Patents

Literature

30results about How to "No paper jams" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

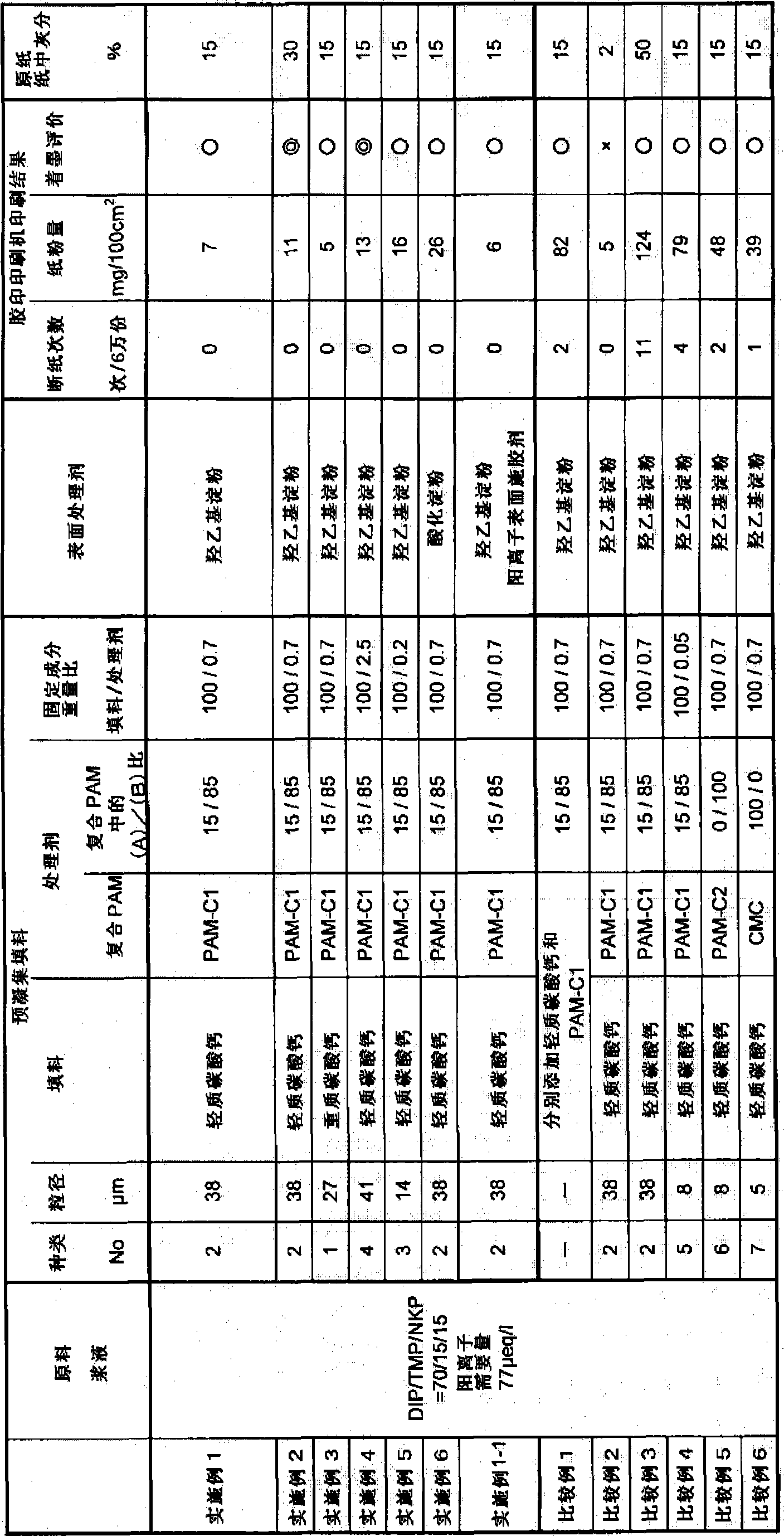

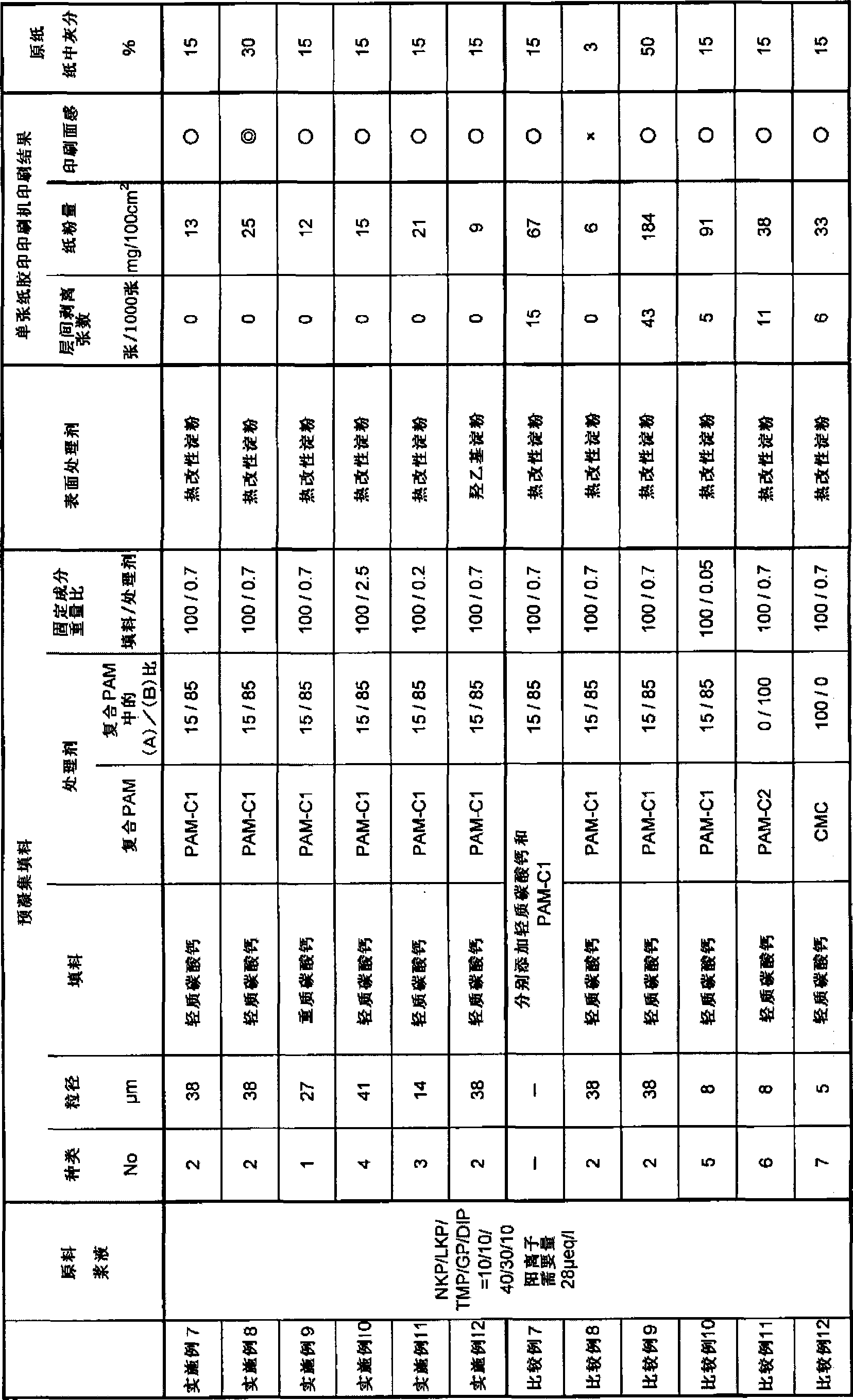

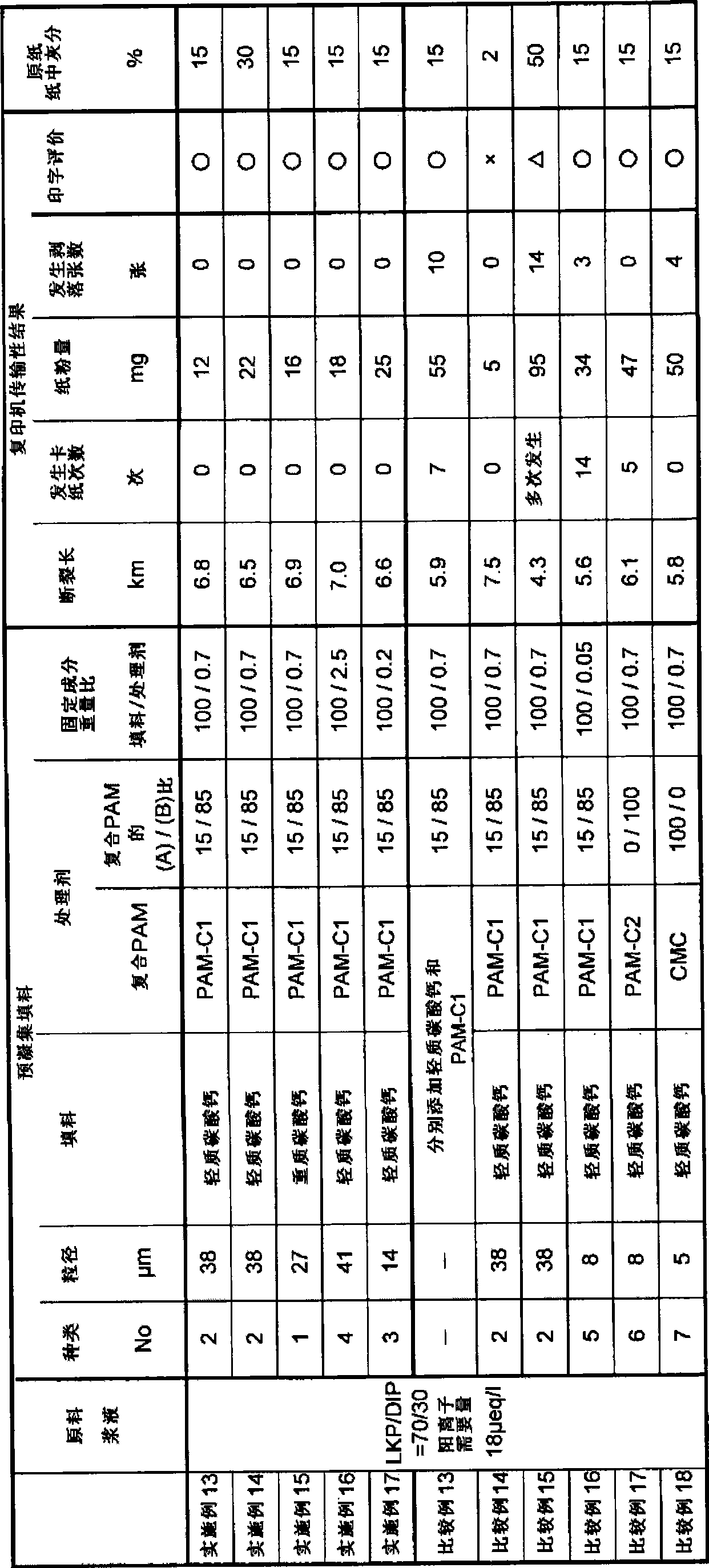

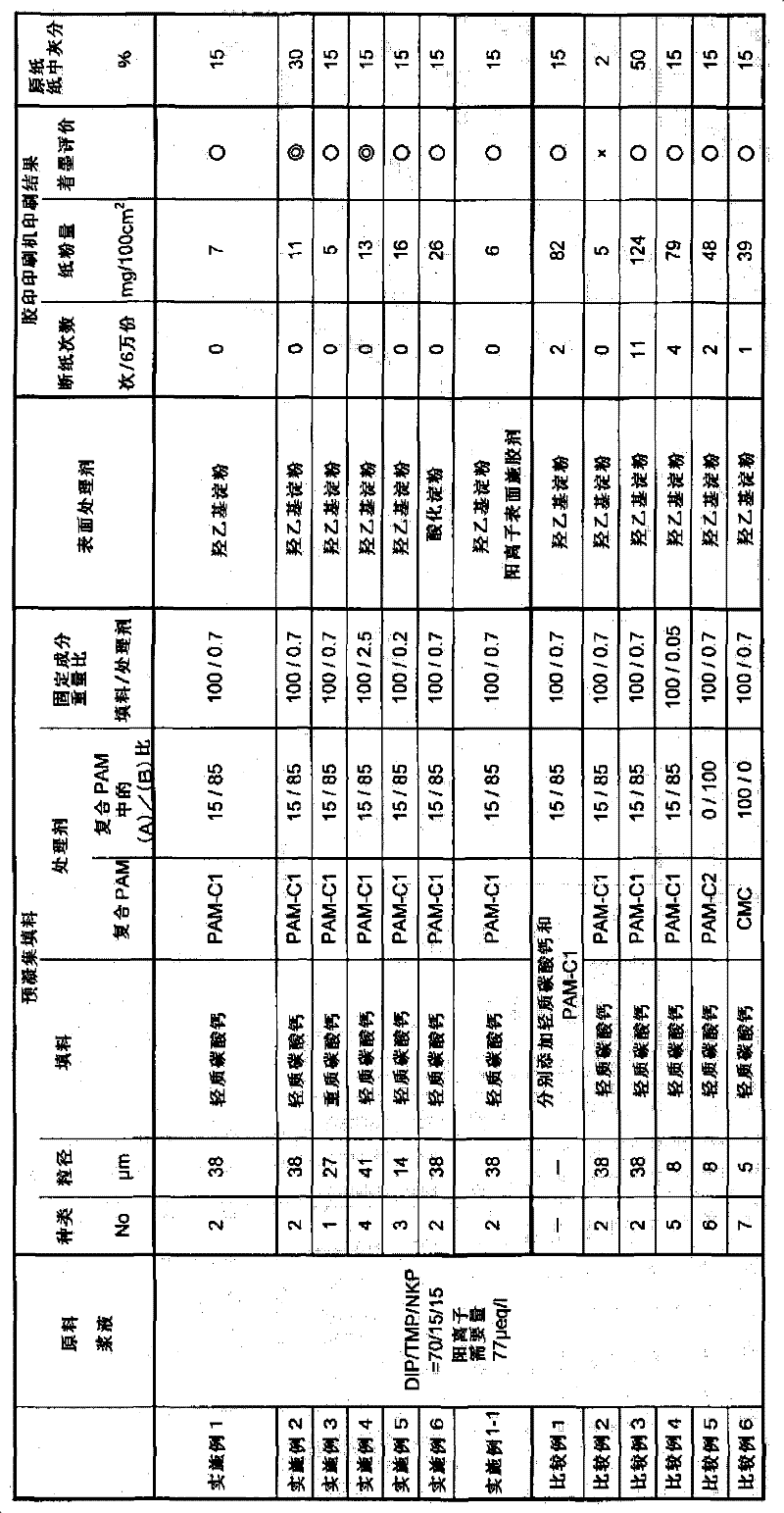

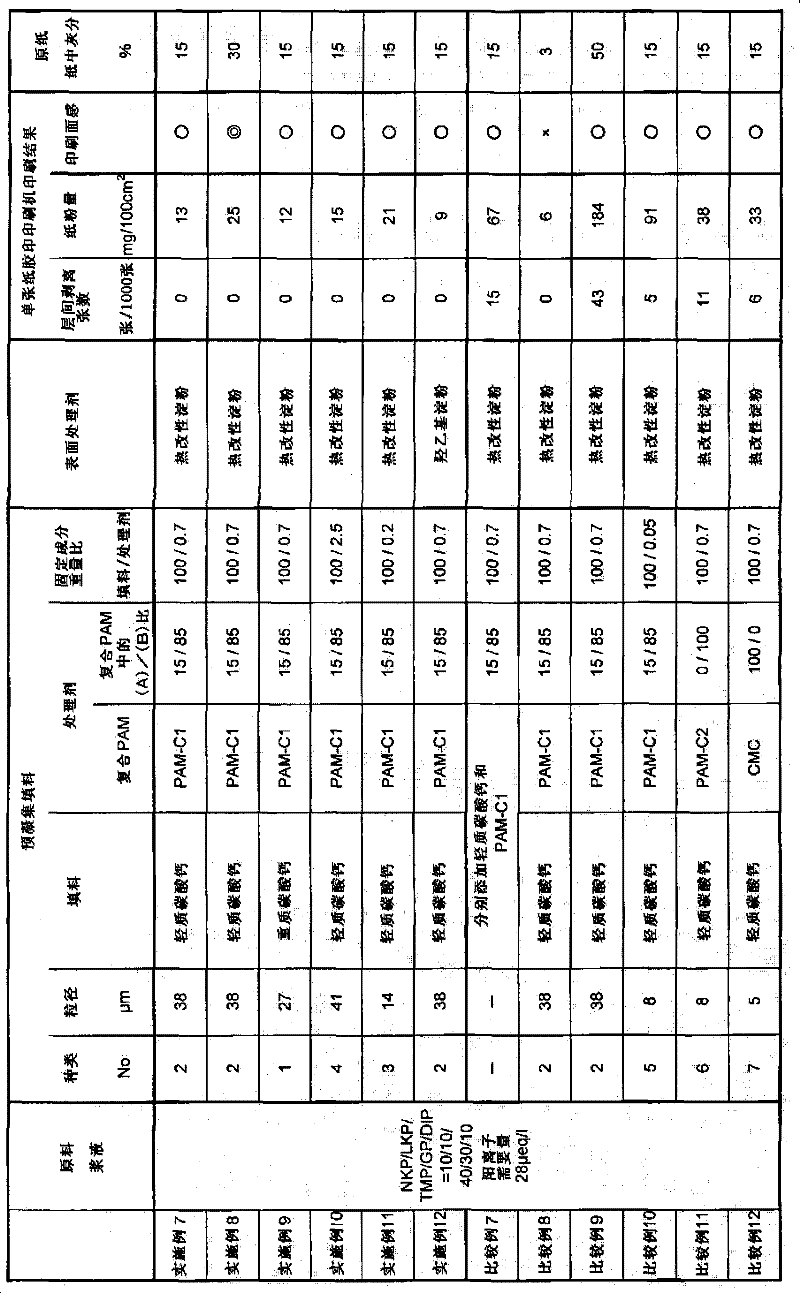

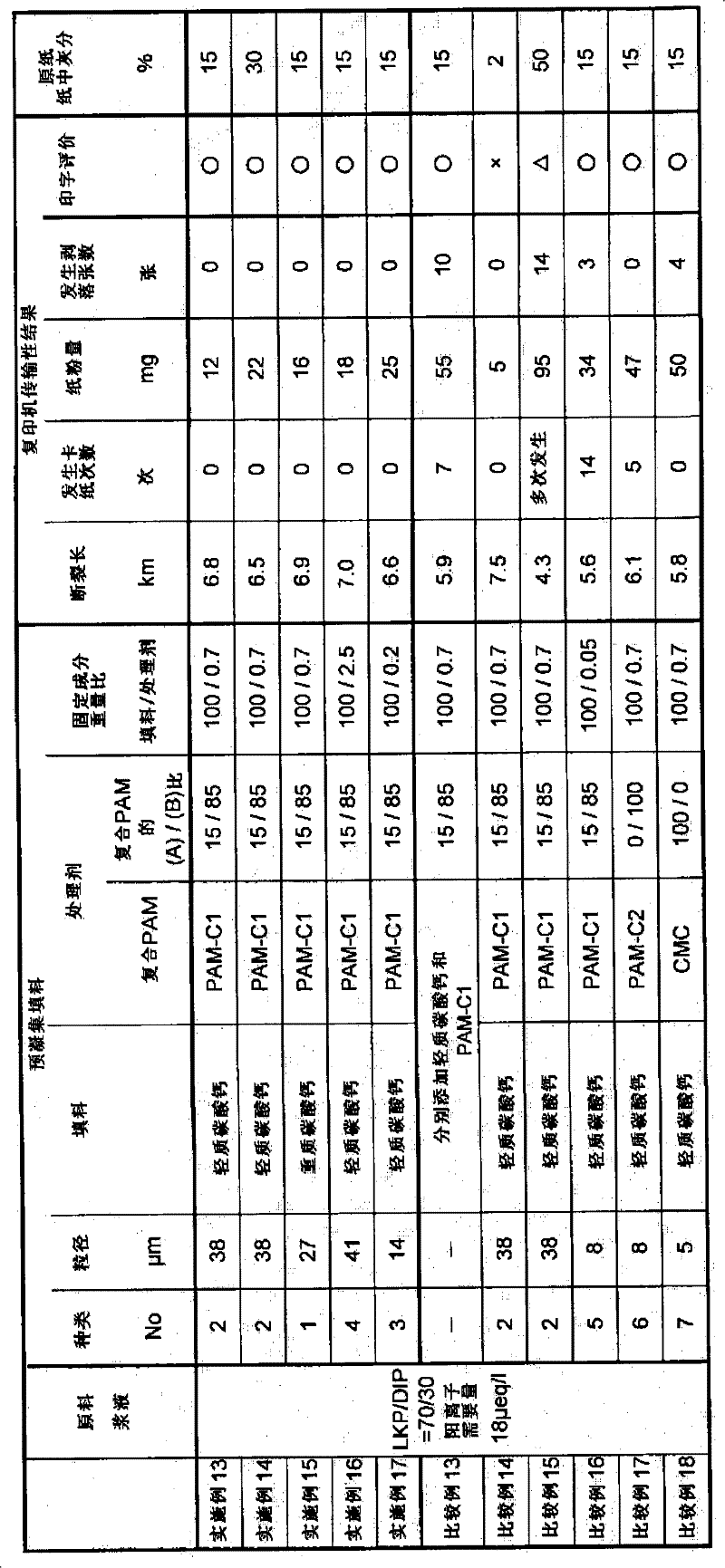

Paper containing preaggregated filler and process for producing the same

ActiveCN101370981AImprove printing qualityImprove smoothnessPaper coatingPaper/cardboardPolysaccharideMaterials science

The invention provides a paper which contains a preaggregated filler having an average particle diameter as determined by laser diffractometry of 10-80 mu m and obtained by treating a filler with a combined acrylamide copolymer comprising (A) an anionic polysaccharide and (B) a cationic and / or ampholytic acrylamide copolymer, in such an amount that the paper has an ash content of 3-40 wt.% on a solid basis. This paper is satisfactory in paper strength including strength and stiffness, has high smoothness, and attains excellent print quality.

