Paper shredding mechanism

A paper pressing mechanism and paper shredding technology, which is applied in the direction of grain processing, etc., can solve the problems that affect the efficiency of automatic shredding, paper jams, etc., and achieve the effects of simple structure, increased shredding speed, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

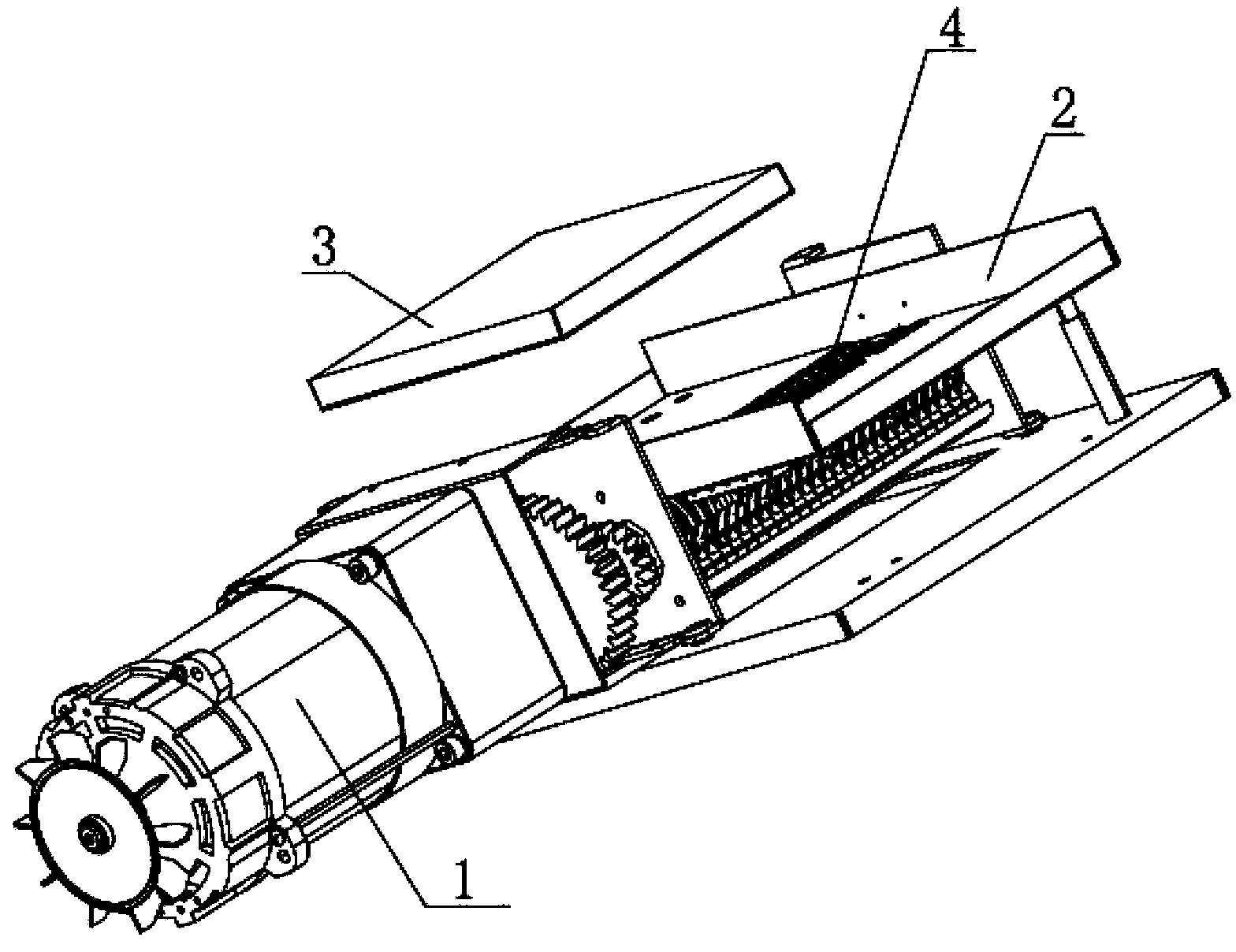

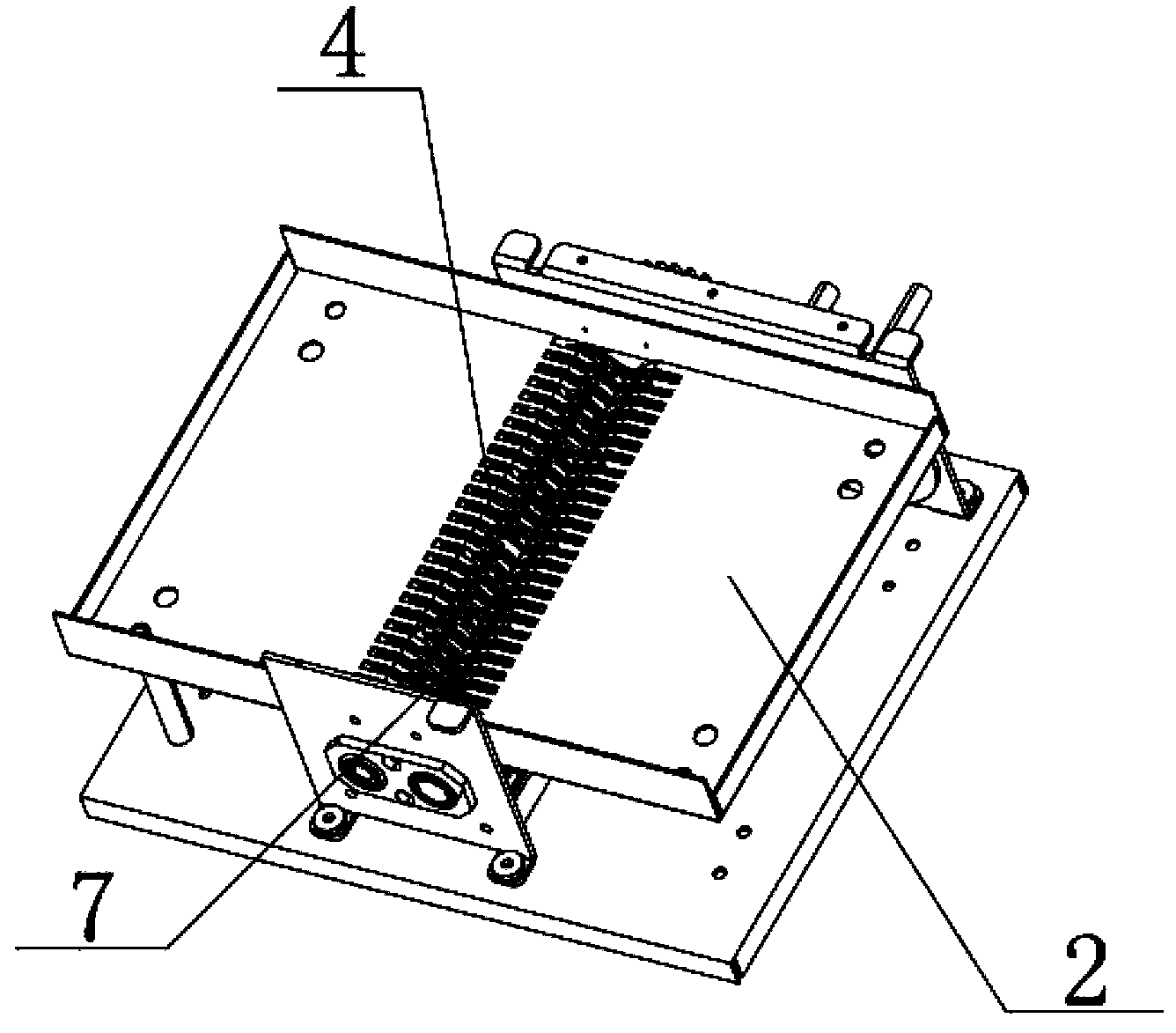

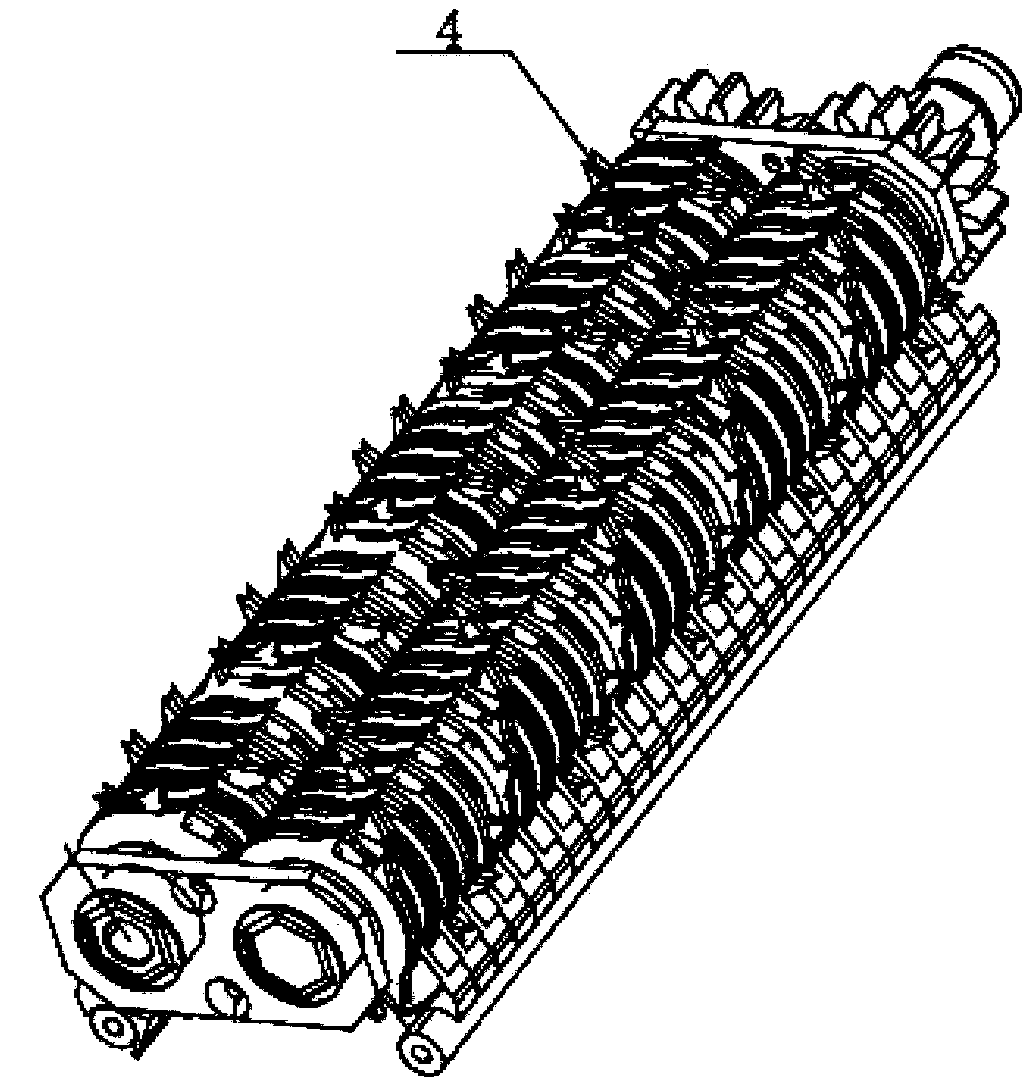

[0024] Place the two rows of shredding knives 4 horizontally with the ground, and place the paper release mechanism 2 horizontally with the ground. shape, a circle of cutting edge 41 is arranged on the outer edge of its circumference, and several gaps 42 are evenly arranged on the cutting edge 41 along the circumference. Withstand the lower end of the paper, the paper pressing mechanism 3 presses the paper downward, the motor 1 is started, and drives