Rapid and stable paper feeding mechanism for printer

A paper feeding mechanism and printer technology, applied in printing devices, printing, etc., can solve the problems of inaccurate paper feeding, slow speed, easy paper jams, etc., and achieve fast and stable paper feeding, long service life, and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

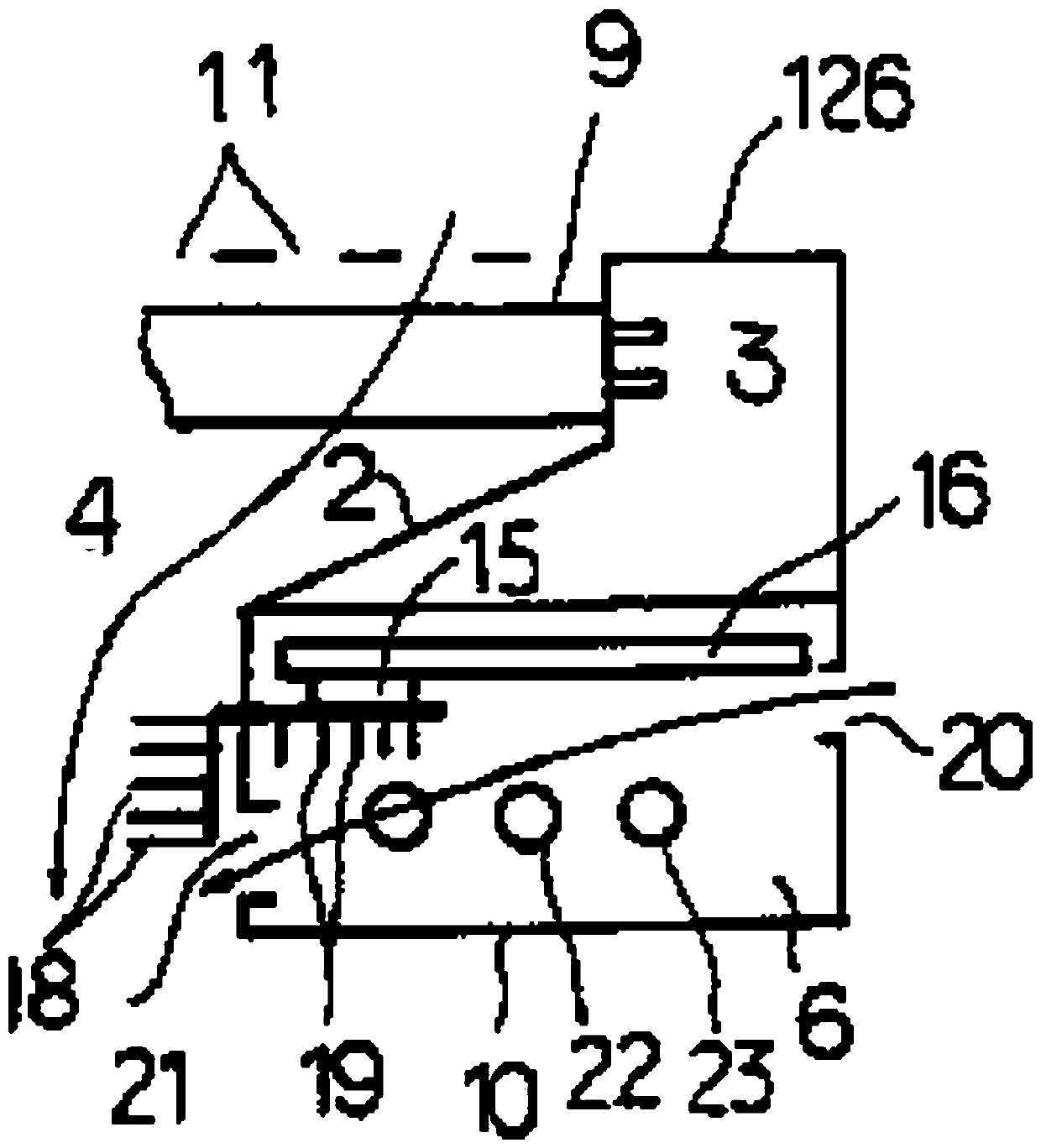

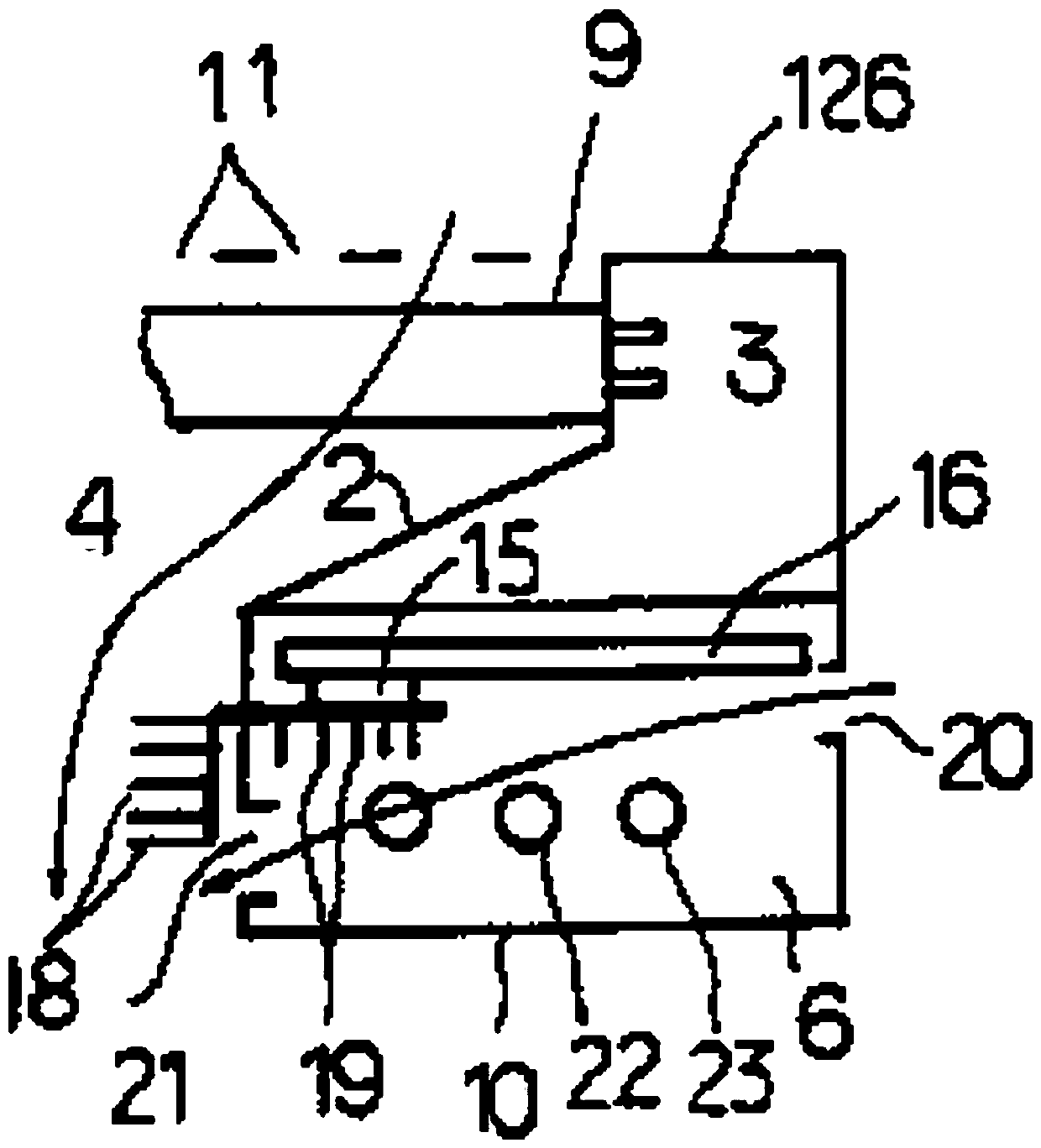

[0015] A fast and stable paper feeding mechanism for a printer of the present invention includes a cooling hole 11, a heating roller 9, a chassis 126, an electrode 3, a baffle plate 2, a printing chamber 4, a blocking brush 18, a paper outlet 21, a paper brush 19, Mounting frame 15, mounting plate 16, paper inlet 20, machine base 10, guide roller 22, auxiliary roller 23, roller frame 6, it is characterized in that: described cabinet 126 is printing chamber 4, and above printing chamber 4 is heating roller 9. Heat dissipation holes 11 are arranged above the heating roller 9; the motor of the heating roller 9 is installed in the chassis 126; the bottom of the chassis 126 is provided with a base, and the base is a roller frame 6, and the roller frame 6 is provided with a guide roller 22 and an auxiliary roller 23 A paper inlet 20 and a paper outlet 21 are provided corresponding to the guide roller 22 and the auxiliary roller 23 .

[0016] As a preferred solution of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com