Owner:HARIMA CHEM INC

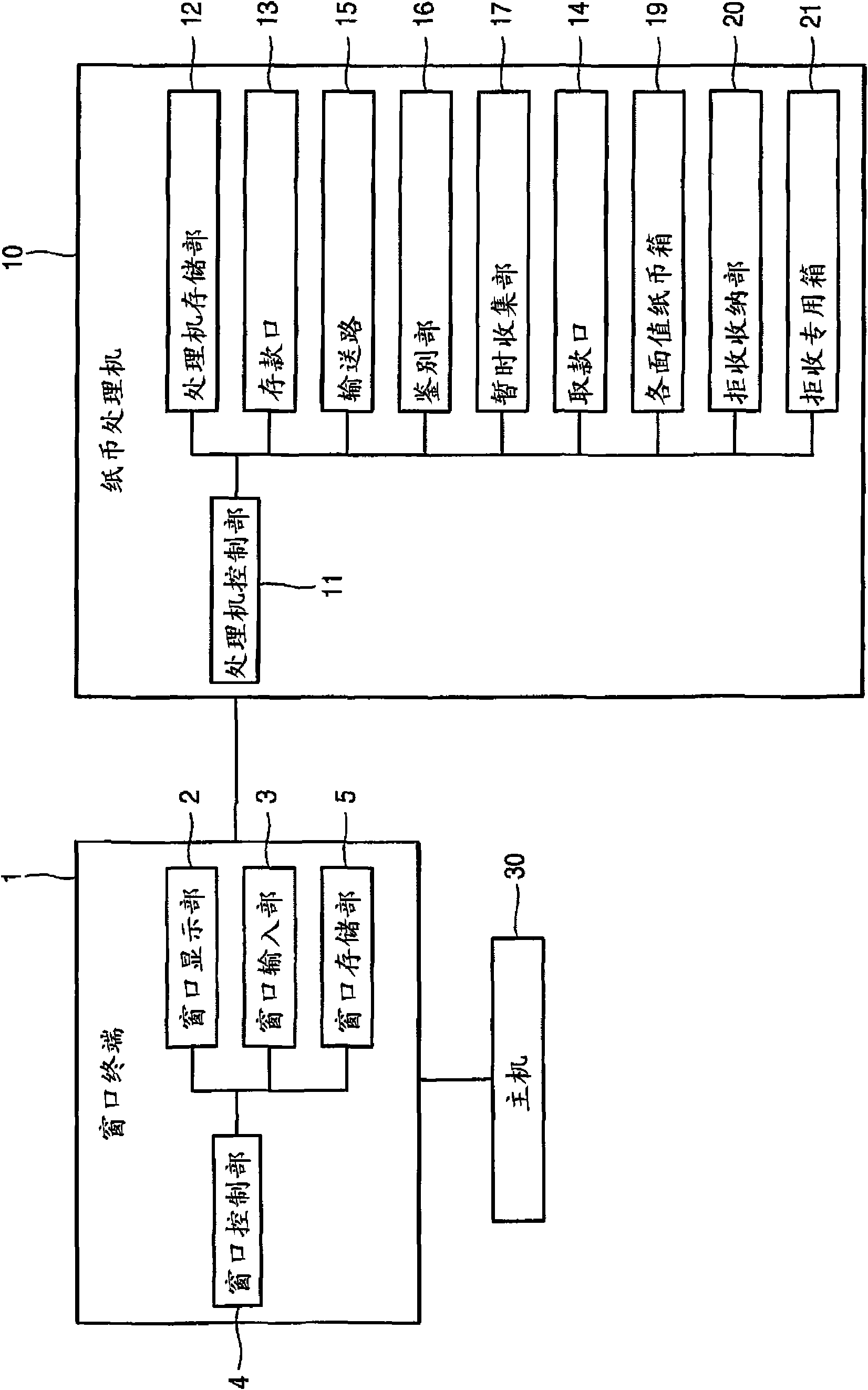

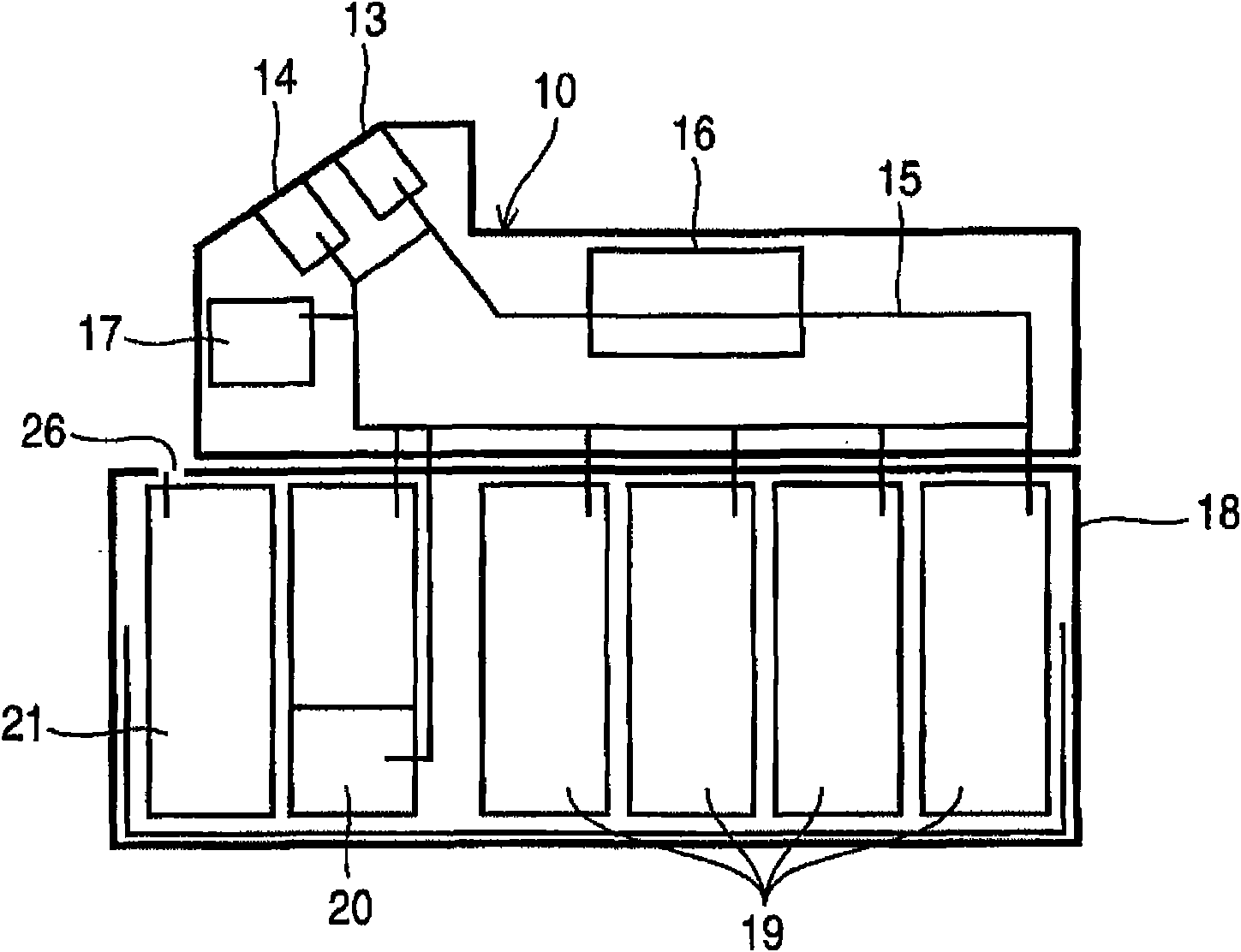

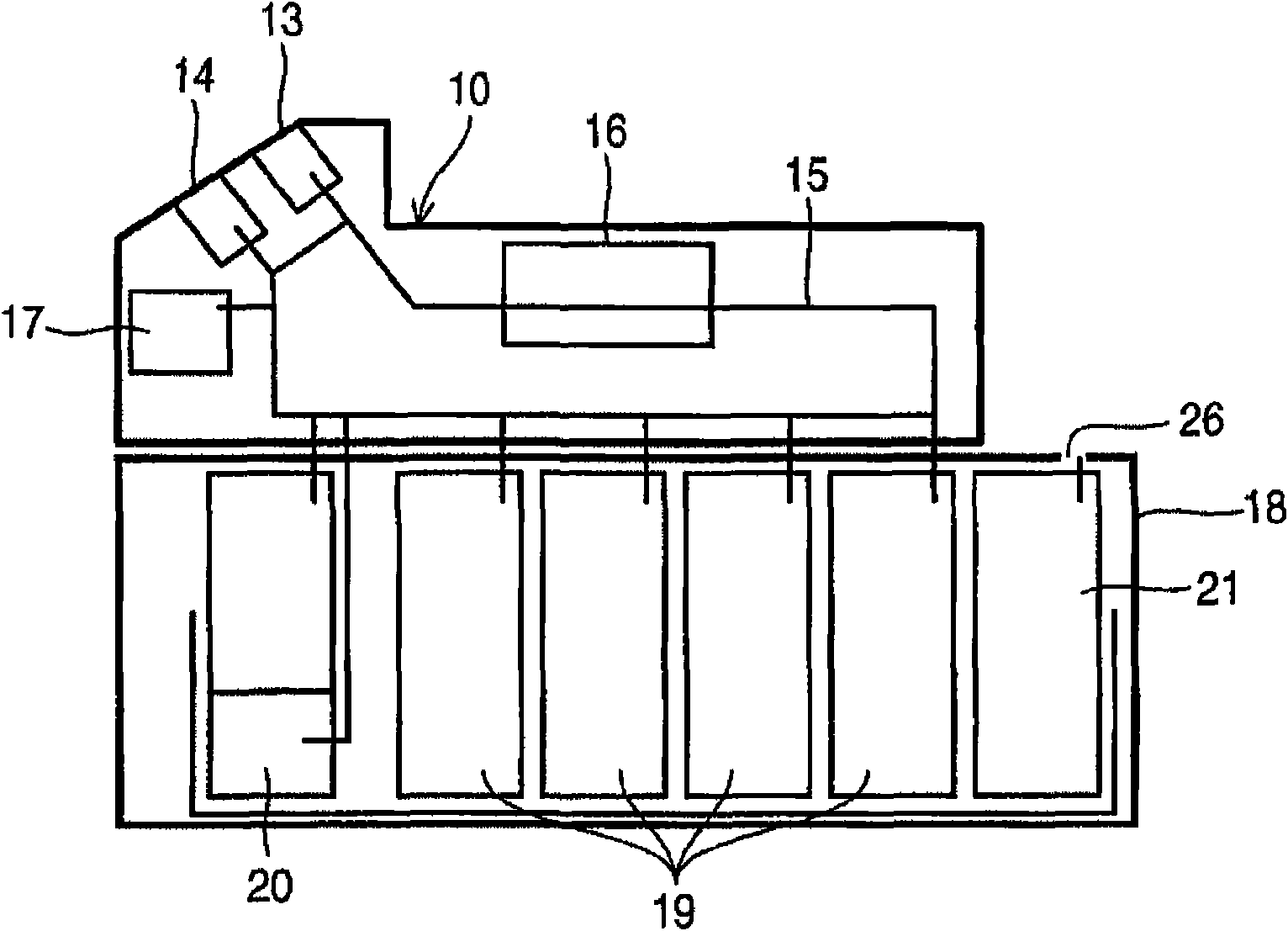

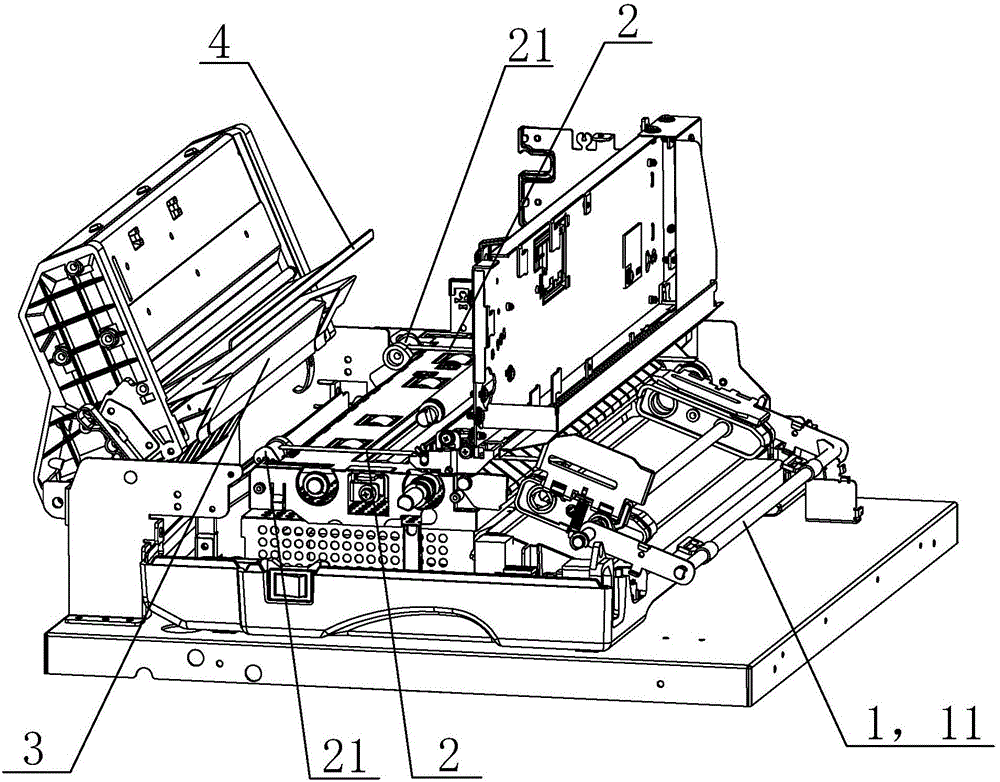

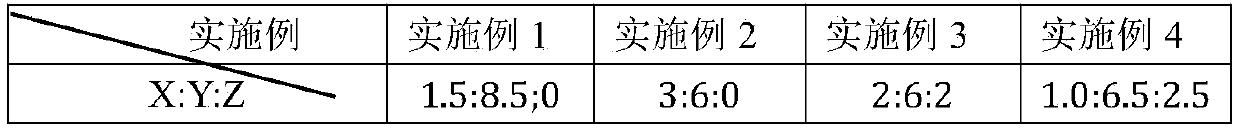

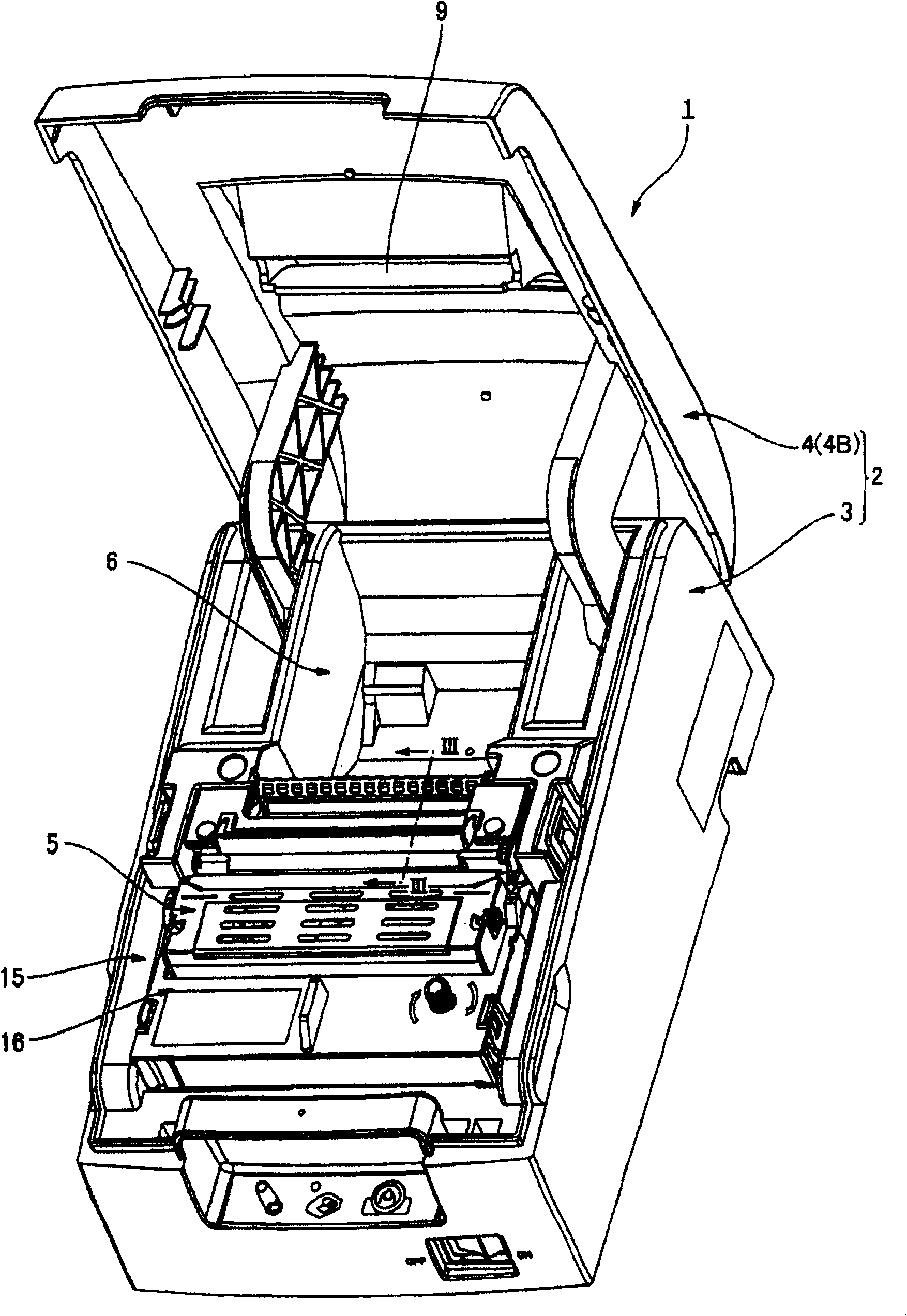

Window cash processor and mandatory cash deposit method

InactiveCN101676961ANo paper jamsComplete banking machinesCoin/currency accepting devicesEngineeringComputer terminal

The present invention relates to a window cash processor and mandatory cash deposit method. In mandatory cash deposits of the window cash processor, when the bank paper is putted into a rejection accepting part directly, the cash will not be reflected in a cash management counter on the side of the device because the bank paper is not stored on the side of the device, therefore, when the cash is settled after ending a business, the cash in the cash processor, the cash of the cash management counter and the rejection accepting part as well as the cash of the cash management counter in terminal window are not identical, then the account can not be settled. The window cash processor of the invention is composed of a note processor having a saving port, a withdrawal port, a transport path, an identifying part as well as a safe case part (18) with cases for saving bank papers of each value, etc.; a window terminal (1) connected with the cash processor (10) and having a window display part, a window input part, a window storage part, etc., characterized in that a rejection private storeroom (21) having an bank paper feed port (22) is arranged in the safe case part.

Owner:OKI ELECTRIC IND CO LTD

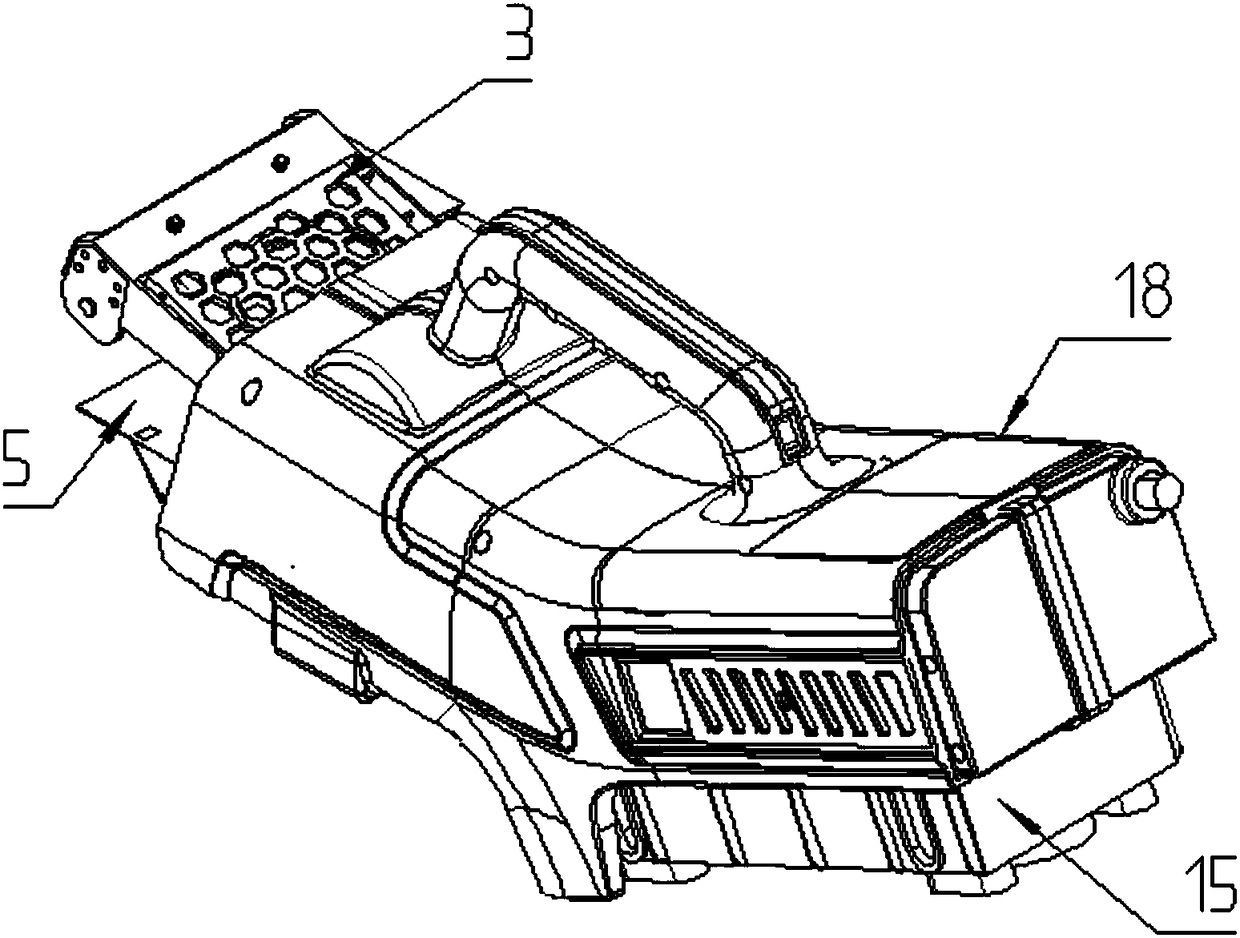

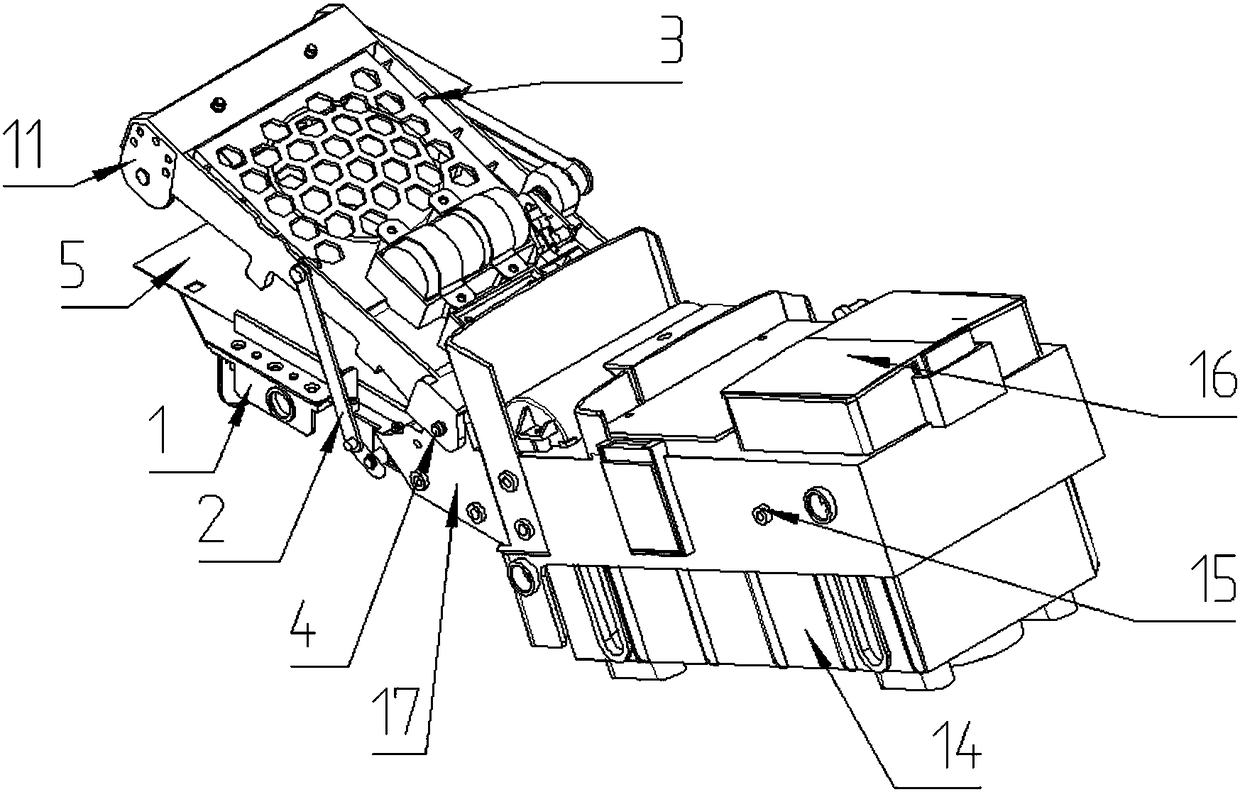

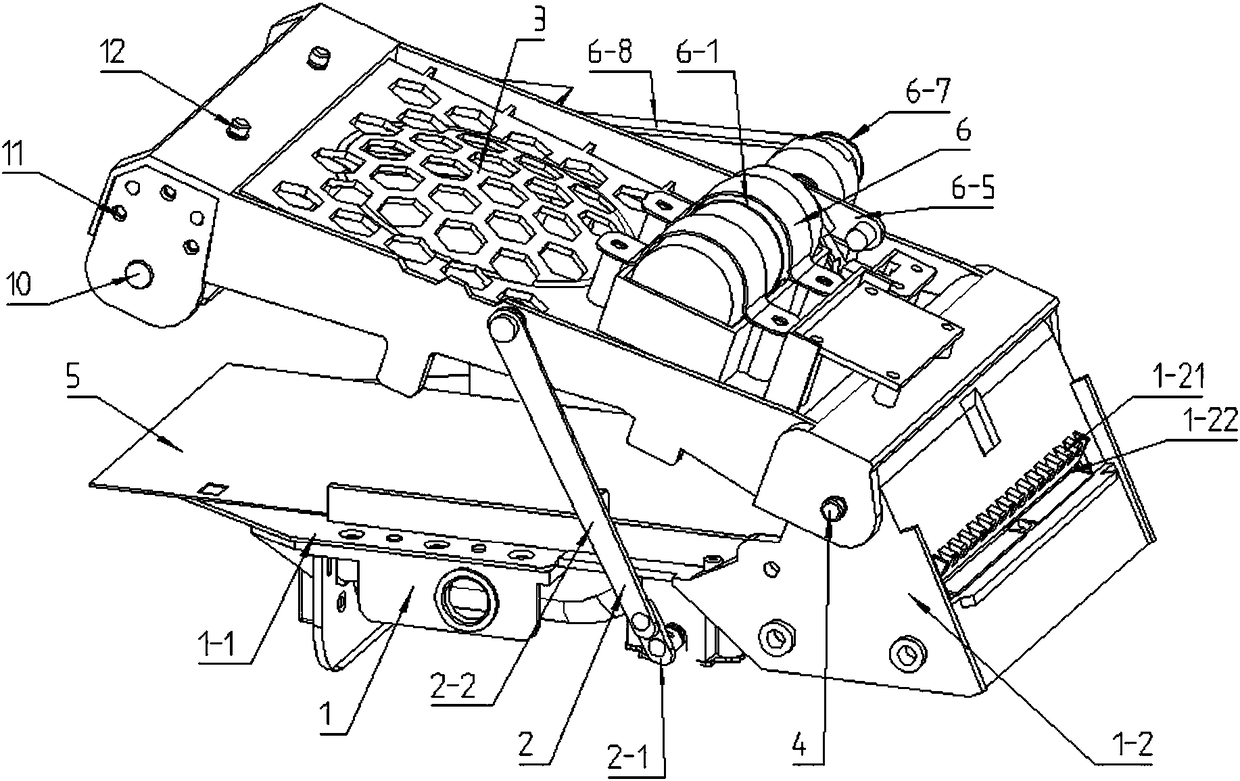

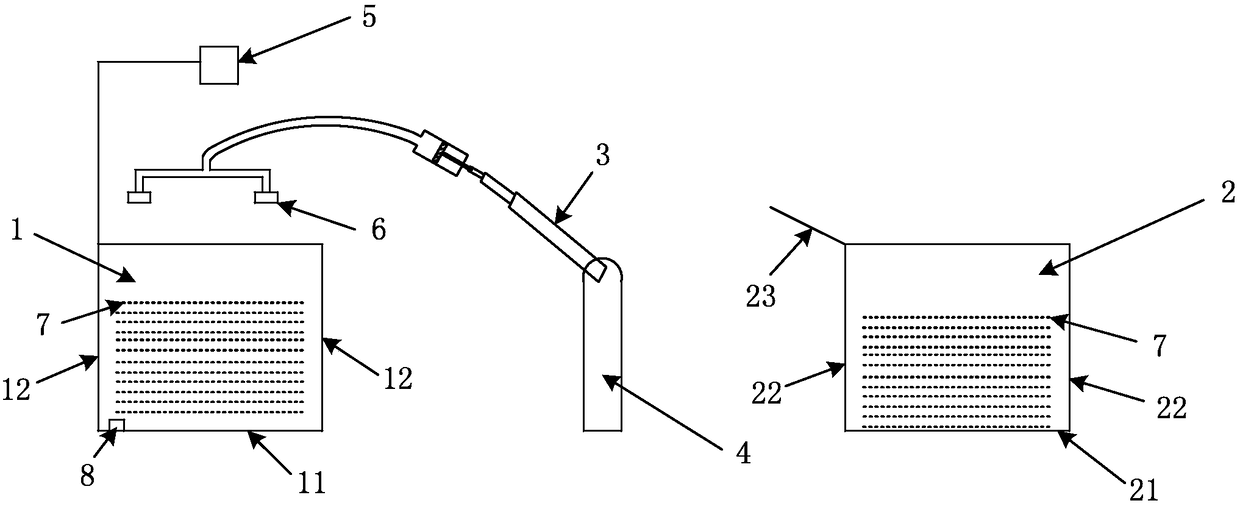

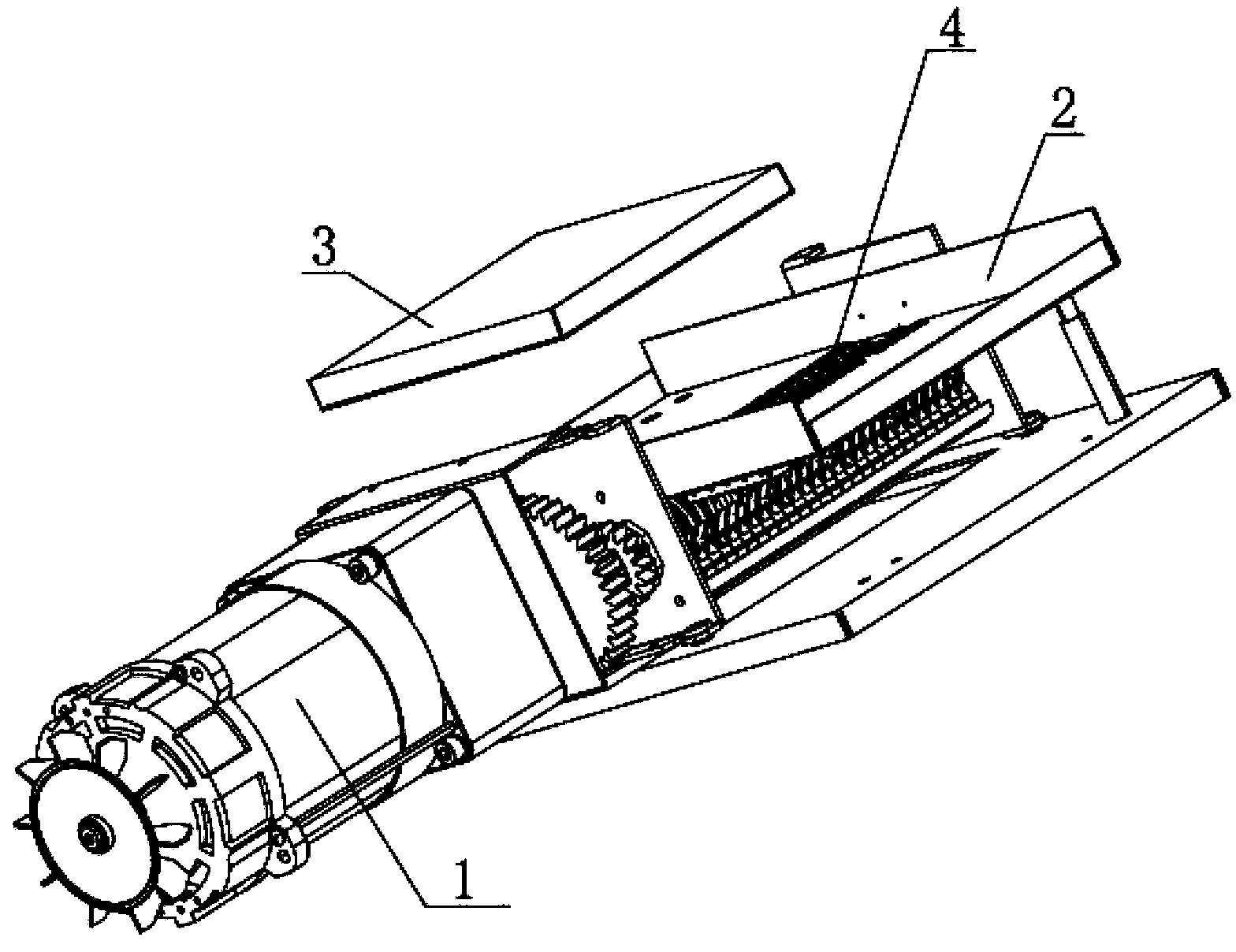

Fruit bagging machine and bagging method

ActiveCN108260452APrevent openingImprove bagging efficiencyPlant protective coveringsButt jointEngineering

The invention relates to a fruit bagging machine, which comprises a machine head, a bag storage device and a machine case, wherein the bag storage device comprises a bag storage box and a bag discharging mechanism; the bag storage box comprises a fruit bag outlet; the machine head comprises an upper jaw plate and a lower jaw plate; the back ends of the upper jaw plate and the lower jaw plate are rotationally connected through a rotating shaft; an opening and closing mechanism is arranged between the upper jaw plate and the lower jaw plate; the back end of the machine head is provided with a fruit bag inlet; the fruit bag inlet is in butt joint with a fruit bag outlet of the bag storage device; the machine head and the bag storage device are connected through a connecting element; an opening sealing mechanism is arranged on the upper jaw plate; the opening sealing mechanism comprises a turning plate and a turning plate driving assembly; the turning plate driving assembly drives the turning plate to rotate; the bag opening of the fruit bag is folded. The structure has the advantages that the weight is light; the bagging efficiency is high; the use is convenient; the opening sealing effect is good. The invention also relates to a bagging method of the fruit bagging machine. By using the method, the bag opening of the fruit bag can be folded twice; the opening sealing effect is good.