the two rows of shredding knives 4 to rotate relatively, and the paper is continuously brought into the shredding gap 7 by the shredding knives 4 for cutting.

Embodiment 2

[0026] The plane formed between the two rows of shredding cutters 4 is at an angle of 35° to the horizontal plane, and the paper releasing mechanism 2 is also at an angle of 35° to the horizontal plane. There are several protruding oblique knife edges 51 evenly arranged on the outer edge of the circumference, 500 sheets of paper are placed on the upper end of the paper platform 2, the shredding cutter 4 withstands the lower end of the paper, the paper pressing mechanism 3 presses the paper downward, and the motor 1 is started. The two rows of knives 4 are driven to rotate relatively, and the paper is continuously brought into the shredding gap 7 by the shredding knives 4 for cutting.

Embodiment 3

[0028] The plane formed between the two rows of shredding cutters 4 is placed perpendicular to the ground, and the paper release mechanism 2 is also perpendicular to the ground. The two rows of shredding cutters 4 are arranged in the middle of the right side of the paper discharge mechanism 2. 4 is a cylinder, and knurling protrusions 61 are arranged on the outer cylindrical surface of the paper shredding tool 4, and 1000 sheets of paper are vertically placed on the left end of the paper-discharging mechanism 2, and the paper-pressing mechanism 3 is perpendicular to the paper-discharging platform 2. The direction of shredding cutter 4 presses the paper in the left direction, the shredding cutter 4 bears against the right side of the paper, the motor 1 starts, and drives the two rows of shredding cutters 4 to rotate relative to each other, and the paper is continuously brought into the shredding gap 7 by the shredding cutter 4 Make a cut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com