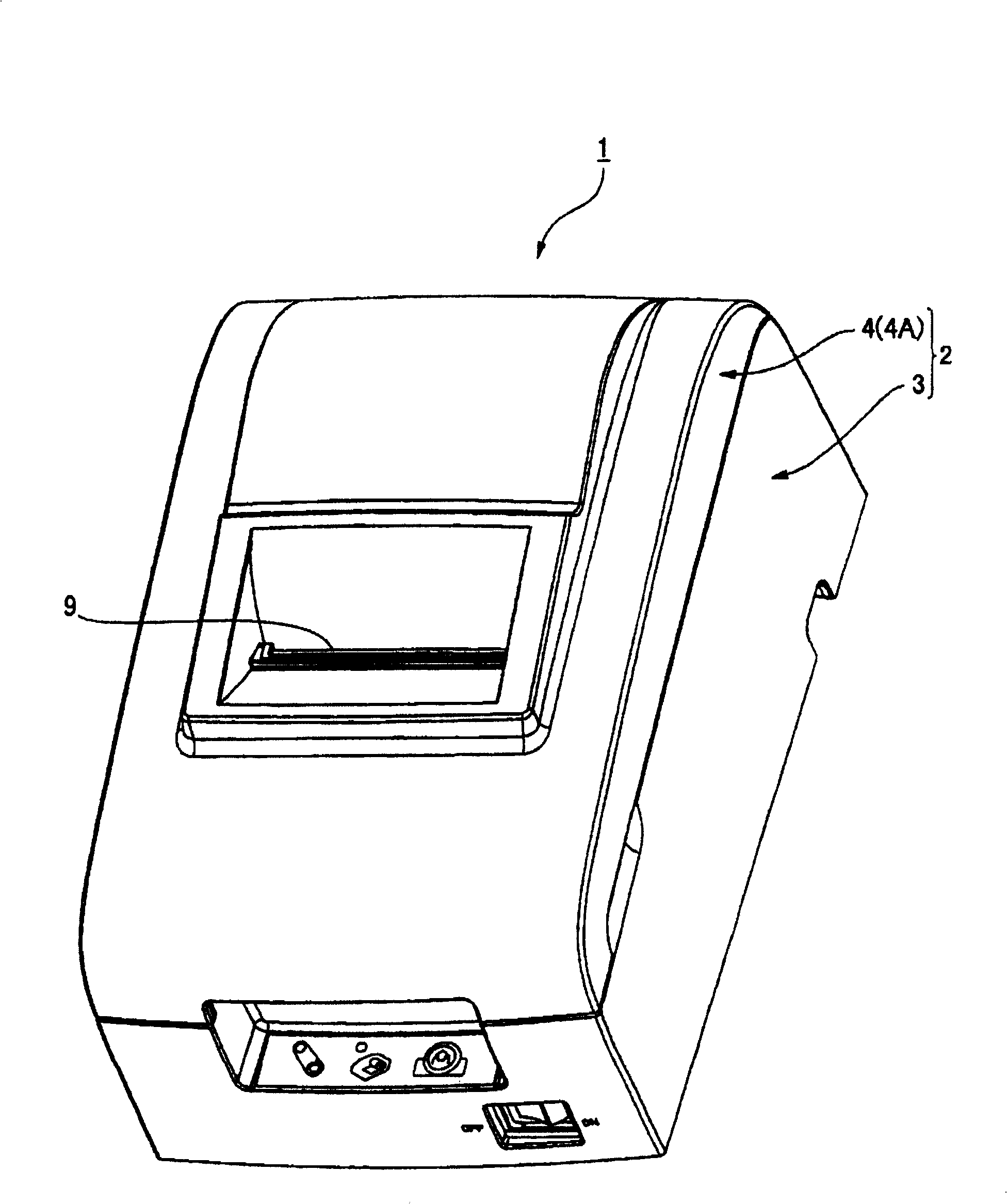

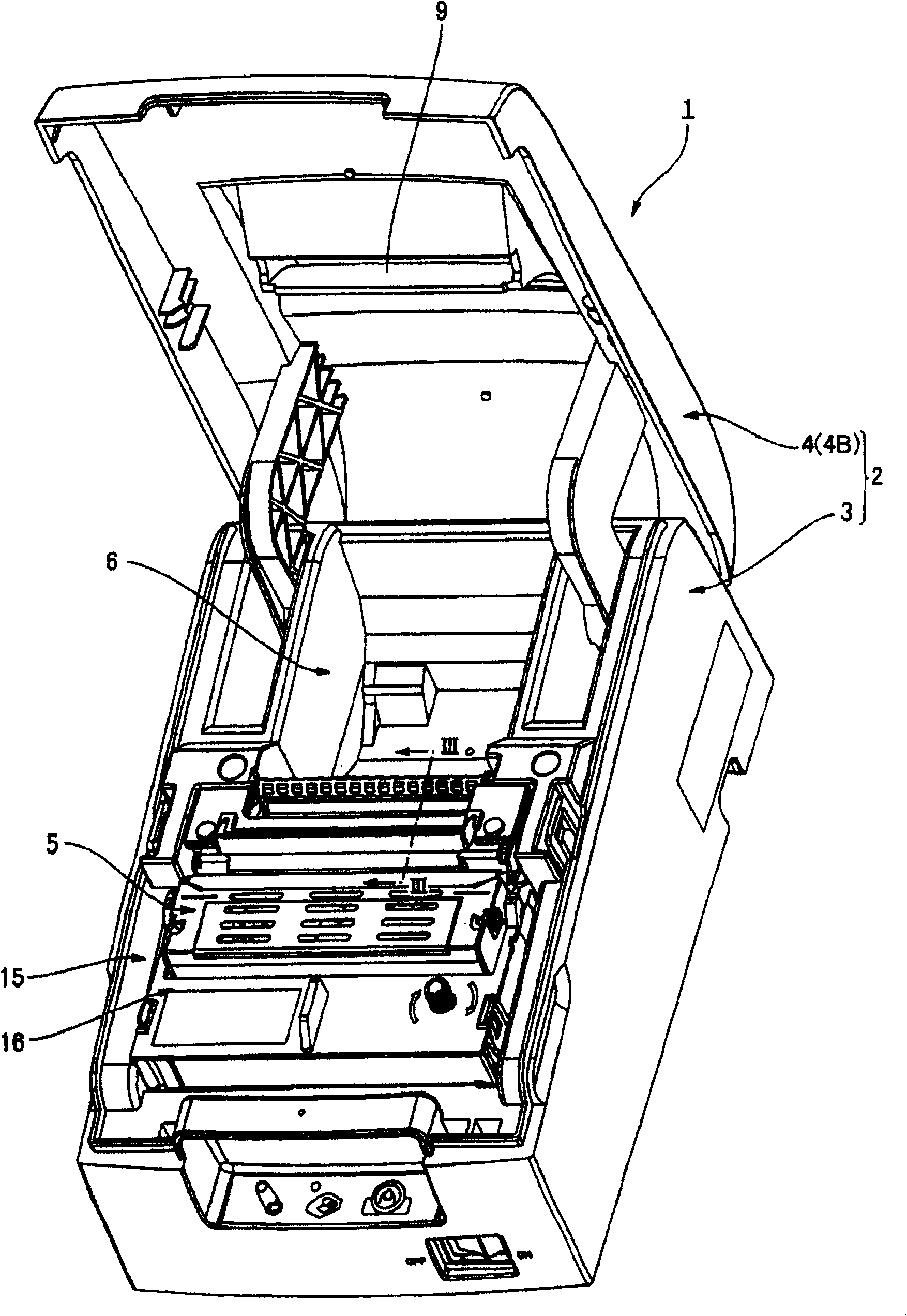

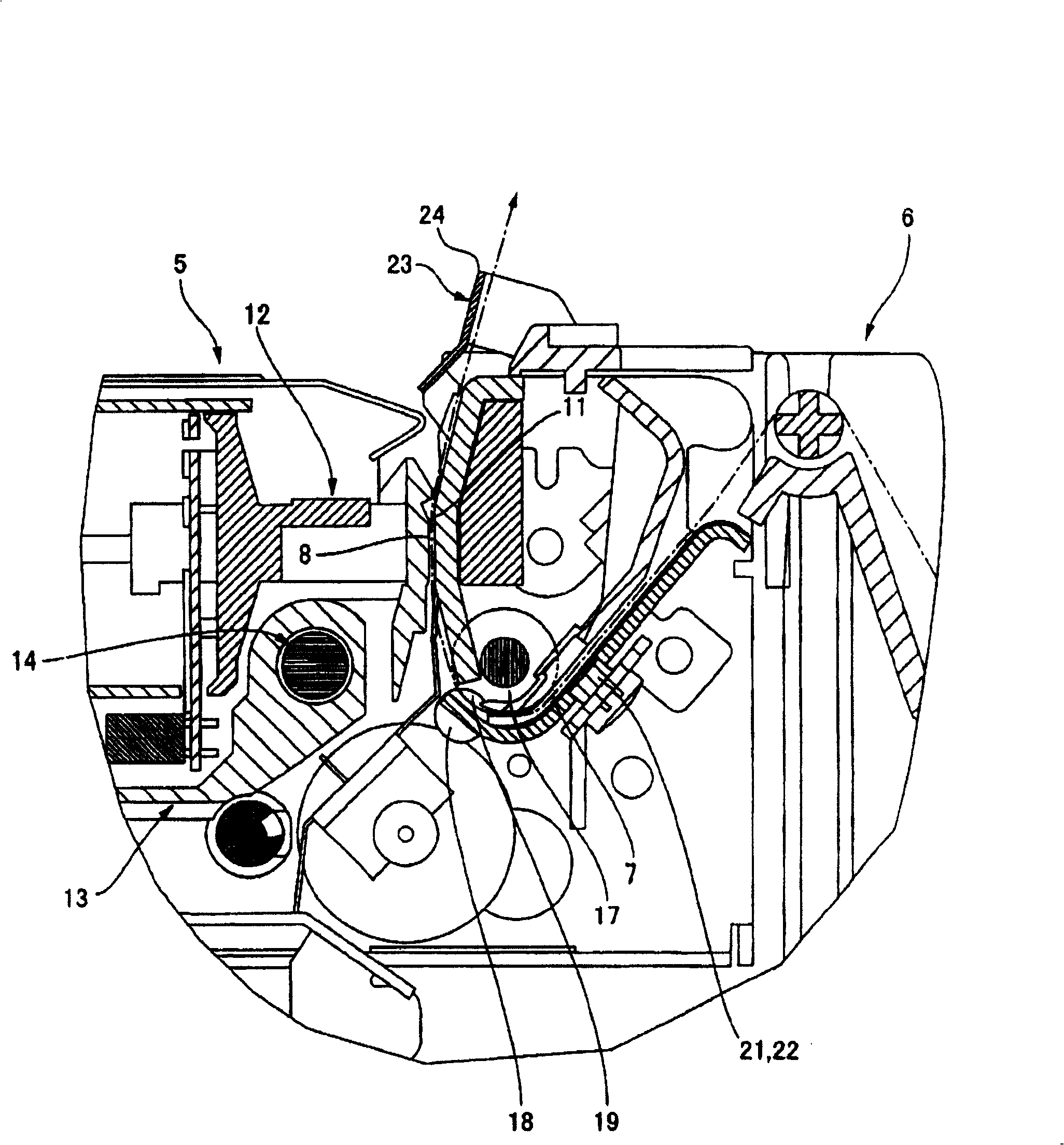

[0025] figure 1 It is a three-dimensional view of the appearance of a roll-fed printer, figure 2 It is a perspective view of the roll-fed printer with the cover opened. in addition, image 3 yes means figure 2 FIG. 4 is a partially enlarged cross-sectional view of the section along line III-III of FIG.

[0026] Such as figure 1 , 2 As shown, the roll-fed printer 1 of this example is equipped with a vertically long rectangular printer case 2 as a whole, and this printer case 2 is equipped with a rectangular frame-shaped box body 3 and a switch cover 4 (case cover). The switch cover 4 is centered on the rotation axis extending in the width direction of the printer at its rear edge, and is rotatably installed on the box body 3, from figure 1 shown in the closed position 4A to figure 2 Rotation is possible between the fully open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com