Owner:烟台梦现自动化设备有限公司

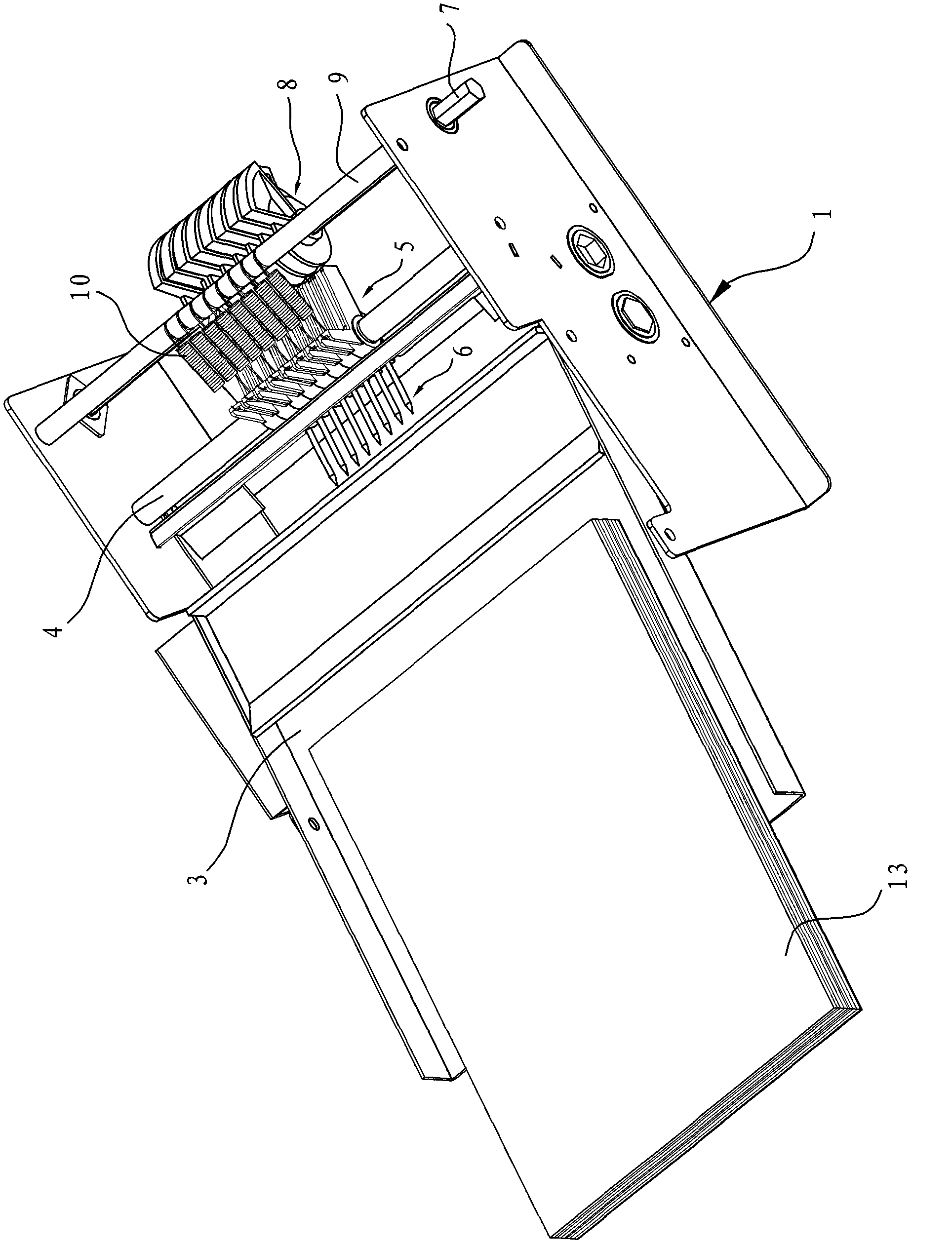

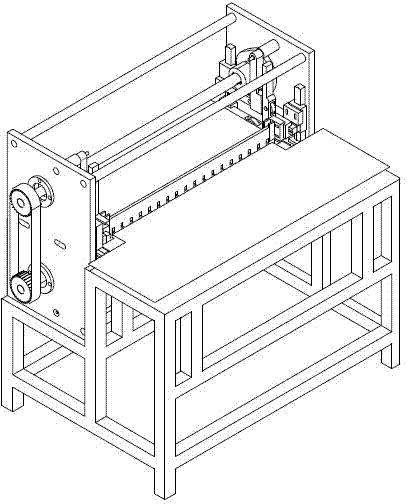

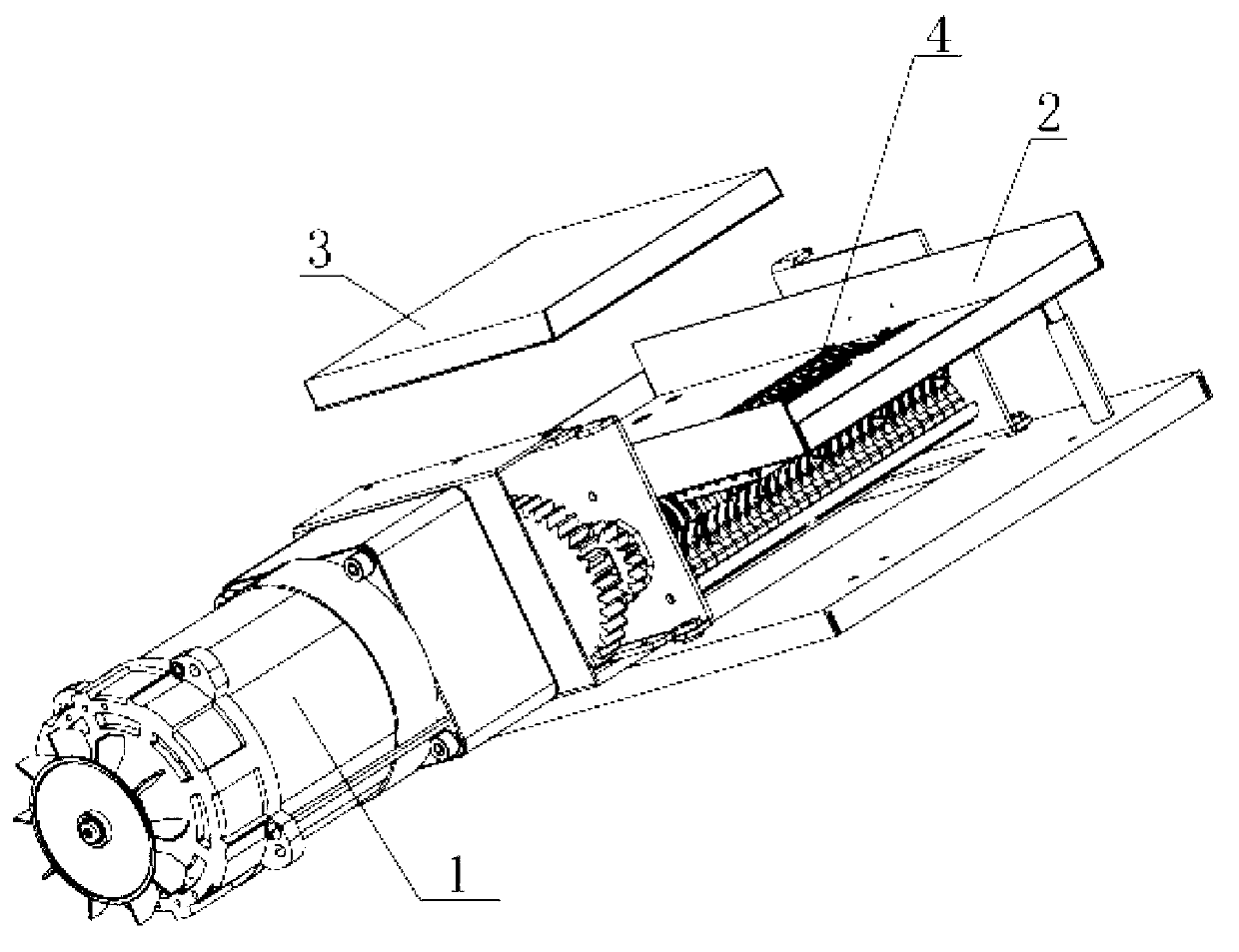

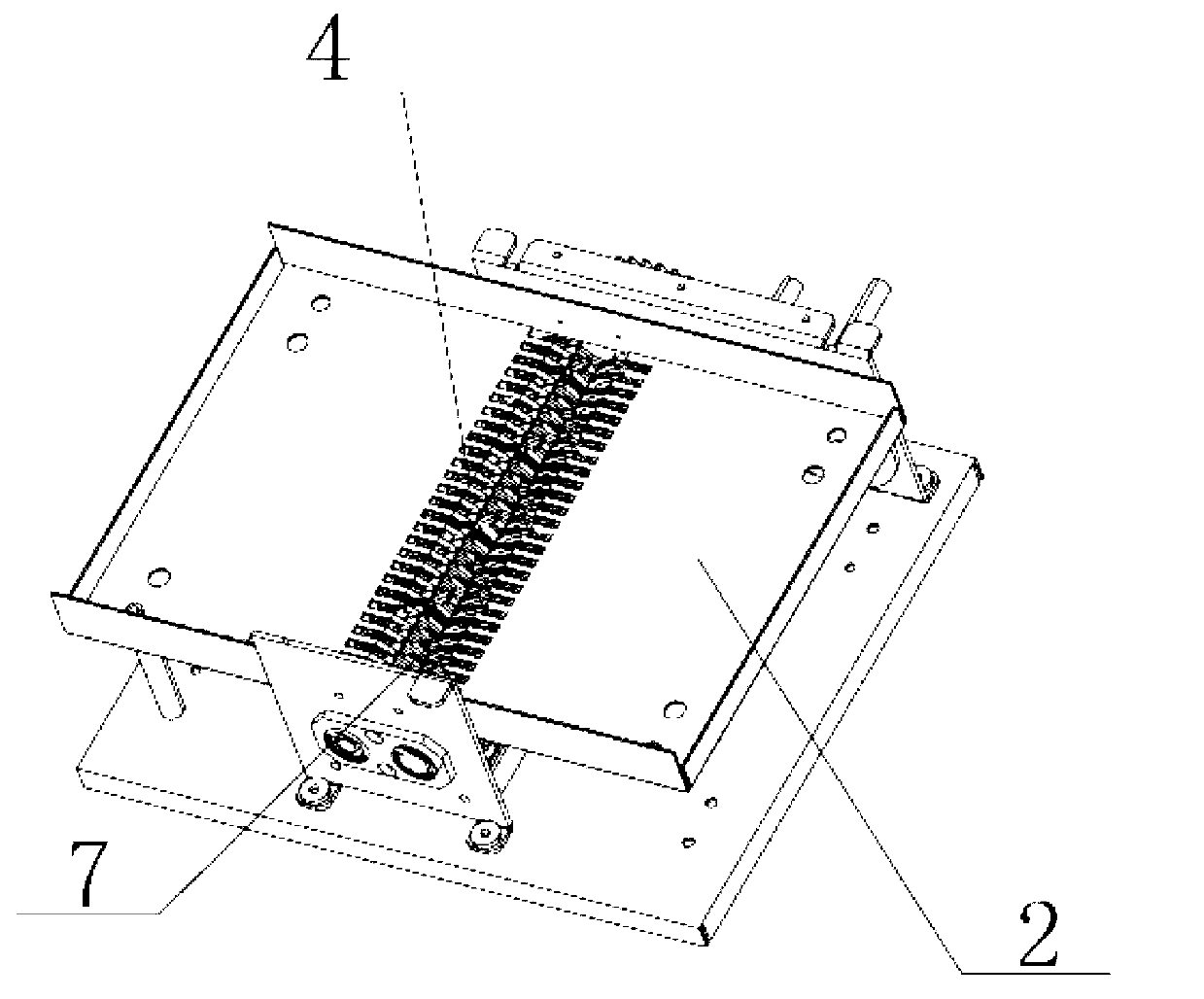

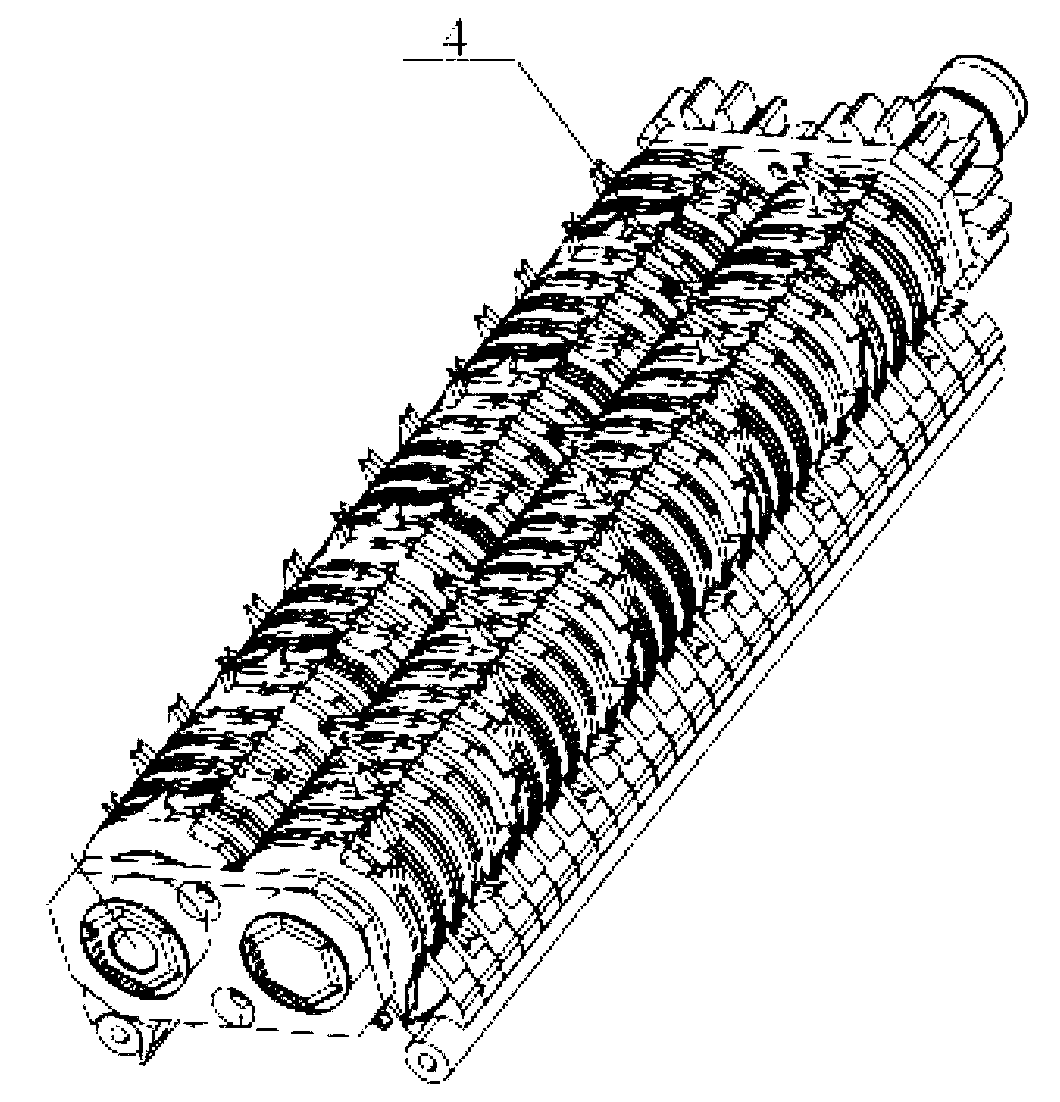

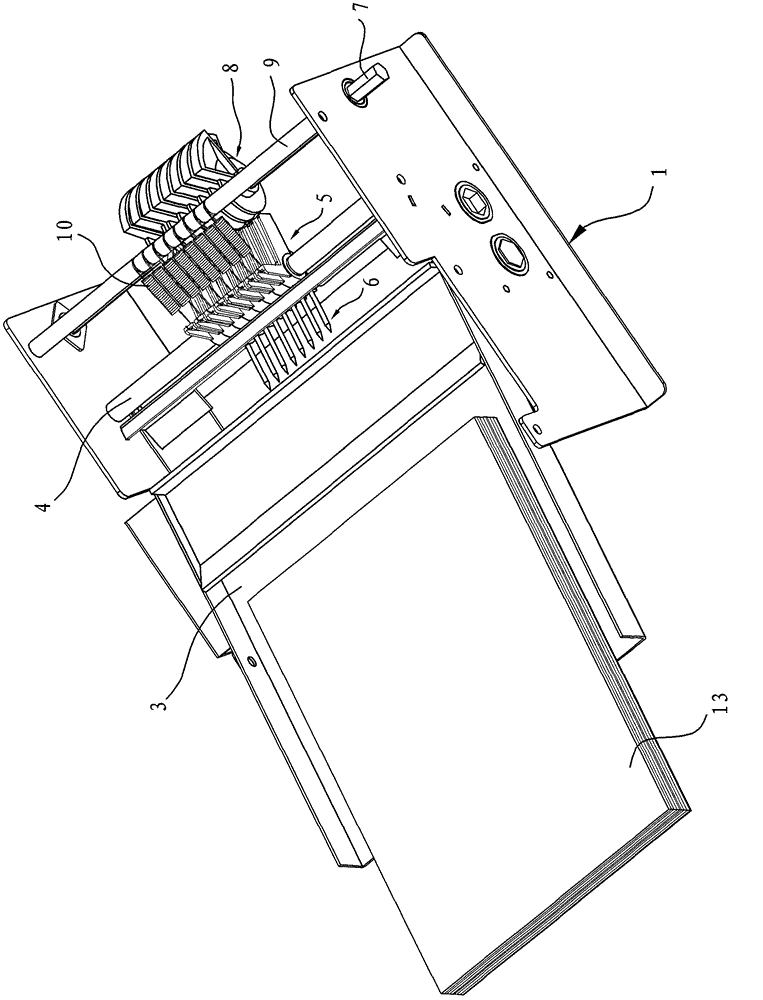

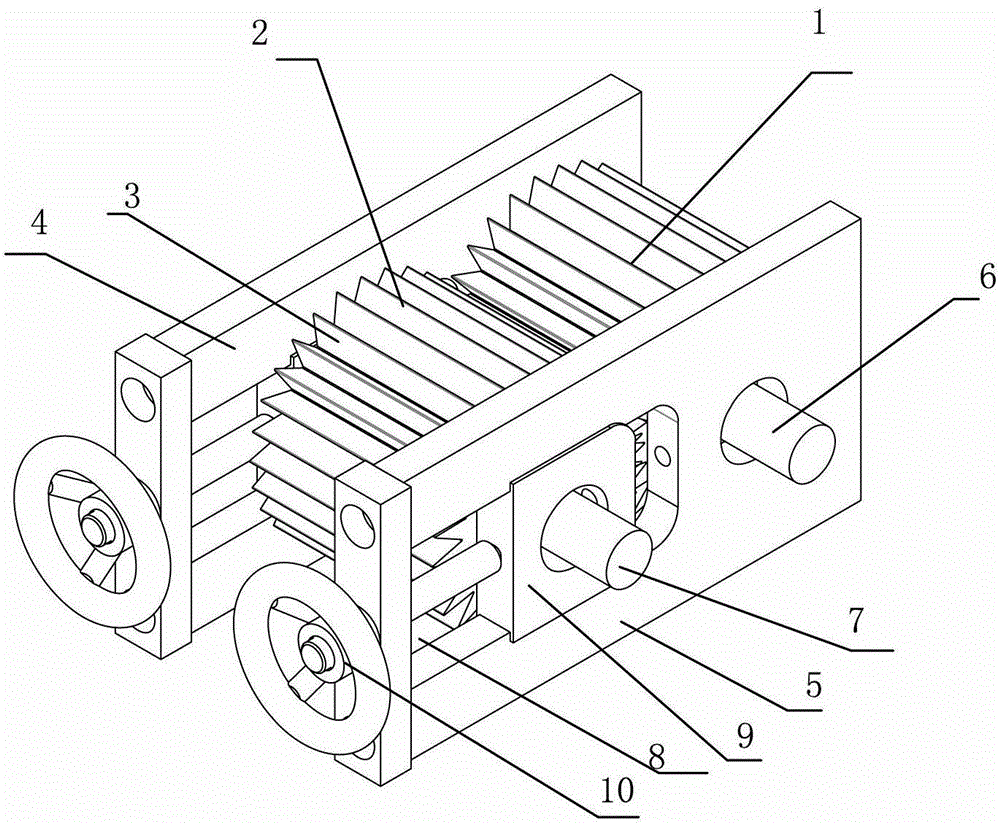

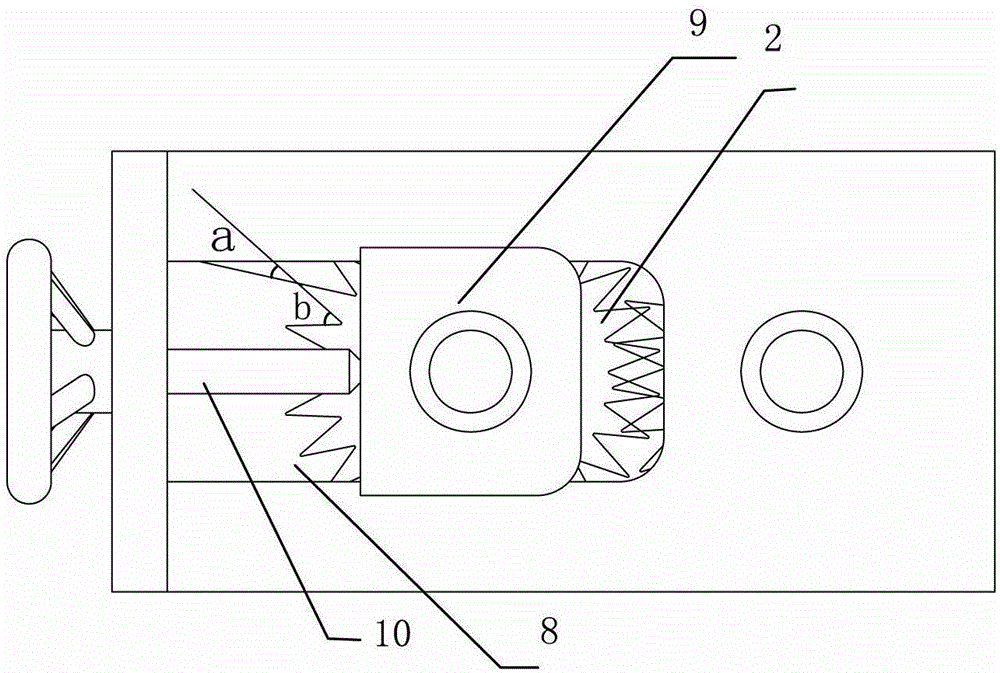

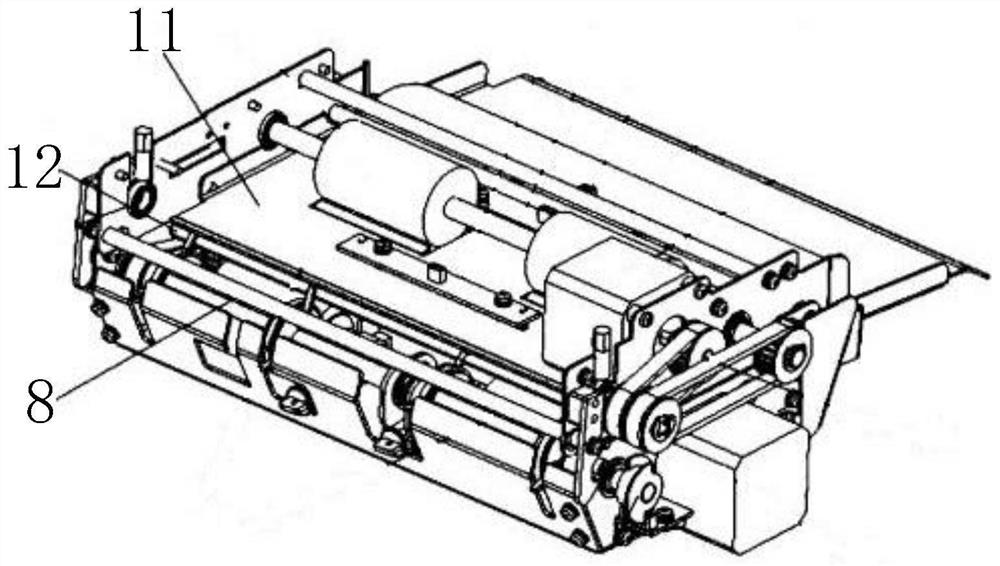

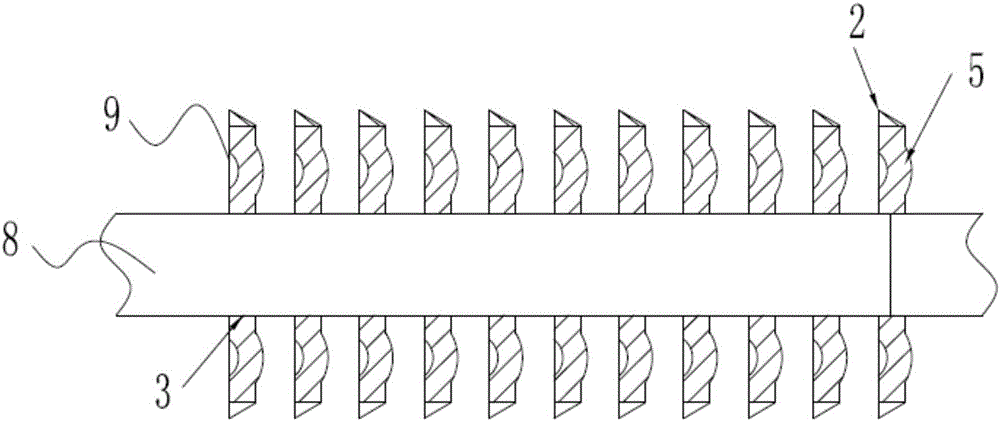

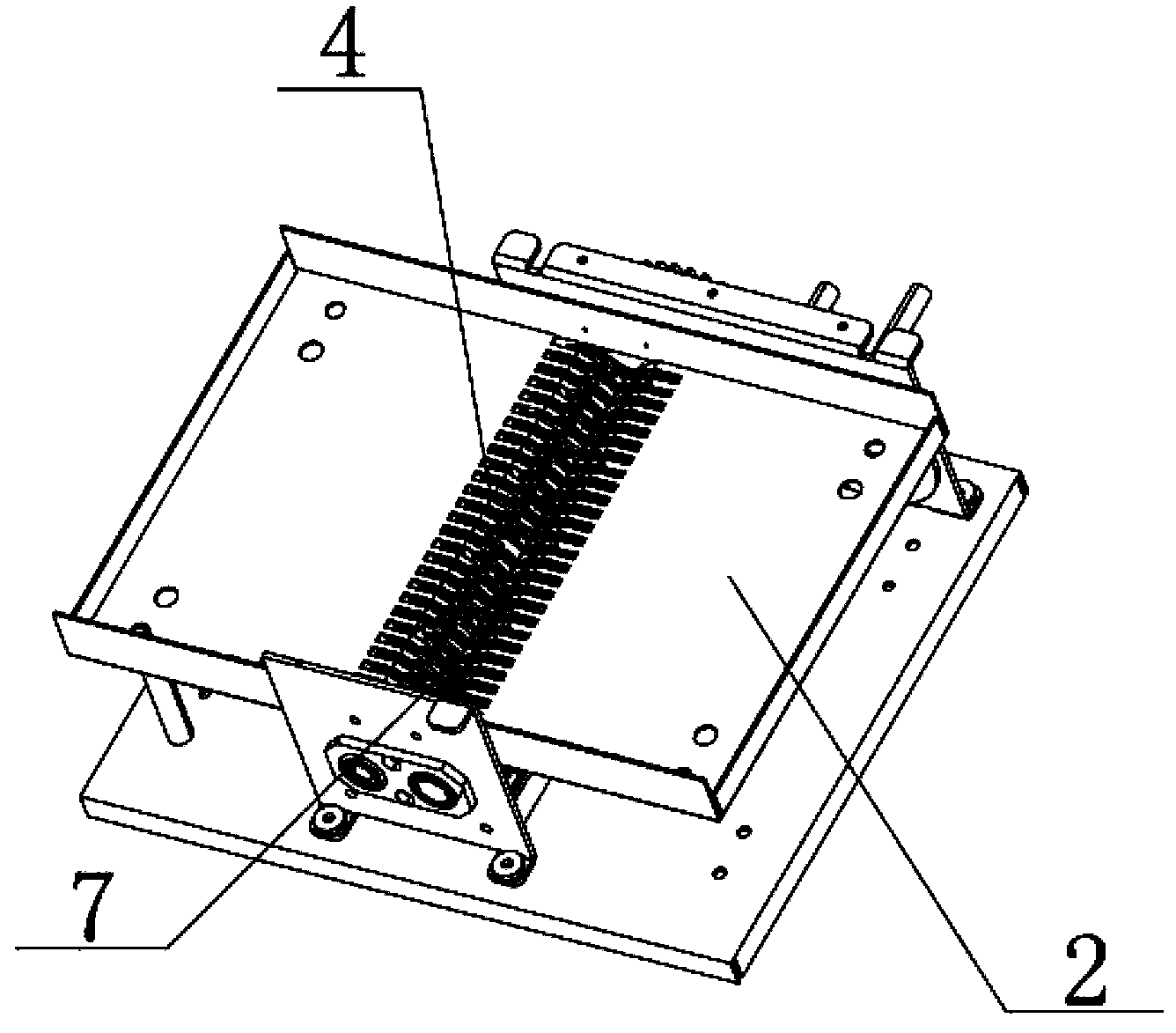

An automatic paper feeding structure of a shredder

InactiveCN102294291AImprove work efficiencyHigh feeding reliabilityGrain treatmentsPulp and paper industryCam

The invention discloses an automatic paper feeding structure of a shredder. The automatic paper feeding structure comprises a frame and a paper feeding channel formed above the frame, wherein the paper outlet of the paper feeding channel is positioned above the paper inlet of a shredding roll set of the shredder. The automatic paper feeding structure is characterized in that: a plurality of paperdistributing needle stands rotating around a fixing shaft are distributed on the fixing shaft of the frame along the axial direction; a paper distributing needle is inserted into each paper distributing needle stand; the paper distributing needles are distributed in sequence in a stepped form in the height direction along the axial direction of the fixing shaft; the needle point of each paper distributing needle faces the paper discharging direction of the paper feeding channel; the frame is provided with a camshaft which is parallel to the fixing shaft; cams which can rotate synchronously along the camshaft and are matched with the paper distributing needle seats one by one are distributed on the camshaft along the axial direction; and the cams act on the paper distributing needle seats to drive corresponding paper distributing needles to rotate towards the paper inlet of the shredding roll set in sequence. Compared with the prior art, the automatic paper feeding structure has the advantages of high paper feeding reliability and capabilities of realizing graded paper feeding and increasing the working efficiency of the shredder.

Owner:NINGBO OFITECH BUSINESS MACHINESE

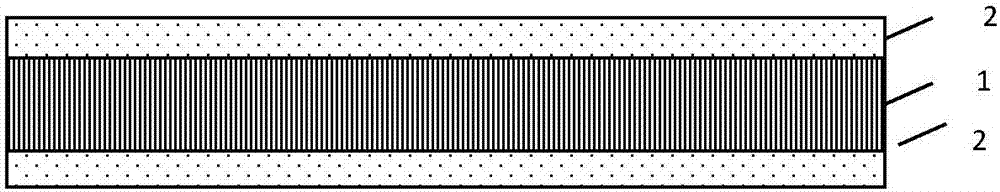

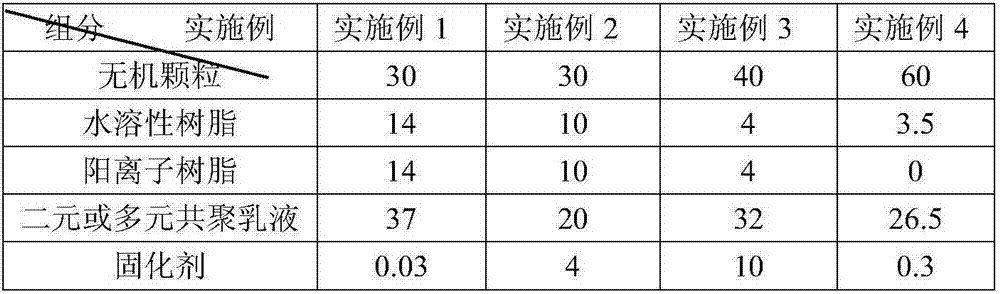

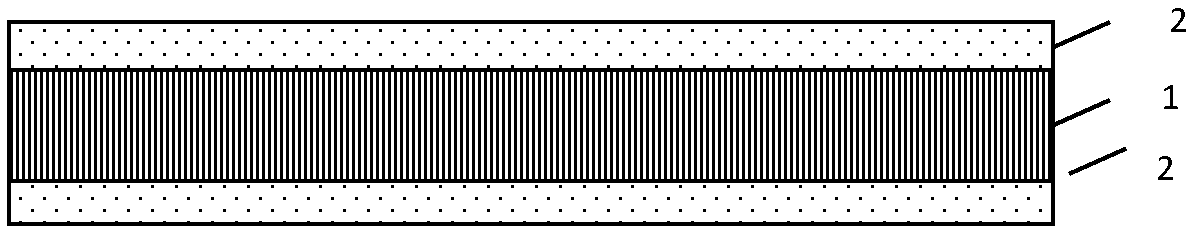

Liquid electronic ink receiving medium

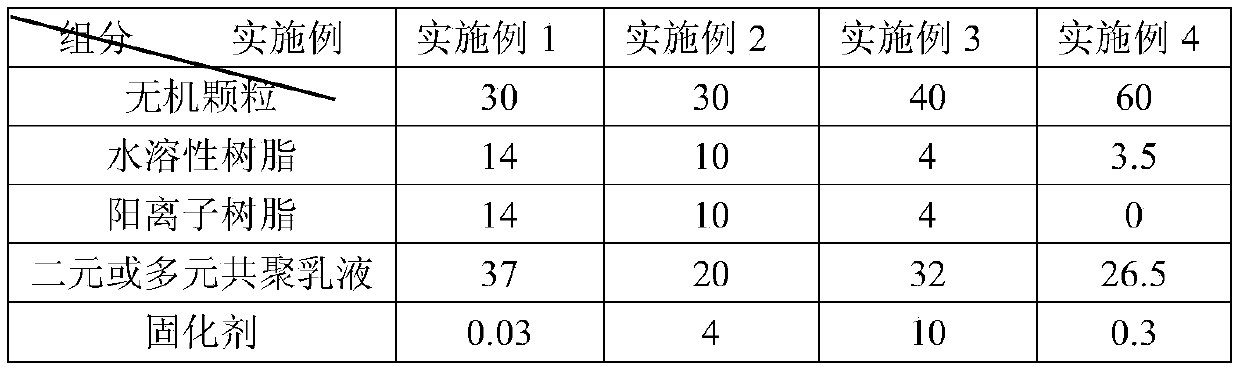

ActiveCN106915171AGood coating fastnessHigh gloss surfaceDuplicating/marking methodsWater dispersibleAdhesive

A liquid electronic ink receiving medium comprises a support body and an ink receiving layer on one side or both sides of the support body. The ink receiving layer comprises, by weight, 30-60 parts of inorganic particles (a), 30-65 parts of an adhesive (b) and 0.03-10 parts of a curing agent (c). The inorganic particles are cationic inorganic particles. The adhesive is selected from one or more of water-soluble resin and binary or polybasic water-dispersible type copolymer emulsion. The liquid electronic ink receiving medium is smoothly conveyed on an HP Indigo series printing press without the paper jamming problem, the printed image is bright in color, the inking capacity is good, the printing ink fastness is good, and the image-stage image quality requirement is met.

