Paper folding machine

An origami machine and origami technology, applied in the field of origami machines, can solve the problems that it is difficult to fold paper into an equilateral shape, the precision of origami is not high, and it is difficult to form a rectangular motion track, so as to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

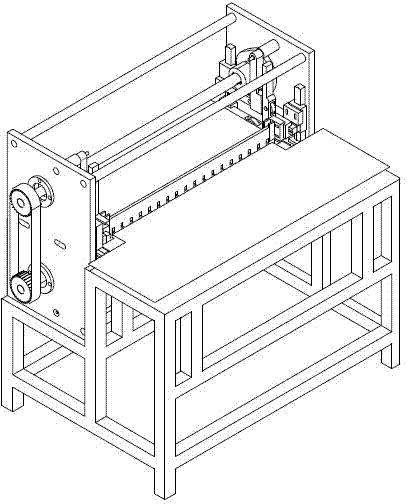

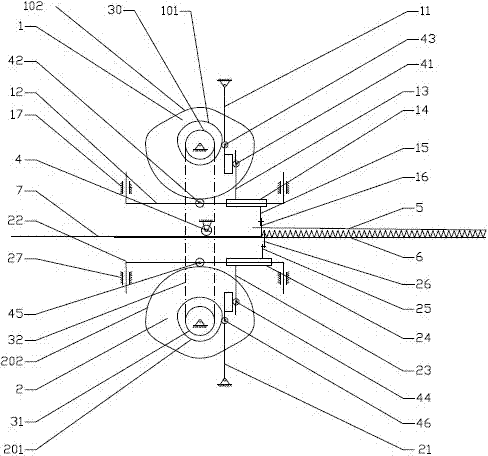

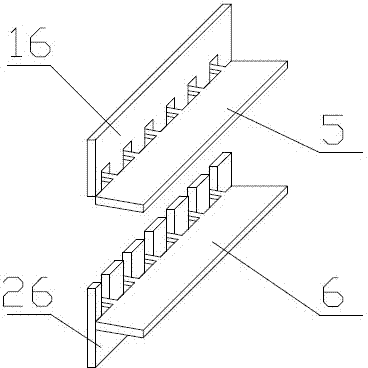

[0023] like figure 1 As shown, the present invention provides a paper folding machine, which includes a frame, a paper folding mechanism and a driving device. like figure 2 shown, figure 2 The left side is the front end, and the right side is the rear end. The folding mechanism includes an upper folding device, a lower folding device, a synchronous pulley device 3, a paper feeding roller 4, an upper pressing board 5 and a lower supporting board 6. The latter half of the above-mentioned upper pressing board 5 and lower supporting board 6 are arranged on the frame in a corresponding up and down manner, forming a paper input port for the folded paper to enter, a paper channel and a paper output port for feeding and outputting paper. The paper feeding roller 4 is installed at the front end of the paper feeding port and cooperates with the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com