Owner:乐凯胶片股份有限公司

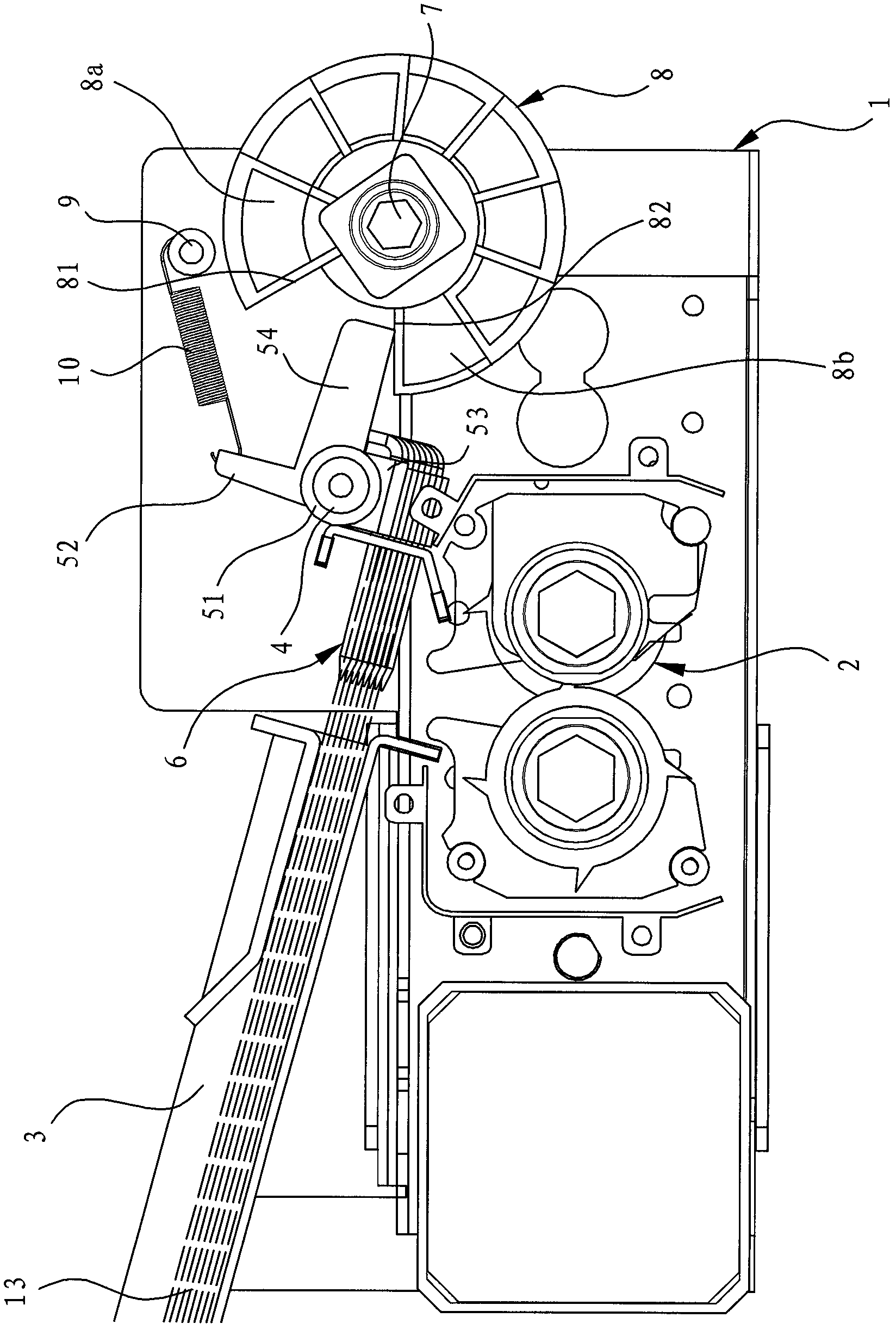

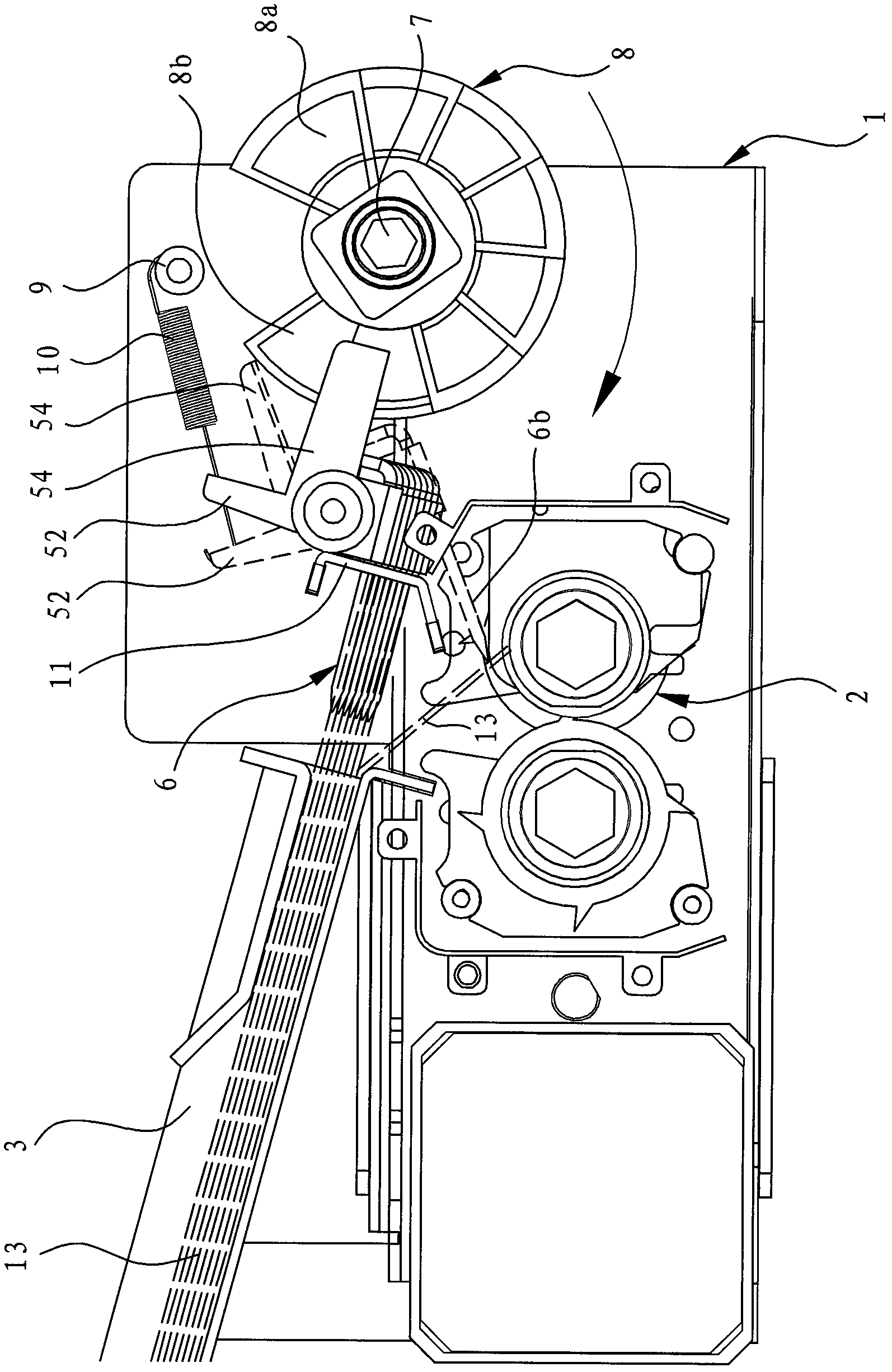

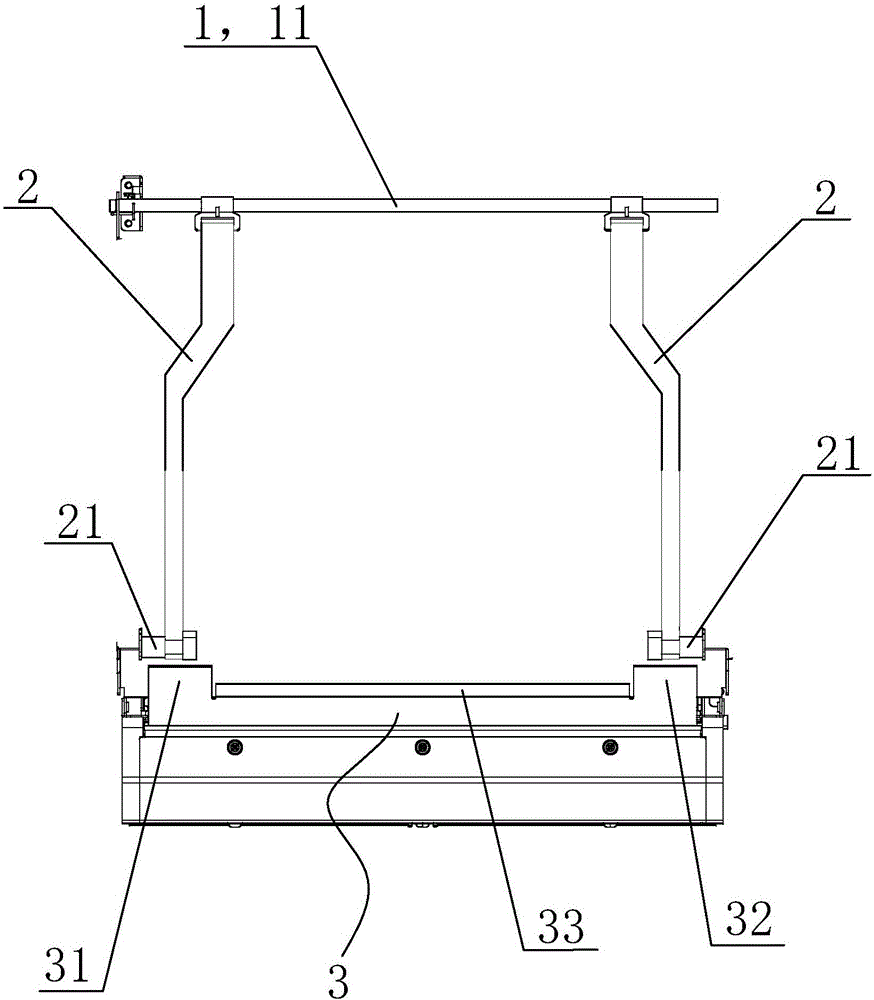

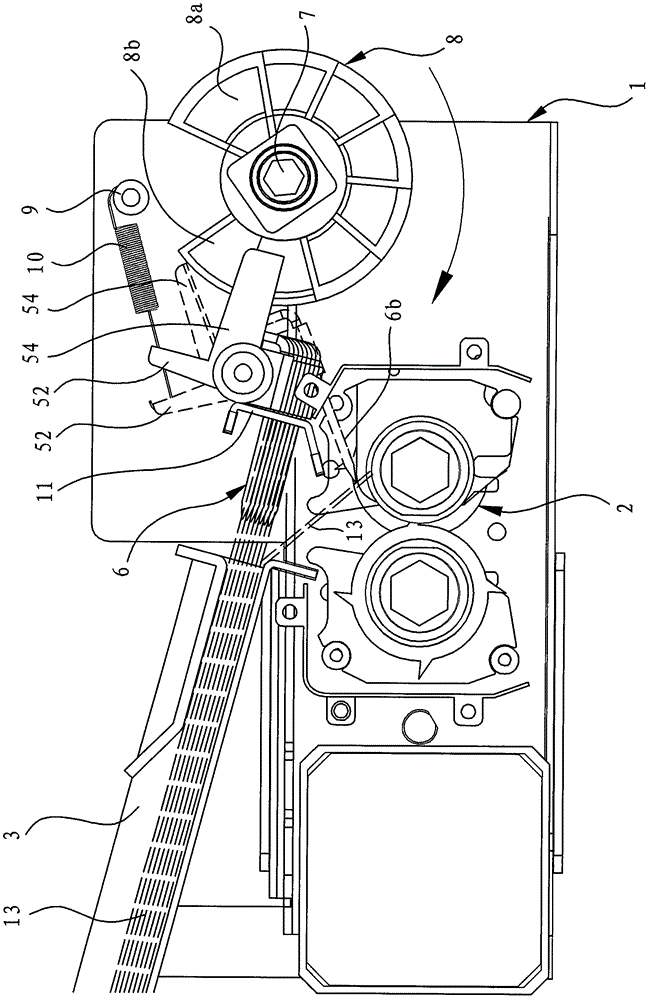

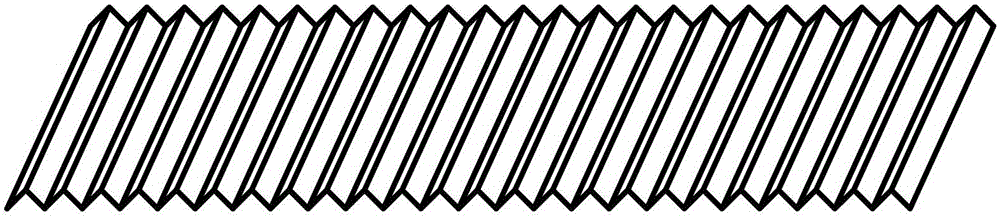

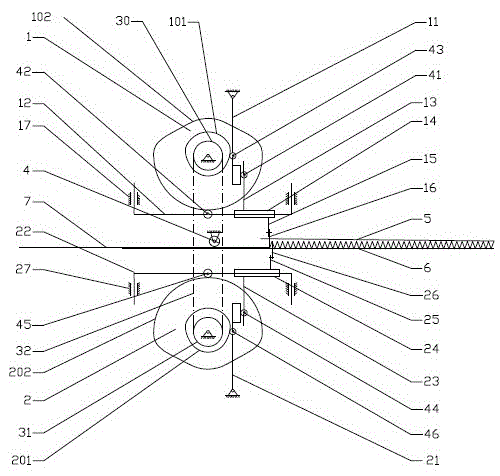

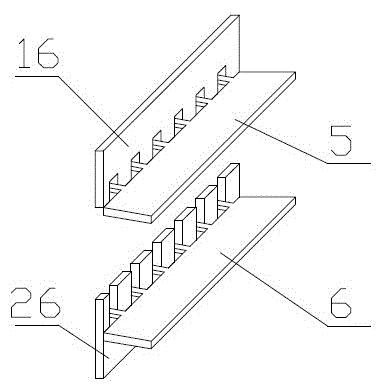

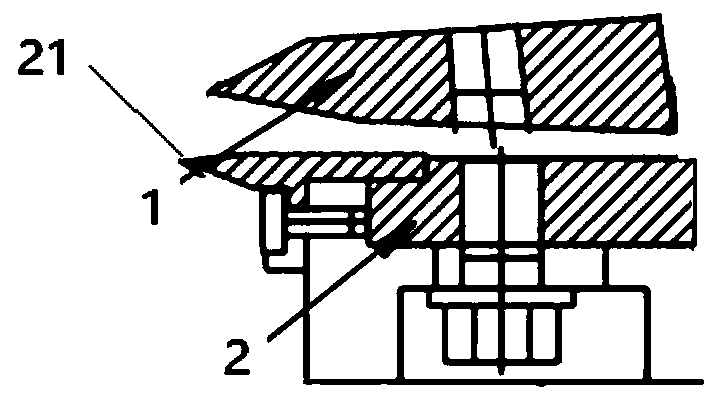

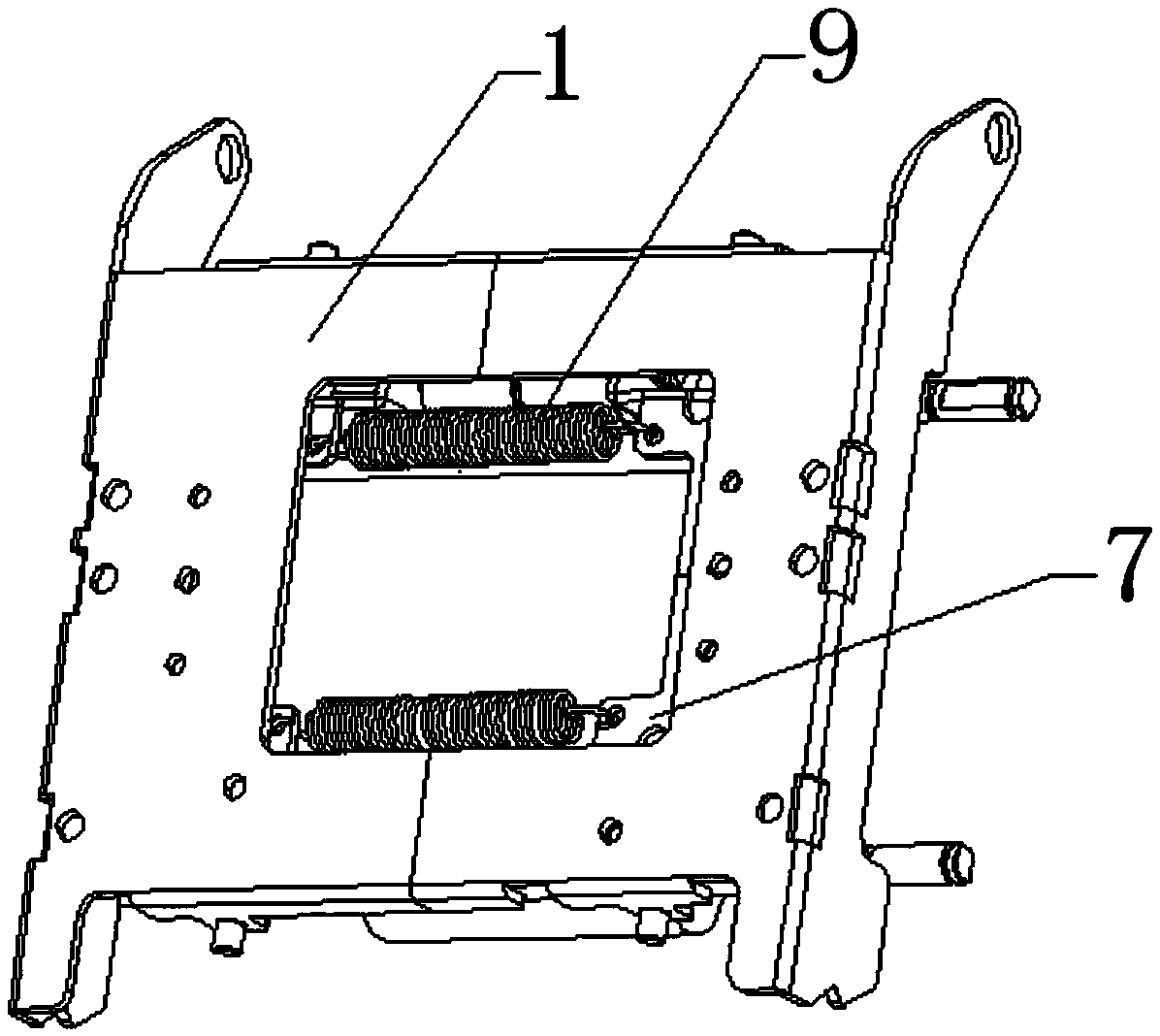

Paper folding machine

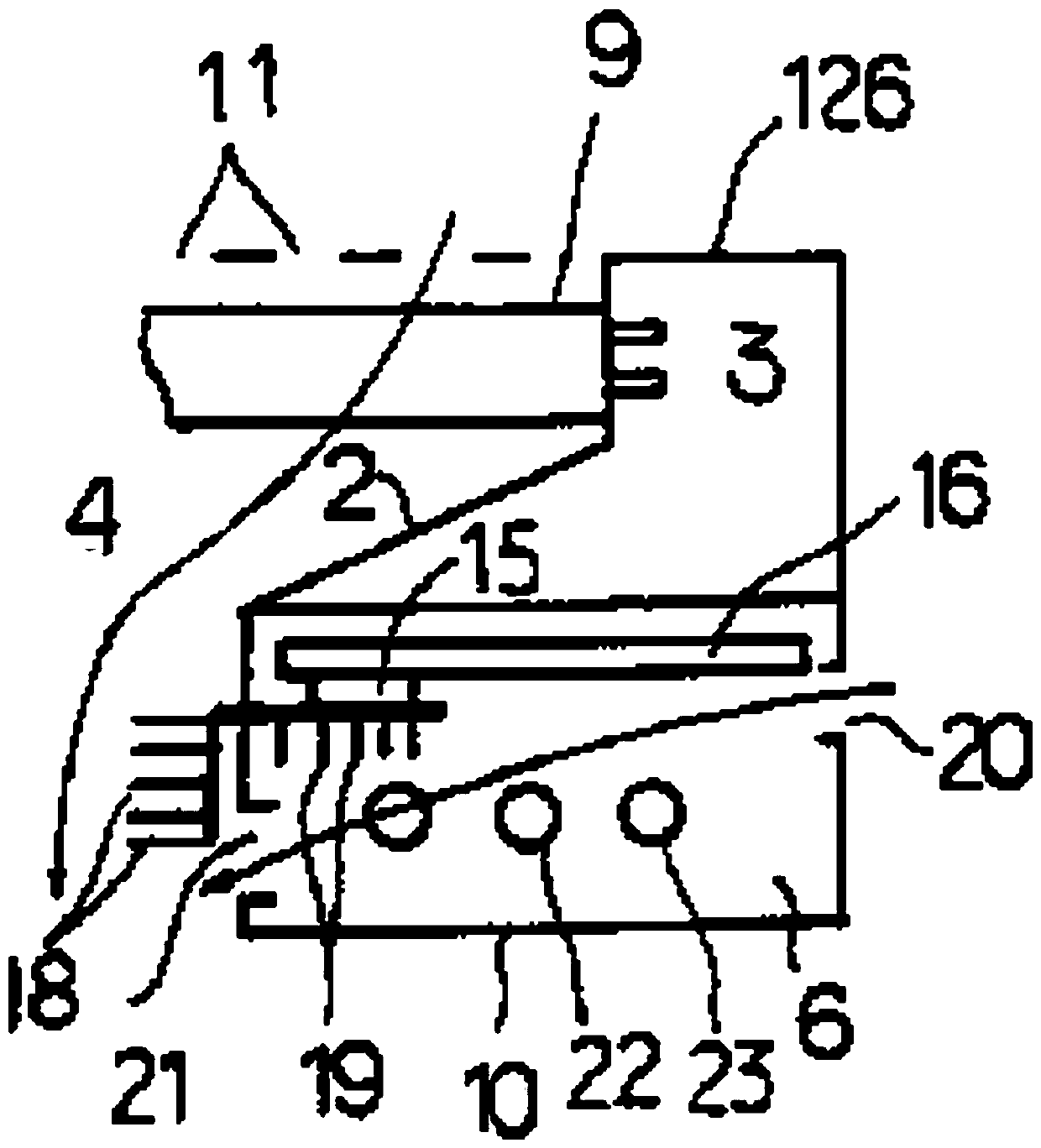

InactiveCN103538294AGuaranteed accuracyRealize the purpose of repeated folding in the forward and reverse directionsMechanical working/deformationPaper sheetPulp and paper industry

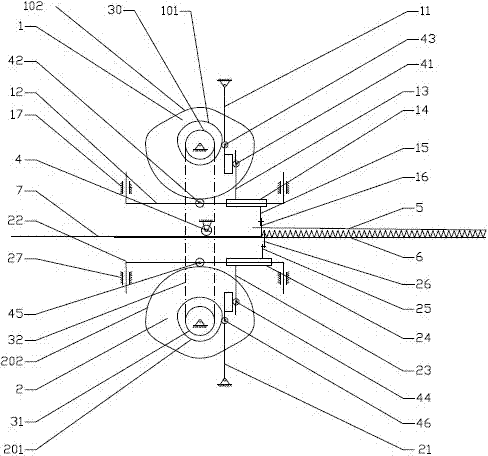

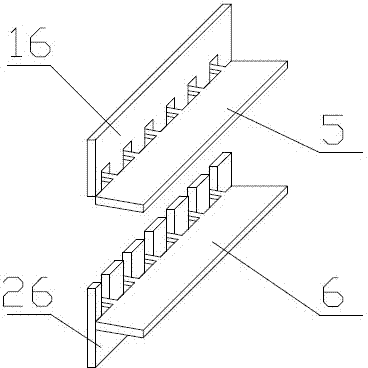

The invention discloses a paper folding machine which comprises a rack, a paper folding mechanism and a driving device. The paper folding mechanism comprises an upper paper folding device (1), a lower paper folding device (2) and a synchronous belt wheel device, the upper paper folding device (1) comprises an upper paper folding baseplate (15), an upper paper pressing cam (102) and an upper paper pushing cam (101), the lower paper folding device (2) comprises a lower paper folding baseplate (25), a lower paper pressing cam (202) and a lower paper pushing cam (201), the synchronous belt wheel device comprises an upper synchronous belt wheel (30), a lower synchronous belt wheel (31) and a synchronous belt (32), two cams in the upper synchronous belt wheel (30) and the upper paper folding device (1) are coaxially and fixedly connected, two cams in the lower synchronous belt wheel (31) and the lower paper folding device (2) are coaxially and fixedly connected, and the upper synchronous belt wheel (30) and the lower synchronous belt wheel (31) is connected with the driving device. The paper folding machine can automatically fold paper to be in the shape of an accordion blade in positive and negative directions.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Paper shredding mechanism

InactiveCN103120972ASimple structureShredding EfficientGrain treatmentsPulp and paper industryDrive motor

Owner:NINGBO HAIBO OFFICE MACHINERY

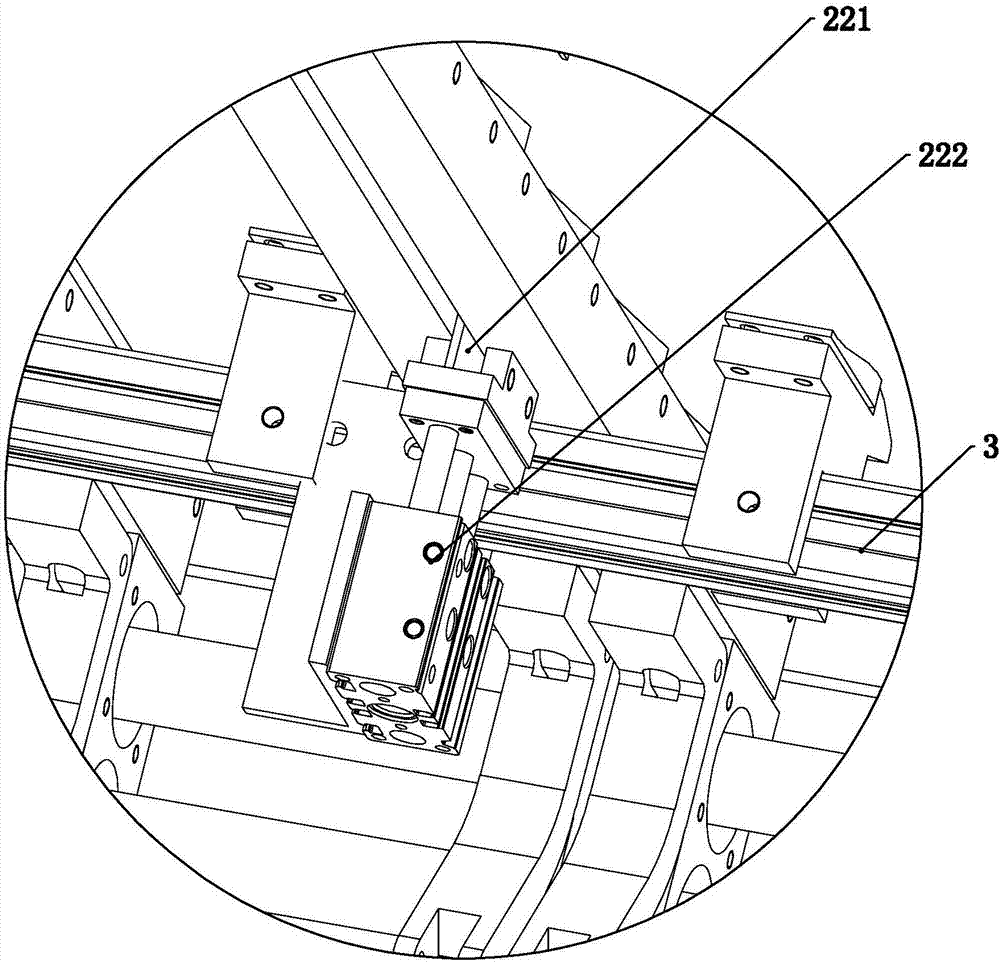

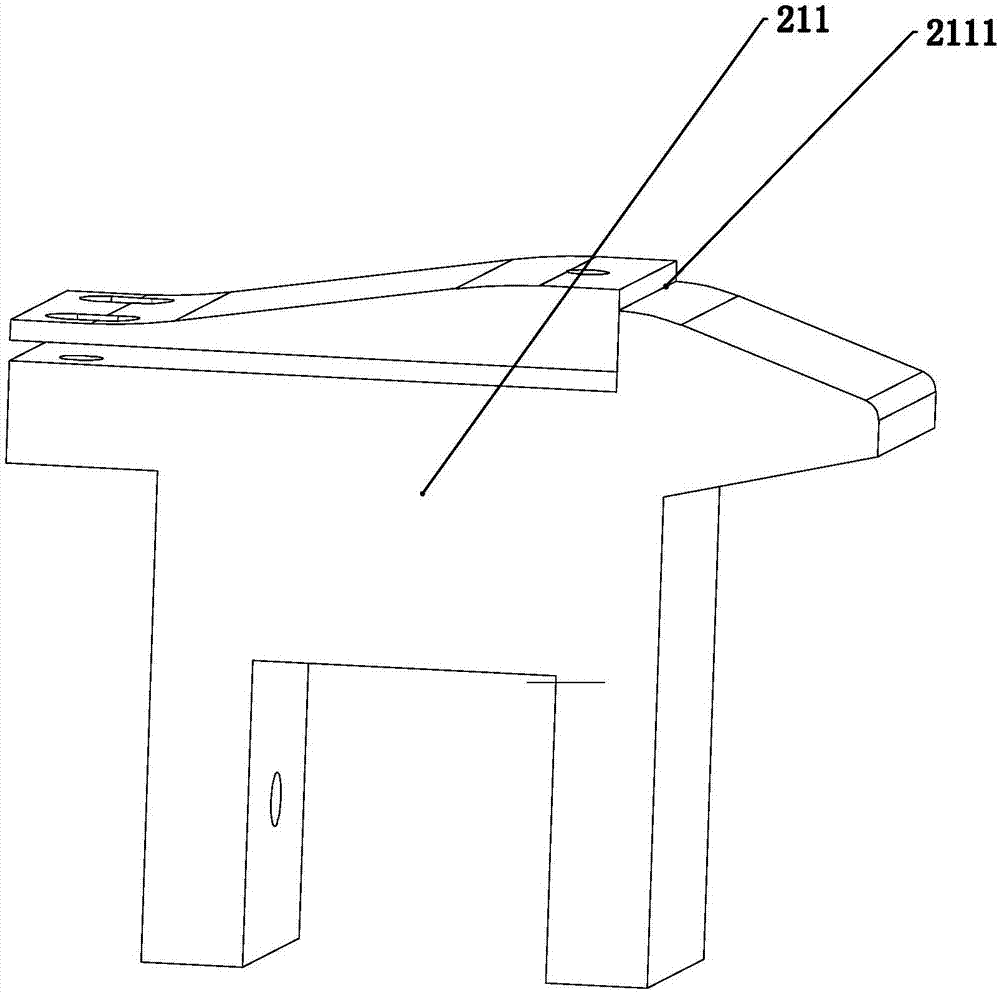

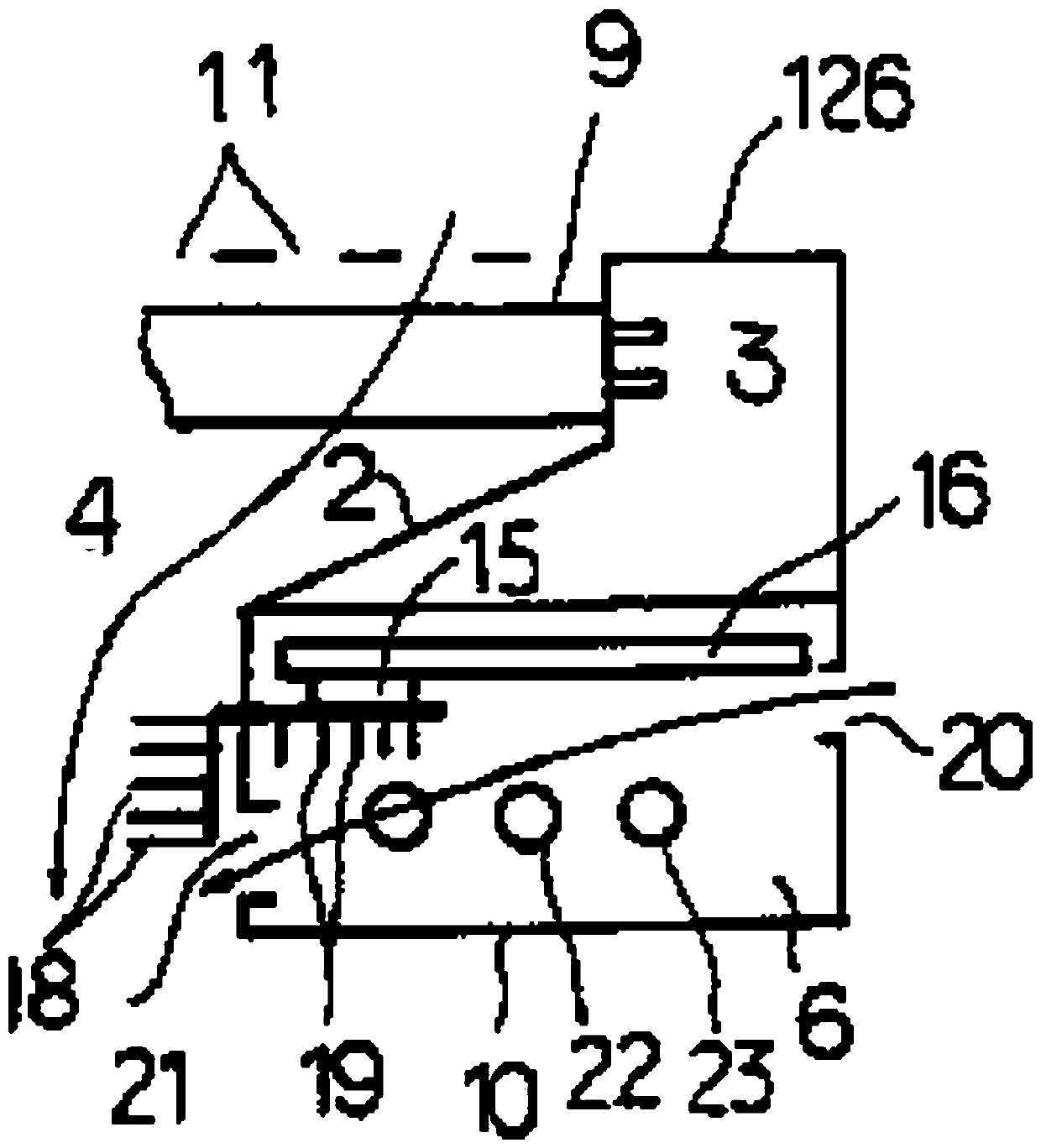

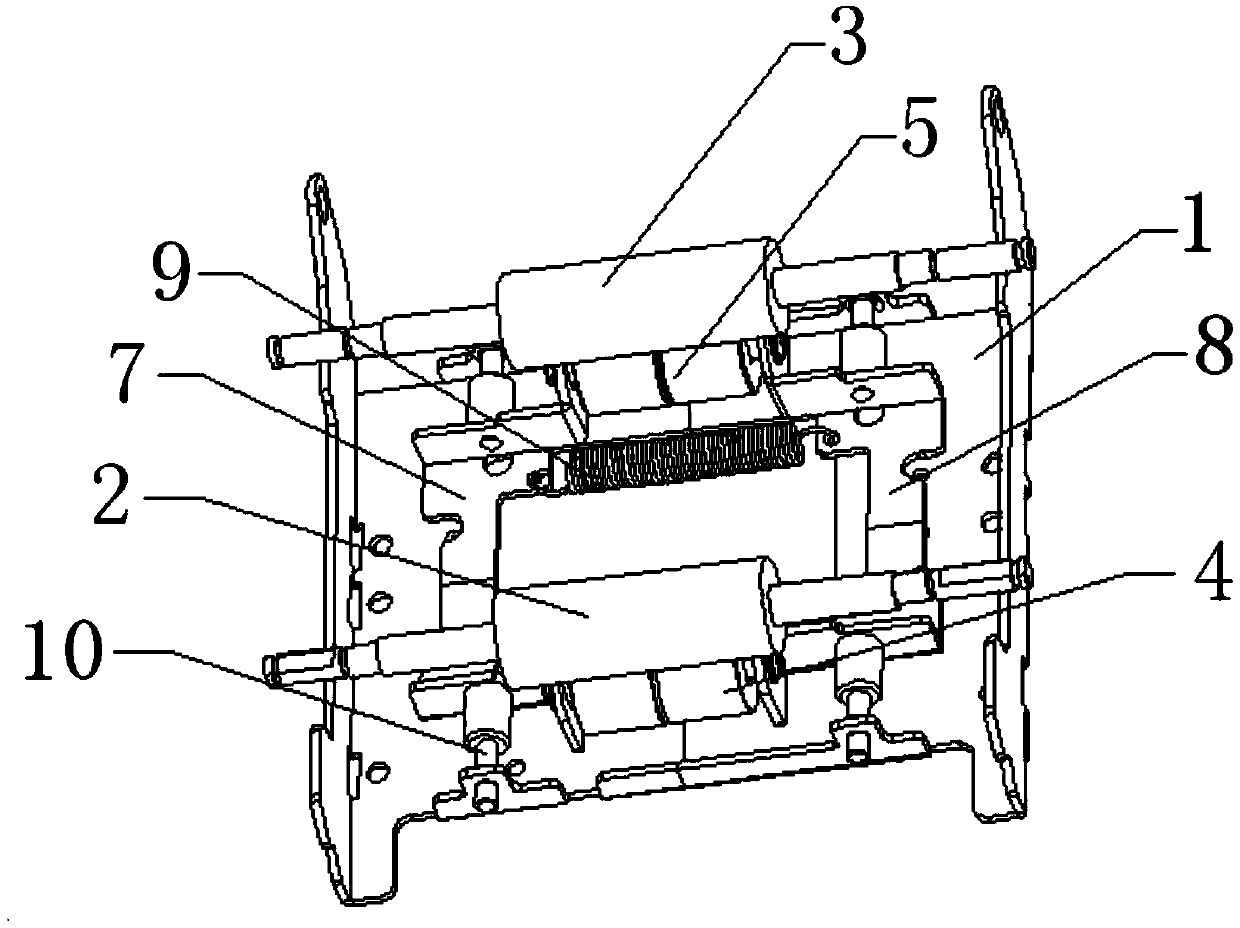

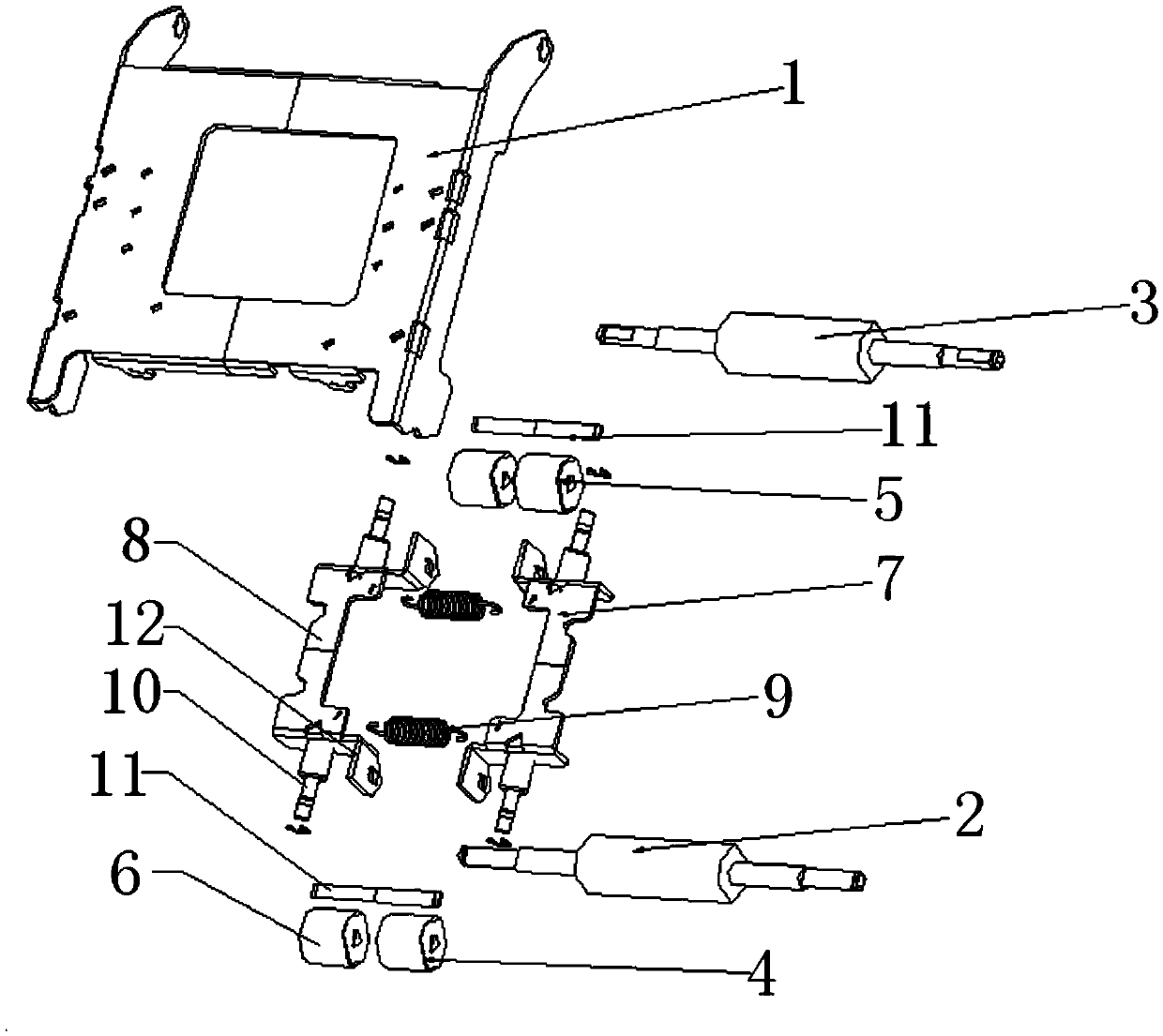

Needle printer sheet separation structure

ActiveCN106739549AAchieve separationEasy to useEnergy efficient computingOther printing apparatusEngineeringMechanical engineering

The invention discloses a needle printer sheet separation structure. The needle printer sheet separation device comprises a layering device which is installed in a printer for guiding a client sheet and a retention sheet correspondingly. The layering device comprises a first guide part, a second guide part and a third guide part, wherein the first guide part and the second guide part are used for guiding the two edge positions of the client sheet and the retention sheet, and the third guide part is used for guiding the middle positions of the client sheet and the retention sheet. The first guide part, the second guide part and the third guide part are provided with upper guide faces used for guiding paper feeding of the client sheet, and lower guide arc faces used for guiding paper feeding of the retention paper, the upper guide faces are connected with the lower guide arc faces through guiding faces. The first guide part and the second guide part protrude out of the third guide part so as to form a U-shaped structure. The client sheet and the retention sheet can be effectively separated, in addition, when the client sheet passes through the laying device, the phenomenon that the layering device blocks the client sheet, and consequently paper is stuck cannot happen, and normal use of the sheet separation printer is ensured.

Owner:JIANGMEN DASCOM COMP PERIPHERAL

Double-side paper feeding device

InactiveCN101237508ANo paper jamsAccurate operationPictoral communicationPulp and paper industryPaper sheet

Owner:PRIMAX ELECTRONICS LTD

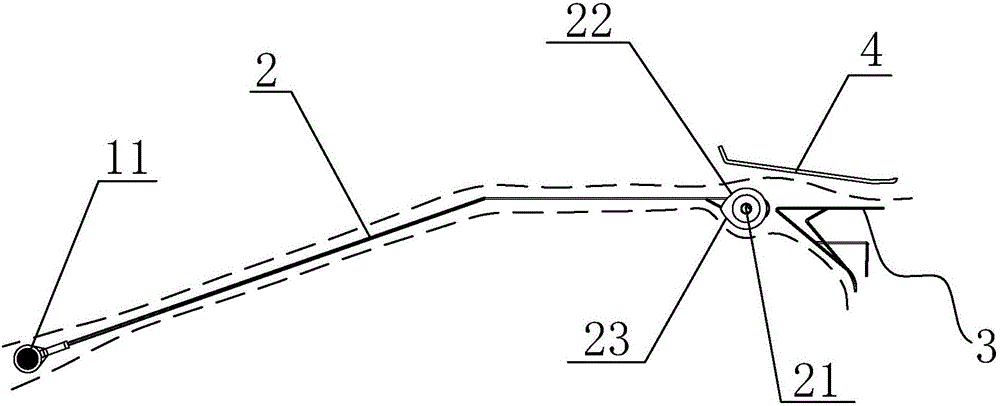

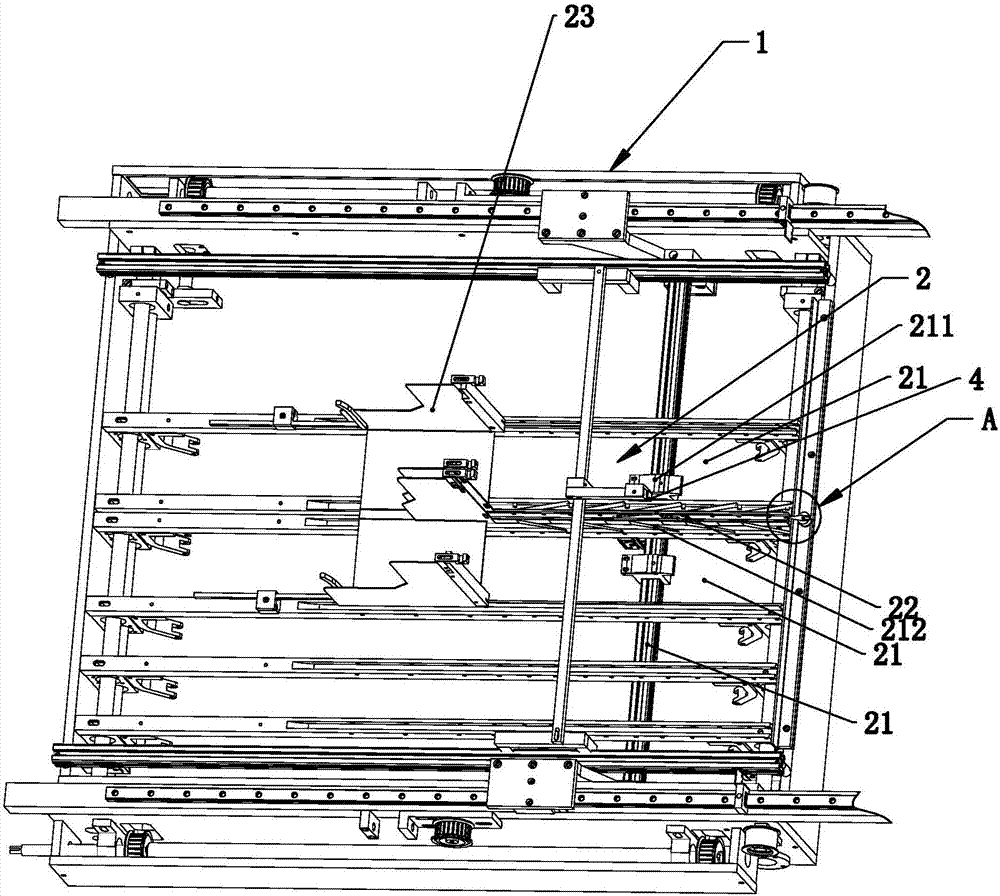

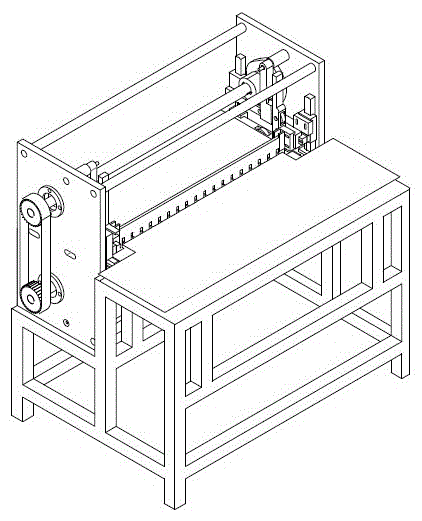

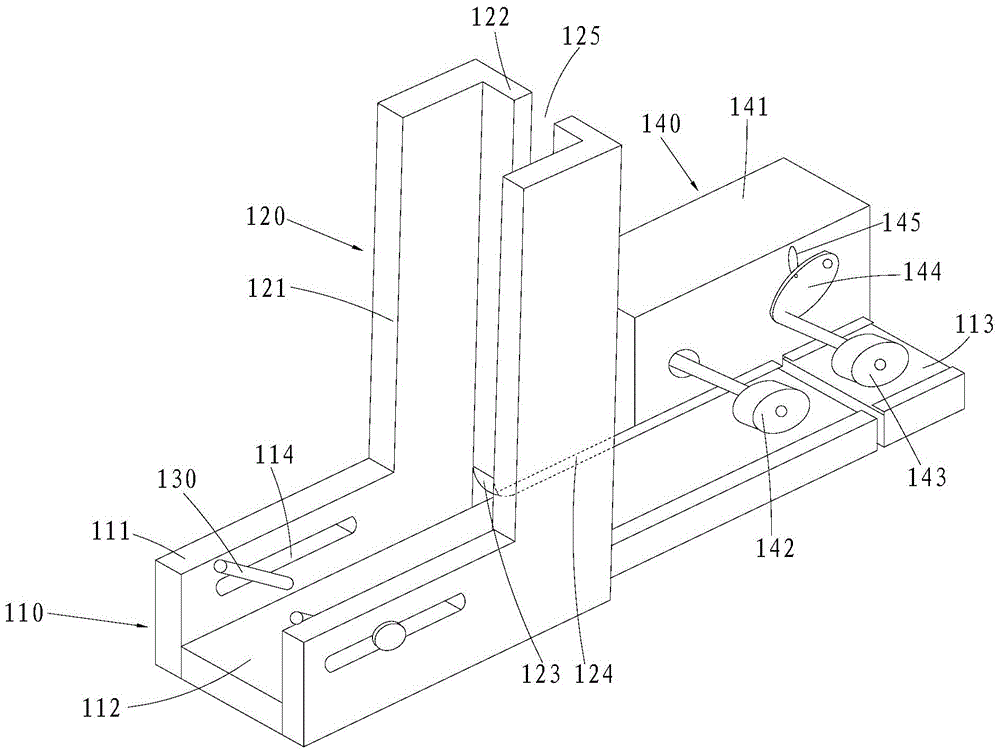

A feeding device for an edge wrapping machine

ActiveCN106185394BEasy to pushGuaranteed to pick upRegistering devicesArticle feedersCardboardPulp and paper industry

The invention relates to an edge-covering machine, and particularly relates to a device for conveying paper boards on a cover making machine and paper thereof. The invention provides the following technical scheme: a feeding device of an edge-covering machine is characterized in that a conveying rail comprises paper board conveying rails and a paper conveying rail; a movable rod is arranged below the conveying rail; the two ends of the movable rod are arranged on a rack through a support and a guide rail; a pushing block at a place corresponding to the paper conveying rail is a paper pushing block; the paper pushing block is arranged on the movable rod through a cylinder; an induction head is arranged above the front end of the paper conveying rail; and the induction head controls telescoping of the cylinder by inducing whether paper exists on the front end of the paper conveying rail or not, thus enabling the paper pushing block to push paper or not. With the adoption of the abovementioned scheme, the invention provides a feeding device of an edge-covering machine, which is simple in structure, convenient to use, and capable of conveying hard paper boards at the two sides and soft paper at the middle part simultaneously.

Owner:浙江浩达智能装备股份有限公司

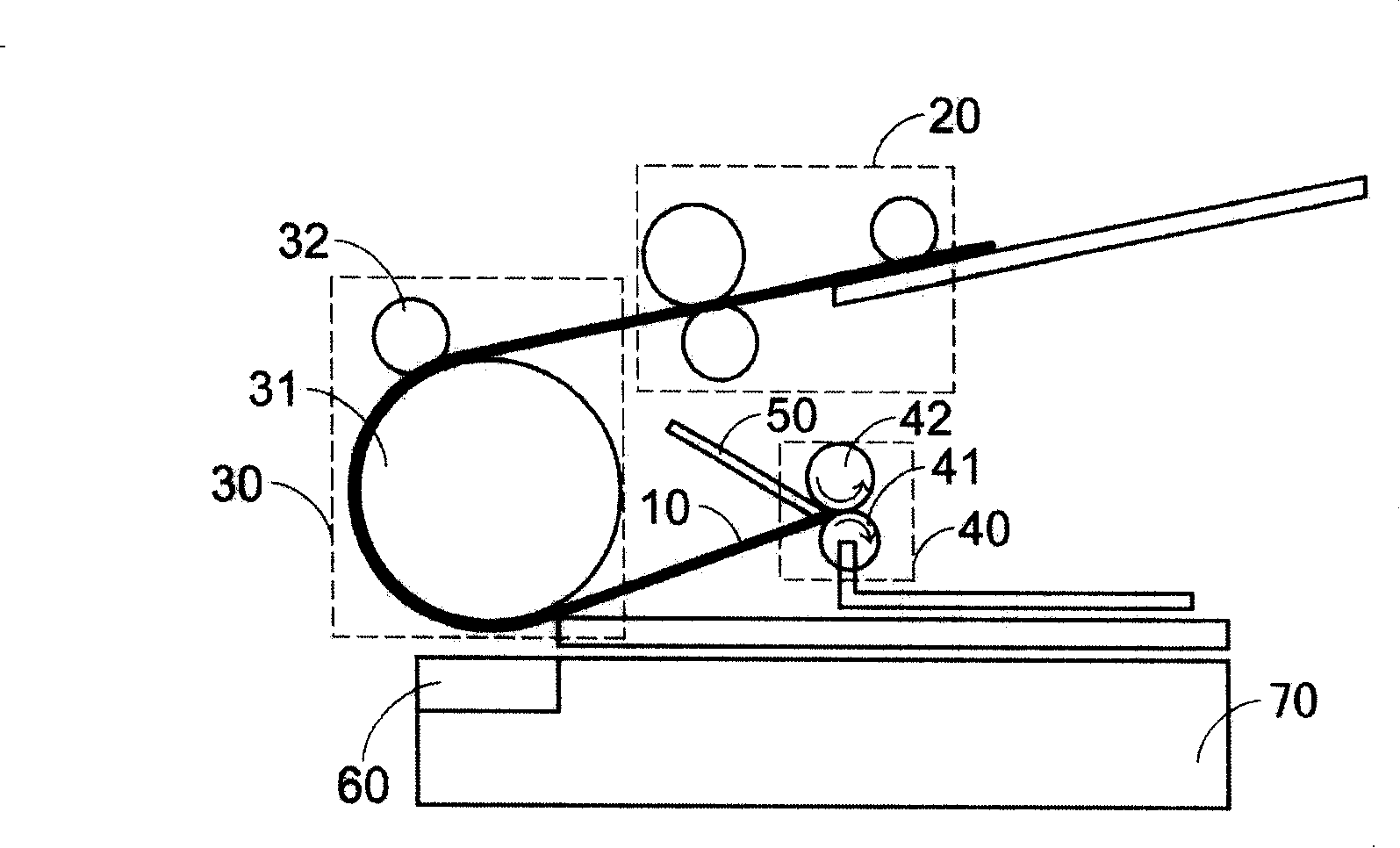

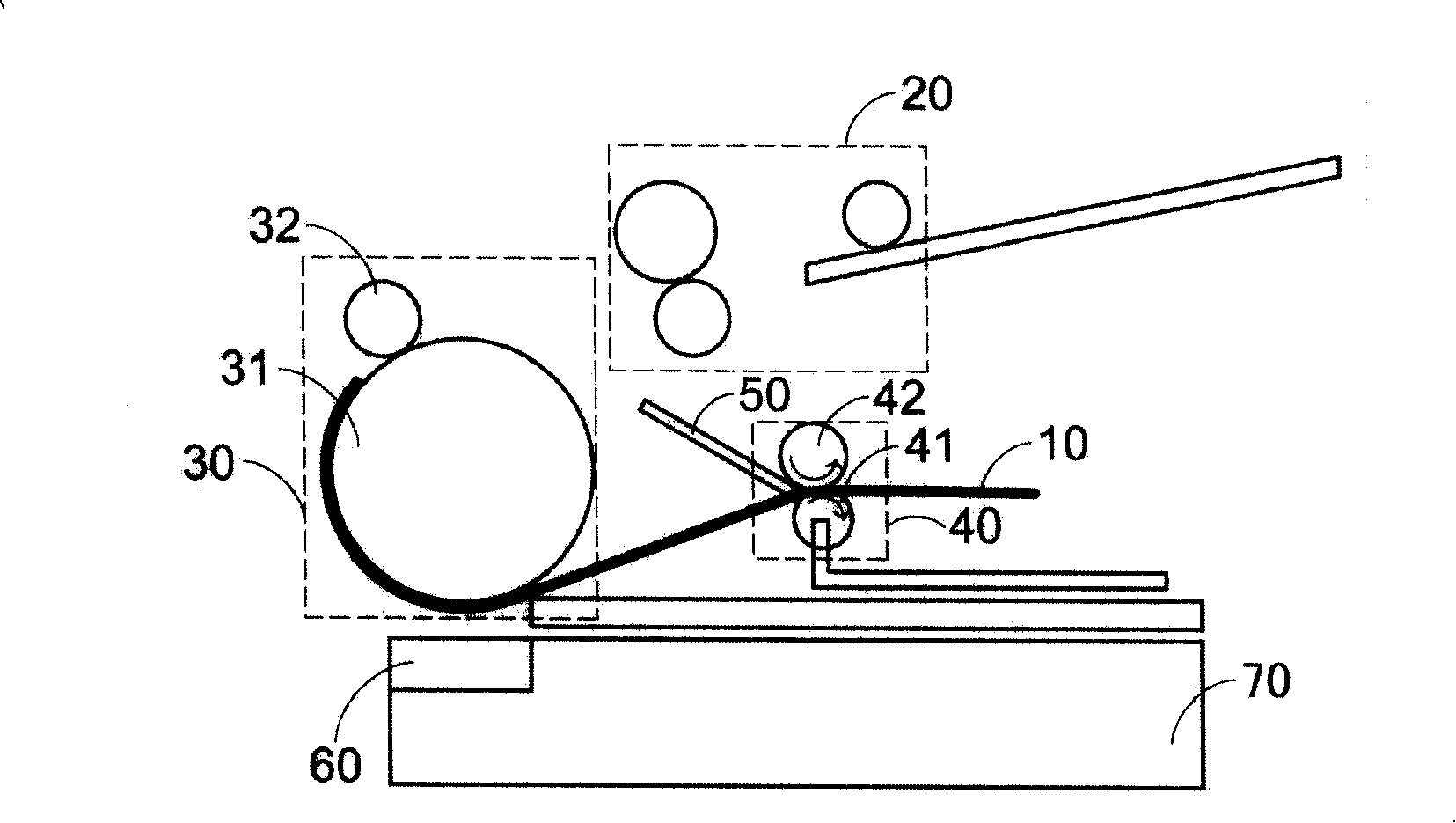

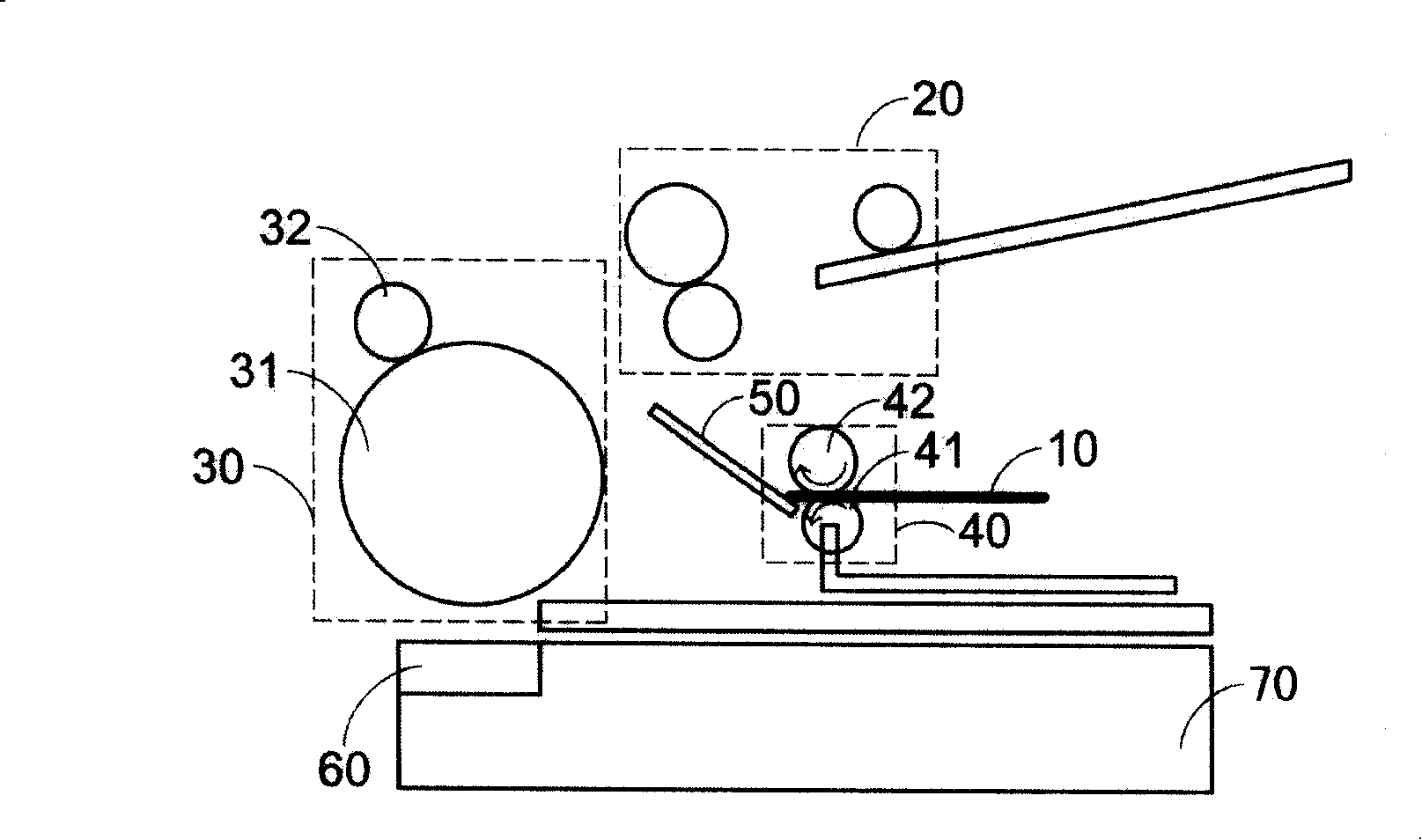

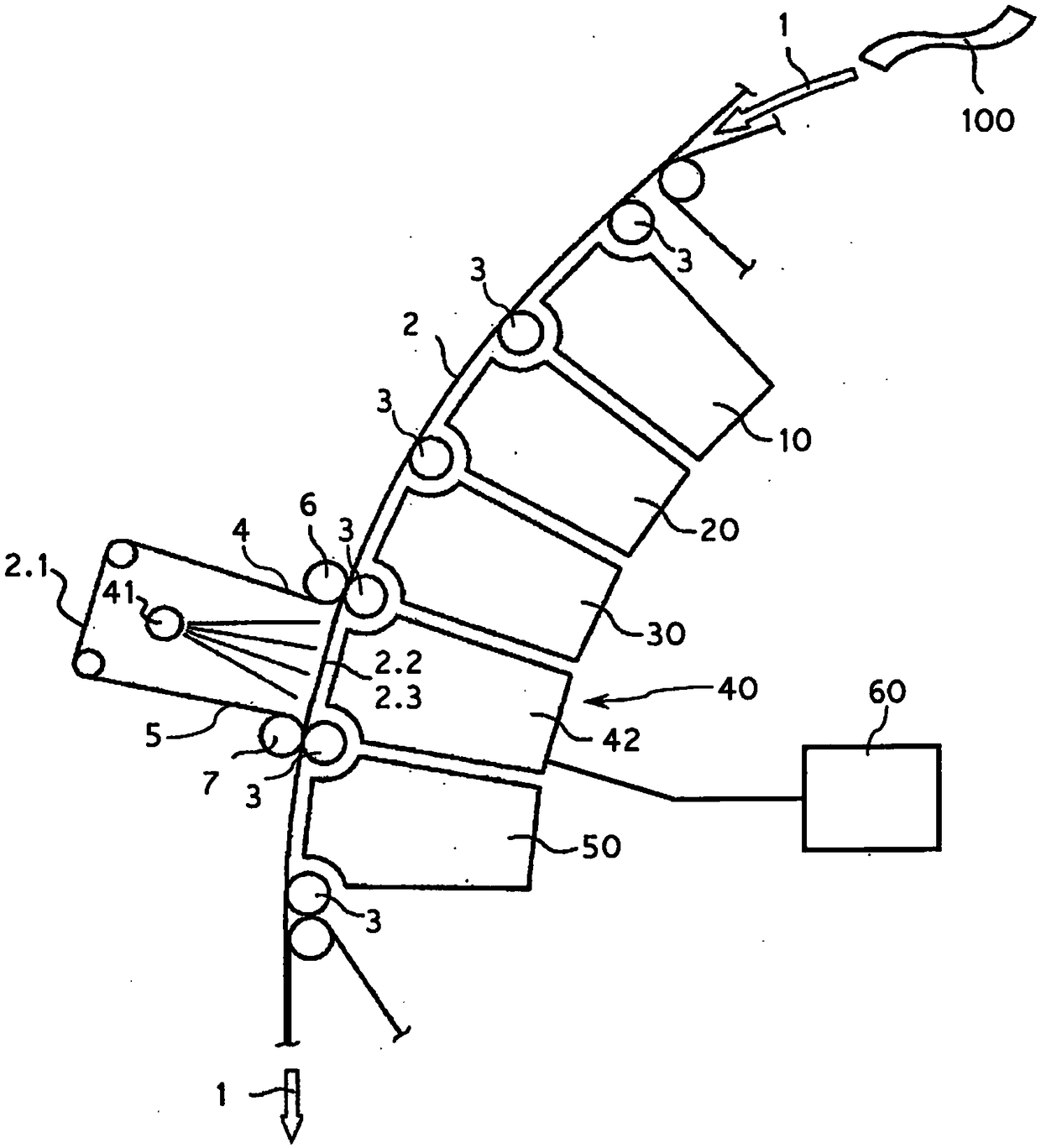

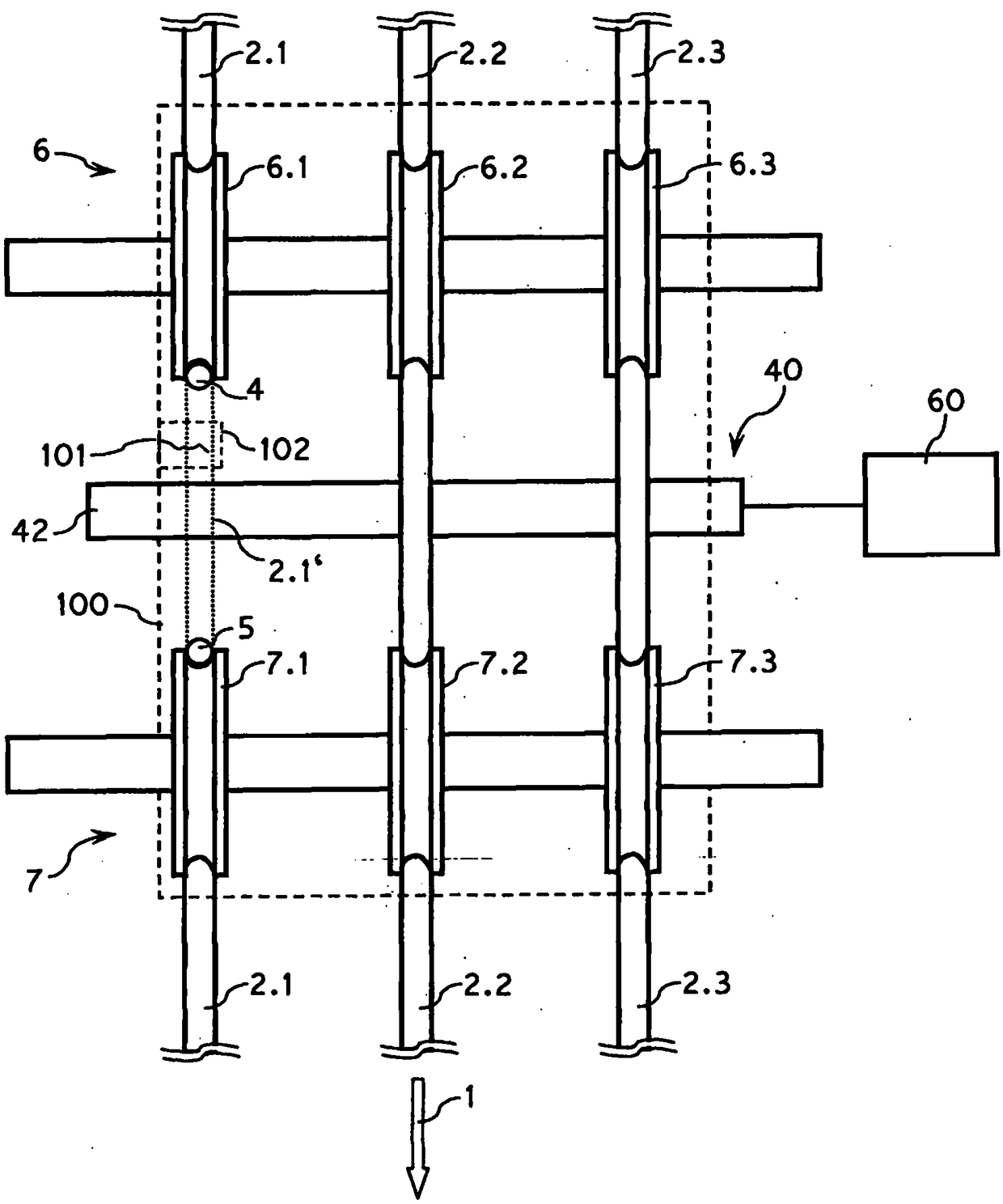

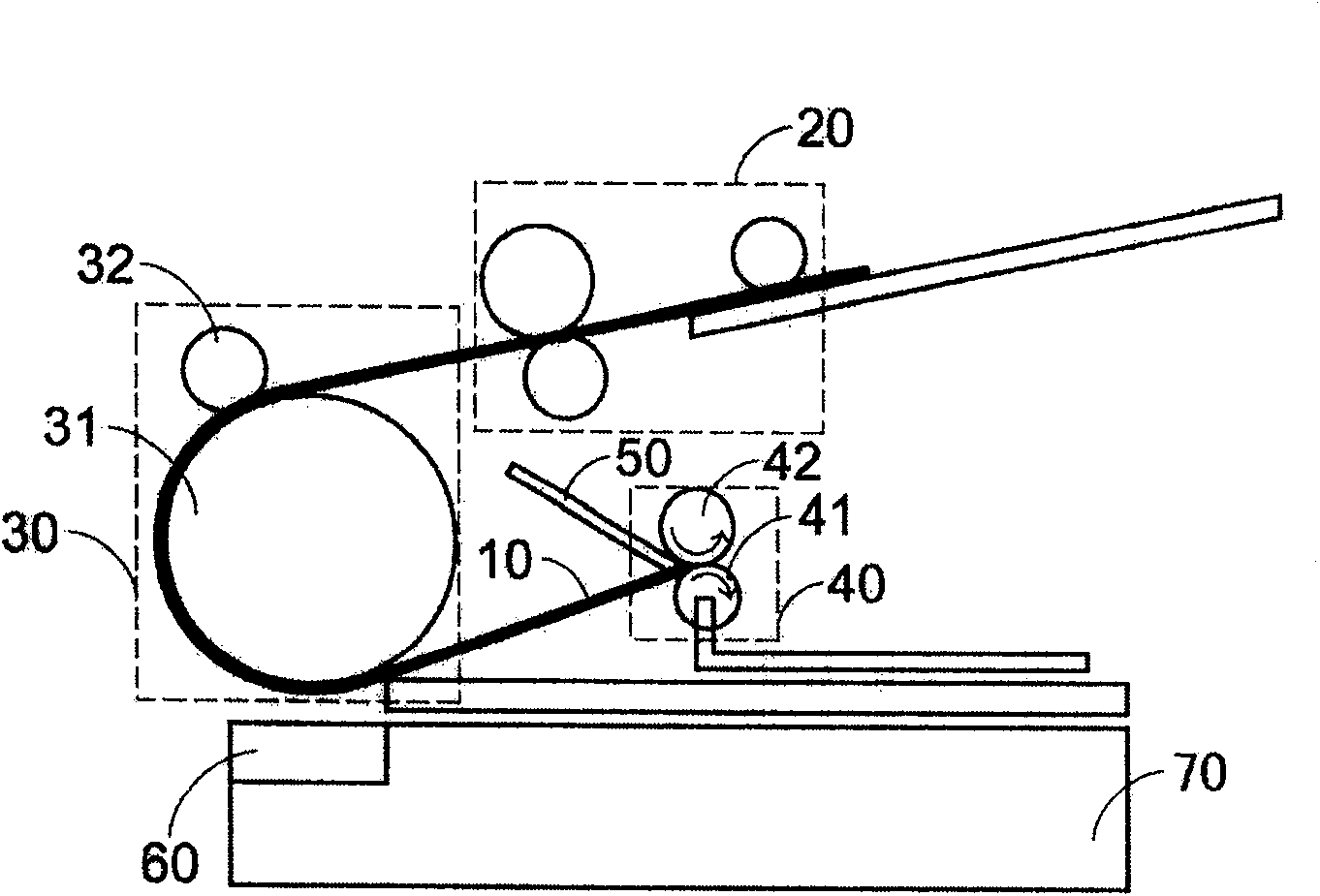

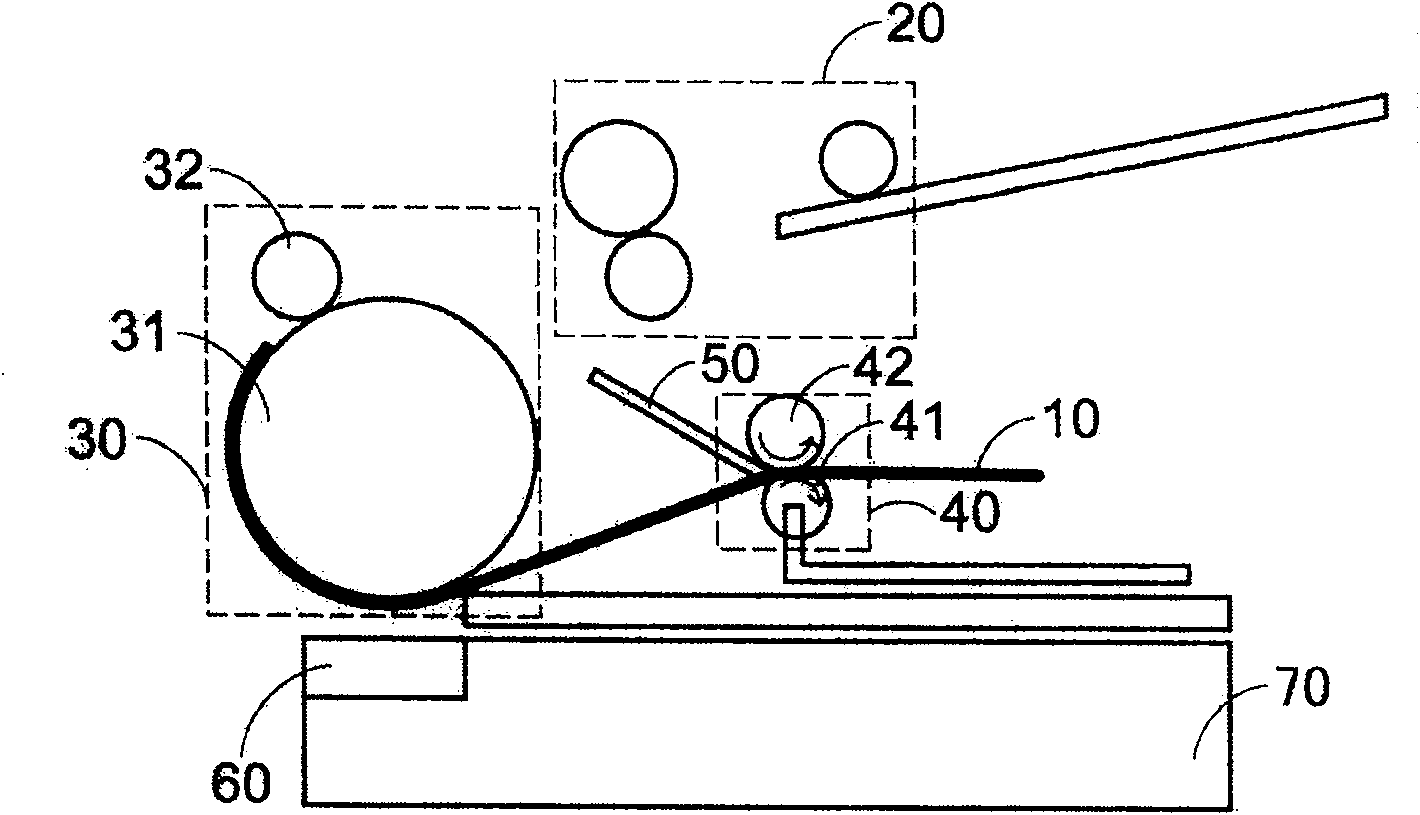

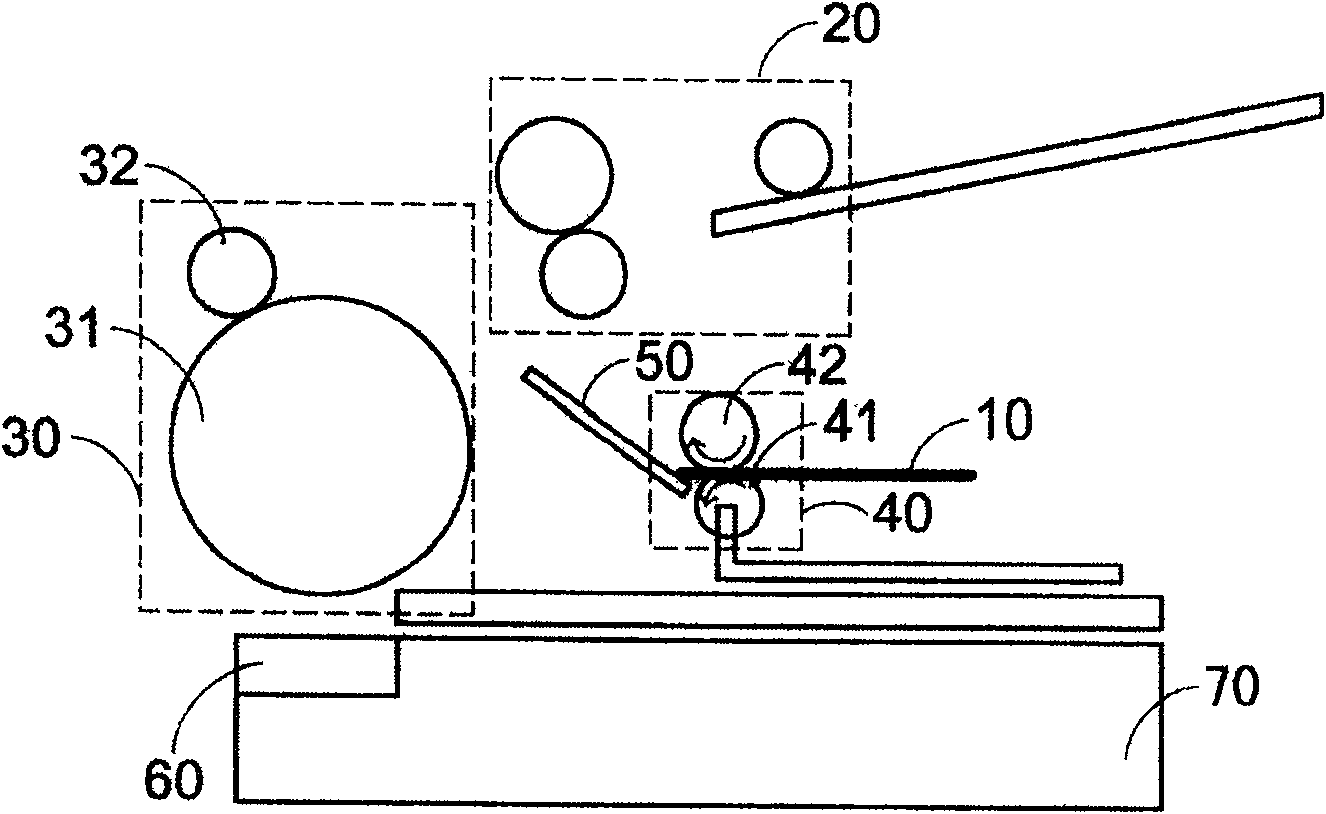

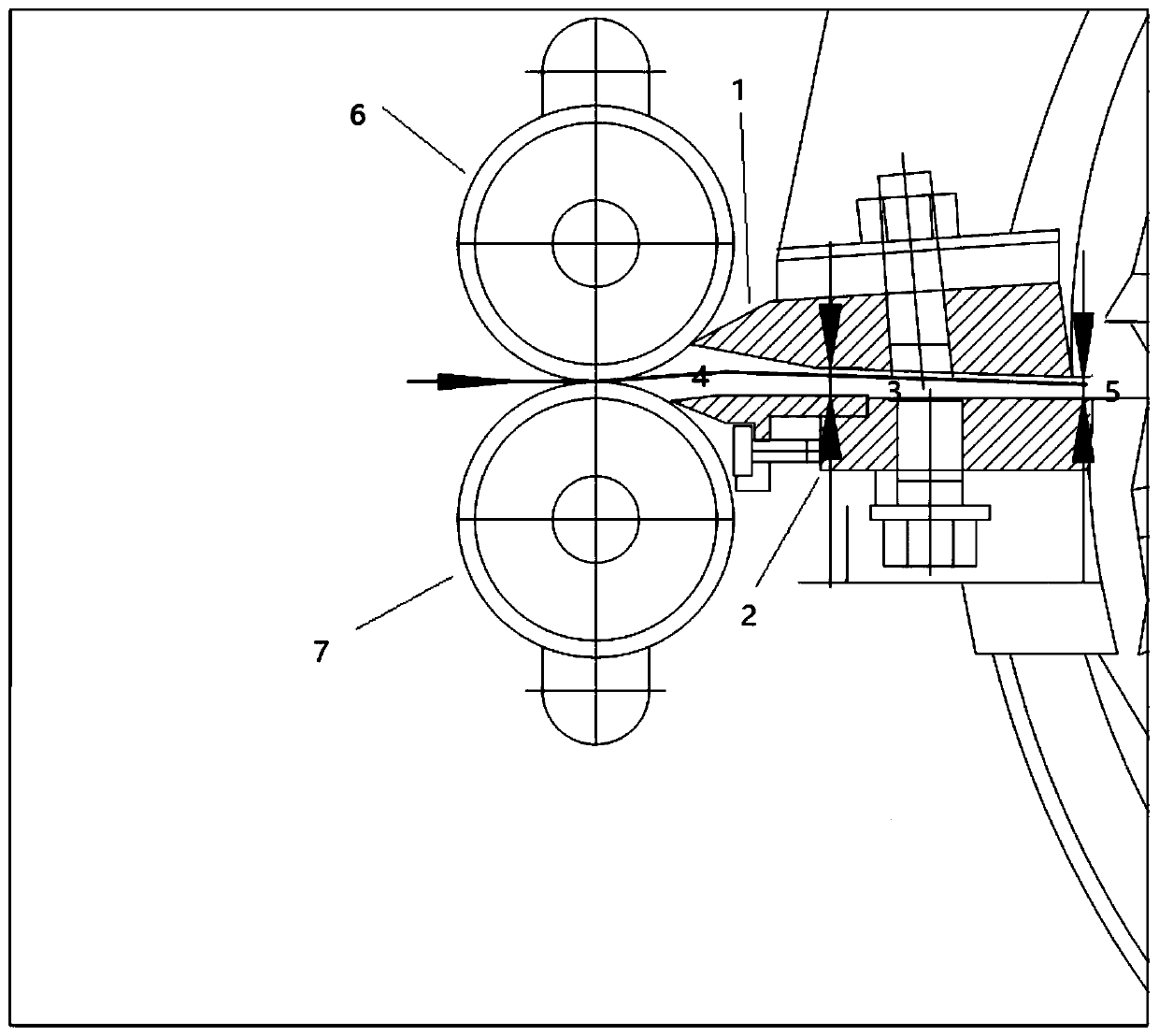

Equipment for processing sheets

ActiveCN107690414BCheck thoroughly and comprehensivelyReduce the possibility of failurePaper-money testing devicesArticle feedersEngineeringBank note

The invention discloses a banknote handling machine, in which banknotes (100) are guided by means of a conveyor belt (2) through two parts (41, 42) of an inspection device (40). The conveyor belt is at least partially guided away from the inspection device by means of guide rollers to allow a better inspection of the banknotes and a trouble-free transport of the banknotes.

Owner:GIESECKE & DEVRIENT CURRENCY TECHNOLOGY GMBH

Automatic paper feeding structure of shredder

InactiveCN102294291BImprove work efficiencyHigh feeding reliabilityGrain treatmentsPulp and paper industryAxial distribution

The invention discloses an automatic paper feeding structure of a shredder. The automatic paper feeding structure comprises a frame and a paper feeding channel formed above the frame, wherein the paper outlet of the paper feeding channel is positioned above the paper inlet of a shredding roll set of the shredder. The automatic paper feeding structure is characterized in that: a plurality of paperdistributing needle stands rotating around a fixing shaft are distributed on the fixing shaft of the frame along the axial direction; a paper distributing needle is inserted into each paper distributing needle stand; the paper distributing needles are distributed in sequence in a stepped form in the height direction along the axial direction of the fixing shaft; the needle point of each paper distributing needle faces the paper discharging direction of the paper feeding channel; the frame is provided with a camshaft which is parallel to the fixing shaft; cams which can rotate synchronously along the camshaft and are matched with the paper distributing needle seats one by one are distributed on the camshaft along the axial direction; and the cams act on the paper distributing needle seats to drive corresponding paper distributing needles to rotate towards the paper inlet of the shredding roll set in sequence. Compared with the prior art, the automatic paper feeding structure has the advantages of high paper feeding reliability and capabilities of realizing graded paper feeding and increasing the working efficiency of the shredder.

Owner:NINGBO OFITECH BUSINESS MACHINESE

Rapid and stable paper feeding mechanism for printer

The invention discloses a rapid and stable paper feeding mechanism for a printer, belongs to the technical field of printer equipment, and particularly relates to the rapid and stable paper feeding mechanism for the printer. The rapid and stable paper feeding mechanism for the printer is simple in structure and rapid and stable in paper feeding. The rapid and stable paper feeding mechanism for theprinter comprises a heat dissipation hole, a heating roller, a machine box, an electrode, a baffle, a printing bin, a blocking brush, a paper outlet, a paper brush, a mounting frame, a mounting plate, a paper inlet, a machine base, a guide roller, an auxiliary roller and a roller frame, and is characterized in that the printing bin is arranged in the machine box, the heating roller is arranged above the printing bin, the heat dissipation hole is formed above the heating roller, a motor of the heating roller is arranged in the machine box, the base is arranged at the lower portion of the machine box, a roller frame is arranged in the base, a guide roller and an auxiliary roller are arranged on the roller frame, and the paper inlet and the paper outlet are formed corresponding to the guideroller and the auxiliary roller.

Owner:沈阳知源科技有限公司

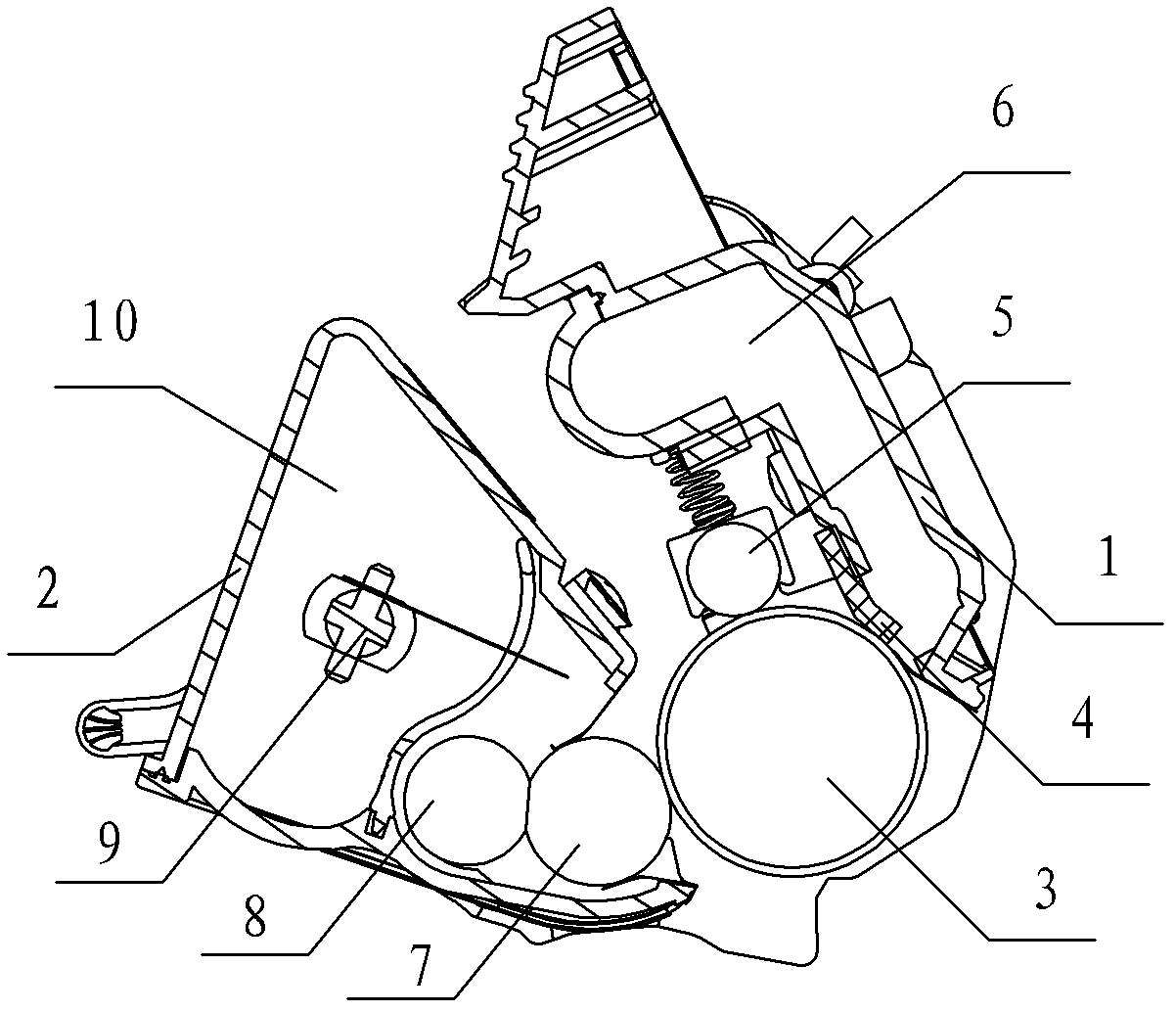

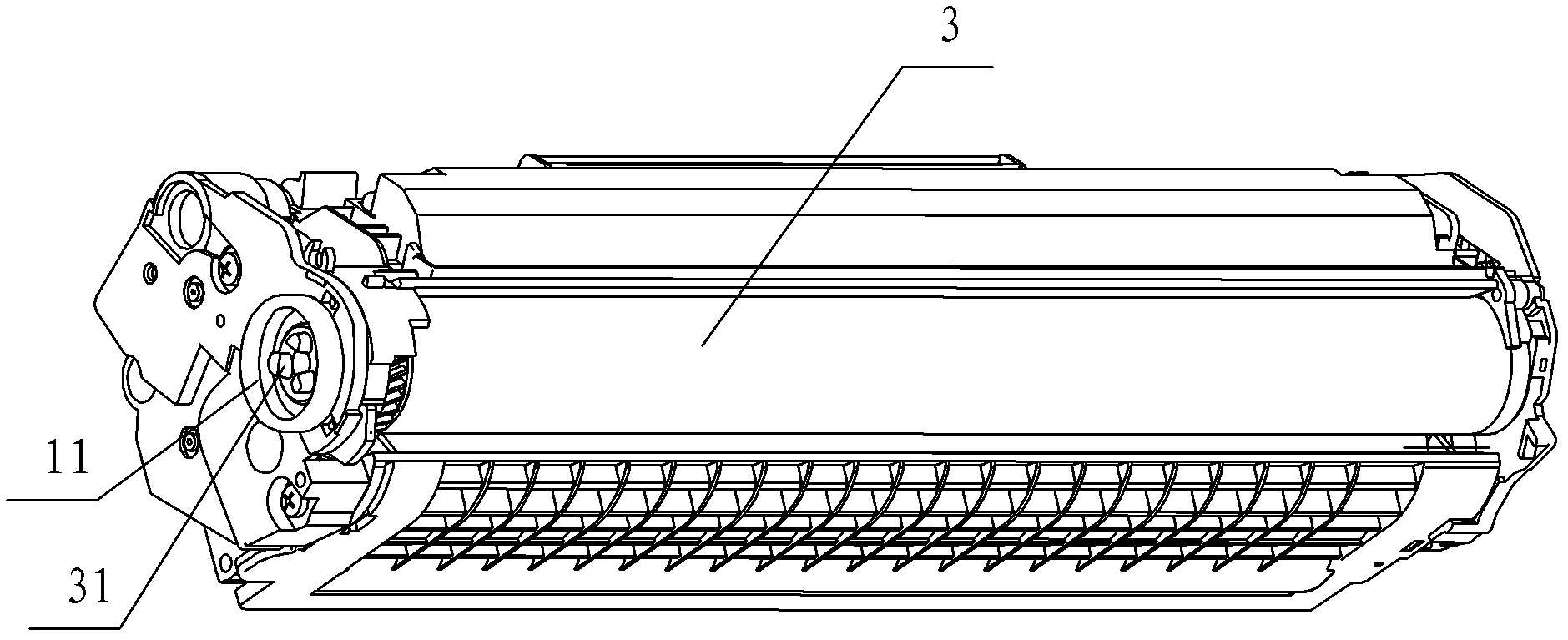

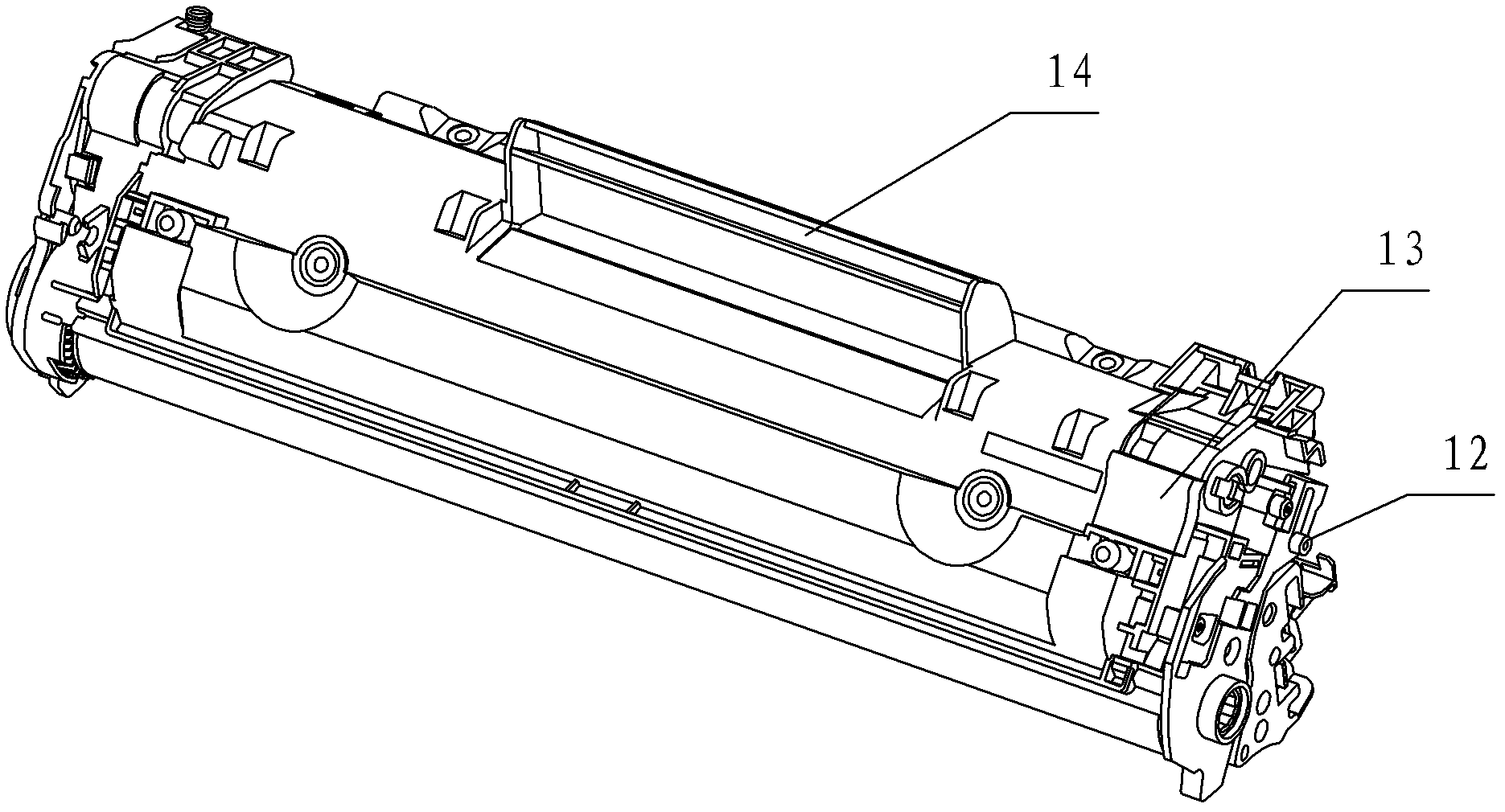

Processing box and method for accurately positioning same

InactiveCN102636983APrecise positioningNo blushingElectrography/magnetographyEngineeringImaging equipment

The invention aims to provide a processing box capable of accurately positioning electronic photographing imaging equipment and a method for accurately positioning the processing box. The processing box provided by the invention comprises a box body, wherein a powder bin containing carbon powder is arranged in the box body; the box body is provided with a pressed part; and the pressed part is located on the downstream side in the mounting direction of the processing box.

Owner:PROSPECT IMAGE PROD LIMITED OF ZHUHAI

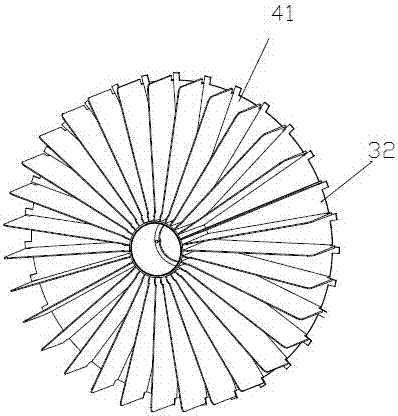

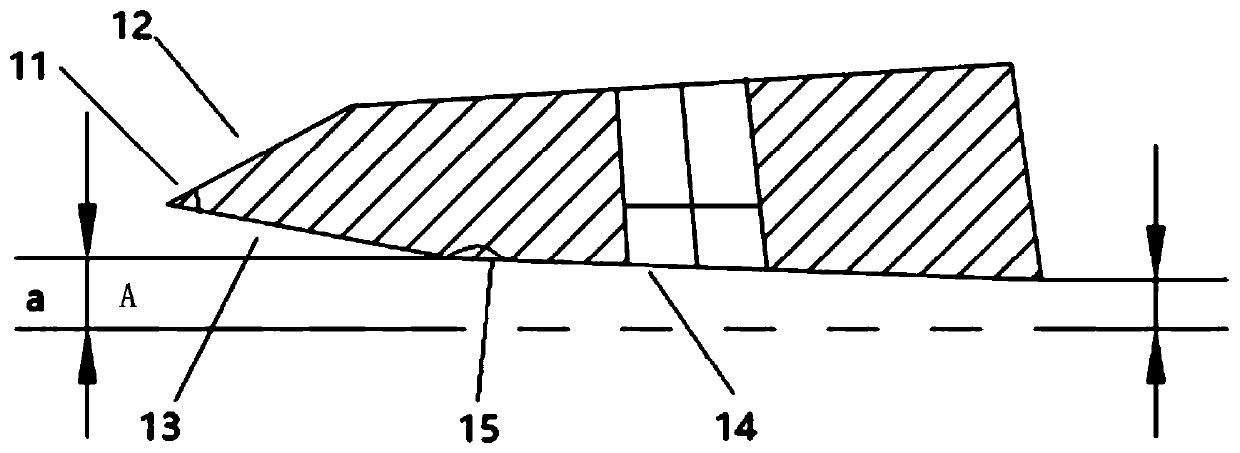

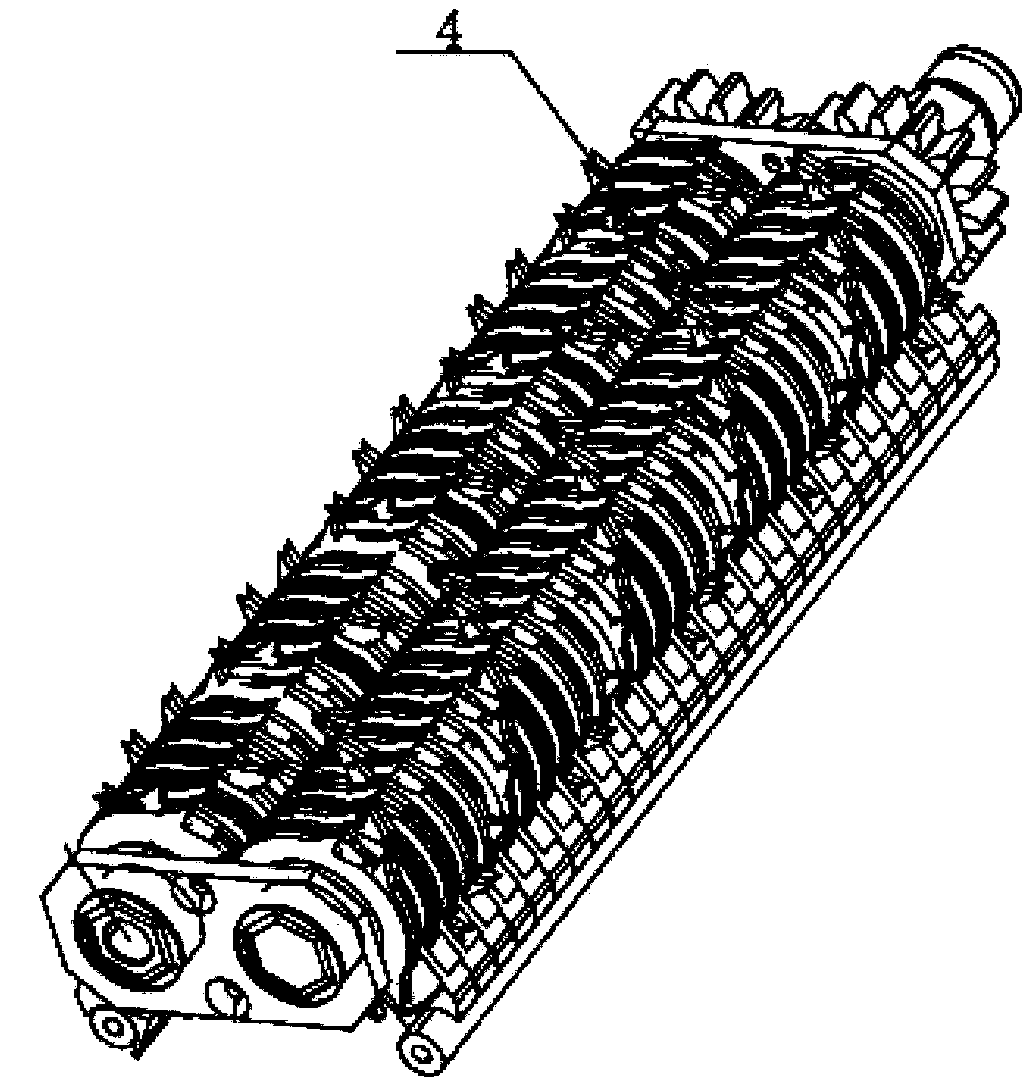

A paper folding fan forming equipment

ActiveCN103350526BPass smoothlyNo paper jamsPaper/cardboard articlesMechanical engineeringRevolutions per minute

The invention discloses paper fan folding and forming equipment which is characterized by comprising a drive mechanism, a driving rolling gear and a driven rolling gear, wherein the drive mechanism is used for driving the driving rolling gear to rotate, the driving rolling gear is used for driving the driven rolling gear to rotate, and the driving rolling gear and the driven rolling gear adopt identical structures; racks are axially and uniformly distributed on the periphery of the driving rolling gear, the cross section of each rack adopts an isosceles triangle shape, the included angle between two inclined surfaces of each rack ranges from 25 degrees to 35 degrees, and the included angle between adjacent surfaces of two racks ranges from 30 degrees to 45 degrees; and the revolving speed of the driving rolling gear or the driven rolling gear is 0-12 revolutions per minute, and after a piece of whole flat paper passes through a gap between the driving rolling wheel and the driven rolling wheel, a piece of folding-fan-shaped paper with a plurality of peaks and valleys is formed.

Owner:CRE8 DIRECT NINGBO CO LTD

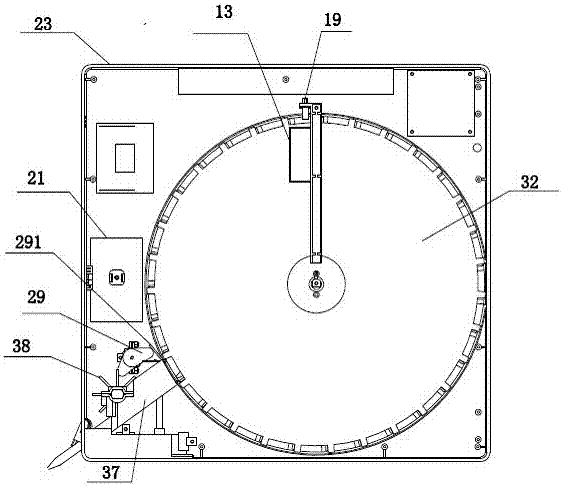

Automatic advertisement vending machine

PendingCN108010223ASimple structureWith ad play functionApparatus for meter-controlled dispensingArticle advertisingPulp and paper industry

The invention discloses an automatic advertisement vending machine. The automatic advertisement vending machine comprises a front shell of a mainframe, a panel mechanism, a paper discharging mechanism, a detection mechanism and a main control PCB. The panel mechanism is movably connected with the front shell of the mainframe through one side of a hinge, a paper storage box is arranged at the backend of the front shell of the mainframe, the main control PCB is loaded into the front shell of the mainframe and locked by screws, a paper storage panel opposite to the paper storage box is arrangedon the front end surface of the front shell of the mainframe, and multiple storage cavities are formed in the paper storage box in a surrounding mode. The paper discharging mechanism is installed at the bottom of the side surface of the front shell of the mainframe, the detection mechanism is mounted on the rotating paper storage box, and the storage paper box is loaded into the front shell of themainframe and driven by a motor mechanism to rotate. The motor mechanism includes a third motor, an upper cover of the third motor and a lower cover of the third motor. The automatic advertisement vending machine has a simple structure, an advertisement playing function, a reasonable overall structure design and no paper jamming problem, achieves purchasing of advertisements through a scanning code, and is convenient and quick.

Owner:武凤英

Paper containing preaggregated filler and process for producing the same

ActiveCN101370981BImprove printing qualityImprove smoothnessPaper coatingPaper/cardboardPolymer sciencePolysaccharide

Owner:HARIMA CHEM INC

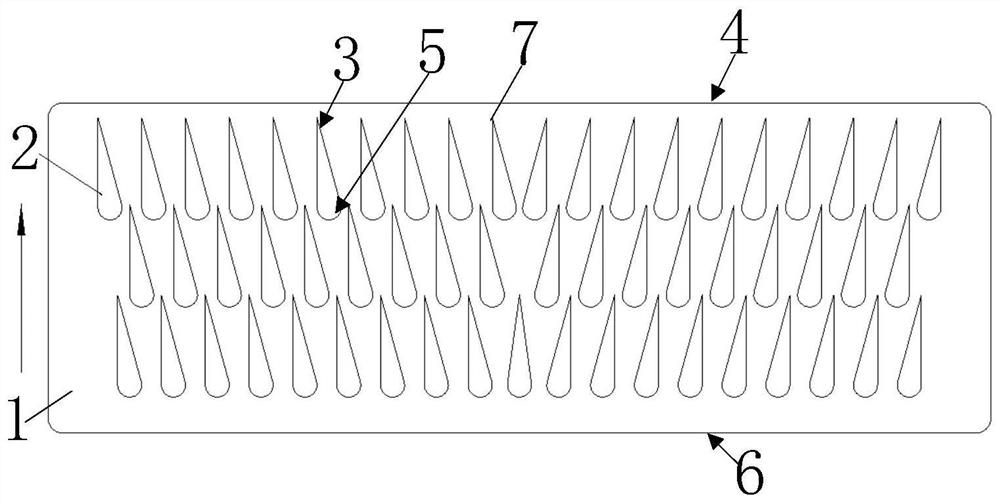

Anti-paper-jam channel plate and stamping machine

PendingCN112046160AReduce jam rateImprove reliabilityArticle feedersStampingStructural engineeringIndustrial engineering

The invention provides an anti-paper-jam channel plate and a stamping machine. The channel plate comprises a plate body used for conveying paper and a plurality of through holes used for preventing paper jam, and the plurality of through holes are formed in the plate body. The anti-paper-jam channel plate has the beneficial effects that the channel plate with the through holes is designed, the effective contact area of a channel and paper is greatly reduced through the dense through holes, and therefore the paper jam probability caused by the fact that the channel is wet or not enough in smoothness is reduced. Paper is prevented from adhering to the plate body, the paper is conveniently separated from the plate body, evaporation of water in the channel is facilitated, and the reliability of the channel is improved.

Owner:BEIJING C&W ELECTRONICS GRP

origami machine

InactiveCN103538294BGuaranteed accuracyRealize the purpose of repeated folding in the forward and reverse directionsMechanical working/deformationPulp and paper industryPaper sheet

The invention discloses a paper folding machine which comprises a rack, a paper folding mechanism and a driving device. The paper folding mechanism comprises an upper paper folding device (1), a lower paper folding device (2) and a synchronous belt wheel device, the upper paper folding device (1) comprises an upper paper folding baseplate (15), an upper paper pressing cam (102) and an upper paper pushing cam (101), the lower paper folding device (2) comprises a lower paper folding baseplate (25), a lower paper pressing cam (202) and a lower paper pushing cam (201), the synchronous belt wheel device comprises an upper synchronous belt wheel (30), a lower synchronous belt wheel (31) and a synchronous belt (32), two cams in the upper synchronous belt wheel (30) and the upper paper folding device (1) are coaxially and fixedly connected, two cams in the lower synchronous belt wheel (31) and the lower paper folding device (2) are coaxially and fixedly connected, and the upper synchronous belt wheel (30) and the lower synchronous belt wheel (31) is connected with the driving device. The paper folding machine can automatically fold paper to be in the shape of an accordion blade in positive and negative directions.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

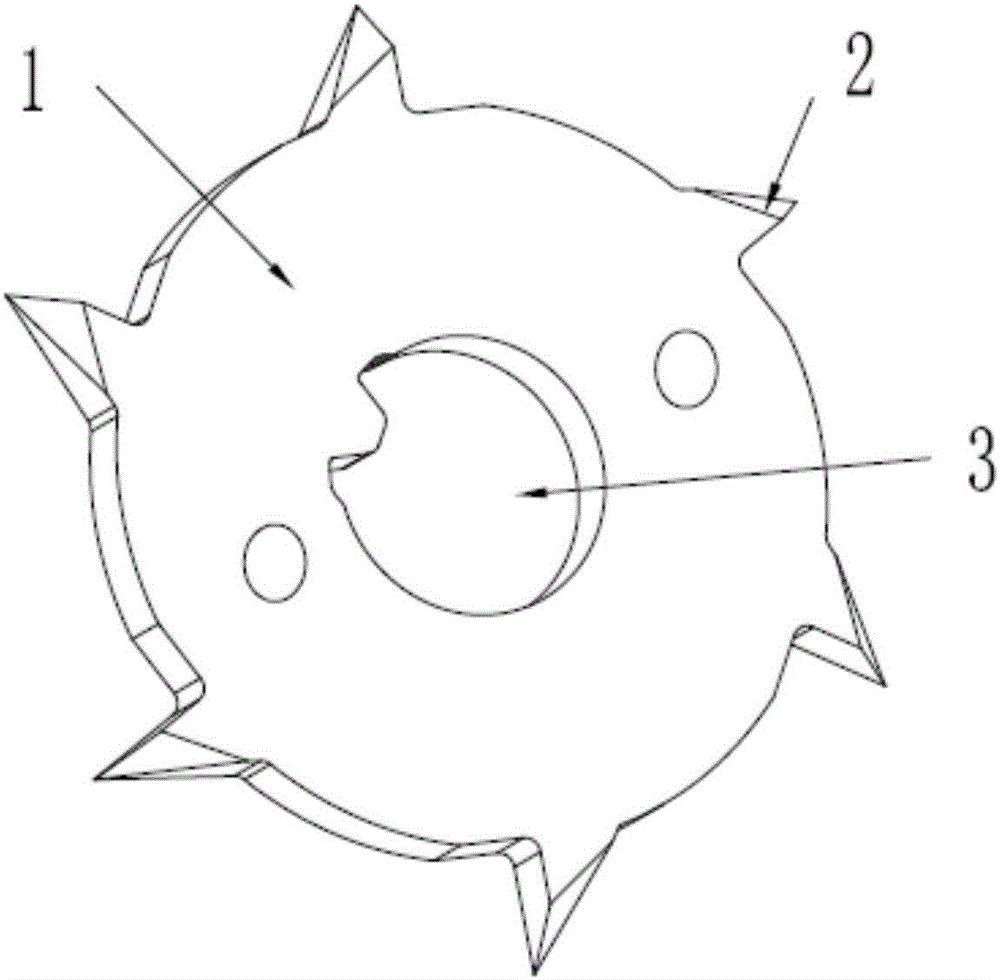

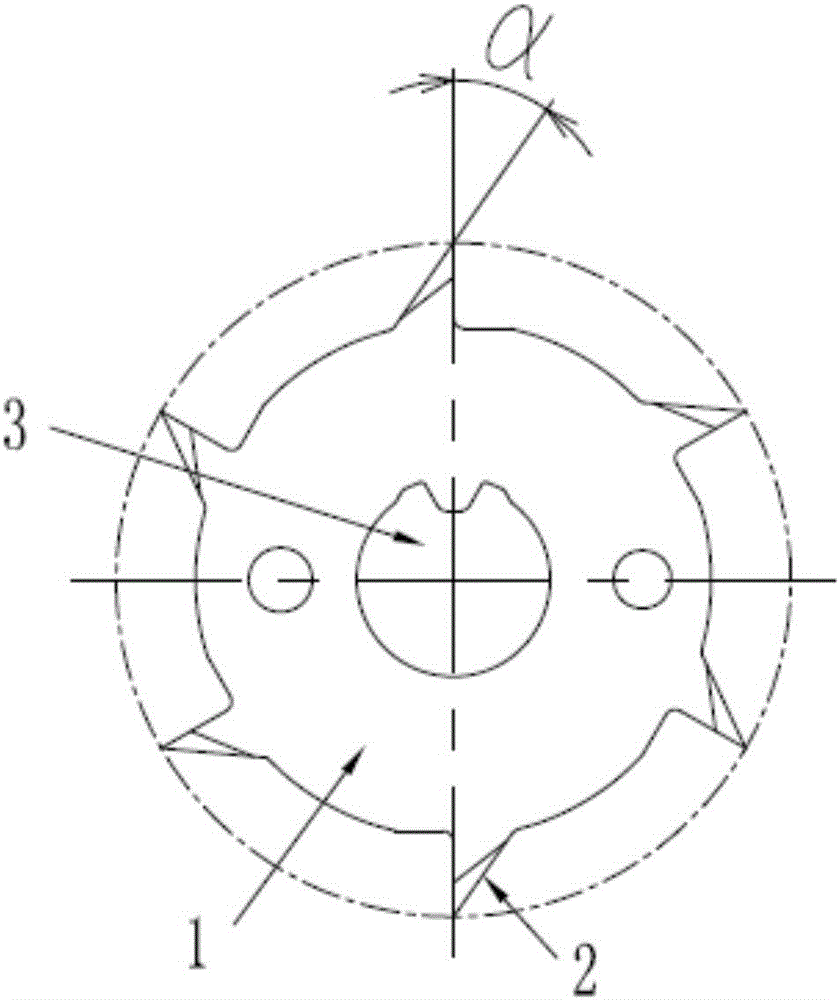

Single blade assembly of paper shredder

The invention discloses a single blade assembly of a paper shredder. The single blade assembly comprises a rotating shaft and a plurality of single blades. Each single blade comprises a circular piece and a plurality of cutting edges arranged on the circular piece in the circumferential direction. Each circular piece comprises a clamping and connecting hole used for clamping and connecting the rotating shaft. The single blades are coaxially connected to the rotating shaft in a sleeving manner through the clamping and connecting holes. An interval is arranged between every two adjacent single blades. According to the single blade assembly of the paper shredder, the single blade arrangement is adopted in the blades of the single blade assembly; and compared with the traditional double-blade arrangement, the technology is simple, cost is low, the manufacturing speed is high, and the phenomenon of paper clamping cannot happen.

Owner:宁波王兴工艺品有限公司

Feeding device of edge-covering machine

ActiveCN106185394AEasy to pushGuaranteed to pick upRegistering devicesArticle feedersCardboardPulp and paper industry

The invention relates to an edge-covering machine, and particularly relates to a device for conveying paper boards on a cover making machine and paper thereof. The invention provides the following technical scheme: a feeding device of an edge-covering machine is characterized in that a conveying rail comprises paper board conveying rails and a paper conveying rail; a movable rod is arranged below the conveying rail; the two ends of the movable rod are arranged on a rack through a support and a guide rail; a pushing block at a place corresponding to the paper conveying rail is a paper pushing block; the paper pushing block is arranged on the movable rod through a cylinder; an induction head is arranged above the front end of the paper conveying rail; and the induction head controls telescoping of the cylinder by inducing whether paper exists on the front end of the paper conveying rail or not, thus enabling the paper pushing block to push paper or not. With the adoption of the abovementioned scheme, the invention provides a feeding device of an edge-covering machine, which is simple in structure, convenient to use, and capable of conveying hard paper boards at the two sides and soft paper at the middle part simultaneously.

Owner:浙江浩达智能装备股份有限公司

Double-side paper feeding device

InactiveCN100574357CNo paper jamsAccurate operationPictoral communicationPaper sheetMultiple function

The present invention proposes a double-sided paper feeding device, which can be applied to various scanning devices such as facsimile machines, printers, scanners, and multi-function business machines. The double-sided paper feeding device includes: a paper fetching module, used to guide the paper to be fed into the first paper feeding channel; a paper control roller module, used to provide the first clamping force to feed the paper passing through the scanning module to a The paper input and output module, and the second clamping force make the paper fed in from the paper input and output module enter a second paper feeding channel, and then make the second side of the paper pass the scanning module; the paper input and output module provides a third The clamping force is used to feed out or feed the paper, and the third clamping force is smaller than the first clamping force and the second clamping force. When the second side of the paper needs to be scanned, the input and output rollers rotate in reverse to provide the third clamping force to feed the paper into the second paper feeding channel inside the duplex paper feeding device. The double-sided paper feeding device of the present invention can control the moving accuracy of the paper, thereby avoiding paper jamming.

Owner:PRIMAX ELECTRONICS LTD

A liquid electronic ink receiving medium

ActiveCN106915171BGood coating fastnessHigh gloss surfaceDuplicating/marking methodsWater dispersibleAdhesive

A liquid electronic ink receiving medium comprises a support body and an ink receiving layer on one side or both sides of the support body. The ink receiving layer comprises, by weight, 30-60 parts of inorganic particles (a), 30-65 parts of an adhesive (b) and 0.03-10 parts of a curing agent (c). The inorganic particles are cationic inorganic particles. The adhesive is selected from one or more of water-soluble resin and binary or polybasic water-dispersible type copolymer emulsion. The liquid electronic ink receiving medium is smoothly conveyed on an HP Indigo series printing press without the paper jamming problem, the printed image is bright in color, the inking capacity is good, the printing ink fastness is good, and the image-stage image quality requirement is met.

Owner:乐凯胶片股份有限公司

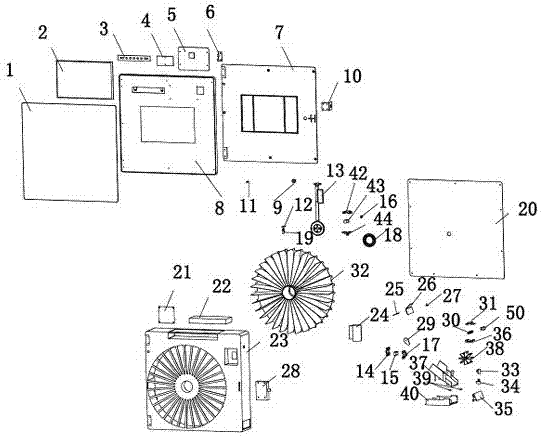

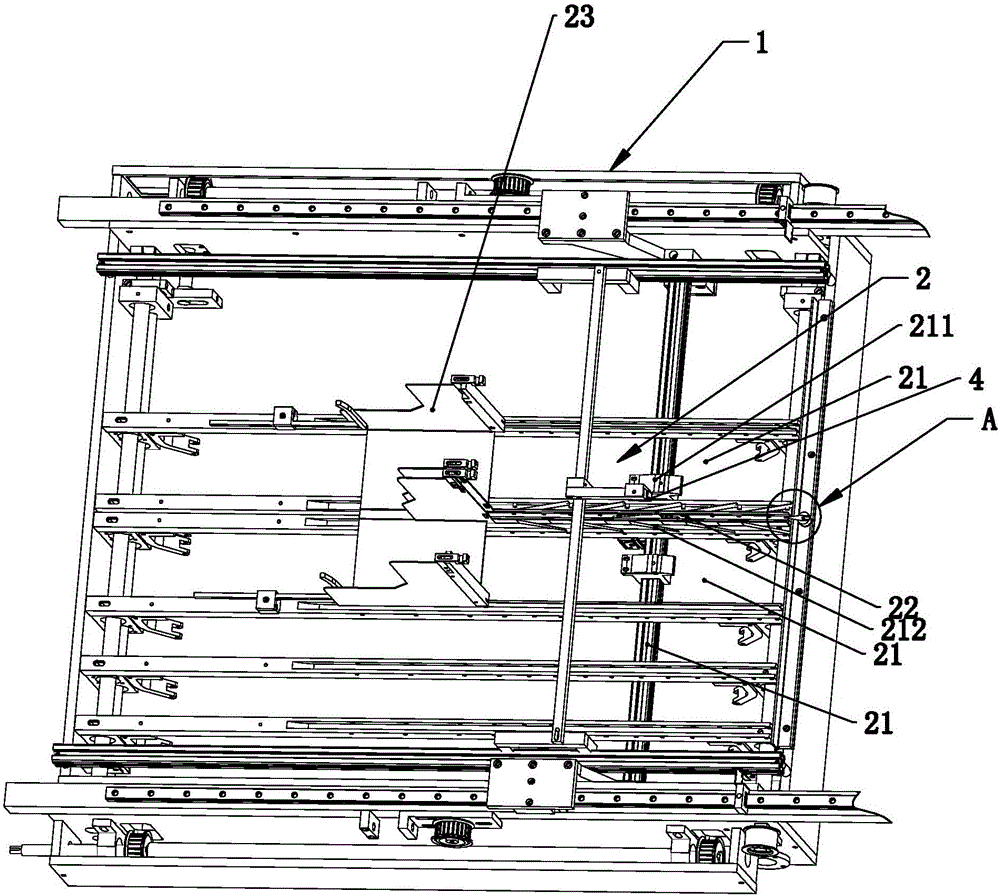

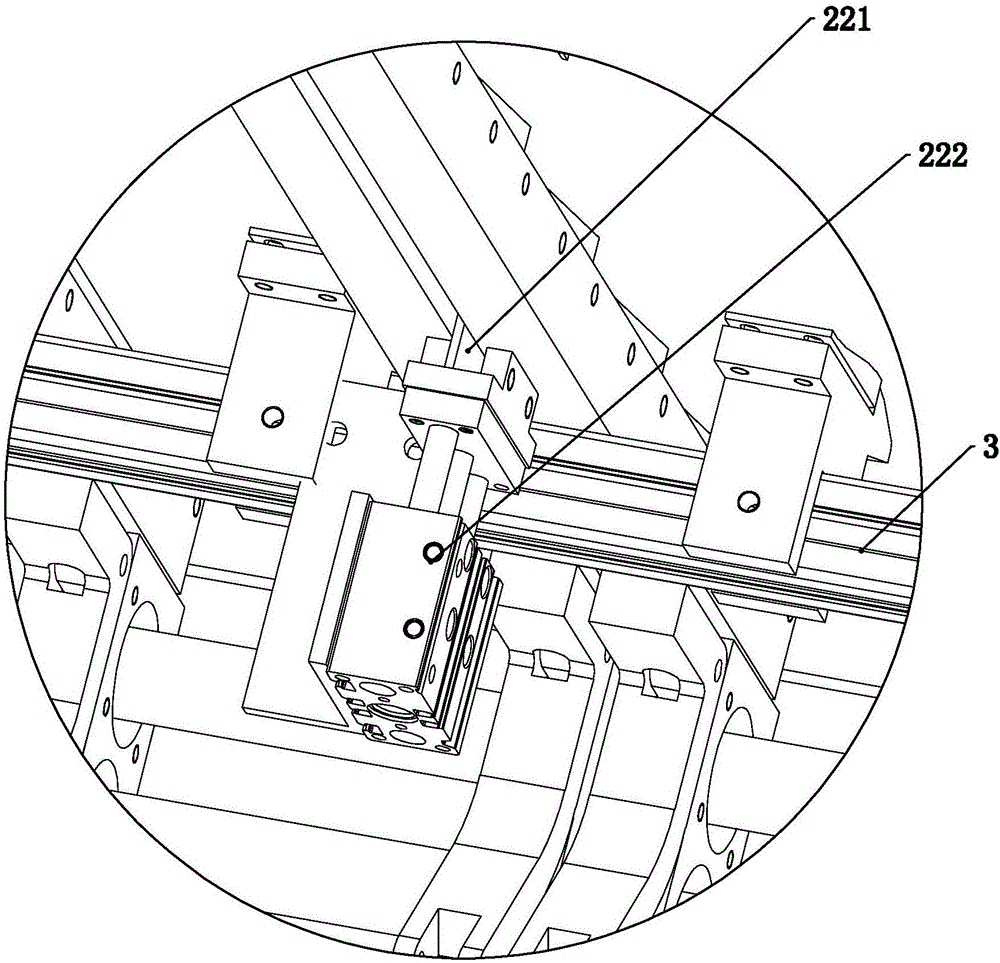

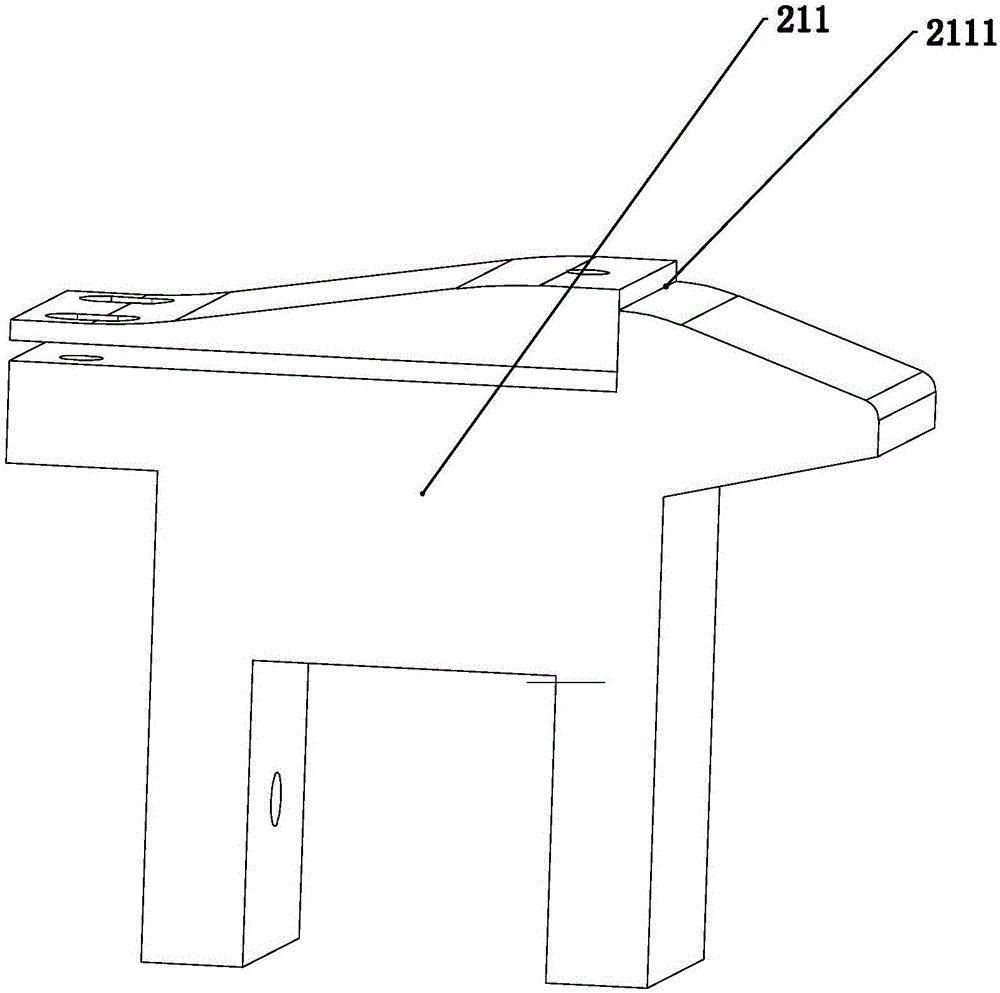

Automatic page-turning device of paper photographing

PendingCN108366180AImprove photo processing efficiencySave human effortBook markersPictoral communicationManipulatorPulp and paper industry

The invention discloses an automatic page-turning device for paper photographing. The automatic page turning device comprises a first bin, a second bin, a manipulator, a fixed part and a camera; the fixed is arranged between the first bin and the second bin; the camera is arranged above the first bin; one end of the manipulator is hinged on the fixed part, and a sucker device is arranged on the manipulator. Through the above way, the automatic page turning device of paper photographing can improve the photographing processing efficiency of multiple sheets of paper, the manpower and time are saved, the device has high adaption capacity to the paper, and the paper jamming phenomenon of a scanner is avoided.

Owner:无锡中育科教技术有限公司

Label paper conveying mechanism

ActiveCN103935784BSimple structureEasy to useArticle feedersArticle separationPulp and paper industry

A label paper conveying mechanism comprises a conveying channel, a paper supply channel, a lower supporting part and a paper discharging unit. The label paper conveying mechanism is simple in structure and convenient to use, single pieces of label paper can be conveyed to the next procedure accurately every time, paper blocking is avoided, efficiency is increased, service life of the label paper conveying mechanism is prolonged, and safety is high.

Owner:MAXIM SMART MFG CO LTD

Feeding system for pulverizer

InactiveCN111097589ARealize the shredding functionA little leakageGrain treatmentsMechanical engineeringRaw material

The invention discloses a feeding system for a pulverizer. The feeding system for the pulverizer comprises an upper pressing bar and a lower pressing bar, the upper pressing bar and the lower pressingbar are fixed to a feeding inlet of the pulverizer in the horizontal direction, a paper feeding inlet is formed in one end of the feeding inlet, and a pulverizing opening is formed in the other end of the feeding inlet; a gap is arranged between the upper pressing bar and the lower pressing bar; the distance of the gap gradually decreases from the paper feeding inlet to the pulverizing opening; and the lower pressing bar comprises a first lower included angle, the upper pressing bar comprises a first upper included angle, and the first lower included angle and the first upper included angle form the paper feeding inlet. According to the feeding system for the pulverizer, the pulverizing function of two raw materials of refined cotton and cotton pulp, the cotton pulp can enter the pulverizer through the feeding inlet, the paper feeding process is stable without paper jamming, the amount of leakage of is cotton powder is a little, and the pulverizing requirement is met.

Owner:泸州北方纤维素有限公司

Paper shredding mechanism

InactiveCN103120972BSimple structureShredding EfficientGrain treatmentsElectric machineryPulp and paper industry

Owner:NINGBO HAIBO OFFICE MACHINERY

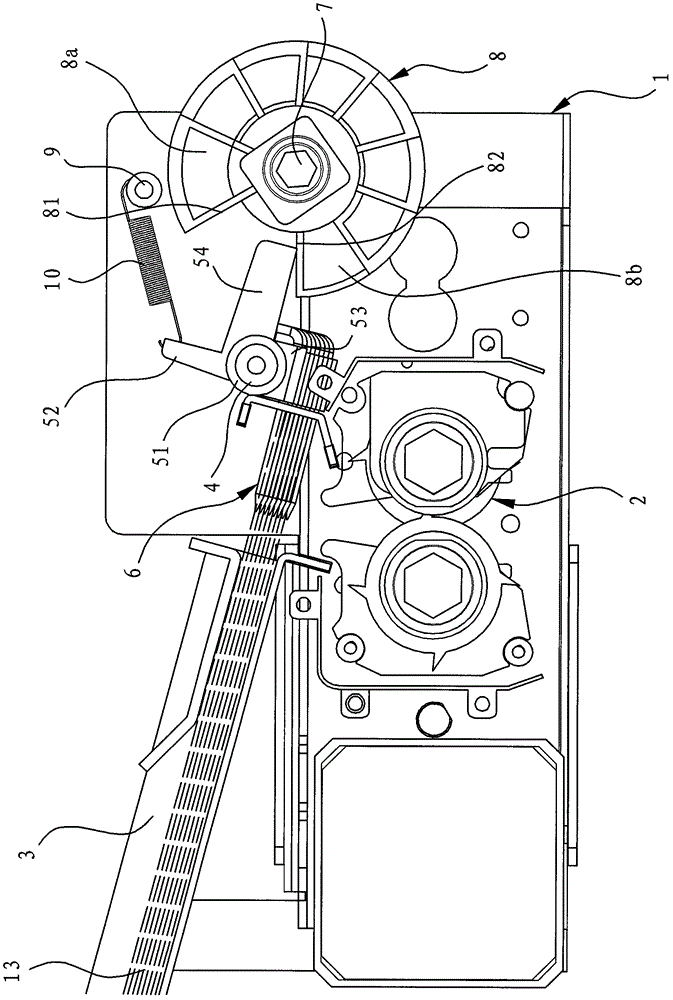

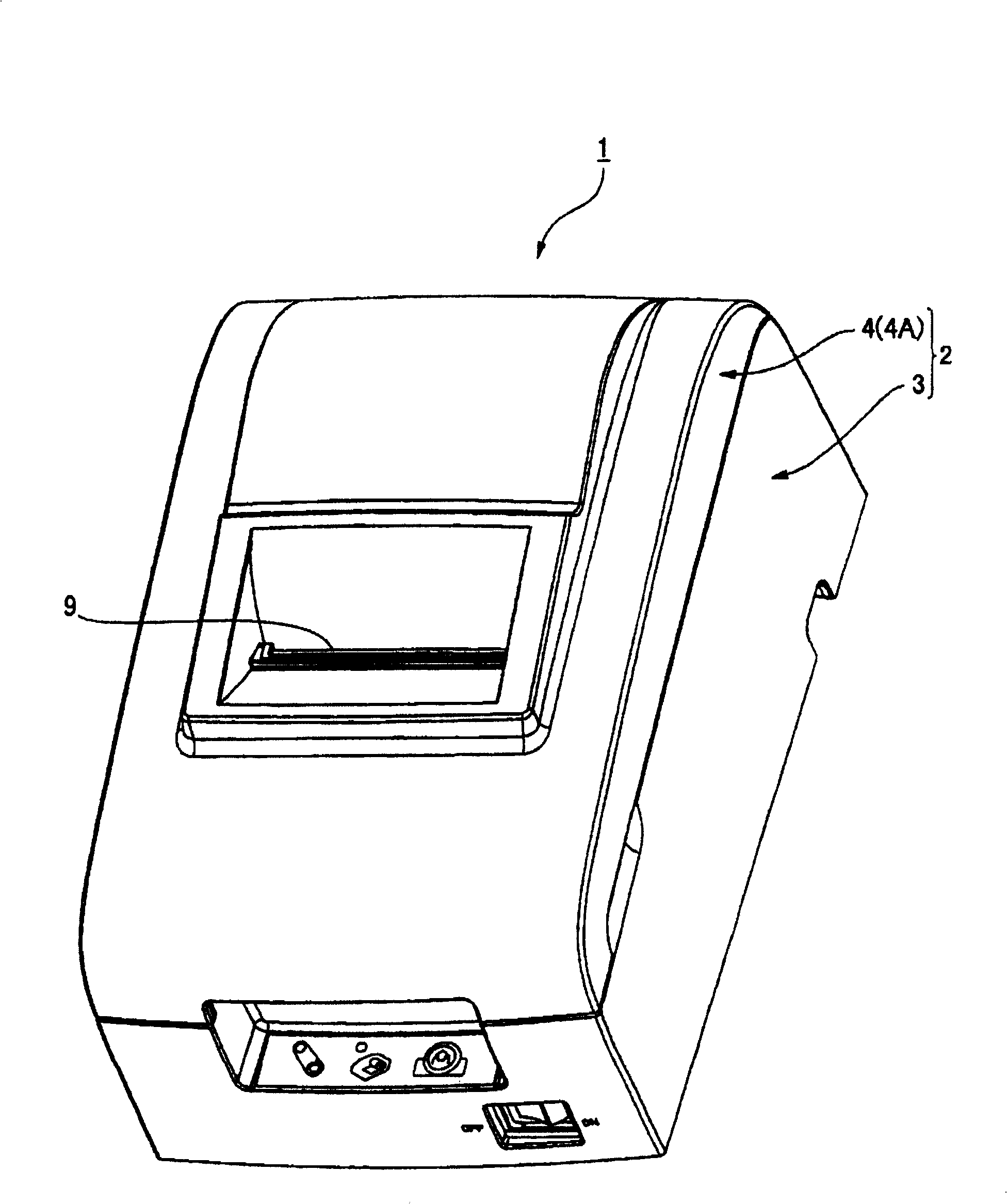

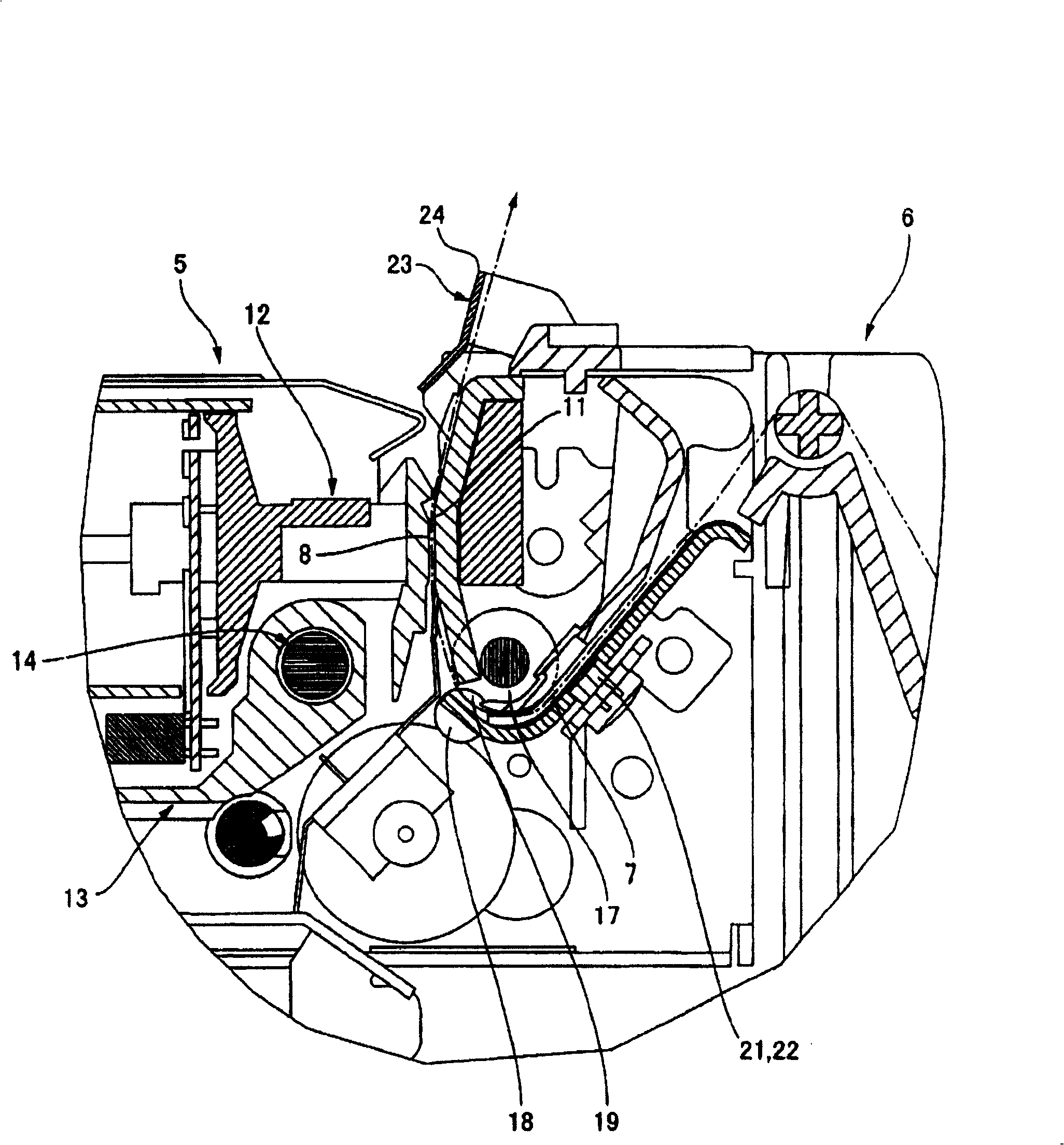

Record paper loading method of printer

InactiveCN100453331CNo wasteNo paper jamsOther printing apparatusSensing by electromagnetic radiationEngineeringMechanical engineering

The present invention provides a mathod of loading recording paper of printer. A rolled sheet 10 is loaded in a rolled sheet loading section 6 of a rolled-sheet printer 1. If the recording paper 10a is pulled out from the section 6 and inserted toward a nip part 19 of a paper-feed roller 17, the recording paper 10a is detected by photosensors 21, 22, then the operation of feeding the paper by the paper-feed roller 17 starts. The recording paper 10a is conveyed only by the 1st feeding rate L1 equal to the distance from the nip part 19 to a cutting position 24 of a manual cutter 23, and the recording-paper tip edge 10d is positioned in the cutting position 24. If the black mark 10c is detected by the photosensors 21, 22 before the feed rate reaches the 1st feeding rate L1, a normal feed-controlling based on the black mark is performed, then the recording-paper tip edge 10d is positioned in the cutting position 24.

Owner:SEIKO EPSON CORP

Printing paper conveying system and printer comprising same

The invention discloses a printing paper conveying system and a printer comprising the same. The printing paper conveying system comprises a fixed frame; the fixed frame is provided with a first driving rolling wheel and a second driving rolling wheel, a first driven rolling wheel and a second driven rolling wheel are arranged below the first driving rolling wheel and the second driving rolling wheel correspondingly, and adjustable spaces for conveying printing paper are arranged between the first driving rolling wheel and the second driving rolling wheel as well as between the first driven rolling wheel and the second driven rolling wheel; the first driven rolling wheel and the second driven rolling wheel each comprise two driven rolling wheel units, and the two driven rolling wheel units are jointed separately; a spring assembly is arranged between the first driven rolling wheel and the second driven rolling wheel and used for stretching the first driven rolling wheel and the second driven rolling wheel towards the two sides.

Owner:YIHE PRECISION IND SUZHOU

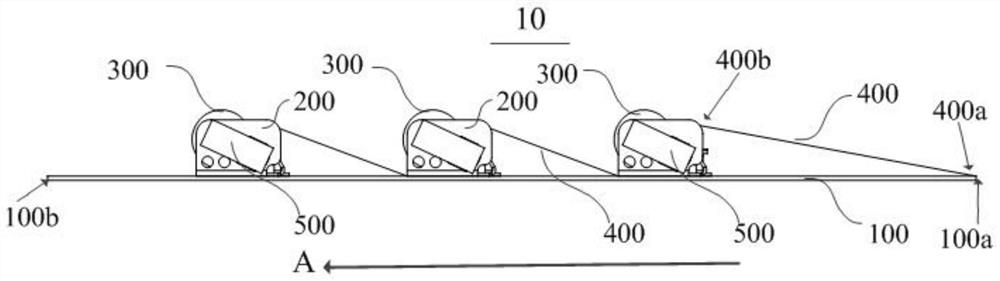

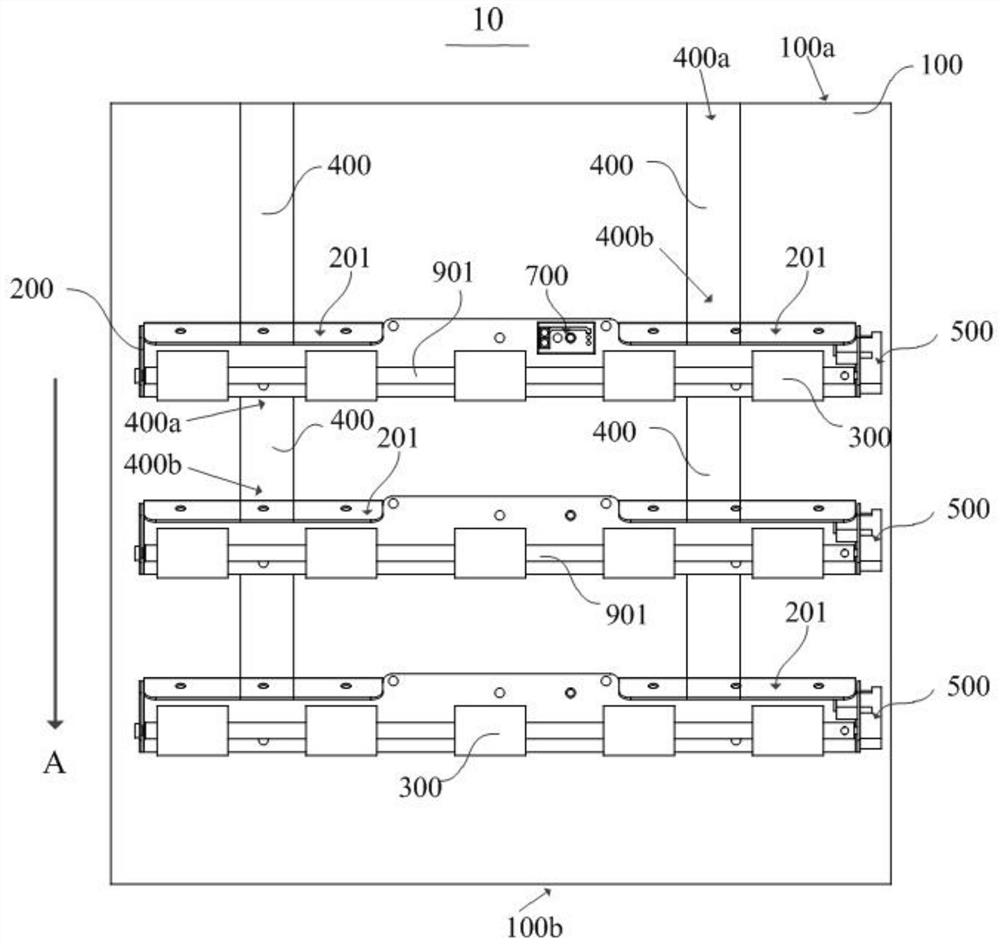

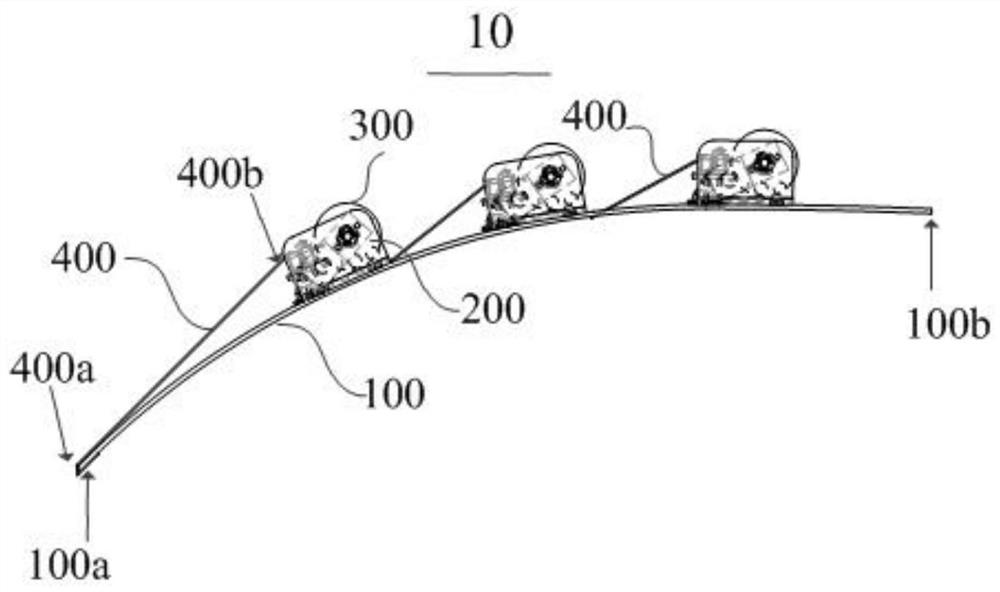

Paper feeder and intelligent equipment with same

PendingCN112551206AGuaranteed normal transportationGuaranteed normal transmissionArticle feedersArticle separationControl engineeringIntelligent equipment

The invention relates to a paper feeder and intelligent equipment with the paper feeder. The paper feeder comprises a base plate, a plurality of paper feeding units, a paper guiding mechanism, a powerpart and a control module. The base plate comprises a paper receiving end and a tail end, wherein paper is conveyed from the paper receiving end to the tail end. The paper feeding units are sequentially arranged on the base plate in the paper conveying direction. Each paper feeding unit comprises a support, at least one paper rubbing roller and a transmission mechanism, wherein the paper rubbingroller is arranged on the transmission mechanism, the transmission mechanism is arranged on the support, and the support is fixed to the base plate. At least one paper guiding mechanism is arranged between the paper receiving end and a first paper feeding unit, and a path for conveying paper is formed on the upper surface of the paper guiding mechanism. The control module controls the power part to work, outputs driving force to the transmission mechanism and drives the paper rubbing rollers to rotate so as to convey paper located on a paper feeder body. According to the paper feeder and the intelligent equipment with same, a horizontal pushing type conveying mode is adopted, and compared with a clamping pushing type conveying mode, paper clamping is avoided, higher stability is achieved,the paper feeding distance can be customized, and better compatibility is achieved.

Owner:NANJING AOTO ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com